Content Menu

● Understanding SMT Components

>> What Are SMT Components?

>> Types of SMT Components

● Factors to Consider When Choosing SMT Components

>> 1. Application Requirements

>> 2. Component Specifications

>> 3. Availability and Lead Time

>> 4. Cost Considerations

>> 5. Reliability and Quality

● Best Practices for Selecting SMT Components

>> 1. Utilize Component Selection Tools

>> 2. Consult Manufacturer Datasheets

>> 3. Prototype Testing

>> 4. Stay Updated on Industry Trends

>> 5. Engage with Community Resources

● Common Challenges When Choosing SMT Components

>> 1. Component Obsolescence

>> 2. Compatibility Issues

>> 3. Supply Chain Disruptions

● Conclusion

● FAQ

>> 1. What are the main types of SMT components used in electronics?

>> 2. How do I determine the right specifications for my SMT components?

>> 3. Why is it important to consult manufacturer datasheets?

>> 4. What challenges might I face when selecting SMT components?

>> 5. How can I stay updated on new SMT components?

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). With the growing complexity of electronic devices, selecting the right SMT components is crucial for ensuring functionality, reliability, and cost-effectiveness in your projects. This article will guide you through the process of identifying and choosing the appropriate SMT components for your projects, focusing on various types of SMT components, their characteristics, and best practices for selection.

Understanding SMT Components

Before diving into the selection process, it is essential to understand what SMT components are and their significance in modern electronics.

What Are SMT Components?

SMT components are electronic parts designed to be mounted directly onto the surface of PCBs. Unlike traditional through-hole components, which require holes drilled into the PCB, SMT components have leads that are soldered onto pads on the board's surface. This technology allows for higher component density and smaller PCB sizes, making it ideal for compact electronic devices.

Types of SMT Components

There are several types of SMT components used in various applications. Understanding these types will help you make informed decisions when selecting components for your project.

- Resistors: Used to limit current flow and divide voltages. They come in various values and power ratings. Resistors can be categorized into fixed resistors, variable resistors (potentiometers), and specialty resistors like thermistors.

- Capacitors: Store electrical energy temporarily. They are available in different types such as ceramic, tantalum, and electrolytic capacitors. Each type has its unique characteristics; for example, ceramic capacitors are known for their stability and reliability in high-frequency applications.

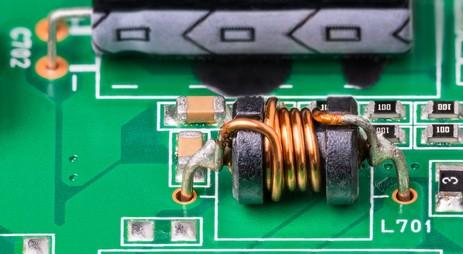

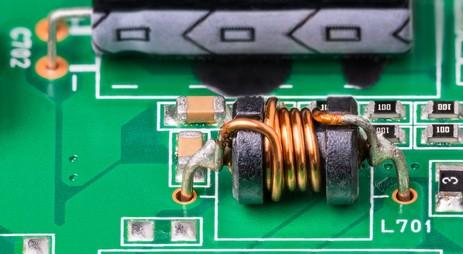

- Inductors: Store energy in a magnetic field when electrical current passes through them. They are used in filtering applications and can be found in various forms such as power inductors and RF inductors.

- Diodes: Allow current to flow in one direction only. Common types include rectifier diodes, Zener diodes (used for voltage regulation), and Schottky diodes (known for their fast switching speeds).

- Transistors: Act as switches or amplifiers in circuits. They can be bipolar junction transistors (BJTs) or field-effect transistors (FETs). BJTs are typically used for analog applications, while FETs are preferred in digital circuits due to their high input impedance.

- Integrated Circuits (ICs): Miniaturized electronic circuits that can perform various functions like amplification, data processing, or signal generation. ICs can be analog or digital and come in various package types including SOIC (Small Outline IC) and QFN (Quad Flat No-lead).

- Connectors: Facilitate connections between different circuits or devices. They come in various shapes and sizes, including headers, sockets, and terminal blocks.

- LEDs: Light-emitting diodes used for display and indicator purposes. SMT LEDs are available in various colors and sizes, making them versatile for different applications.

Factors to Consider When Choosing SMT Components

Selecting the right SMT components involves considering several factors that can affect performance, reliability, and cost.

1. Application Requirements

Identify the specific requirements of your project. Consider factors such as:

- Operating Voltage: Ensure that the component can handle the voltage levels present in your application without risk of breakdown.

- Current Rating: Choose components that can handle the maximum current they will encounter during operation to prevent overheating or failure.

- Frequency Response: For RF applications or high-speed digital circuits, consider how well the component performs at different frequencies.

