Content Menu

● Understanding the Importance of Maintenance

● Regular Inspection and Preventive Maintenance

>> Daily Inspections

>> Weekly Maintenance

>> Monthly Maintenance

● Proper Cleaning Techniques

>> Step 1: Preparation

>> Step 2: Remove Excess Solder Paste

>> Step 3: Apply Cleaning Solution

>> Step 4: Clean the Stencil

>> Step 5: Rinse and Dry

>> Step 6: Clean the Printer Frame and Components

● Best Practices for Stencil Care

● Optimizing Printer Settings

>> Squeegee Pressure and Speed

>> Stencil-to-Board Separation Speed

>> Print Stroke Length

● Troubleshooting Common Issues

>> Poor Print Quality

>> Paste Smearing

>> Incomplete Aperture Fill

● Training and Documentation

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. How often should I clean my manual SMT stencil printer?

>> 2. What cleaning solutions are safe to use on my stencil?

>> 3. How can I extend the lifespan of my manual SMT stencil printer?

>> 4. What signs indicate that my stencil needs replacement?

>> 5. Can I repair a damaged manual SMT stencil printer stencil?

● Citations:

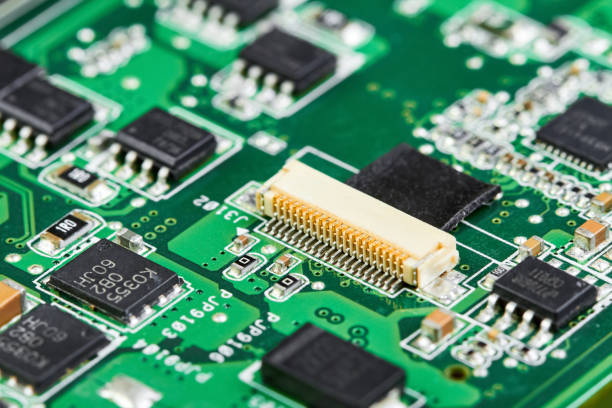

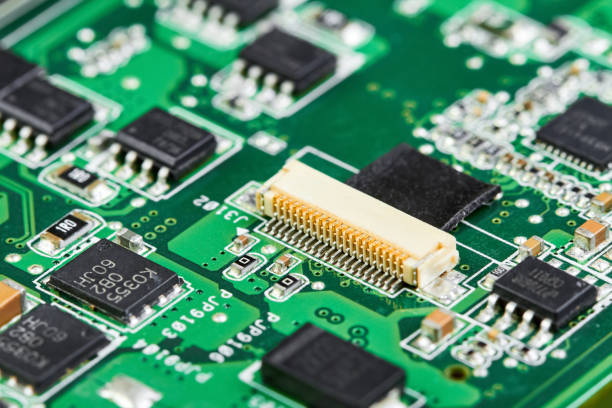

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, and at the heart of this process lies the manual SMT stencil printer. This crucial piece of equipment is responsible for accurately applying solder paste to printed circuit boards (PCBs), ensuring proper component placement and reliable solder joints. To maintain the precision and efficiency of your manual SMT stencil printer, proper maintenance and cleaning are essential. This comprehensive guide will explore the best practices for maintaining and cleaning your manual SMT stencil printer, ultimately extending its lifespan and improving your production quality.

Understanding the Importance of Maintenance

Before delving into the specifics of maintenance and cleaning, it's crucial to understand why these practices are so important for your manual SMT stencil printer. Regular maintenance and cleaning:

1. Ensure consistent print quality

2. Extend the lifespan of the stencil and printer

3. Reduce downtime and production delays

4. Minimize defects and rework

5. Improve overall production efficiency

By implementing a robust maintenance and cleaning routine, you can significantly enhance the performance and longevity of your manual SMT stencil printer.

