Content Menu

● Understanding SMT PCB Layout Design Rules

>> Categories of SMT PCB Design Rules

● Key Principles to Improve SMT PCB Layouts

>> 1. Use Proper Footprints and Land Patterns

>> 2. Optimize Component Placement

>> 3. Keep SMT Components on One Side When Possible

>> 4. Follow Design for Manufacturing (DFM) Guidelines

>> 5. Maintain Adequate Spacing and Clearance

>> 6. Use Test Points for Easy Troubleshooting

● Implementing SMT PCB Layout Design Rules in CAD Tools

>> Examples of SMT-Specific Design Rules in Altium Designer

● Best Practices Summary for SMT PCB Layout Design Rule Application

● Conclusion

● FAQ

>> 1. What is the importance of SMT PCB layout design rules?

>> 2. How much spacing should be maintained between SMT components?

>> 3. Why should SMT components be placed on one side of the PCB?

>> 4. What role do test points play in SMT PCB layouts?

>> 5. How do CAD tools help enforce SMT PCB layout design rules?

● Citations:

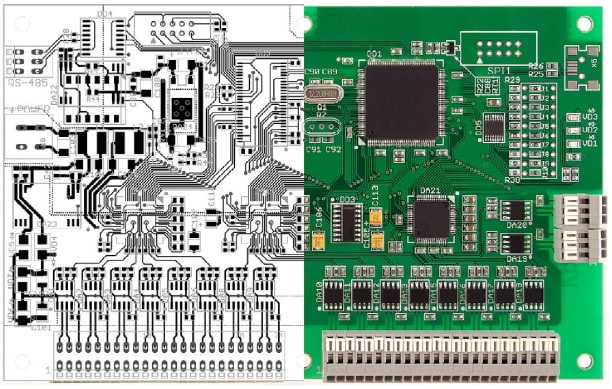

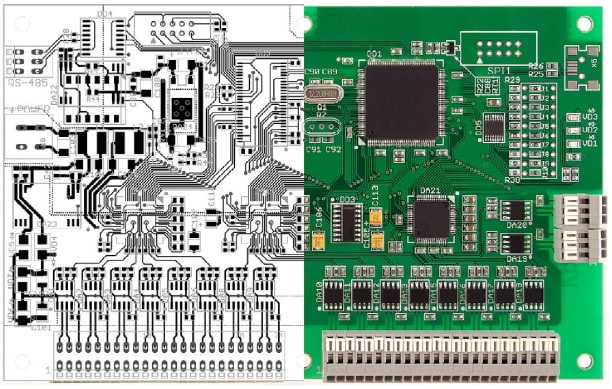

Surface Mount Technology (SMT) has revolutionized printed circuit board (PCB) manufacturing by enabling smaller, faster, and more cost-effective electronic assemblies. However, the success of SMT assembly heavily depends on the quality of the PCB layout and adherence to proper design rules. This article explores how to improve SMT PCB layouts by applying effective SMT PCB layout design rules, ensuring manufacturability, reliability, and performance.

Understanding SMT PCB Layout Design Rules

SMT PCB layout design rules are a set of constraints and guidelines that govern the placement, routing, and spacing of surface mount components on a PCB. These rules ensure that the board can be manufactured and assembled without defects, while also optimizing electrical performance and mechanical robustness.

Categories of SMT PCB Design Rules

- Electrical Rules: Define parameters such as trace width, impedance control, and clearance to prevent electrical failures.

- Routing Rules: Include trace width, via styles, routing layers, and fanout control to optimize signal integrity and manufacturability.

- SMT Rules: Specific to surface mount devices, these rules govern pad sizes, component spacing, and placement orientation.

- Manufacturing Rules: Address minimum annular rings, hole sizes, solder mask clearances, and board outline clearances to ensure fabrication and assembly quality[7][8].

