Content Menu

● Understanding the SMT Screen PCB Stencil Printer

● Why Maintenance of SMT Screen PCB Stencil Printer is Crucial

● Daily Maintenance Practices for SMT Screen PCB Stencil Printer

>> 1. Cleaning the Stencil and Printer Components

>> 2. Inspection and Adjustment

>> 3. Preventive Maintenance

● Cleaning Methods for SMT Screen PCB Stencil Printers

>> Manual Cleaning

>> Automated Cleaning

● Advanced Maintenance Tips

>> Use Nanocoated Stencils

>> Optimize Cleaning Frequency

>> Avoid Excessive Use of Isopropyl Alcohol (IPA)

>> Maintain Printer Calibration

● Troubleshooting Common Issues in SMT Screen PCB Stencil Printing

● Conclusion

● FAQ

>> 1. How often should I clean my SMT screen PCB stencil printer?

>> 2. What cleaning agents are recommended for SMT stencil printers?

>> 3. Can manual cleaning damage the stencil?

>> 4. What advantages do nanocoated stencils offer?

>> 5. How do I ensure the stencil tension is correct?

Maintaining your SMT screen PCB stencil printer is essential to achieving consistent, high-quality solder paste application in surface-mount technology (SMT) assembly. Proper maintenance not only ensures precise printing but also extends the life of your equipment and reduces defects in your PCB production. This article provides an in-depth guide on how to maintain your SMT screen PCB stencil printer for optimal performance, covering daily maintenance, cleaning methods, advanced tips, and troubleshooting.

