Content Menu

● Understanding SMT Nozzles

>> Importance of Proper Maintenance

● Best Practices for Cleaning SMT Nozzles

>> 1. Manual Cleaning

>> 2. Ultrasonic Cleaning

>> 3. Automated Cleaning Machines

>> 4. Specialized Cleaning Solutions

● Regular Maintenance Practices

>> 1. Inspection and Monitoring

>> 2. Proper Storage

>> 3. Timely Replacement

● Impact of Nozzle Maintenance on Production Efficiency

● Advanced Techniques for Extending Nozzle Lifespan

>> 1. Monitoring Nozzle Tip Length

>> 2. Utilizing ESD-Safe Materials

>> 3. Training Operators

>> 4. Implementing a Maintenance Schedule

● Conclusion

● FAQ

>> 1. What are the best practices for cleaning SMT nozzles?

>> 2. How often should SMT nozzles be cleaned?

>> 3. Can I use alcohol-based cleaners on SMT nozzles?

>> 4. What signs indicate that an SMT nozzle needs replacement?

>> 5. How should I store SMT nozzles when not in use?

● Citations:

Content Menu

● Understanding SMT Nozzles

>> Importance of Proper Maintenance

● Best Practices for Cleaning SMT Nozzles

>> 1. Manual Cleaning

>> 2. Ultrasonic Cleaning

>> 3. Automated Cleaning Machines

>> 4. Specialized Cleaning Solutions

● Regular Maintenance Practices

>> 1. Inspection and Monitoring

>> 2. Proper Storage

>> 3. Timely Replacement

● Impact of Nozzle Maintenance on Production Efficiency

● Advanced Techniques for Extending Nozzle Lifespan

>> 1. Monitoring Nozzle Tip Length

>> 2. Utilizing ESD-Safe Materials

>> 3. Training Operators

>> 4. Implementing a Maintenance Schedule

● Conclusion

● FAQ

>> 1. What are the best practices for cleaning SMT nozzles?

>> 2. How often should SMT nozzles be cleaned?

>> 3. Can I use alcohol-based cleaners on SMT nozzles?

>> 4. What signs indicate that an SMT nozzle needs replacement?

>> 5. How should I store SMT nozzles when not in use?

● Citations:

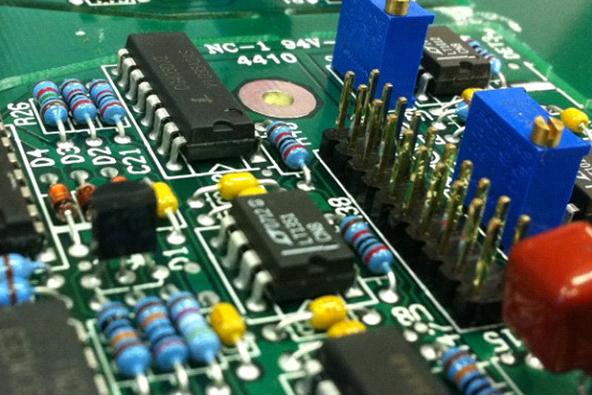

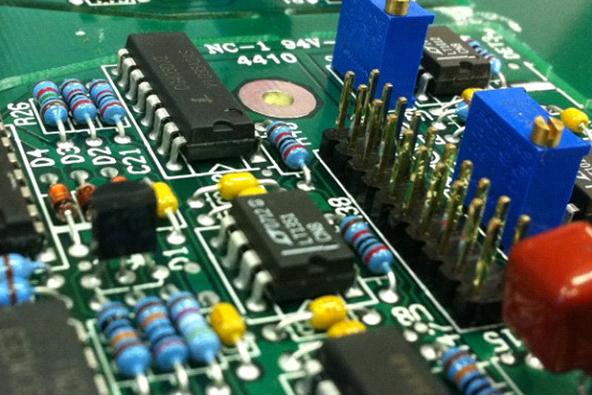

Surface Mount Technology (SMT) nozzles are essential components in the electronics manufacturing process, particularly in pick-and-place machines. These nozzles facilitate the accurate placement of electronic components onto printed circuit boards (PCBs). Given their critical role, extending the lifespan of SMT nozzles is vital for maintaining production efficiency and reducing operational costs. This article provides a comprehensive guide on how to maintain and extend the lifespan of SMT nozzles through effective cleaning, proper handling, and timely maintenance practices.

