Content Menu

● Understanding the Importance of Maintenance for SMD LED Soldering Machines

● Essential Maintenance Practices for Your SMD LED Soldering Machine

>> 1. Keep the Machine Clean

>> 2. Regular Inspection and Checkups

>> 3. Maintain the Conveyor Belt

>> 4. Monitor and Control Temperature and Humidity

>> 5. Use High-Quality Materials

>> 6. Proper Handling and Storage of SMD LEDs

● Additional Tips for Longevity of Your SMD LED Soldering Machine

● Conclusion

● FAQ

>> 1. How often should I clean my SMD LED soldering machine?

>> 2. What is the ideal temperature range for soldering SMD LEDs?

>> 3. How do I know when to replace the conveyor belt?

>> 4. Why is humidity control important in SMD LED soldering?

>> 5. Can I use any solder paste with my SMD LED soldering machine?

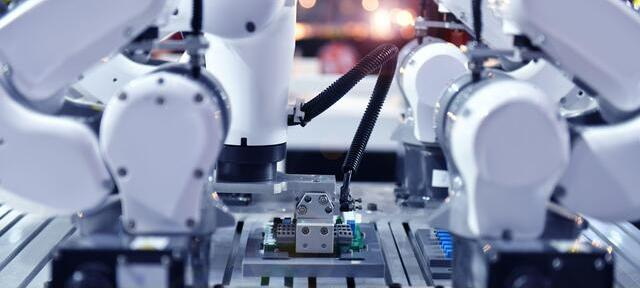

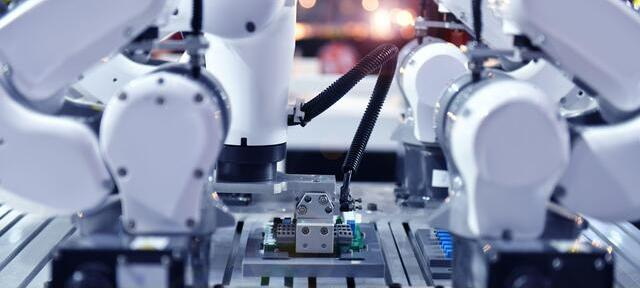

Surface Mount Device (SMD) LED soldering machines play a pivotal role in the electronics manufacturing industry, especially in the assembly of modern LED lighting and display technologies. These machines provide precise, efficient, and repeatable soldering of tiny LED components onto printed circuit boards (PCBs). However, to ensure consistent performance, high-quality solder joints, and a long operational life, proper maintenance of your SMD LED soldering machine is indispensable.

This comprehensive guide will walk you through the essential maintenance practices, expert tips, and troubleshooting advice to help you maximize the lifespan and efficiency of your SMD LED soldering machine.

Understanding the Importance of Maintenance for SMD LED Soldering Machines

SMD LED soldering machines operate under highly controlled thermal and mechanical conditions. They are designed to handle delicate components that require exact temperature profiles and precise handling. Over time, factors such as dust accumulation, mechanical wear, improper handling, and environmental conditions can negatively impact the machine's performance.

Neglecting regular maintenance can lead to:

- Frequent soldering defects such as cold joints, bridging, or tombstoning

- Unexpected machine breakdowns causing costly downtime

- Reduced accuracy in temperature control, risking damage to sensitive SMD LEDs

- Increased wear on mechanical parts like conveyor belts and heating elements

- Contamination of PCBs due to flux residues and dust

By performing routine maintenance, you not only protect your investment but also ensure your production line runs smoothly and efficiently.

Essential Maintenance Practices for Your SMD LED Soldering Machine

1. Keep the Machine Clean

One of the simplest yet most effective maintenance steps is to keep your SMD LED soldering machine clean. Dust, solder residues, and flux can build up inside the machine and on moving parts, leading to malfunctions and poor soldering quality.

Best practices for cleaning include:

- Use a soft brush or compressed air to remove dust from internal components without damaging sensitive parts.

- Wipe the conveyor belt with a lint-free cloth dampened with isopropyl alcohol to remove flux residues and solder splashes.

- Avoid abrasive cleaning agents or tools that can scratch or damage surfaces.

- Clean the soldering tips regularly to prevent oxidation and ensure good heat transfer.

A clean machine ensures smooth mechanical operation and prevents contamination of PCBs, which is critical when working with sensitive SMD LEDs.

2. Regular Inspection and Checkups

Scheduled inspections help identify potential issues before they cause machine failure or production defects.

Inspection checklist:

- Heating Elements: Look for discoloration, cracks, or uneven heating which can indicate deterioration. Replace heating elements as recommended by the manufacturer.

- Conveyor Belt: Check for fraying, cracks, or loss of tension. A loose or damaged belt can cause misalignment and uneven soldering.

- Sensors and Controllers: Verify temperature sensors, thermocouples, and control units are functioning accurately. Faulty sensors can lead to incorrect temperature profiles.

- Electrical Wiring: Inspect wiring and connectors for signs of wear, corrosion, or damage. Loose connections can cause intermittent faults.

- Mechanical Parts: Lubricate moving parts such as rollers and gears with manufacturer-approved lubricants to reduce friction and wear.

Professional servicing by qualified technicians at regular intervals can recalibrate the machine and replace worn parts, ensuring optimal performance.