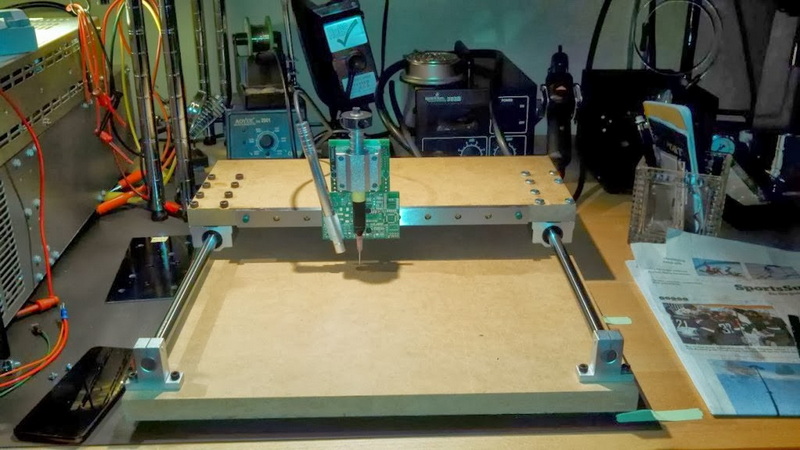

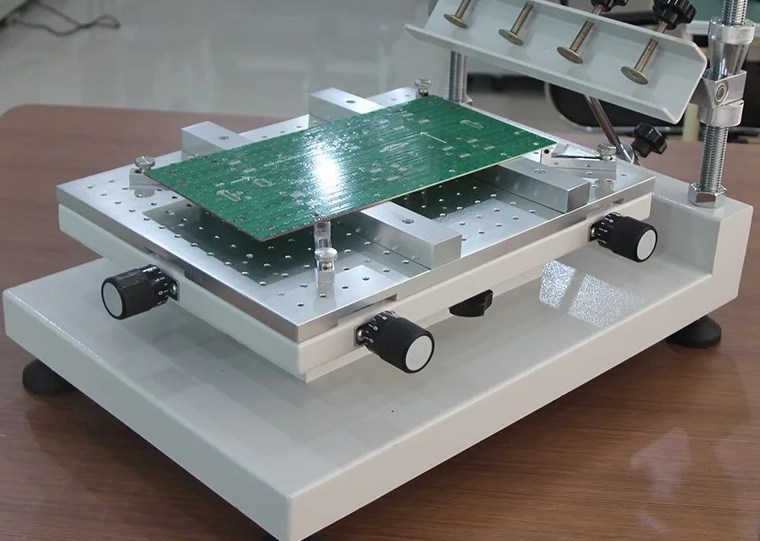

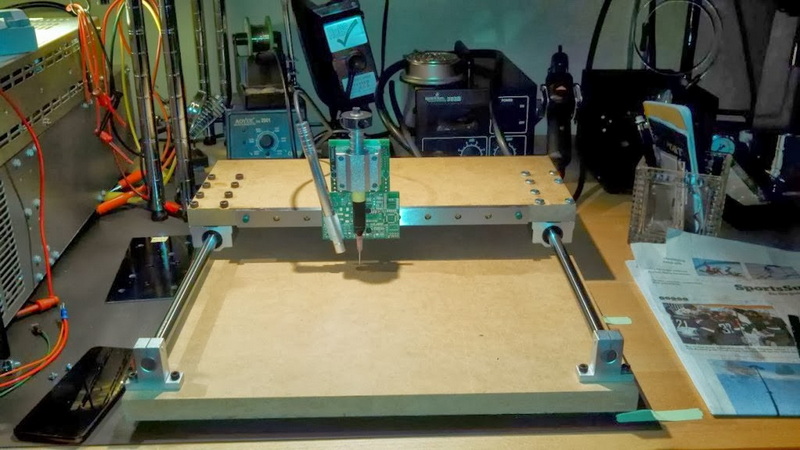

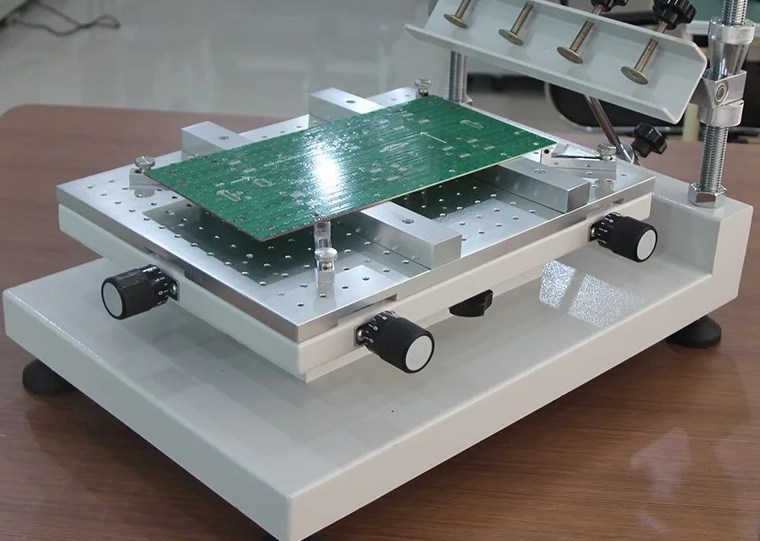

Understanding the SMT Screen PCB Stencil Printer

The SMT screen PCB stencil printer is a critical machine in the SMT assembly line. It deposits solder paste onto the PCB pads through a metal stencil that has apertures matching the PCB layout. The quality of the solder paste print directly affects solder joint reliability and the overall functionality of the finished PCB.

The stencil is usually made of stainless steel or nickel and is precision laser-cut to ensure accurate paste deposition. Over time, solder paste residues, dust, and mechanical wear can degrade the stencil and printer performance, making maintenance indispensable.

Why Maintenance of SMT Screen PCB Stencil Printer is Crucial

- Ensures Print Accuracy: Clean and well-maintained stencils produce sharp, uniform solder paste deposits.

- Reduces Defects: Prevents issues such as solder bridging, insufficient solder, or solder balls caused by clogged apertures or misalignment.

- Extends Equipment Life: Regular upkeep reduces mechanical wear and prevents damage to sensitive components.

- Improves Yield and Efficiency: Stable printing parameters minimize rework, scrap, and downtime.

- Cost Savings: Proper maintenance reduces the frequency of stencil replacement and costly repairs.

Daily Maintenance Practices for SMT Screen PCB Stencil Printer

1. Cleaning the Stencil and Printer Components

- Stencil Cleaning: After each print cycle, remove solder paste residues immediately to prevent hardening and aperture clogging. Use lint-free wipes and cleaning agents compatible with the solder paste chemistry. Avoid harsh solvents that may damage stencil coatings.

- Printer Cleaning: Clean the squeegee blades, scraper, and printer surfaces regularly to prevent paste buildup and contamination.

- Under-stencil Wipe: Frequently wipe the underside of the stencil during printing to maintain a clean surface and prevent solder paste bleed-through or smudging.

2. Inspection and Adjustment

- Visual Inspection: Examine stencil apertures for any clogging, burrs, or damage before and after printing.

- Stencil Tension: Check that the stencil is properly tensioned to avoid snap-back during printing. Typical tension ranges from 35 to 40 N/cm.

- Print Pressure and Alignment: Verify the squeegee pressure and stencil-to-board alignment to ensure consistent paste deposition.

