Content Menu

● Understanding PCB Board SMT Pricing

>> Factors Affecting PCB Board SMT Pricing

● Researching PCB Board SMT Price Lists

>> 1. Online PCB Manufacturers

>> 2. Request for Quotations (RFQs)

>> 3. Industry Forums and Communities

>> 4. Trade Shows and Exhibitions

● Analyzing PCB Board SMT Price Lists

>> 1. Compare Apples to Apples

>> 2. Look Beyond the Base Price

>> 3. Evaluate Minimum Order Quantities (MOQs)

>> 4. Assess Lead Times

● Negotiating Better Prices

>> 1. Bundle Services

>> 2. Long-Term Contracts

>> 3. Prototype Discounts

>> 4. Payment Terms

● Balancing Cost and Quality

>> 1. Request Samples

>> 2. Check Certifications

>> 3. Read Reviews and Testimonials

>> 4. Consider Local vs. Overseas Manufacturing

● Leveraging Technology for Better Pricing

>> 1. Automated Design for Manufacturing (DFM) Checks

>> 2. AI-Powered Quoting Systems

>> 3. Virtual Factory Tours

● Environmental Considerations

>> 1. RoHS Compliance

>> 2. Waste Reduction Practices

>> 3. Energy-Efficient Manufacturing

● Conclusion

● FAQ

>> 1. What is the average cost per square inch for PCB assembly?

>> 2. How does production volume affect PCB assembly pricing?

>> 3. What are the main factors that influence PCB assembly costs?

>> 4. How can I reduce PCB assembly costs without compromising quality?

>> 5. What should I look for in a PCB assembly price list?

● Citations:

In the ever-evolving world of electronics manufacturing, finding the right PCB board SMT price list for your project can be a daunting task. Whether you're a seasoned engineer or a hobbyist embarking on your first PCB design journey, understanding the factors that influence pricing and knowing where to look for the best deals can make a significant difference in your project's success and budget. This comprehensive guide will walk you through the process of finding the optimal PCB board SMT price list, helping you navigate the complexities of PCB manufacturing and assembly costs.