Understanding SMT Nozzles

SMT nozzles come in various shapes and sizes, tailored to handle different component types. The material and design of the nozzle significantly affect its performance and durability. Common materials include ceramics and specialized plastics that can withstand rigorous manufacturing environments.

Importance of Proper Maintenance

The maintenance of SMT nozzles is crucial for several reasons:

- Accuracy: Well-maintained nozzles ensure precise placement of components, reducing errors during assembly.

- Efficiency: Regular maintenance minimizes downtime caused by nozzle malfunctions or replacements.

- Cost-effectiveness: Extending the lifespan of nozzles reduces replacement costs and enhances overall production efficiency.

Best Practices for Cleaning SMT Nozzles

Cleaning is one of the most critical aspects of maintaining SMT nozzles. Various cleaning methods can be employed to ensure that nozzles remain free from contaminants that could impair their function.

1. Manual Cleaning

Manual cleaning involves using soft cloths or brushes to wipe the nozzle surfaces. This method is particularly effective for removing surface contaminants without damaging the nozzle.

- Use a non-abrasive cloth: Ensure that the cloth used for wiping is soft and non-abrasive to avoid scratching the nozzle surface.

- Avoid harsh chemicals: Use specialized cleaning agents designed for SMT components instead of alcohol-based cleaners, which can degrade nozzle materials over time.

2. Ultrasonic Cleaning

Ultrasonic cleaning utilizes high-frequency sound waves to agitate a cleaning solution, effectively removing dirt and debris from the nozzle's intricate surfaces.

- Advantages:

- Thoroughly cleans internal structures without damaging them.

- Restores vacuum performance by removing blockages.

- Disadvantages:

- Care must be taken to prevent overlapping of nozzles during cleaning, which can lead to damage.

3. Automated Cleaning Machines

Investing in automated cleaning machines can significantly enhance the cleaning process. These machines often combine ultrasonic cleaning with high-pressure rinsing and drying capabilities.

- Benefits:

- Consistent cleaning results.

- Reduced labor costs as machines handle the entire process automatically.

- Effective at cleaning even the smallest nozzle holes.

4. Specialized Cleaning Solutions

Using specialized cleaning compounds can further enhance the effectiveness of nozzle cleaning. For instance, Universal Instruments has developed a custom-formulated cleaning compound called UIC Nozzle Clean, which is designed specifically for SMT nozzles. This solution not only cleans effectively but also helps maintain the integrity of the nozzle material, prolonging its lifespan[1].

Regular Maintenance Practices

In addition to cleaning, regular maintenance practices are essential for extending the lifespan of SMT nozzles.

1. Inspection and Monitoring

Regular inspections help identify wear and tear before they lead to performance issues.

- Check for wear: Monitor nozzle tips for signs of wear or damage. Replace nozzles that show significant wear to prevent misplacement during operation.

- Vacuum performance checks: Test the vacuum strength regularly; a decrease may indicate clogging or wear that needs addressing.

2. Proper Storage

When not in use, storing nozzles correctly can prevent damage.

- Use protective cases: Store nozzles in designated protective cases provided by manufacturers to avoid physical damage or contamination.

- Keep them clean: Ensure that storage areas are clean and free from dust or debris that could contaminate the nozzles when they are not in use.

3. Timely Replacement

Recognizing when to replace a nozzle is crucial for maintaining production quality.

- Signs of replacement need:

- Decreased accuracy in component placement.

- Visible cracks or wear on the nozzle body.

- Frequent machine errors during pick-and-place operations.

Impact of Nozzle Maintenance on Production Efficiency

Proper maintenance of SMT nozzles plays a critical role in overall production efficiency. Poorly maintained nozzles can lead to a range of issues:

- Loss of vacuum: This can cause components to drop during transport or fail to pick up from feeders, leading to increased defects and downtime[4].

