Content Menu

● Understanding the Importance of Maintenance for Your SMD Pick and Place Machine Set

● Daily Maintenance Tasks

>> Cleaning the Machine Surface and Components

>> Inspecting the Tape Feeders and Belts

>> Warm-Up Procedures

● Weekly Maintenance Tasks

>> Lubrication of Moving Parts

>> Nozzle and Vacuum System Checks

● Monthly Maintenance Tasks

>> Deep Cleaning and Component Inspection

>> Electrical and Mechanical Checks

● Annual Maintenance Tasks

>> Comprehensive Inspection and Part Replacement

● Key Maintenance Procedures for Optimal Performance

>> Cleaning and Inspecting Feeders and Nozzles

>> Calibration and Alignment

● Troubleshooting Common Issues

● Best Practices for Using Your SMD Pick and Place Machine Set

● Conclusion

● FAQ

>> 1. How often should I clean the nozzles on my SMD pick and place machine?

>> 2. What lubricant is recommended for the moving parts of the pick and place machine?

>> 3. How can I prevent component placement errors?

>> 4. What should I do if my machine frequently alarms during operation?

>> 5. How important is operator training for maintaining the pick and place machine?

Maintaining your SMD pick and place machine set is crucial for achieving consistent, high-quality production and extending the lifespan of this vital SMT equipment. Proper maintenance minimizes downtime, prevents component placement errors, and ensures the machine operates at peak efficiency. This comprehensive guide will cover essential maintenance tasks, best practices, troubleshooting tips, and a FAQ section to help you keep your SMD pick and place machine running smoothly.

Understanding the Importance of Maintenance for Your SMD Pick and Place Machine Set

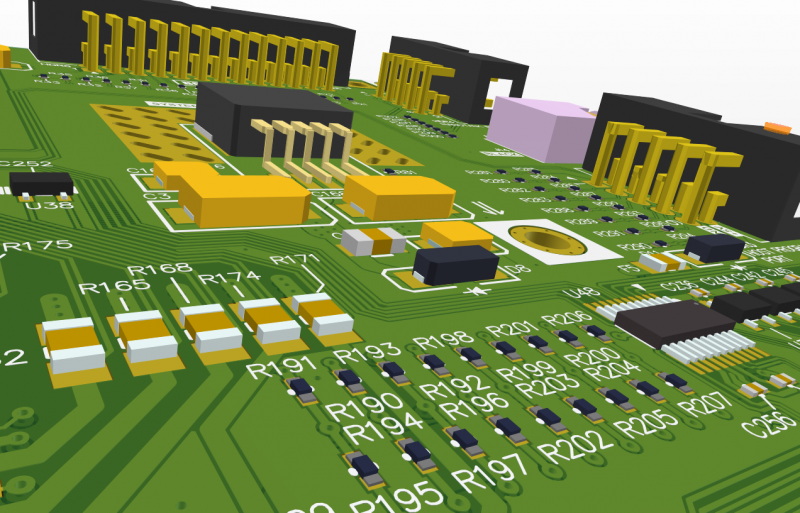

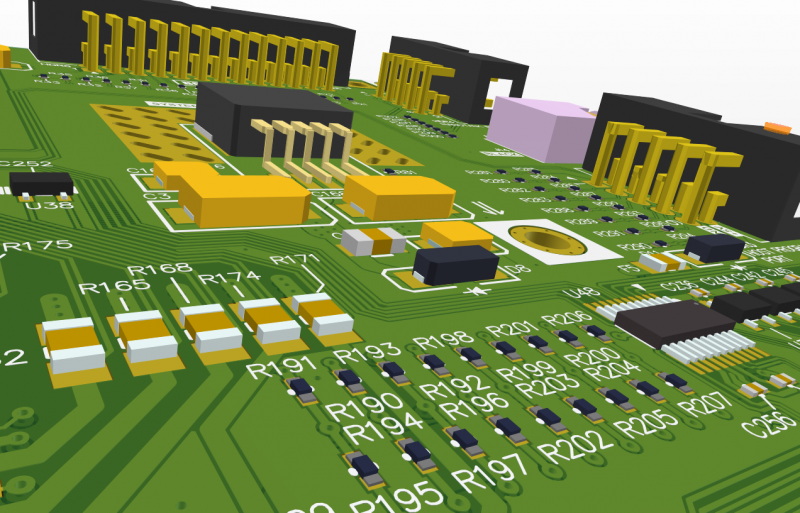

The SMD pick and place machine set is the heart of any SMT production line, responsible for the precise placement of components on printed circuit boards (PCBs). Over time, dust, dirt, wear, and mechanical issues can degrade machine performance, causing placement inaccuracies, component damage, and production delays.

Regular maintenance helps to:

- Maintain placement accuracy and product quality

- Reduce unexpected downtime and costly repairs

- Extend the machine's operational life

- Optimize production efficiency and throughput

Without a well-maintained machine, production quality can suffer, leading to increased scrap rates, rework, and customer dissatisfaction. Therefore, understanding and implementing a systematic maintenance plan is essential for any electronics manufacturer relying on an SMD pick and place machine set.