Understanding PCB Board SMT Pricing

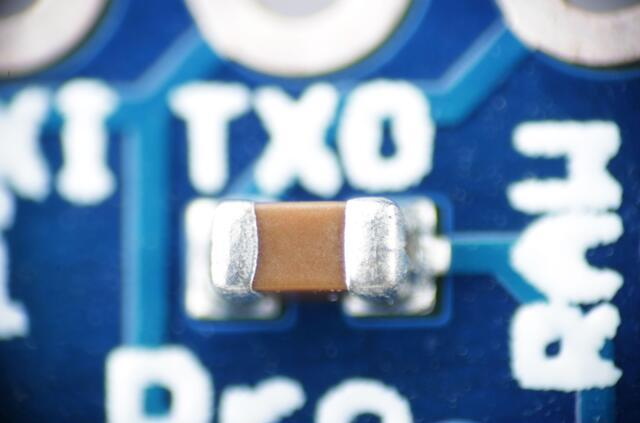

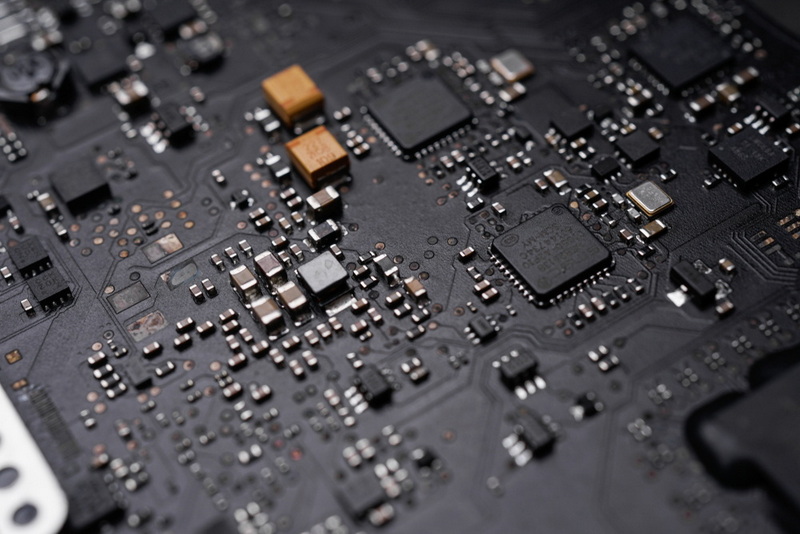

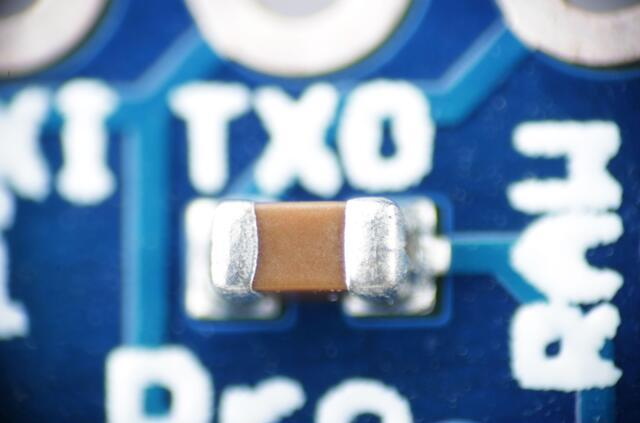

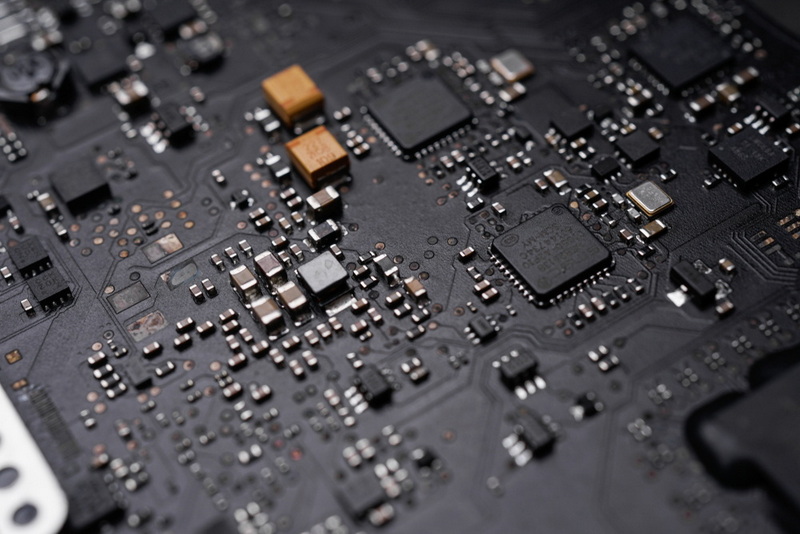

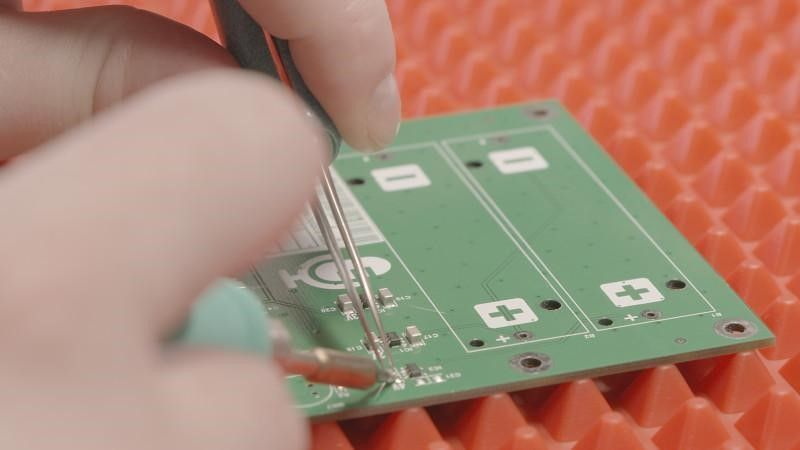

Before diving into the search for the best PCB board SMT price list, it's crucial to understand the components that contribute to the overall cost. Surface Mount Technology (SMT) has become the standard for modern PCB assembly due to its efficiency and ability to handle high-density designs. However, the pricing for SMT assembly can vary widely based on several factors.