3. Preventive Maintenance

- Schedule routine checks of mechanical components such as conveyor belts, motors, and sensors.

- Inspect squeegee blades and scrapers for wear and replace as necessary.

- Lubricate moving parts according to manufacturer guidelines.

Cleaning Methods for SMT Screen PCB Stencil Printers

Manual Cleaning

Manual cleaning is suitable for low-volume production or prototyping:

- Use plastic scrapers to gently remove excess solder paste.

- Soak the stencil in a compatible cleaning solution to soften residues.

- Employ soft brushes or foam swabs to clean apertures carefully.

- Rinse thoroughly and dry with compressed air or by air drying.

Manual cleaning requires caution to avoid scratching or damaging the stencil surface.

Automated Cleaning

For high-volume production, automated cleaning systems provide consistent and efficient stencil maintenance:

- Ultrasonic cleaning removes solder paste residues from apertures and stencil surfaces without mechanical abrasion.

- Spray cleaning systems use specialized solvents and rinsing cycles.

- Automated drying ensures the stencil is ready for immediate use.

Automated cleaning improves throughput and reduces the risk of stencil damage.

Advanced Maintenance Tips

Use Nanocoated Stencils

Nanocoatings create a non-stick surface on the stencil, reducing solder paste adhesion:

- Results in cleaner apertures and stencil undersides.

- Extends intervals between cleaning cycles.

- Improves print quality and reduces solvent consumption.

Optimize Cleaning Frequency

Adjust cleaning intervals based on:

- PCB complexity and volume.

- Solder paste type and flux chemistry.

- Environmental conditions such as humidity and temperature.

Frequent cleaning prevents aperture clogging and maintains consistent print quality.

Avoid Excessive Use of Isopropyl Alcohol (IPA)

While IPA is a common cleaning solvent, excessive use during under-stencil wiping can alter solder paste viscosity and increase solvent evaporation, negatively impacting print consistency.

Maintain Printer Calibration

Regularly calibrate printer parameters such as stencil alignment, squeegee pressure, and conveyor speed to ensure repeatable and accurate printing.

Troubleshooting Common Issues in SMT Screen PCB Stencil Printing

| Issue | Possible Cause | Recommended Action |

| Solder bridging | Clogged apertures or misalignment | Clean stencil apertures; check alignment |

| Insufficient solder | Low print pressure or worn squeegee | Adjust pressure; replace squeegee if needed |

| Solder balls | Excessive print pressure or dirty stencil | Reduce pressure; clean stencil thoroughly |

| Paste smearing | Stencil snap-back or poor tension | Increase stencil tension; check printer setup |

| Aperture damage | Improper cleaning or mechanical wear | Use gentle cleaning methods; replace stencil if necessary |

Conclusion

Maintaining your SMT screen PCB stencil printer is fundamental to achieving high-quality solder paste printing and reliable PCB assembly. By implementing daily cleaning routines, performing regular inspections, and adopting advanced maintenance techniques such as using nanocoated stencils and automated cleaning systems, manufacturers can significantly improve print consistency, reduce defects, and extend the life of their stencil printers. Proper maintenance not only enhances product quality but also contributes to cost savings and production efficiency. Incorporate these best practices into your SMT process to ensure optimal performance and long-term success.

FAQ

1. How often should I clean my SMT screen PCB stencil printer?

Cleaning frequency depends on production volume and solder paste type. For low-volume runs, clean after every print. For higher volumes, cleaning every 5 to 10 prints is typical to maintain aperture clarity and print quality.

2. What cleaning agents are recommended for SMT stencil printers?

Use cleaning agents specifically formulated for SMT stencil cleaning, including aqueous and solvent-based solutions compatible with your solder paste chemistry. Avoid harsh solvents that can damage stencil coatings.

3. Can manual cleaning damage the stencil?

Yes, using abrasive tools or excessive force can damage stencil surfaces and apertures. Always use lint-free wipes, soft brushes, and plastic scrapers to minimize the risk of damage.

4. What advantages do nanocoated stencils offer?

Nanocoated stencils repel solder paste and flux, resulting in cleaner apertures, longer cleaning intervals, improved print definition, and reduced solvent use, ultimately enhancing productivity.

5. How do I ensure the stencil tension is correct?

Stencil tension should typically be between 35 and 40 N/cm. Proper tension prevents stencil snap-back and ensures clean paste release. Use tension meters or follow manufacturer guidelines to verify tension regularly.