- Increased rejection rates: Components may not be placed accurately due to worn or damaged nozzles, resulting in higher rejection rates during quality inspections[10].

- Damage from electrostatic discharge (ESD): The movement of nozzles can generate static electricity, which may damage sensitive electronic components if not properly managed[8].

By implementing proactive maintenance strategies, manufacturers can mitigate these risks and enhance their overall production capabilities.

Advanced Techniques for Extending Nozzle Lifespan

Beyond basic maintenance practices, there are advanced techniques that manufacturers can adopt to further extend the lifespan of SMT nozzles:

1. Monitoring Nozzle Tip Length

Regularly monitoring the length of nozzle tips can help schedule preventive maintenance before significant wear occurs. This practice allows manufacturers to replace or repair tips before they impact component placement accuracy[10].

2. Utilizing ESD-Safe Materials

Choosing nozzles made from electrostatic dissipative (ESD) materials can help reduce the risk of electrostatic discharge damaging components during assembly processes[8]. Manufacturers should ensure their suppliers provide ESD-safe options that meet industry standards.

3. Training Operators

Training operators on proper handling techniques is crucial in preventing accidental damage to nozzles during operation. Operators should be aware of how to safely install and remove nozzles from machines without causing undue stress on their components[6].

4. Implementing a Maintenance Schedule

Creating a structured maintenance schedule that includes regular inspections, cleaning routines, and replacement timelines will ensure that all aspects of nozzle care are addressed systematically. This proactive approach helps maintain optimal performance over time[3].

Conclusion

Extending the lifespan of SMT nozzles is essential for maintaining high efficiency and accuracy in electronics manufacturing. By implementing effective cleaning methods, conducting regular inspections, ensuring proper storage, and replacing worn-out nozzles promptly, manufacturers can significantly enhance their production processes while minimizing costs. Investing time and resources into maintaining these critical components will yield substantial returns in terms of productivity and quality assurance.

In summary, manufacturers should prioritize nozzle maintenance as part of their overall production strategy to ensure smooth operations and high-quality outputs in their assembly processes.

FAQ

1. What are the best practices for cleaning SMT nozzles?

The best practices include manual wiping with non-abrasive cloths, ultrasonic cleaning for thorough internal cleansing, and using automated cleaning machines for consistent results.

2. How often should SMT nozzles be cleaned?

Nozzle cleaning frequency depends on usage but should generally occur after every production run or when performance issues arise.

3. Can I use alcohol-based cleaners on SMT nozzles?

It is advisable to avoid alcohol-based cleaners as they can degrade certain materials used in nozzle construction over time.

4. What signs indicate that an SMT nozzle needs replacement?

Signs include decreased accuracy in component placement, visible wear or cracks on the nozzle body, and frequent errors during operation.

5. How should I store SMT nozzles when not in use?

Store SMT nozzles in protective cases provided by manufacturers to prevent physical damage and contamination while ensuring they remain clean.

Citations:

[1] https://www.uic.com/universal-instruments-new-smt-nozzle-cleaning-solution/

[2] https://www.linkedin.com/pulse/how-improve-smt-nozzles-useful-life-joyce-tang

[3] https://www.zj-smttech.com/blog-detail/tips-for-maintaining-and-extending-the-lifespan-of-smt-nozzles

[4] https://smtnet.com/library/files/upload/preventative-maintenance-smt.pdf

[5] https://www.odm-technology.com/mobile/prod/auto-smt-nozzle-cleaner

[6] https://silmantech.com/cleaning-and-maintenance-methods-for-pick-and-place-machine-nozzles/

[7] https://www.neodensmt.com/news/what-is-used-to-clean-smt-nozzle-48216762.html

[8] https://www.myemssolutions.com/the-most-common-smt-errors-during-the-manufacturing-process/

[9] https://ikrorwxhnjmplp5m-static.micyjz.com/ETA+SMT+Nozzle+Cleaning+Machine+ETA-24-aidlpBprKknloSRqirlopmniq.pdf

[10] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616