Content Menu

● Understanding SMT Feeders

● Common Issues with SMT Feeders

● Identifying Issues in SMT Feeders

>> Visual Inspection

>> Monitoring Performance Metrics

>> Utilizing Diagnostic Tools

>> Engaging Operators

● Fixing Common SMT Feeder Issues

>> 1. Component Jams

>> 2. Misalignment

>> 3. Feeding Errors

>> 4. Electrical Failures

>> 5. Wear and Tear

● Preventative Maintenance Strategies

>> Regular Cleaning

>> Scheduled Maintenance

>> Operator Training

● Conclusion

● FAQ

>> 1. What are common signs that my SMT feeder is malfunctioning?

>> 2. How often should I perform maintenance on my SMT feeder?

>> 3. Can I fix my SMT feeder myself?

>> 4. What tools do I need for diagnosing SMT feeder issues?

>> 5. How can I prevent feeding errors in my SMT feeder?

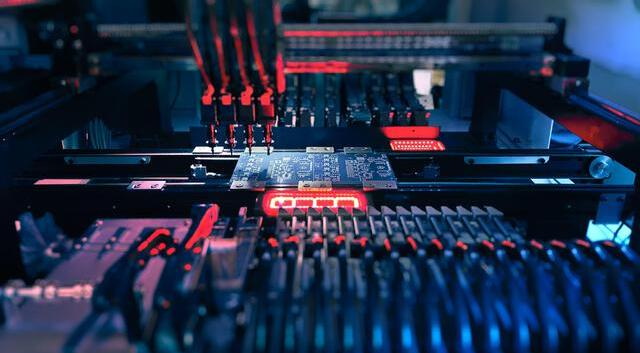

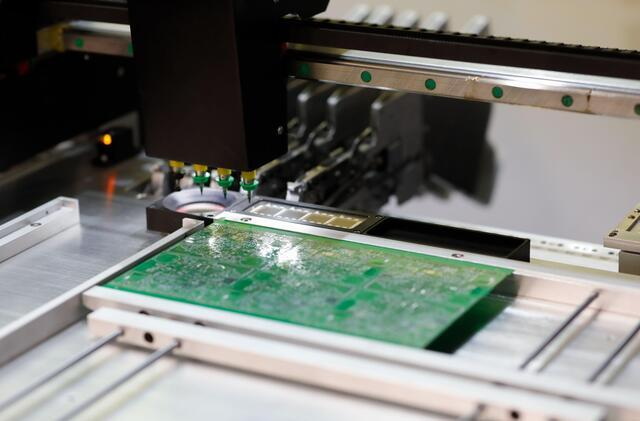

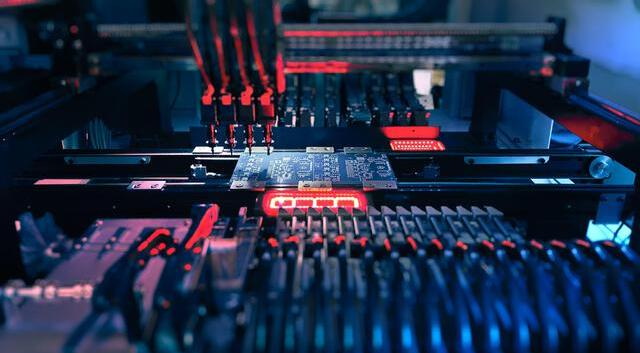

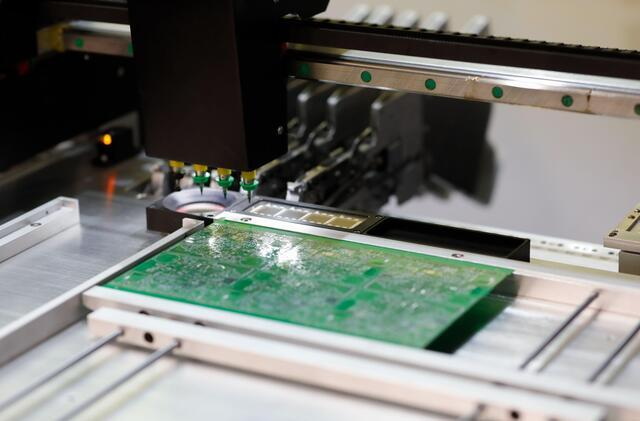

Surface Mount Technology (SMT) feeders are essential components in the assembly process of electronic circuits. They play a critical role in ensuring that components are delivered accurately and efficiently to the pick-and-place machines. However, like any mechanical system, SMT feeders can encounter issues that may disrupt production. Identifying and fixing these issues promptly is vital for maintaining productivity and minimizing downtime. This article will explore common problems associated with SMT feeders, methods for identifying these issues, and effective strategies for resolving them quickly.

Understanding SMT Feeders

SMT feeders are devices that hold and supply surface mount components to automated assembly machines. They come in various types, including:

- Vibratory Feeders: Use vibration to move components.

- Tape Feeders: Deliver components from a tape reel.

- Stick Feeders: Hold components in a stick format.

Each feeder type has its unique advantages and challenges, but they all require regular maintenance and troubleshooting to ensure optimal performance.

Common Issues with SMT Feeders