- Environmental Conditions: Assess whether the components will be exposed to extreme temperatures, humidity levels, or other environmental factors that could affect their performance.

2. Component Specifications

Review the specifications of potential components carefully. Key specifications include:

- Value: For resistors and capacitors, ensure you select the correct value needed for your circuit design.

- Tolerance: This indicates how much a component's value may vary from its stated value; lower tolerance is usually preferred for precision applications.

- Power Rating: Ensure that the component can dissipate heat effectively without exceeding its rated power limit.

- Package Size: Select a package size that fits your PCB layout while considering assembly processes.

3. Availability and Lead Time

Ensure that the components you choose are readily available from suppliers. Long lead times can delay your project. Check multiple suppliers to compare availability and lead times to avoid potential bottlenecks in production.

4. Cost Considerations

Budget constraints play a significant role in component selection. Compare prices from different suppliers while considering bulk discounts for larger orders. However, be cautious about compromising quality for lower costs; it's essential to balance budget with reliability.

5. Reliability and Quality

Choose components from reputable manufacturers known for quality and reliability. Look for certifications such as ISO 9001 or RoHS compliance to ensure that you are sourcing reliable parts that meet industry standards.

Best Practices for Selecting SMT Components

To streamline the selection process and ensure optimal results, follow these best practices:

1. Utilize Component Selection Tools

Many online platforms offer component selection tools that allow you to filter options based on your project requirements. These tools can save time and help you find suitable components quickly by providing comparisons based on key specifications.

2. Consult Manufacturer Datasheets

Always refer to manufacturer datasheets for detailed information about component specifications, pin configurations, application notes, and thermal characteristics necessary for proper integration into your design.

3. Prototype Testing

Before finalizing your component choices, create prototypes to test their performance within your circuit design. This step helps identify any potential issues early in the development process and allows adjustments before mass production.

4. Stay Updated on Industry Trends

The electronics industry is constantly evolving with new technologies and components being introduced regularly. Stay informed about trends through industry publications, webinars, or trade shows to ensure you are using the latest and most efficient components available.

5. Engage with Community Resources

Participating in online forums or local maker communities can provide valuable insights into component selection based on shared experiences from other engineers or hobbyists who have faced similar challenges.

Common Challenges When Choosing SMT Components

While selecting SMT components can be straightforward, several challenges may arise during the process:

1. Component Obsolescence

As technology advances rapidly, some components may become obsolete or difficult to source after a few years of production. Always have alternative options ready in case your primary choice becomes unavailable by keeping an eye on component lifecycle announcements from manufacturers.

2. Compatibility Issues

Ensure that selected components are compatible with each other within your circuit design by checking specifications such as voltage ratings and pin configurations carefully before finalizing designs to avoid mismatched specifications which can lead to circuit failure or malfunctions during operation.

3. Supply Chain Disruptions

Global supply chain issues can affect component availability and pricing significantly due to factors like geopolitical tensions or natural disasters disrupting manufacturing facilities worldwide; having contingency plans in place helps mitigate these risks effectively by identifying alternative suppliers ahead of time if necessary.

Conclusion

Choosing the right SMT components is a critical aspect of designing efficient and reliable electronic devices. By understanding the types of SMT components available, considering key factors during selection, following best practices throughout development phases while being aware of common challenges faced along this journey—engineers can ensure their projects meet intended specifications while remaining cost-effective without compromising quality standards expected within today's competitive market landscape.

As you embark on your next electronics project, remember to stay informed about industry trends continuously refine your component selection process accordingly so that you adapt seamlessly amidst changing technologies shaping our future innovations across diverse fields ranging from consumer electronics all way up through aerospace applications requiring utmost precision engineering capabilities!

FAQ

1. What are the main types of SMT components used in electronics?

The main types of SMT components include resistors, capacitors, inductors, diodes, transistors, integrated circuits (ICs), connectors, and LEDs.

2. How do I determine the right specifications for my SMT components?

To determine the right specifications for your SMT components, consider application requirements such as operating voltage, current rating, frequency response, and environmental conditions.

3. Why is it important to consult manufacturer datasheets?

Consulting manufacturer datasheets is important because they provide detailed information about component specifications, pin configurations, application notes, and reliability data necessary for proper integration into your design.

4. What challenges might I face when selecting SMT components?

Common challenges include component obsolescence; compatibility issues between different parts within a circuit design; supply chain disruptions affecting availability; pricing fluctuations due to market demand changes over time impacting overall project budgets significantly if not managed proactively beforehand!

5. How can I stay updated on new SMT components?

You can stay updated on new SMT components by following industry news sources; subscribing to electronics newsletters; attending trade shows or webinars; participating actively within online forums related specifically towards electronics design sharing knowledge among peers fostering collaborative learning environments beneficially enhancing skills collectively over time!