Factors Affecting PCB Board SMT Pricing

1. Board Complexity: The number of layers, size, and shape of your PCB directly impact the cost. More complex designs with multiple layers or irregular shapes typically come with a higher price tag[1].

2. Component Selection: The types and quantities of components used in your design play a significant role in determining the final cost. High-end or specialized components will increase the overall expense[4].

3. Production Volume: Economies of scale apply to PCB manufacturing. Larger production runs generally result in lower per-unit costs, as setup fees and other fixed costs are spread across more boards[5].

4. Turnaround Time: Expedited services for quick turnaround times often come at a premium. Planning ahead and allowing for standard production times can lead to significant savings[2].

5. Quality Requirements: Higher-grade materials and more stringent quality control processes will increase costs but may be necessary for certain applications, especially in industries like aerospace or medical devices[5].

Researching PCB Board SMT Price Lists

With a solid understanding of the factors influencing costs, you can begin your search for the best PCB board SMT price list. Here are some effective strategies to help you find competitive pricing:

1. Online PCB Manufacturers

Many PCB manufacturers offer online quoting tools that can provide instant price estimates based on your specifications. These tools are excellent for quickly comparing prices across different manufacturers. Some popular options include:

- SMT LTD

- PCBWay

- Seeed Studio

- Advanced Circuits

When using these online tools, input your project specifications carefully to ensure accurate quotes. Pay attention to any additional fees for services like SMT assembly, testing, or special finishes[4].

2. Request for Quotations (RFQs)

For more complex projects or when you need a more detailed breakdown of costs, sending out RFQs to multiple manufacturers is advisable. This approach allows you to:

- Provide detailed specifications

- Ask questions about manufacturing processes

- Negotiate pricing for large orders

- Discuss custom requirements

When preparing your RFQ, be as specific as possible about your project requirements, including board specifications, component lists, and any special manufacturing needs[1].

3. Industry Forums and Communities

Engaging with online communities of electronics enthusiasts and professionals can be an invaluable resource. Platforms like:

- Reddit's r/PrintedCircuitBoard

- EEVblog Forum

- Stack Exchange's Electrical Engineering community

These forums often have threads discussing PCB manufacturing costs and recommendations for reliable, cost-effective manufacturers. Members may share their experiences with different suppliers, helping you identify potential options for your project[2].

4. Trade Shows and Exhibitions

Attending electronics trade shows and PCB-specific exhibitions can provide opportunities to:

- Meet manufacturers face-to-face

- See samples of their work

- Discuss pricing and capabilities directly

- Learn about new technologies that might benefit your project

While this approach requires more time and potentially travel, it can lead to valuable connections and insights into the PCB manufacturing industry[5].

Analyzing PCB Board SMT Price Lists

Once you've gathered price lists from various sources, it's time to analyze them effectively. Here are some key points to consider:

1. Compare Apples to Apples

Ensure that you're comparing similar services across different manufacturers. Some may include services like electrical testing or conformal coating in their base price, while others might charge extra[1].

2. Look Beyond the Base Price

Consider the total cost of ownership, including:

- Shipping fees

- Import duties (for international orders)

- Potential rework costs

- Customer support quality

A slightly higher upfront cost from a manufacturer with excellent quality control might save money in the long run by reducing the need for rework or replacements[2].

3. Evaluate Minimum Order Quantities (MOQs)

Some manufacturers offer better pricing for larger orders. If your project requires multiple iterations or you anticipate future production runs, consider how MOQs affect the overall cost per board[5].

