Content Menu

● Understanding SMT Stencil Frames and Their Importance

>> What Are SMT Stencil Frames?

>> Why Are SMT Stencil Frames Important?

● Best Practices for Maintaining SMT Stencil Frames

>> 1. Regular Cleaning of Stencil Frames and Foils

>> 2. Proper Handling and Storage

>> 3. Correct Installation Procedures

>> 4. Maintain Proper Tension on Stencil Foil

>> 5. Monitor Environmental Conditions

● Common Mistakes to Avoid When Using SMT Stencil Frames

● Cleaning Methods in Detail

>> Manual Wiping

>> Ultrasonic Cleaning

>> Automated Cleaning Machines

● Additional Tips to Extend SMT Stencil Frame Life

● Conclusion

● FAQ

>> 1. What is the difference between framed and frameless SMT stencil frames?

>> 2. How often should SMT stencil frames be cleaned?

>> 3. What is the importance of stencil foil tension in the frame?

>> 4. How does stencil aperture design affect solder paste printing?

>> 5. What environmental conditions should be controlled when using SMT stencil frames?

Surface Mount Technology (SMT) stencil frames are indispensable tools in modern PCB assembly lines. They play a crucial role in the solder paste printing process, ensuring precise and consistent deposition of solder paste onto printed circuit boards (PCBs). Proper maintenance and cleaning of stencil frame SMT components are essential to maintain print quality, reduce defects, and extend the lifespan of stencil frames. This comprehensive guide will explore in detail how to maintain and clean SMT stencil frames properly, covering best practices, cleaning methods, handling tips, common mistakes, and frequently asked questions to help you optimize your SMT production process.

Understanding SMT Stencil Frames and Their Importance

Before diving into maintenance and cleaning procedures, it is essential to understand what SMT stencil frames are and why they are critical in PCB assembly.

What Are SMT Stencil Frames?

An SMT stencil frame is a rigid structure, typically made of aluminum or stainless steel, that holds the stencil foil taut during the solder paste printing process. The stencil foil contains precisely etched apertures that correspond to the PCB pads where solder paste needs to be deposited.

There are two main types of SMT stencil frames:

- Framed SMT Stencils: These consist of a pre-stretched stencil foil permanently mounted on an aluminum frame. The frame provides consistent tension and stability, making them ideal for high-volume and high-precision production environments.

- Frameless SMT Stencils: These are simply the stencil foils without frames. They require separate tensioning mechanisms during printing and are often used in smaller production runs or prototyping due to their lower cost and compact size.

Why Are SMT Stencil Frames Important?

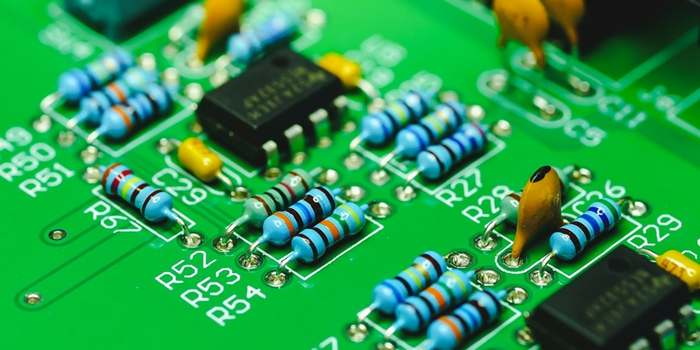

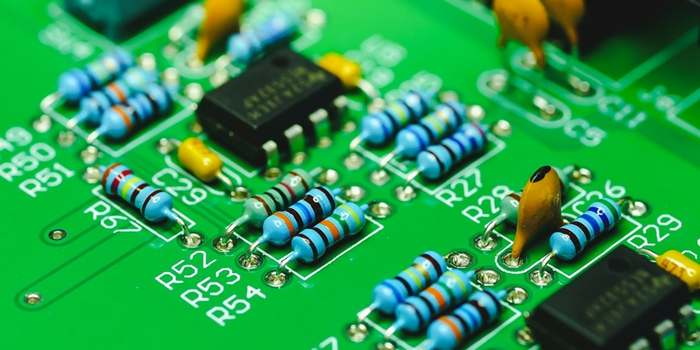

The stencil frame's primary function is to keep the stencil foil flat and taut during the printing process. This stability ensures that solder paste is deposited accurately and consistently onto the PCB pads. Without a properly maintained and cleaned stencil frame, you risk:

- Solder bridging: Excess solder paste connecting adjacent pads, causing shorts.

