Content Menu

● Understanding SMT Production Lines

● The Role of Visual Planning in SMT Production Line Installation

● Key Steps for Optimizing SMT Production Line Installation

>> 1. Assess Production Requirements

>> 2. Select Appropriate Equipment

>> 3. Design an Efficient Layout

>> 4. Implement Visual Planning Tools

>> 5. Integrate Systems for Seamless Operation

>> 6. Conduct Thorough Testing and Calibration

>> 7. Implement Continuous Monitoring

>> 8. Establish Regular Maintenance Protocols

● Best Practices for Optimizing SMT Production Line Installation

● Enhancing Production Efficiency

● Continuous Improvement Strategies

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. Why is visual planning important in SMT installation?

>> 3. What are key pieces of equipment needed for an SMT line?

>> 4. How can maintenance affect SMT production efficiency?

>> 5. What role does operator training play in optimizing SMT lines?

● Citations:

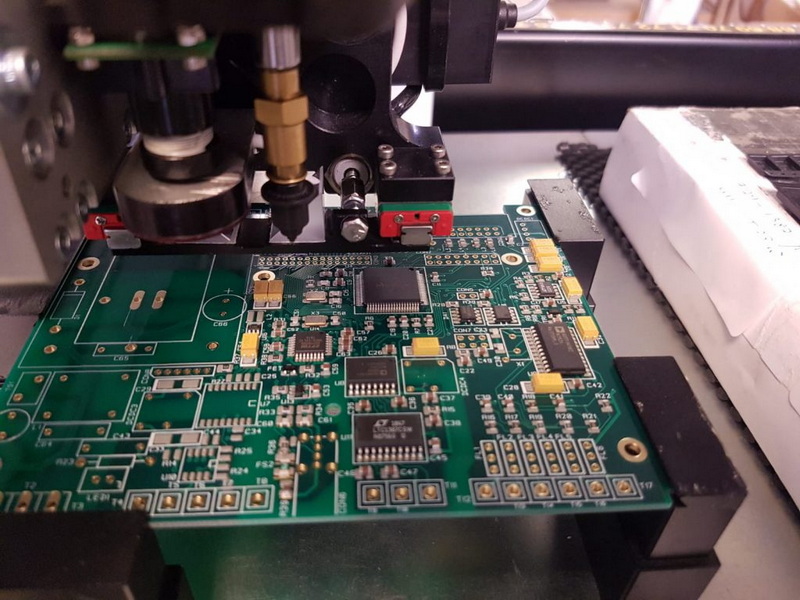

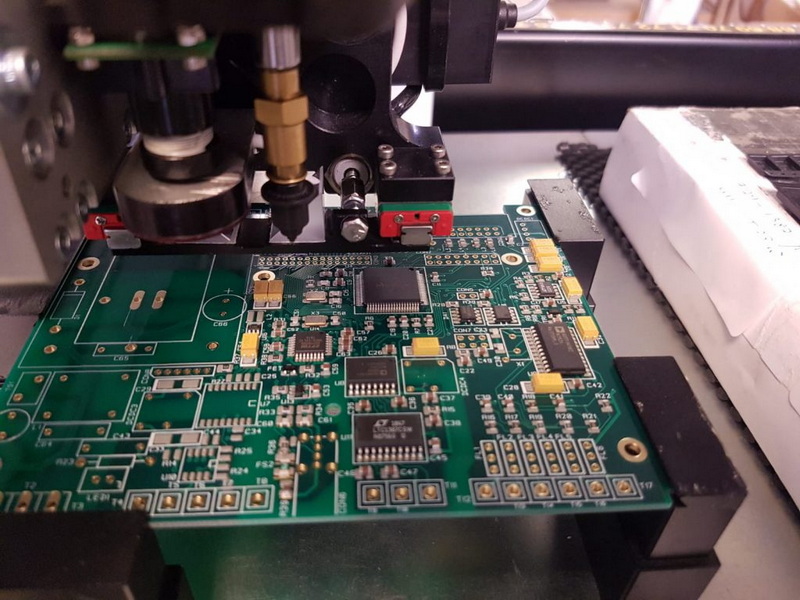

Surface Mount Technology (SMT) is a critical process in electronics manufacturing, enabling the efficient assembly of printed circuit boards (PCBs). As the demand for electronic devices continues to grow, optimizing SMT production lines has become essential for manufacturers aiming to enhance productivity, reduce costs, and improve product quality. One effective approach to achieving these goals is through the use of a visual plan during the installation of SMT production lines. This article will explore how to optimize SMT production line installation using a visual plan, detailing key strategies, best practices, and the importance of continuous improvement.