Daily Maintenance Tasks

Daily maintenance is the foundation of keeping your SMD pick and place machine in top condition. These tasks are generally quick but critical, preventing the accumulation of dust and debris that could impair machine function.

Cleaning the Machine Surface and Components

- Wipe down the machine body, PCB cameras, and component cameras with a soft, lint-free cloth to remove dust and debris.

- Remove any waste materials from the table surface using a brush or vacuum.

- Clean sensors and optical components such as laser heads and camera lenses to ensure accurate component recognition.

Dust accumulation on cameras or sensors can lead to misalignment or incorrect component recognition, causing placement errors. Keeping these parts clean ensures the vision system works optimally.

Inspecting the Tape Feeders and Belts

- Check tape feeders for debris between tape guides and plates; clean using a brush to prevent component misfeeds.

- Inspect belts on the X and Y axes for dirt or damage; clean and lubricate as needed to maintain smooth motion.

Tape feeders are critical for feeding components correctly. Dirt or tape residue can jam feeders, causing stoppages. Similarly, belts that are dirty or worn can slip or break, disrupting the entire placement process.

Warm-Up Procedures

- Allow the machine to warm up automatically for at least 20 minutes before production to stabilize mechanical and electronic components.

A proper warm-up period ensures that motors, sensors, and electronic circuits reach optimal operating temperatures, reducing errors caused by thermal expansion or contraction.

Weekly Maintenance Tasks

Weekly maintenance involves more detailed inspections and lubrication to keep mechanical parts functioning smoothly.

Lubrication of Moving Parts

- Apply the correct lubricating oil to moving parts such as slide rails, shafts, and guide rails to reduce friction and wear.

- Remove hardened grease and replace it with fresh lubricant to ensure smooth operation of the X and Y axes.

Proper lubrication prevents premature wear and tear on the machine's mechanical components. Use only manufacturer-recommended lubricants to avoid damaging seals or attracting excessive dust.

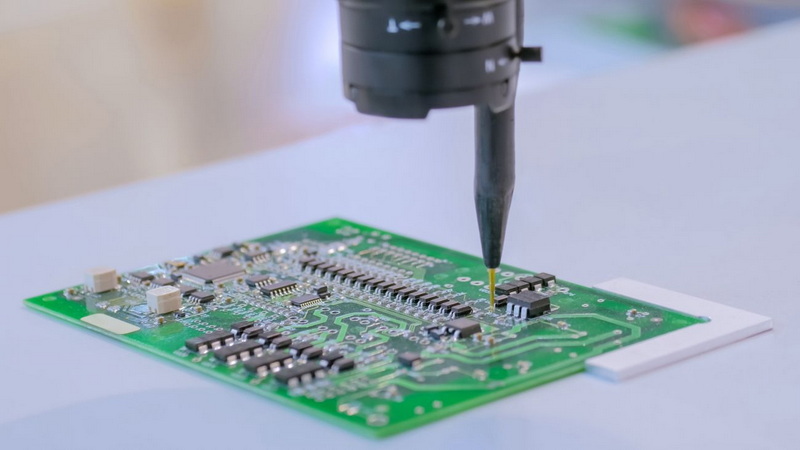

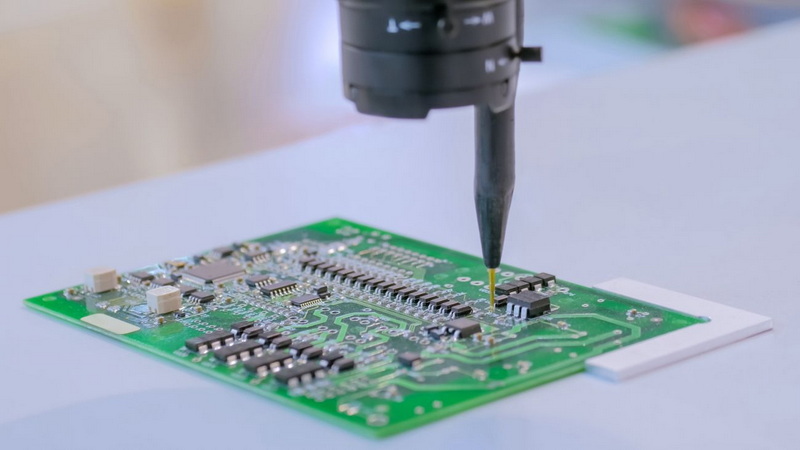

Nozzle and Vacuum System Checks

- Inspect suction nozzles for clogging; clean or replace nozzles as necessary to maintain proper vacuum pressure for component pickup.

- Add liquid oil to maintain the vacuum system's efficiency and prevent nozzle blockages.

Nozzles are the critical interface between the machine and components. Clogged or damaged nozzles can cause components to be dropped or misplaced, leading to production defects.

Monthly Maintenance Tasks

Monthly maintenance is more comprehensive and involves detailed cleaning, inspection, and parts replacement as needed.

