Content Menu

● Understanding Your SMD IC Soldering Machine

● Essential Maintenance Practices for Longevity

>> 1. Regular Cleaning of the Soldering Iron and Machine

>> 2. Proper Tip Care and Replacement

>> 3. Lubrication of Moving Parts (For Automated Machines)

>> 4. Temperature Calibration and Control

>> 5. Inspection and Preventive Maintenance

● Cleaning and Maintenance Methods for SMT Machines

● Troubleshooting Common Issues Related to SMD IC Soldering Machines

>> Soldering Tip Oxidation and Wear

>> Inconsistent Temperature Control

>> Poor Heat Transfer

>> Mechanical Failures (For Automated Machines)

>> Flux Residue Buildup

● Best Practices to Extend the Life of Your SMD IC Soldering Machine

● Conclusion

● FAQ

>> 1. How often should I clean the soldering iron tip on my SMD IC soldering machine?

>> 2. What temperature should I use for soldering SMD ICs?

>> 3. How do I calibrate the temperature on my soldering machine?

>> 4. Can I use any soldering tip for SMD IC soldering?

>> 5. What maintenance should I perform on an automated SMD IC soldering machine?

● Citations:

Maintaining your SMD IC soldering machine is essential to ensure precision, reliability, and extended service life. Surface Mount Device (SMD) integrated circuits (ICs) require delicate handling and accurate soldering, making the condition of your soldering machine critical. This comprehensive guide covers practical maintenance tips, cleaning routines, calibration, and troubleshooting to maximize the longevity of your SMD IC soldering machine.

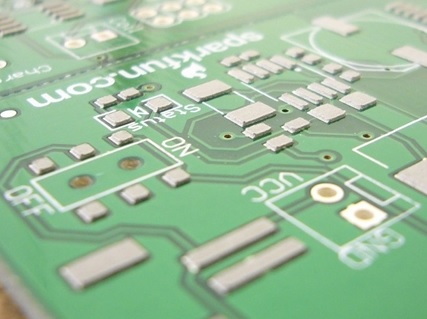

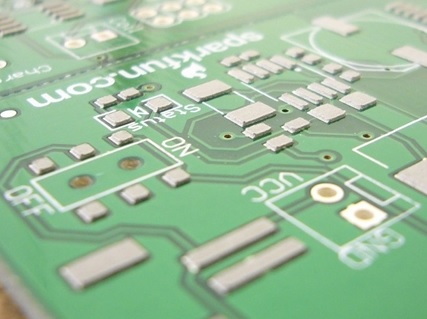

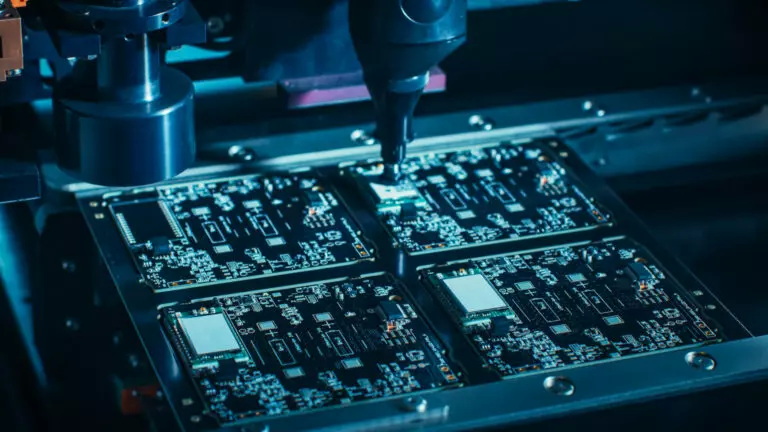

Understanding Your SMD IC Soldering Machine

An SMD IC soldering machine is designed to solder tiny surface mount components onto printed circuit boards (PCBs) with precision heat control. These machines often include temperature-controlled soldering irons or stations, hot air rework stations, and sometimes automated soldering systems. The primary goal is to deliver consistent heat without damaging sensitive components, ensuring strong and reliable solder joints.