Regular Inspection and Preventive Maintenance

Daily Inspections

Start each day by performing a quick visual inspection of your manual SMT stencil printer. Look for any signs of wear, damage, or misalignment. Pay close attention to:

- The stencil surface for any visible defects or debris

- The alignment pins and clamps for proper positioning

- The squeegee blades for wear or damage

- The frame for any signs of warping or damage

Weekly Maintenance

On a weekly basis, perform a more thorough inspection and maintenance routine:

1. Check and adjust the tension of the stencil if necessary

2. Inspect and clean the underside of the stencil

3. Verify the alignment of the printer using a test print

4. Lubricate moving parts as recommended by the manufacturer

5. Check and tighten any loose screws or bolts

Monthly Maintenance

Once a month, perform a comprehensive maintenance check:

1. Conduct a full calibration of the printer

2. Replace worn squeegee blades

3. Deep clean all components of the printer

4. Inspect and replace any worn gaskets or seals

5. Update firmware or software if applicable

Proper Cleaning Techniques

Cleaning your manual SMT stencil printer is crucial for maintaining print quality and extending the life of your equipment. Here's a step-by-step guide to cleaning your stencil and printer:

Step 1: Preparation

Before cleaning, gather all necessary materials:

- Lint-free wipes

- Isopropyl alcohol or specialized stencil cleaning solution

- Soft-bristled brushes

- Compressed air

- Personal protective equipment (gloves, safety glasses)

Step 2: Remove Excess Solder Paste

Begin by removing any excess solder paste from the stencil:

1. Use a plastic scraper or spatula to gently remove large deposits of paste[1].

2. Be careful not to damage the stencil surface or apertures.

Step 3: Apply Cleaning Solution

Next, apply the cleaning solution to the stencil:

1. Use a lint-free wipe or soft brush to apply the cleaning solution to the stencil surface[1].

2. Pay special attention to the apertures and areas with dried paste.

3. Allow the solution to sit for a few minutes to loosen stubborn residues.

Step 4: Clean the Stencil

Now, clean the stencil thoroughly:

1. Use a lint-free wipe to gently wipe the stencil in one direction, following the tension of the stencil[1].

2. For stubborn residues, use a soft-bristled brush to gently scrub the affected areas.

3. Pay extra attention to the apertures, ensuring they are completely clear of paste.

Step 5: Rinse and Dry

After cleaning, rinse and dry the stencil:

1. Use isopropyl alcohol or a specialized rinsing solution to remove any remaining cleaning solution.

2. Dry the stencil thoroughly using compressed air or lint-free wipes.

3. Ensure no moisture remains, as this can lead to oxidation or corrosion.

Step 6: Clean the Printer Frame and Components

Don't forget to clean other parts of the printer:

1. Wipe down the frame, squeegee blades, and other components with a lint-free cloth dampened with isopropyl alcohol.

2. Clean the alignment pins and clamps to ensure proper positioning.

3. Inspect and clean the underside of the stencil support system.

Best Practices for Stencil Care

To maximize the lifespan of your stencil and maintain print quality, follow these best practices:

1. Handle stencils with care, using gloves to prevent fingerprints and contamination[2].

2. Store stencils in a clean, dry environment when not in use[2].

3. Use proper tension when mounting the stencil to prevent warping or damage.

4. Clean the stencil immediately after use to prevent paste from drying and hardening.

5. Use only recommended cleaning solutions and materials to avoid damaging the stencil.

Optimizing Printer Settings

Proper maintenance also involves optimizing your manual SMT stencil printer settings:

Squeegee Pressure and Speed

Adjust the squeegee pressure and speed to achieve optimal paste deposition:

1. Start with the manufacturer's recommended settings.

2. Perform test prints and adjust as needed for your specific paste and PCB requirements.

3. Monitor print quality and adjust settings if you notice any issues.

Stencil-to-Board Separation Speed

The speed at which the stencil separates from the PCB can affect print quality:

1. Set the separation speed to allow for clean release of the paste from the apertures.

2. Adjust based on the viscosity of your solder paste and the complexity of your PCB design.

Print Stroke Length

Optimize the print stroke length to ensure complete coverage:

1. Set the stroke length to slightly overlap the PCB edges.

2. Avoid excessive overhang, which can lead to paste waste and potential contamination.

Troubleshooting Common Issues

Even with proper maintenance, you may encounter issues with your manual SMT stencil printer. Here are some common problems and solutions:

Poor Print Quality

If you notice inconsistent or poor print quality:

1. Check the cleanliness of the stencil and apertures.

2. Verify the stencil tension and alignment.

3. Inspect the squeegee blades for wear or damage.

4. Adjust printer settings as needed.

Paste Smearing

If solder paste is smearing on the PCB:

1. Check the stencil-to-board separation speed.

2. Verify the viscosity of your solder paste.

3. Ensure the stencil is clean and free from residue.

Incomplete Aperture Fill

If apertures are not filling completely:

1. Check the squeegee pressure and speed.

2. Verify the solder paste viscosity and temperature.

3. Inspect the apertures for blockages or damage.

Training and Documentation

Proper maintenance and cleaning procedures are only effective if they are consistently followed. To ensure this:

1. Develop clear, written procedures for maintenance and cleaning tasks.

2. Train all operators on these procedures and the importance of following them.

3. Create a maintenance log to track all inspections, cleanings, and repairs.

4. Regularly review and update procedures based on equipment performance and any issues encountered.

Conclusion

Maintaining and cleaning a manual SMT stencil printer is crucial for ensuring longevity and consistent print quality. By implementing regular inspection routines, proper cleaning techniques, and optimizing printer settings, you can significantly extend the life of your equipment and improve your overall production efficiency. Remember that prevention is key – addressing small issues before they become major problems can save time, money, and frustration in the long run.

Investing time and resources into proper maintenance and cleaning of your manual SMT stencil printer will pay dividends in terms of improved print quality, reduced downtime, and extended equipment lifespan. By following the guidelines outlined in this article and staying vigilant in your maintenance efforts, you can ensure that your manual SMT stencil printer remains a reliable and efficient tool in your electronics manufacturing process for years to come.

Frequently Asked Questions (FAQ)

1. How often should I clean my manual SMT stencil printer?

The frequency of cleaning depends on your production volume and the type of solder paste used. As a general rule, clean the stencil after each production run or at least daily for high-volume operations. For low-volume production, clean the stencil at the end of each day or whenever you switch to a different solder paste type[1].

2. What cleaning solutions are safe to use on my stencil?

Most stencils can be safely cleaned with isopropyl alcohol or specialized stencil cleaning solutions. Avoid using harsh chemicals or abrasive materials that could damage the stencil surface. Always consult your stencil manufacturer's recommendations for specific cleaning products[1].

3. How can I extend the lifespan of my manual SMT stencil printer?

To extend the lifespan of your manual SMT stencil printer, follow these tips:

- Implement a regular maintenance schedule

- Clean the stencil and printer components thoroughly after each use

- Handle stencils with care and store them properly when not in use

- Train operators on proper use and maintenance procedures

- Address any issues or abnormalities promptly[2]

4. What signs indicate that my stencil needs replacement?

Signs that your stencil may need replacement include:

- Visible damage or deformation of the stencil surface

- Consistent print quality issues that persist after cleaning and adjustment

- Apertures that no longer meet size or shape specifications

- Difficulty maintaining proper tension

- Excessive wear around high-use areas of the stencil[2]

5. Can I repair a damaged manual SMT stencil printer stencil?

Minor damage to a stencil, such as small scratches or dents, can sometimes be repaired by a professional stencil manufacturer. However, significant damage or wear usually requires stencil replacement. It's essential to assess the cost of repair versus replacement and consider the potential impact on print quality when deciding whether to repair a damaged stencil[2].

Citations:

[1] https://www.raypcb.com/smt-stencil-cleaning-operation-content-and-precautions/

[2] https://silmantech.com/how-to-prolong-the-lifespan-of-smt-stencils/

[3] https://rigidflexpcb.org/smt-stencil-and-laser-stencil/

[4] https://patents.google.com/patent/US20100170621A1

[5] https://www.youtube.com/watch?v=cCT7bWHyGxM

[6] https://artist-3d.com/comprehensive-guide-to-smt-stencils/

[7] https://fctsolder.com/wp-content/uploads/2017/08/2017-APEX-Durability-of-Stencil-Nanocoatings-Final.pdf

[8] https://www.made-in-china.com/products-search/hot-china-products/Smt_Stencil_Printer.html

[9] https://rigidflexpcb.org/comprehensive-guide-to-smt-stencils/

[10] https://blog.caplinq.com/improving-the-performance-of-your-smt-process-understanding-stencil-treatments_4167/