Understanding SMT Production Lines

SMT production lines consist of various interconnected machines that perform specific tasks in the PCB assembly process. These tasks typically include:

- Solder Paste Printing: Applying solder paste to designated areas on the PCB.

- Component Placement: Using pick-and-place machines to accurately position components on the solder paste.

- Reflow Soldering: Melting the solder paste to create electrical connections between components and the PCB.

- Inspection: Utilizing automated optical inspection (AOI) systems to detect defects in component placement and solder joints.

Each of these stages must be carefully planned and executed to ensure a smooth workflow and high-quality output.

The Role of Visual Planning in SMT Production Line Installation

Visual planning involves creating a detailed layout and workflow diagram that outlines the arrangement of equipment, material flow, and operator tasks within the SMT production line. This approach offers several benefits:

- Clarity: A visual plan provides a clear overview of the entire production process, making it easier for teams to understand their roles and responsibilities.

- Efficiency: By optimizing the layout based on the flow of materials and components, manufacturers can minimize bottlenecks and reduce unnecessary movement.

- Flexibility: Visual plans can be easily adjusted to accommodate changes in production requirements or equipment upgrades.

Key Steps for Optimizing SMT Production Line Installation

1. Assess Production Requirements

Before creating a visual plan, it is crucial to assess your production requirements. Consider factors such as:

- Volume of production

- Types of components used

- Complexity of assemblies

This information will guide decisions regarding equipment selection and layout design.

2. Select Appropriate Equipment

Choosing the right equipment is vital for an efficient SMT line. Key pieces of equipment include:

- Solder Paste Printers: Ensure consistent application of solder paste.

- Pick-and-Place Machines: Select machines that can handle the required component sizes and types.

- Reflow Ovens: Choose ovens that provide uniform heating for reliable solder joints.

- Inspection Systems: Implement AOI systems for quality control.

3. Design an Efficient Layout

The layout of your SMT line should facilitate a smooth flow of materials and components. Consider the following aspects:

- Arrange equipment in a logical sequence that mirrors the production process.

- Ensure adequate spacing between machines for maintenance access.

- Designate areas for material storage and operator tasks to minimize movement.

4. Implement Visual Planning Tools

Utilize visual planning tools such as flowcharts, diagrams, or software applications to create a comprehensive layout. These tools can help visualize:

- Equipment placement

- Material flow paths

- Operator workflows

5. Integrate Systems for Seamless Operation

Ensure that all machines are interconnected for efficient communication. This may involve setting up network connections and configuring data exchange protocols between:

- Pick-and-place machines

- Solder paste printers

- Inspection systems

6. Conduct Thorough Testing and Calibration

After installation, it is essential to conduct thorough testing and calibration of all equipment. This includes:

- Running test boards through the line

- Verifying component placement accuracy

- Adjusting settings based on initial test results

7. Implement Continuous Monitoring

Continuous monitoring is crucial for maintaining efficiency in your SMT line. Utilize real-time data analytics to identify bottlenecks and make informed decisions for process improvements.

8. Establish Regular Maintenance Protocols

Implement a regular maintenance schedule for all equipment in your SMT line. This includes cleaning, lubrication, and replacement of worn parts to prevent unexpected downtime.

Best Practices for Optimizing SMT Production Line Installation

To further enhance the efficiency of your SMT production line installation, consider implementing these best practices:

- Lean Manufacturing Principles: Adopt lean principles to minimize waste and optimize workflows throughout the production process.