4. Assess Lead Times

Balance the need for quick turnaround with cost considerations. If your project timeline allows, opting for standard production times rather than rush services can lead to significant savings[4].

Negotiating Better Prices

Once you've identified potential manufacturers and analyzed their price lists, there may be room for negotiation, especially for larger orders or ongoing partnerships.

1. Bundle Services

If you need both PCB fabrication and assembly, ask about package deals. Many manufacturers offer discounts for combined services[1].

2. Long-Term Contracts

For ongoing projects, discuss the possibility of long-term contracts with guaranteed order volumes in exchange for better pricing[5].

3. Prototype Discounts

Some manufacturers offer discounts on prototype runs, especially if there's potential for future production orders. Inquire about these opportunities when discussing your project[2].

4. Payment Terms

Flexible payment terms, such as net 30 or 60, can improve cash flow for your project. Some manufacturers may offer discounts for upfront payments[4].

Balancing Cost and Quality

While finding the best PCB board SMT price list is important, it's crucial to balance cost considerations with quality requirements. Here are some strategies to ensure you're getting the best value:

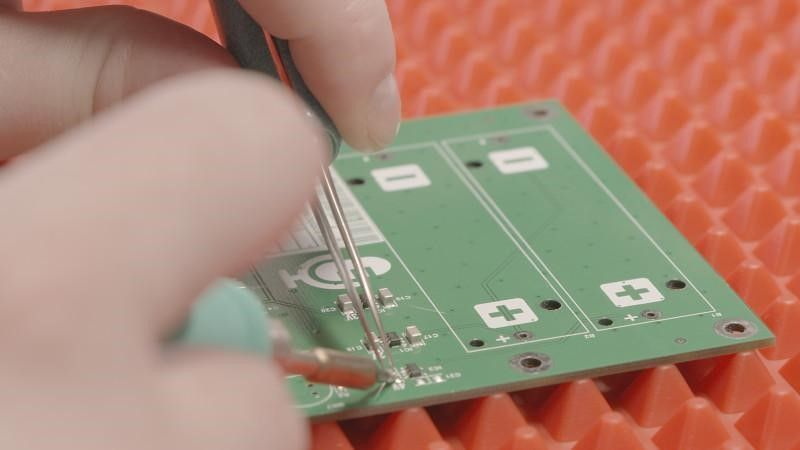

1. Request Samples

Before committing to a large order, request samples or a small prototype run to assess the manufacturer's quality and capabilities[1].

2. Check Certifications

Look for manufacturers with relevant industry certifications (e.g., ISO 9001, IPC standards) to ensure they meet quality standards[5].

3. Read Reviews and Testimonials

Research the manufacturer's reputation by reading customer reviews and testimonials. Pay attention to feedback regarding quality, communication, and adherence to specifications[2].

4. Consider Local vs. Overseas Manufacturing

While overseas manufacturing can often offer lower prices, consider factors like communication ease, shipping times, and potential quality control issues when making your decision[4].

Leveraging Technology for Better Pricing

Advancements in technology are continually shaping the PCB manufacturing industry, often leading to more competitive pricing. Here are some technological factors to consider:

1. Automated Design for Manufacturing (DFM) Checks

Many online PCB manufacturers now offer automated DFM checks as part of their quoting process. These tools can help identify potential manufacturing issues early, reducing the risk of costly revisions or production delays[1].

2. AI-Powered Quoting Systems

Some manufacturers are implementing AI algorithms to optimize their quoting process, potentially leading to more accurate and competitive pricing based on real-time manufacturing capacity and material costs[4].

3. Virtual Factory Tours

With the rise of virtual reality and 360-degree video technology, some PCB manufacturers now offer virtual factory tours. This can give you insight into their capabilities and processes without the need for on-site visits, helping you make more informed decisions about potential partners[5].

Environmental Considerations

As sustainability becomes increasingly important in manufacturing, consider how a manufacturer's environmental practices might affect pricing and align with your project's values:

1. RoHS Compliance

Ensure that the manufacturer complies with RoHS (Restriction of Hazardous Substances) standards. While this may slightly increase costs, it's often necessary for many markets and applications[2].