Deep Cleaning and Component Inspection

- Clean the machine head thoroughly and replace lubrication on movable shafts.

- Clean dirt and dust from moving parts and air cylinders, applying anti-rust oil where needed.

- Check and tighten screws, belts, and O-rings; replace any worn or aged parts to maintain machine stability and precision.

Loose screws or worn belts can cause vibrations or misalignment, reducing placement accuracy. Regular tightening and inspection prevent mechanical failures.

Electrical and Mechanical Checks

- Inspect grounding wires and electrical connections for secure contact.

- Replace LED lights if brightness diminishes, ensuring optimal visibility of machine status.

Proper grounding prevents electrical noise that can interfere with sensors or control systems. Bright indicator lights help operators quickly identify machine status or errors.

Annual Maintenance Tasks

Annual maintenance is a thorough overhaul to ensure the machine remains reliable over the long term.

Comprehensive Inspection and Part Replacement

- Conduct a detailed inspection of all electrical and mechanical components, including solenoid valves, cylinders, motors, and sensors.

- Replace worn or aged parts proactively to avoid unexpected breakdowns during production.

- Verify the power connection to the electrical box and ensure all safety interlocks and emergency stops function correctly.

Annual checks often require professional technicians or factory service to fully disassemble and inspect critical components.

Key Maintenance Procedures for Optimal Performance

Cleaning and Inspecting Feeders and Nozzles

- Power off the machine before maintenance to ensure safety.

- Remove feeders and clean tape guides, belts, and component pathways to prevent jams and misfeeds.

- Clean nozzles manually with lint-free cloths and fine wires for small apertures, or use professional nozzle cleaning machines for thorough cleaning.

Regular feeder maintenance ensures smooth component supply, while clean nozzles guarantee reliable component pickup and placement.

Calibration and Alignment

- Regularly calibrate the vision system and fiducial recognition to ensure accurate component placement.

- Adjust placement head height and pressure according to PCB thickness and component size to avoid damage or misplacement.

Calibration is essential after maintenance or part replacement to maintain the machine's precision.

Troubleshooting Common Issues

| Issue | Common Causes | Solutions |

| Failure to place components accurately | Incorrect calibration, damaged feeders, poor maintenance | Recalibrate machine, replace feeders, perform routine maintenance |

| Component damage during placement | Malfunctioning machine, overworked parts, poor-quality components | Proper operation, regular checks, use quality components |

| Inaccurate fiducial recognition | Dirty camera lens, calibration errors, software faults | Clean lenses, recalibrate, service software |

| Component pick-up and release issues | Vacuum pressure problems, worn nozzles, vibration errors | Check vacuum and nozzle condition, replace nozzles, verify vibration |

| Machine alarms and errors | Sensor contamination, loose belts, electrical faults | Clean sensors, tighten belts, check electrical connections |

Best Practices for Using Your SMD Pick and Place Machine Set

- Ensure the machine is properly grounded and placed on a stable, level surface to avoid mechanical stress.

- Maintain a controlled workshop environment with stable temperature and humidity, free from flammable materials.

- Train operators thoroughly on the machine's operation and emergency procedures to prevent accidents and damage.

- Always shut down the machine and press the emergency stop before performing any part replacements or repairs.

Environmental factors such as temperature fluctuations or dust can affect machine performance. Maintaining a clean, stable environment helps prevent issues.

Conclusion

Maintaining your SMD pick and place machine set is essential for achieving optimal performance, minimizing downtime, and ensuring high-quality SMT production. By following a structured maintenance schedule-daily cleaning, weekly lubrication, monthly inspections, and annual comprehensive checks-you can significantly extend the lifespan of your equipment and reduce costly failures. Regular calibration, careful inspection of feeders and nozzles, and prompt troubleshooting of common issues will keep your machine running smoothly and reliably. Investing time and effort into maintenance not only protects your equipment but also enhances your production efficiency and product quality.

FAQ

1. How often should I clean the nozzles on my SMD pick and place machine?

Nozzles should be cleaned daily to remove dust and debris. For thorough cleaning, use a professional nozzle cleaning machine periodically to avoid blockages and maintain vacuum efficiency.

2. What lubricant is recommended for the moving parts of the pick and place machine?

Use machine-specific lubricating oils recommended by the manufacturer. Avoid over-lubrication and remove hardened grease before applying fresh lubricant weekly to ensure smooth movement.

3. How can I prevent component placement errors?

Regularly calibrate the vision system and fiducial recognition, inspect and replace damaged feeders, and maintain clean nozzles and sensors to ensure accurate placement.

4. What should I do if my machine frequently alarms during operation?

Check for sensor contamination, clean sensors without excessive lubricating oil, inspect belts for looseness or damage, verify air pressure, and ensure all electrical connections are secure.

5. How important is operator training for maintaining the pick and place machine?

Operator training is critical to avoid misuse, ensure proper maintenance procedures, and handle emergencies safely. Well-trained operators help maintain machine longevity and production quality.