Key Principles to Improve SMT PCB Layouts

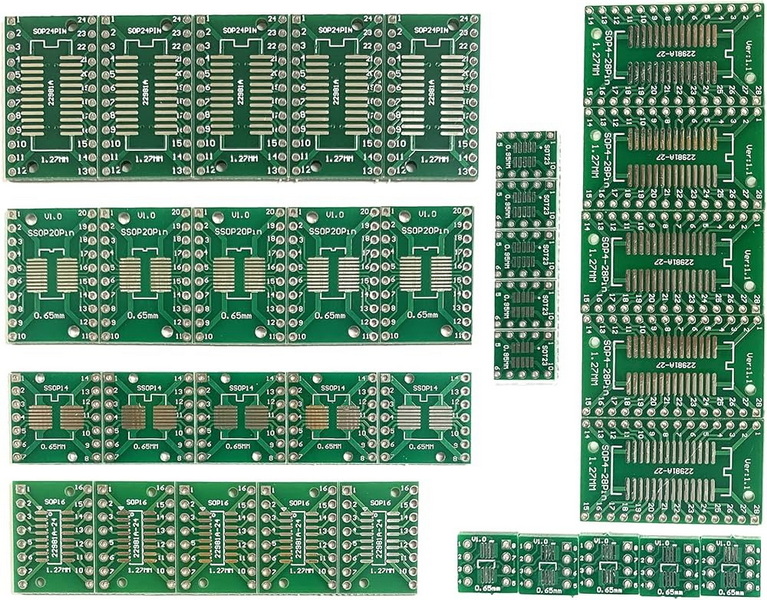

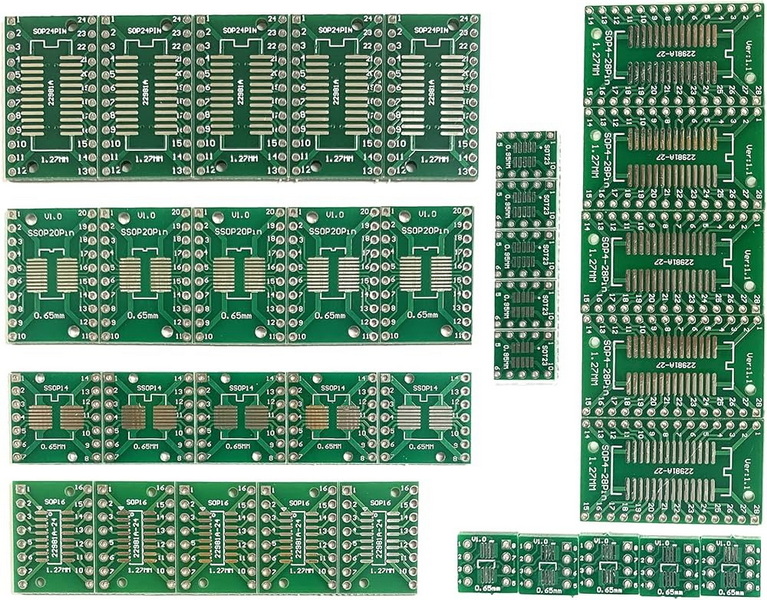

1. Use Proper Footprints and Land Patterns

Accurate component footprints are fundamental to successful SMT assembly. Footprints must comply with manufacturer specifications and IPC standards to ensure correct pad sizes and soldering areas. Proper toe, heel, and side clearances in footprints help prevent solder bridging and improve joint reliability[4].

2. Optimize Component Placement

- Logical Grouping: Place related components close together to minimize trace lengths and reduce electromagnetic interference (EMI).

- Orientation Consistency: Align all SMT components in the same orientation to facilitate faster and more accurate assembly.

- Avoid Overcrowding: Maintain sufficient spacing between components to ease solder paste application, inspection, and rework. Recommended minimum spacing is ≥0.3mm for homogeneous components and adjusted for height differences in heterogeneous components[3][4].

3. Keep SMT Components on One Side When Possible

Placing all SMT components on one side simplifies assembly, reduces errors, and lowers manufacturing costs. While double-sided SMT is common in miniaturized designs, single-sided placement remains preferable for ease of assembly and higher yield[4][5].

4. Follow Design for Manufacturing (DFM) Guidelines

DFM guidelines provided by assembly houses include recommendations on component spacing, orientation, and pad design. Adhering to these guidelines reduces assembly defects and improves yield. For example, components near PCB edges should be aligned parallel to the board outline to withstand mechanical stresses during depaneling[3][4].

5. Maintain Adequate Spacing and Clearance

Proper spacing between pads, traces, and components prevents solder bridging and shorts. Design rules should specify minimum clearances based on manufacturing capabilities and electrical requirements. For example, line widths should not be smaller than 6 mils, and font sizes for silkscreen should be no smaller than 50 mils to ensure readability and manufacturability[2][3].

6. Use Test Points for Easy Troubleshooting

Including clearly marked test points in accessible locations facilitates post-assembly testing and debugging. Test points should be placed away from dense component areas to allow probe access without damaging components[4].