2. Waste Reduction Practices

Some manufacturers have implemented advanced waste reduction techniques, which can lead to cost savings that may be passed on to customers. Inquire about these practices when discussing pricing[5].

3. Energy-Efficient Manufacturing

Manufacturers investing in energy-efficient equipment and processes may offer more competitive pricing in the long term due to reduced operational costs[4].

Conclusion

Finding the best PCB board SMT price list for your project requires a comprehensive approach that considers various factors beyond just the base price. By understanding the components that contribute to PCB manufacturing and assembly costs, researching multiple sources, and carefully analyzing price lists, you can make an informed decision that balances cost, quality, and project requirements.

Remember that the cheapest option isn't always the best value. Consider the total cost of ownership, including potential rework costs, shipping fees, and the manufacturer's reputation for quality and reliability. Leverage technology to your advantage, whether it's through online quoting tools, automated DFM checks, or virtual factory tours.

Lastly, don't underestimate the power of negotiation and building relationships with manufacturers. For ongoing projects or larger orders, there may be opportunities for better pricing or value-added services that can significantly benefit your project in the long run.

By following the strategies outlined in this guide, you'll be well-equipped to navigate the complex landscape of PCB board SMT pricing and find the best solution for your specific needs.

FAQ

1. What is the average cost per square inch for PCB assembly?

PCB assembly typically costs between $0.02 and $0.05 per square inch. However, this estimate can vary significantly based on factors such as complexity, component costs, and production volume[7].

2. How does production volume affect PCB assembly pricing?

Production volume significantly impacts PCB assembly pricing due to economies of scale. Larger production runs generally result in lower per-unit costs as fixed expenses like setup fees are spread across more units. Manufacturers often offer tiered pricing structures that provide discounts for higher quantities[5].

3. What are the main factors that influence PCB assembly costs?

The main factors influencing PCB assembly costs include:

- Board complexity (number of layers, size, and shape)

- Component selection and quantity

- Production volume

- Turnaround time requirements

- Quality standards and certifications needed

- Special processes or materials required[1][4][5]

4. How can I reduce PCB assembly costs without compromising quality?

To reduce PCB assembly costs while maintaining quality:

- Optimize your design for manufacturability

- Choose standard components where possible

- Consider larger production runs if feasible

- Allow for standard turnaround times instead of rush services

- Bundle PCB fabrication and assembly services

- Negotiate long-term contracts for ongoing projects[1][2][4]

5. What should I look for in a PCB assembly price list?

When evaluating a PCB assembly price list, consider:

- Base price per board or square inch

- Component costs and markup

- Setup fees and minimum order quantities

- Additional charges for services like electrical testing or conformal coating

- Shipping costs and lead times

- Any discounts for volume orders or combined services

- The manufacturer's quality certifications and capabilities[1][4][5]

Citations:

[1] https://www.anypcba.com/blogs/pcb-manufacturing-knowledge/decoding-pcb-manufacturing-equipment-prices-a-comprehensive-guide.html

[2] https://sfmpcb.com/key-factors-behind-pcb-price-variability/

[3] https://fliphtml5.com/ppflo/mvfu/Complete_and_Complementary_Range_of_PCB_Assembly_Services_and_Solutions/

[4] https://jlcpcb.com/help/article/pcb-assembly-faqs

[5] https://www.jycircuitboard.com/news/deciphering-pcb-manufacturing-price-factors-that-impact-pcb-price-473.html

[6] https://www.ourpcb.com/sitemap

[7] https://www.pcbasic.com/blog/PCB_Assembly_Cost.html

[8] https://www.nextpcb.com/blog/pcb-assembly-cost-affecting-factors-and-way-to-save-money

[9] https://hackaday.io/project/184378-jlcpcb-smt-assembly-service-complete-guide

[10] https://www.anzer-usa.com/resources/pcb-assembly-cost-factors/