Before diving into identification and resolution techniques, it's essential to understand the typical problems that can occur with SMT feeders:

- Component Jams: Components can become stuck in the feeder, preventing proper delivery.

- Misalignment: If the feeder is not correctly aligned with the pick-and-place machine, it can lead to misplacement of components.

- Feeding Errors: Inconsistent feeding of components can result from mechanical wear or improper setup.

- Electrical Failures: Issues with the feeder's electrical components can disrupt operation.

- Wear and Tear: Over time, parts of the feeder may wear out, affecting performance.

Identifying Issues in SMT Feeders

To maintain efficiency, operators must be able to identify issues quickly. Here are some effective methods for diagnosing problems:

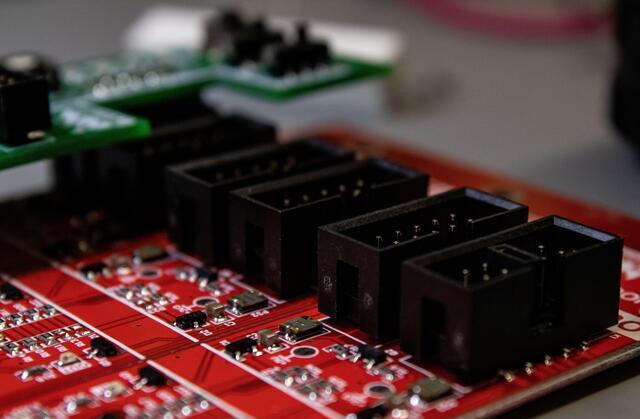

Visual Inspection

Conducting regular visual inspections of SMT feeders is crucial. Look for:

- Signs of wear on moving parts.

- Loose connections or damaged wiring.

- Accumulation of dust or debris that could obstruct movement.

Monitoring Performance Metrics

Keep track of key performance indicators (KPIs) such as:

- Component placement accuracy.

- Downtime duration.

- Frequency of feeding errors.

Analyzing these metrics can help identify patterns that indicate underlying issues.

Utilizing Diagnostic Tools

Many modern SMT feeders come equipped with diagnostic tools that can provide real-time data on their performance. Use these tools to:

- Monitor error codes.

- Track component flow rates.

- Assess electrical performance.

Engaging Operators

Operators who work closely with the feeders often have valuable insights into recurring issues. Regularly engage them in discussions about their experiences and observations.

Fixing Common SMT Feeder Issues

Once an issue has been identified, it's crucial to address it promptly. Here are some common problems and their solutions:

1. Component Jams

Identification: If the feeder stops delivering components or you hear unusual noises, a jam may have occurred.