The lifespan of these machines depends heavily on:

- Quality of construction and components

- Frequency and intensity of use

- Proper maintenance and cleaning

- Correct calibration and temperature control

Neglecting these factors can lead to premature wear, inaccurate soldering, and costly repairs. Understanding the internal workings and external components of your SMD IC soldering machine is the first step toward effective maintenance.

Essential Maintenance Practices for Longevity

1. Regular Cleaning of the Soldering Iron and Machine

Flux residue, solder splashes, and dust can accumulate on the soldering iron tip and machine surfaces, reducing heat transfer efficiency and causing oxidation. This buildup not only affects soldering quality but can also shorten the lifespan of your equipment.

- Tip Cleaning: Clean the soldering iron tip frequently using a brass sponge or a damp cellulose sponge. Avoid using abrasive materials that can damage the tip.

- Tip Tinning: After cleaning, always apply a thin layer of solder (tinning) to the tip. This protective coating prevents oxidation and improves heat transfer.

- Machine Exterior: Dust and dirt can clog cooling vents and fans, leading to overheating. Use compressed air to blow out dust from vents and clean the machine's exterior surfaces regularly.

- Flux Residue Removal: Use isopropyl alcohol and lint-free cloths to remove flux residues from the soldering iron and machine parts. Flux residues can be corrosive and conductive, potentially causing shorts or damage.

2. Proper Tip Care and Replacement

The soldering tip is the most critical part of the machine, directly affecting solder joint quality and machine longevity.

- Choosing the Right Tip: Use the correct tip shape and size for your SMD IC soldering tasks. Fine conical or small chisel tips are ideal for precision work on tiny components.

- Avoid Excessive Pressure: Applying too much pressure during soldering can deform or damage the tip, reducing its effectiveness.

- Tip Replacement: Replace tips once they become pitted, oxidized beyond cleaning, or physically damaged. Using worn tips leads to poor heat transfer and inconsistent soldering.