- Insufficient solder paste: Leading to weak solder joints or open circuits.

- Misalignment: Resulting in poor solder joint formation and component placement issues.

- Stencil damage: Which can cause permanent defects and require costly replacement.

Maintaining the stencil frame SMT components properly is therefore critical to achieving high-quality solder joints and minimizing production defects.

Best Practices for Maintaining SMT Stencil Frames

Proper maintenance of SMT stencil frames involves regular cleaning, careful handling, correct installation, and environmental control. Below are detailed best practices to ensure your stencil frames remain in optimal condition.

1. Regular Cleaning of Stencil Frames and Foils

Cleaning is the most crucial maintenance step to prevent solder paste buildup and aperture clogging.

- Frequency: Ideally, clean the stencil frame SMT after every printing cycle or at least once per shift. Frequent cleaning prevents solder paste from drying and hardening within apertures, which can cause defects.

- Cleaning Methods:

- Manual wiping: Use lint-free cloths or specialized stencil wipe papers pre-soaked with isopropyl alcohol (IPA) or a mild detergent solution. This method is suitable for removing fresh solder paste.

- Ultrasonic cleaning: Employs high-frequency sound waves to dislodge solder paste residues from apertures and stencil surfaces. Ultrasonic cleaning is highly effective for fine-pitch stencils and hard-to-clean areas.

- Automated cleaning machines: These machines provide consistent, reproducible cleaning cycles using spray or immersion methods combined with controlled drying. Automated cleaning reduces operator error and mechanical damage risks.

- Cleaning Agents: Use cleaning agents compatible with stencil materials. Isopropyl alcohol, deionized water, and specialized stencil cleaning solutions are commonly used. Avoid harsh chemicals like acetone or strong acids that can degrade stencil foil, frame coatings, or adhesives.

- Temperature Control: Clean at temperatures below 110°F (43°C) to avoid weakening heat-cured adhesives bonding the stencil foil to the frame and prevent foil distortion.

2. Proper Handling and Storage

- Storage: Store stencil frames vertically in dedicated stencil racks designed to prevent bending or scratching. Avoid stacking stencils horizontally or placing them on abrasive surfaces.

- Handling: Always handle stencil frames by the edges of the frame, avoiding contact with the stencil foil surface to prevent contamination or damage. Use gloves to prevent oils and dirt from hands transferring onto the stencil.

- Environmental Conditions: Keep stencil frames in a clean, dry environment to prevent corrosion, oxidation, and contamination. Avoid exposure to moisture and dust.

3. Correct Installation Procedures

- Squeegee Installation: Install squeegees before mounting the stencil frame to avoid accidental damage to the stencil foil. Do not place squeegees on the stencil foil surface during installation.

- Alignment: Use fiducial marks and automated alignment systems to ensure precise registration of the stencil frame to the PCB. Misalignment can cause solder paste misplacement and defects.

- Tension Adjustment: For frameless stencils, ensure the foil is tensioned correctly in the tensioning system before mounting. For framed stencils, verify the frame's tension integrity regularly.

4. Maintain Proper Tension on Stencil Foil

- Importance of Tension: Proper tension keeps the stencil foil flat and stable during printing, preventing sagging or fluttering that leads to inconsistent paste deposition.

- Avoid Over-Tensioning: Excessive tension can cause the foil to tear or deform, reducing stencil life.

- Avoid Under-Tensioning: Insufficient tension results in foil sagging, aperture deformation, and poor print quality.

5. Monitor Environmental Conditions

- Humidity: High humidity can cause solder paste to slump or degrade, affecting print quality. Maintain controlled humidity levels in the production area.

- Temperature: Avoid excessive heat exposure to stencil frames, which can affect adhesive bonds and foil flatness.

- Cleanliness: Keep the printing area free of dust and airborne contaminants that can settle on stencil frames and foils.

Common Mistakes to Avoid When Using SMT Stencil Frames

Even with the best equipment, improper use or neglect can lead to stencil frame damage and printing defects. Avoid these common mistakes:

- Improper Alignment: Misaligned stencil frames cause solder paste to be deposited off-pad, leading to bridging or insufficient solder.

- Incorrect Tensioning: Over- or under-tensioning the stencil foil causes foil damage or poor paste transfer.

- Using Wrong Frame Material or Size: Using frames incompatible with your stencil foil or printing system can reduce durability and print quality.