3. Maintain the Conveyor Belt

The conveyor belt is a critical component that transports PCBs through different soldering zones.

Maintenance tips:

- Clean the conveyor belt daily to remove flux, solder paste residues, and dust.

- Check belt tension regularly and adjust it to avoid slipping or misalignment.

- Lubricate conveyor rollers and bearings to ensure smooth movement.

- Replace the belt immediately if it shows signs of wear or damage to prevent PCB misplacement.

Proper conveyor maintenance ensures consistent PCB positioning and uniform soldering, which is especially important for the tiny and delicate SMD LEDs.

4. Monitor and Control Temperature and Humidity

Temperature control is fundamental in SMD LED soldering. LEDs are sensitive to thermal stress, and improper temperature profiles can cause irreversible damage.

Key points for temperature and humidity control:

- Temperature Calibration: Regularly calibrate the machine's temperature sensors and controllers to maintain accurate heat profiles. Use calibrated thermocouples or thermal cameras for verification.

- Optimal Temperature Settings: Follow manufacturer guidelines for soldering temperatures. For many SMD LEDs, peak reflow temperatures should not exceed 245°C, and manual soldering irons should be set below 315°C.

- Humidity Control: Maintain ambient humidity below 60% relative humidity (RH). Excess moisture can lead to oxidation and soldering defects such as solder balls or voids.

- Environmental Control: Use dehumidifiers or air conditioning in the production area to maintain stable temperature and humidity levels.

Consistent temperature and humidity control protect both the machine and the sensitive SMD LEDs, ensuring reliable solder joints.

5. Use High-Quality Materials

The quality of solder paste, flux, and other consumables directly impacts soldering quality and machine health.

Recommendations:

- Use solder paste and flux specifically formulated for SMD LED applications, as these often have tailored melting points and flux activity.

- Avoid expired or improperly stored solder paste, which can cause poor wetting, bridging, or solder balling.

- Store solder paste in a refrigerated environment and allow it to reach room temperature before use to prevent condensation.

- Use fresh and compatible flux to avoid corrosion or residue buildup inside the machine.

High-quality materials reduce the risk of soldering defects and minimize contamination that can degrade machine components.

6. Proper Handling and Storage of SMD LEDs

Since your machine is designed for SMD LED soldering, proper handling and storage of these components are crucial.

Best practices:

- Store SMD LEDs in moisture barrier bags with desiccants to control moisture absorption.

- Follow Moisture Sensitivity Level (MSL) guidelines recommended by component manufacturers.

- If storage time exceeds recommended limits or if moisture exposure occurs, bake the LEDs at specified temperatures to remove absorbed moisture before soldering.

- Handle LEDs with anti-static tools and wear ESD protection to prevent electrostatic damage.

Proper handling preserves LED integrity and prevents soldering failures caused by moisture or electrostatic discharge.

Additional Tips for Longevity of Your SMD LED Soldering Machine

- Avoid Overheating: Use the lowest effective temperature settings and minimize soldering time to reduce thermal stress on machine components and soldering tips.

- Tip Maintenance: Regularly clean and re-tin soldering iron tips to prevent oxidation and extend tip life. Use tip cleaners or brass wire sponges recommended for SMD soldering.

- Operator Training: Ensure all operators are trained in correct machine operation, maintenance procedures, and troubleshooting to reduce misuse and accidental damage.

- Document Maintenance: Keep detailed logs of maintenance activities, inspections, repairs, and part replacements. This helps track machine health and anticipate future maintenance needs.

- Use Manufacturer-Recommended Parts: Always use genuine replacement parts and consumables recommended by the machine manufacturer to maintain warranty coverage and optimal performance.

Conclusion

Maintaining your SMD LED soldering machine is essential for ensuring its longevity, reliability, and the production of high-quality solder joints. By implementing a routine maintenance schedule that includes thorough cleaning, regular inspections, conveyor belt upkeep, precise temperature and humidity control, and the use of high-quality materials, you can significantly extend the life of your soldering machine. Proper handling and storage of SMD LEDs further enhance soldering quality and protect your investment.

With these best practices, you will reduce downtime, prevent costly repairs, and maintain consistent production quality, ensuring your SMD LED soldering machine remains a valuable asset in your manufacturing process for years to come.

FAQ

1. How often should I clean my SMD LED soldering machine?

It is recommended to clean the machine daily or after each production run to prevent dust and solder residue buildup that can affect performance and solder joint quality.

2. What is the ideal temperature range for soldering SMD LEDs?

For manual soldering, keep the iron temperature below 315°C and soldering time under 2 seconds to avoid damaging the LEDs. Automated reflow profiles typically peak around 245°C but must be precisely controlled according to the LED manufacturer's specifications.

3. How do I know when to replace the conveyor belt?

Replace the conveyor belt if it shows signs of wear such as fraying, cracks, or if it becomes loose and cannot be properly tightened. A worn belt can cause PCB misalignment leading to soldering defects.

4. Why is humidity control important in SMD LED soldering?

High humidity can cause oxidation and moisture absorption in LEDs, leading to soldering defects and damage during reflow soldering. Maintaining humidity below 60% RH is critical to prevent these issues.

5. Can I use any solder paste with my SMD LED soldering machine?

No, it is important to use high-quality, certified solder paste compatible with SMD LED soldering. Using inappropriate or expired solder paste can cause poor solder joints and contaminate the machine.