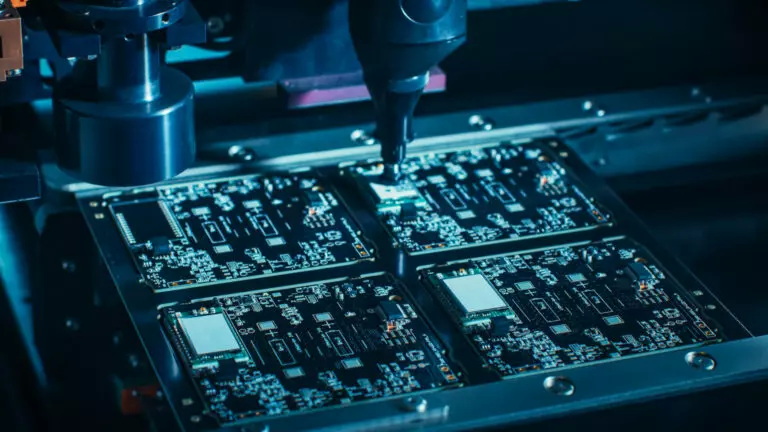

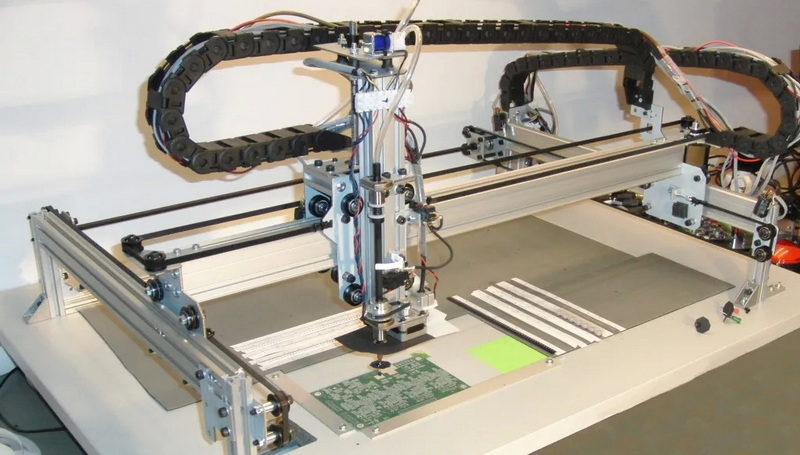

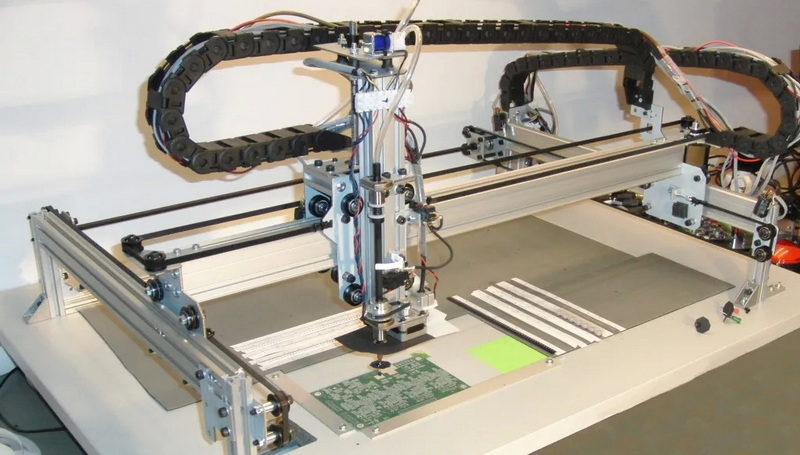

3. Lubrication of Moving Parts (For Automated Machines)

If your soldering machine includes mechanical parts, such as robotic arms or pick-and-place heads, regular lubrication is necessary to prevent wear and ensure smooth operation.

- Use Recommended Lubricants: Always use lubricants specified by the manufacturer to avoid chemical incompatibility.

- Avoid Over-Lubrication: Excess lubricant can attract dust and cause residue buildup, which may interfere with machine operation.

- Scheduled Lubrication: Follow a regular lubrication schedule based on usage intensity to keep mechanical parts functioning optimally.

4. Temperature Calibration and Control

Accurate temperature control is vital for soldering sensitive SMD ICs without damaging components.

- Regular Calibration: Use a reliable temperature probe or thermocouple to measure the actual tip temperature and adjust the soldering station settings accordingly.

- Avoid Overheating: Excessive heat accelerates tip oxidation and can damage delicate ICs. Use the lowest effective temperature for soldering.

- Temperature Stability: Ensure that the soldering machine maintains a stable temperature during operation to avoid thermal shock to components.

5. Inspection and Preventive Maintenance

Routine inspections and preventive maintenance can catch issues before they cause machine failure.

- Check Cables and Connectors: Look for frayed cables, loose connectors, or signs of wear that could cause electrical faults.

- Verify Grounding: Proper grounding is essential for operator safety and to prevent electrostatic discharge (ESD) damage to sensitive components.

- Inspect Heating Elements: Heating elements degrade over time; monitor their performance and replace them as needed.

- Document Maintenance: Keep a maintenance log to track cleaning, calibration, repairs, and part replacements.

Cleaning and Maintenance Methods for SMT Machines

SMT (Surface Mount Technology) machines, including SMD IC soldering machines, require specific cleaning methods to maintain peak performance.

- Dry Cleaning: Use soft brushes and compressed air to remove dust and loose particles from the machine's surface and internal components.

- Wet Cleaning: Apply isopropyl alcohol with lint-free wipes to clean flux residues and other contaminants from soldering tips and machine parts.

- Ultrasonic Cleaning: For delicate components such as nozzles or small mechanical parts, ultrasonic cleaning can remove stubborn residues without causing damage. This method uses high-frequency sound waves in a cleaning solution to gently dislodge contaminants.

- Avoid Water Exposure: Never immerse electronic parts in water or cleaning solutions; use minimal liquid and ensure thorough drying before operation.

Troubleshooting Common Issues Related to SMD IC Soldering Machines

Despite proper maintenance, issues may occasionally arise. Understanding common problems and their solutions can save time and money.

Soldering Tip Oxidation and Wear

- Cause: High-temperature soldering, lack of tip maintenance, or using incompatible solder alloys.