Fix:

- Stop the machine immediately to prevent further damage.

- Open the feeder and carefully remove any jammed components.

- Check for debris or misaligned parts that could cause future jams.

2. Misalignment

Identification: If components are consistently misaligned during placement, this could indicate an alignment issue.

Fix:

- Adjust the feeder's position according to the machine's specifications.

- Use alignment tools or guides to ensure proper positioning.

3. Feeding Errors

Identification: If you notice inconsistent component delivery or skipped placements, feeding errors may be present.

Fix:

- Check for worn-out parts such as belts or rollers and replace them if necessary.

- Ensure that the feeder is calibrated correctly according to the component specifications.

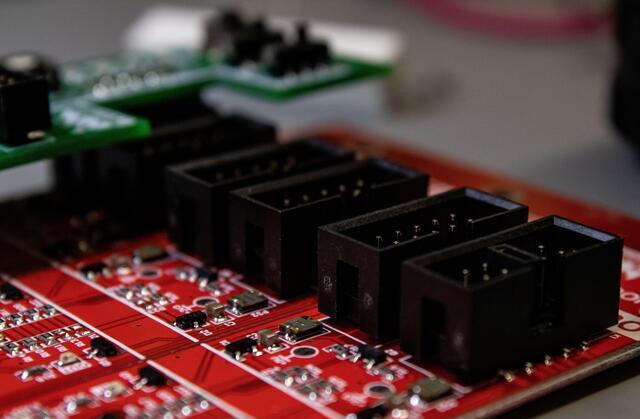

4. Electrical Failures

Identification: If the feeder fails to operate or shows error codes, electrical issues may be at play.

Fix:

- Inspect wiring for damage or loose connections.

- Test electrical components with a multimeter to identify faults and replace faulty parts as needed.

5. Wear and Tear

Identification: Regular use can lead to wear on various parts of the feeder.

Fix:

- Schedule routine maintenance checks to replace worn parts before they fail.

- Lubricate moving parts regularly to reduce friction and wear.

Preventative Maintenance Strategies

To minimize downtime and extend the lifespan of SMT feeders, implement preventative maintenance strategies:

Regular Cleaning

Keep feeders clean by removing dust and debris regularly. A clean environment reduces the risk of jams and mechanical failures.

Scheduled Maintenance

Establish a routine maintenance schedule that includes inspections, part replacements, and calibrations based on usage frequency.

Operator Training

Ensure operators are well-trained in handling feeders properly. This training should cover troubleshooting techniques, maintenance procedures, and best practices for component handling.

Conclusion

Identifying and fixing issues in SMT feeders quickly is essential for maintaining efficient production lines in electronics manufacturing. By understanding common problems, employing effective diagnostic techniques, and implementing preventative maintenance strategies, operators can ensure their SMT feeders operate smoothly. Regular training for operators also plays a crucial role in minimizing downtime caused by feeder issues. Ultimately, a proactive approach will lead to increased productivity and reduced costs associated with repairs and replacements.

FAQ

1. What are common signs that my SMT feeder is malfunctioning?

Common signs include unusual noises during operation, frequent component jams, misalignment during placement, or error codes displayed on diagnostic tools.

2. How often should I perform maintenance on my SMT feeder?

It is recommended to perform routine maintenance checks at least once a month or more frequently depending on usage intensity.

3. Can I fix my SMT feeder myself?

Many minor issues can be resolved by trained operators; however, complex electrical problems may require professional assistance from a technician.

4. What tools do I need for diagnosing SMT feeder issues?

Basic tools include screwdrivers for adjustments, multimeters for electrical testing, alignment tools for positioning checks, and cleaning supplies for maintenance.

5. How can I prevent feeding errors in my SMT feeder?

Regular calibration of the feeder according to component specifications, replacing worn-out parts promptly, and ensuring proper setup can help prevent feeding errors.