- Neglecting Regular Cleaning: Allowing solder paste to build up clogs apertures, reduces print consistency, and increases defects.

- Ignoring Environmental and Handling Conditions: Exposure to moisture, dust, or rough handling causes contamination and physical damage.

- Using Incorrect Stencil Thickness or Aperture Design: Aperture size and stencil thickness directly affect solder paste volume and print quality.

- Failing to Adjust Printing Parameters: Squeegee pressure, speed, and angle must be optimized for each stencil frame and PCB combination.

Cleaning Methods in Detail

Manual Wiping

Manual wiping is the most straightforward cleaning method and is widely used for quick cleaning between print runs.

- Use lint-free cloths or specialized stencil wipe paper.

- Pre-soak wipes with isopropyl alcohol or mild detergent.

- Gently wipe the stencil foil surface, focusing on apertures.

- Avoid excessive pressure to prevent foil deformation.

- Best for removing fresh solder paste or light contamination.

Ultrasonic Cleaning

Ultrasonic cleaning is highly effective for deep cleaning, especially for fine-pitch stencils where apertures are tiny and easily clogged.

- Stencils are submerged in a cleaning solution.

- High-frequency sound waves create cavitation bubbles that dislodge solder paste residues.

- Cleaning time is typically a few minutes.

- After cleaning, stencils are rinsed and dried carefully.

- Ultrasonic cleaning can remove baked-on solder paste that manual wiping cannot.

Automated Cleaning Machines

Automated stencil cleaning machines are designed for high-volume production environments.

- Use spray or immersion cleaning combined with ultrasonic agitation.

- Include drying cycles at controlled temperatures.

- Provide consistent cleaning quality and reduce operator variability.

- Reduce mechanical damage risks compared to manual cleaning.

- Can be programmed for specific stencil frame SMT sizes and materials.

Additional Tips to Extend SMT Stencil Frame Life

- Use Protective Coatings: Some stencil foils have nanocoatings that reduce solder paste adhesion and facilitate cleaning. Handle these coatings carefully to avoid damage.

- Inspect Stencils Regularly: Check for signs of wear, damage, or aperture deformation. Replace stencils that show significant defects to maintain print quality.

- Train Operators: Proper training on stencil handling, cleaning, and installation reduces human error and extends stencil life.

- Document Maintenance Procedures: Maintain logs of cleaning schedules, inspection results, and stencil usage to track performance and identify issues early.

Conclusion

Maintaining and cleaning SMT stencil frames properly is a fundamental aspect of ensuring high-quality solder paste printing and reliable PCB assembly. Regular cleaning using appropriate methods such as manual wiping, ultrasonic cleaning, or automated cleaning machines prevents aperture clogging and solder paste buildup. Proper handling, storage, and installation practices protect stencil frames from damage and contamination. Maintaining correct foil tension and controlling environmental conditions further enhance print consistency and stencil longevity.

Avoiding common mistakes like misalignment, improper tensioning, and neglecting cleaning routines can significantly reduce defects such as solder bridging and insufficient solder joints. By implementing these best practices, manufacturers can improve yield, reduce downtime, and extend the lifespan of their stencil frame SMT components, ultimately leading to more efficient and cost-effective SMT production.

FAQ

1. What is the difference between framed and frameless SMT stencil frames?

Framed stencils include a rigid aluminum frame with pre-stretched foil, providing stability and ease of use in high-volume production. Frameless stencils consist only of the foil and require tensioning systems during printing, making them more suitable for low-volume or prototyping applications.

2. How often should SMT stencil frames be cleaned?

SMT stencil frames should be cleaned after every printing cycle or at least once per shift to prevent solder paste residue buildup and aperture clogging, which can cause printing defects.

3. What is the importance of stencil foil tension in the frame?

Proper foil tension ensures the stencil remains flat and stable during printing. Over-tensioning can cause foil tears or deformation, while under-tensioning leads to sagging and inconsistent solder paste deposition, resulting in defects.

4. How does stencil aperture design affect solder paste printing?

Aperture size, shape, and area ratio determine the volume of solder paste deposited. Poor aperture design can cause excessive or insufficient solder paste, leading to bridging, shorts, or weak solder joints.

5. What environmental conditions should be controlled when using SMT stencil frames?

Humidity and temperature should be controlled to prevent solder paste degradation and stencil contamination. Stencils should be stored in clean, dry environments to avoid corrosion and damage.