- Training Programs: Invest in training programs for operators to ensure they are skilled in using equipment and troubleshooting issues effectively.

- Feedback Loops: Establish feedback mechanisms that allow operators to share insights on potential improvements or challenges faced during production.

- Automation Integration: Where possible, integrate automation solutions such as automated conveyors or robotic arms to streamline processes and reduce human error.

Enhancing Production Efficiency

To maximize productivity on your SMT line, consider these additional strategies:

- Load Distribution Balance: Ensure that each machine has an equal workload by balancing component placement across machines. This helps prevent bottlenecks caused by one machine working significantly harder than others[1].

- Equipment Optimization: Optimize each machine's settings based on its capabilities to achieve maximum speed without sacrificing quality[1][2].

- Component Sequencing: Arrange components in the order they will be placed on PCBs, reducing setup time between runs[2].

- Minimize Changeovers: Reduce the number of different components used in a single run; fewer changes lead to less downtime[1][6].

- Utilize Automation Technologies: Incorporate advanced automation technologies like AI-driven monitoring systems that can predict failures before they occur[3][4][6].

Continuous Improvement Strategies

Continuous improvement is key to maintaining an efficient SMT line over time:

- Regular Training Updates: Keep staff updated with new technologies and methods through ongoing training sessions[10][11].

- Data Analytics Utilization: Use data analytics tools to monitor performance metrics continuously, allowing quick identification of inefficiencies or defects[3][4].

- Supplier Relationship Management: Maintain strong relationships with suppliers to ensure timely delivery of high-quality components needed for assembly[11].

Conclusion

Optimizing SMT production line installation using a visual plan is an essential strategy for manufacturers seeking to enhance productivity, reduce costs, and improve product quality. By assessing production requirements, selecting appropriate equipment, designing efficient layouts, integrating systems, conducting thorough testing, implementing continuous monitoring, and establishing regular maintenance protocols, manufacturers can create a highly efficient SMT production environment. Embracing best practices such as lean manufacturing principles, training programs, feedback loops, automation integration, load distribution balance, equipment optimization strategies, continuous improvement initiatives will further contribute to long-term success in electronics manufacturing.

FAQ

1. What is Surface Mount Technology (SMT)?

SMT is an assembly technique used to mount electronic components directly onto the surface of PCBs without drilling holes into them.

2. Why is visual planning important in SMT installation?

Visual planning provides clarity on workflow processes, optimizes equipment layout for efficiency, and allows flexibility in adapting to changing production needs.

3. What are key pieces of equipment needed for an SMT line?

Essential equipment includes solder paste printers, pick-and-place machines, reflow ovens, and inspection systems like Automated Optical Inspection (AOI).

4. How can maintenance affect SMT production efficiency?

Regular maintenance prevents unexpected downtime by ensuring that all machines operate at peak performance levels while maintaining consistent product quality.

5. What role does operator training play in optimizing SMT lines?

Well-trained operators are more adept at identifying issues quickly, performing preventive maintenance effectively, and ensuring smooth operation throughout the production process.

Citations:

[1] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[2] https://txjpcb.com/the-best-practices-for-smt-line-balancing-and-optimization/

[3] https://quality-line.com/smt-quality/

[4] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=58069&news_id=30605

[5] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[6] https://www.rayprasad.com/three-steps-to-improve-smt-yield

[7] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[8] https://www.raypcb.com/line-efficiency/

[9] https://www.linkedin.com/pulse/how-improve-smt-production-efficiency-

[10] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[11] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[12] https://www.smthelp.com/methods-and-measures-to-improve-the-production-efficiency-of-smt-production-line

[13] https://prototypepcbassembly.com/optimizing-smt-production-lines-for-maximum-efficiency/

[14] https://resources.pcb.cadence.com/blog/2020-how-to-optimize-pcb-design-for-smt-assembly-process-flow

[15] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[16] https://www.tronstol.com/how-to-optimize-smt-mounter-machine-equipment.html

[17] https://www.zjyingxing.com/info/how-to-improve-the-production-efficiency-of-sm-76854084.html