- Solution: Use low-temperature soldering when possible, clean and tin tips regularly, and replace tips when they become oxidized or worn.

Inconsistent Temperature Control

- Cause: Faulty temperature sensors, calibration drift, or damaged heating elements.

- Solution: Calibrate the temperature regularly, inspect and replace sensors or heating elements as needed.

Poor Heat Transfer

- Cause: Dirty or oxidized soldering tips, insufficient tip tinning.

- Solution: Clean tips frequently, keep them tinned, and replace when necessary.

Mechanical Failures (For Automated Machines)

- Cause: Lack of lubrication, worn mechanical parts, or misalignment.

- Solution: Lubricate moving parts regularly, inspect and replace worn components, and recalibrate mechanical systems.

Flux Residue Buildup

- Cause: Excessive or improper flux use, infrequent cleaning.

- Solution: Use recommended flux types and amounts, clean residue promptly with isopropyl alcohol.

Best Practices to Extend the Life of Your SMD IC Soldering Machine

- Invest in Quality Equipment: Choose soldering machines from reputable manufacturers known for durability and support.

- Follow Manufacturer Guidelines: Adhere strictly to recommended operating temperatures, duty cycles, and maintenance schedules.

- Store Properly: When not in use, store the soldering iron in a stand with the tip tinned to prevent oxidation.

- Use Proper Soldering Techniques: Avoid excessive pressure, use appropriate solder alloys, and minimize soldering time to reduce stress on the machine.

- Maintain a Clean Work Environment: Dust and contaminants can accelerate wear; keep your workspace clean and well-ventilated.

- Train Operators: Ensure all users understand proper machine handling and maintenance procedures.

Conclusion

Maintaining your SMD IC soldering machine is a multifaceted process involving regular cleaning, careful tip maintenance, precise temperature calibration, and preventive inspections. By adhering to these best practices, you can significantly extend the lifespan of your soldering equipment, ensure consistent soldering quality, and reduce downtime caused by equipment failure. Proper maintenance not only protects your investment but also improves the reliability of your soldering work on delicate SMD IC components. Remember, a well-maintained soldering machine is the foundation of successful surface mount technology assembly and repair.

FAQ

1. How often should I clean the soldering iron tip on my SMD IC soldering machine?

You should clean the soldering iron tip frequently during use, ideally after every few solder joints, using a brass sponge or damp sponge. After finishing, always tin the tip before storage to prevent oxidation.

2. What temperature should I use for soldering SMD ICs?

Use the lowest temperature possible that still melts the solder effectively, typically around 250°C to 300°C. High temperatures accelerate tip wear and can damage sensitive components.

3. How do I calibrate the temperature on my soldering machine?

Use a reliable temperature probe or thermometer to measure the actual tip temperature. Adjust the soldering station settings accordingly to match the desired temperature. Calibration should be done regularly to maintain accuracy.

4. Can I use any soldering tip for SMD IC soldering?

No, it is best to use fine conical or small chisel tips designed for precision work on small SMD components. Using the correct tip improves heat transfer and reduces the risk of damage to components.

5. What maintenance should I perform on an automated SMD IC soldering machine?

Lubricate moving parts as recommended, clean nozzles and surfaces regularly using dry, wet, or ultrasonic cleaning methods, and perform routine inspections to detect wear or damage early.

Citations:

1.https://www.aixuntech.com/newsinfo/lifespan-of-soldering-station/

2.https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

3.https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html

4.https://www.circuitspecialists.com/blog/soldering-station-maintenance/

5.https://www.techspray.com/ultimate-guide-to-electronic-soldering

6.https://www.aixuntech.com/newsinfo/5%20Frequently%20Asked%20Questions%20about%20SMD%20soldering/

7.https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

8.https://www.instructables.com/How-to-Solder-SMD-ICs-the-easy-way/

9.https://www.chiefdelphi.com/t/smd-soldering/139351

10.https://www.aimsolder.com/wp-content/uploads/legacy-files/smt_ts.pdf

11.https://forum.arduino.cc/t/smd-soldering-do-i-need-hot-air-soldering-station/212692