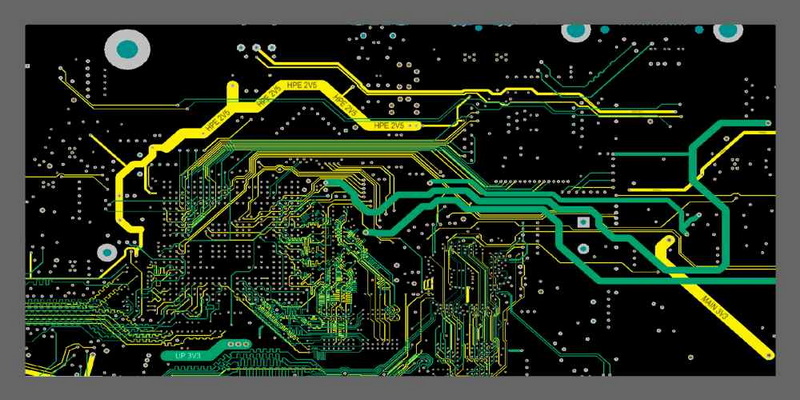

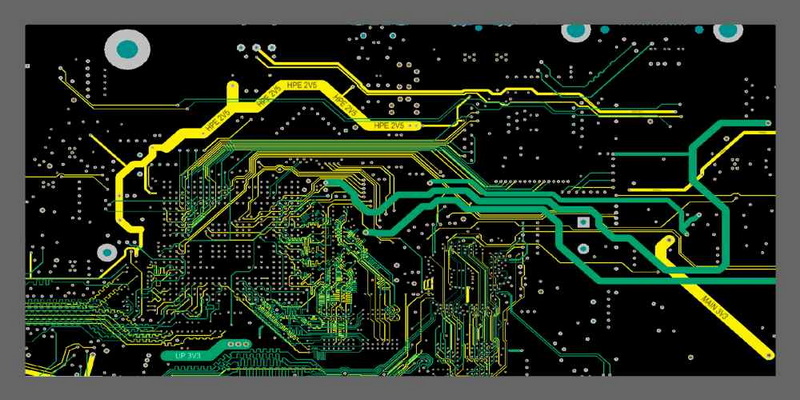

Implementing SMT PCB Layout Design Rules in CAD Tools

Modern PCB design software like Altium Designer allows designers to define and enforce SMT PCB layout design rules through rule-based systems. These rules can be hierarchical and prioritized to resolve conflicts automatically during layout.

Examples of SMT-Specific Design Rules in Altium Designer

- SMD to Corner Rule: Defines the minimum distance from surface mount device pads to board corners to avoid mechanical stress.

- SMD Entry Rule: Controls where routing is allowed to enter or exit SMD pads.

- Fanout Control: Manages via placement and trace routing from SMT pads to inner layers[1][7][9].

By setting these rules early in the design process, designers can prevent common layout errors and ensure compliance with manufacturing constraints.

Best Practices Summary for SMT PCB Layout Design Rule Application

| Aspect | Best Practice |

| Footprint Design | Use IPC-compliant footprints with correct pad sizes and solder mask openings |

| Component Placement | Group related components, maintain consistent orientation, avoid overcrowding |

| Component Side | Prefer placing SMT components on one side of the PCB |

| Spacing and Clearance | Maintain minimum spacing (≥0.3mm or per DFM), ensure clearances for soldering and inspection |

| Routing | Use appropriate trace widths, avoid sharp corners, and follow fanout rules |

| Mechanical Considerations | Align components near board edges parallel to outline, avoid placing components too close to edges |

| Thermal Management | Use thermal vias and copper pours to dissipate heat |

| Signal Integrity | Maintain controlled impedance, differential pair routing, and minimize crosstalk |

| Testing | Include accessible test points for post-assembly verification |

Conclusion

Improving SMT PCB layouts with proper design rules is essential for achieving high-quality, reliable, and manufacturable electronic assemblies. By carefully applying SMT PCB layout design rules—covering footprint accuracy, component placement, spacing, orientation, and adherence to DFM guidelines—designers can minimize assembly defects, reduce costs, and enhance product performance. Leveraging rule-driven PCB design tools further streamlines the process, ensuring that the layout meets stringent manufacturing and electrical requirements. Ultimately, a well-optimized SMT PCB layout is a critical foundation for successful surface mount assembly and long-term product reliability.

FAQ

1. What is the importance of SMT PCB layout design rules?

SMT PCB layout design rules ensure that the PCB can be manufactured and assembled without defects, improving reliability, reducing costs, and optimizing electrical performance[4][7].

2. How much spacing should be maintained between SMT components?

A minimum spacing of 0.3mm is recommended for homogeneous components, with adjustments for height differences in heterogeneous components to facilitate soldering and inspection[3].

3. Why should SMT components be placed on one side of the PCB?

Placing SMT components on one side simplifies assembly, reduces errors, and lowers manufacturing costs, although double-sided placement is common in compact designs[4][5].

4. What role do test points play in SMT PCB layouts?

Test points allow easy access for testing and troubleshooting after assembly, helping identify faults and ensuring product quality[4].

5. How do CAD tools help enforce SMT PCB layout design rules?

CAD tools like Altium Designer provide rule-based systems to define, prioritize, and automatically check SMT design rules during layout, preventing errors and ensuring manufacturability[1][7][9].

Citations:

[1] https://www.altium.com/documentation/altium-designer/pcb-smt-rules

[2] https://resources.pcb.cadence.com/blog/2023-pcb-design-layout-guidelines-for-engineers

[3] https://wellerpcb.com/pcb-layout-guidelines-for-smt-assembly-process-limits

[4] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[5] https://www.proto-electronics.com/blog/best-rules-for-pcb-components-placement

[6] https://resources.altium.com/p/pcb-layout-guidelines

[7] https://www.altium.com/cn/documentation/altium-designer/pcb-design-rule-types?version=17

[8] https://www.protoexpress.com/kb/pcb-layout-rules/

[9] https://www.altium.com/cn/documentation/altium-nexus/pcb-smt-rule-smd-to-corner?version=2.0