Content Menu

● What is Customized SMT PCB Assembly?

>> Key Benefits of Customized SMT PCB Assembly:

● The Step-by-Step Process of Customized SMT PCB Assembly

>> 1. Design and Preparation

>>> Advanced Design Considerations

>> 2. Solder Paste Application

>>> Optimizing Solder Paste Application

>> 3. Component Placement

>>> Advanced Placement Techniques

>> 4. Reflow Soldering

>>> Reflow Profile Optimization

>> 5. Inspection and Quality Control

>>> Advanced Inspection Techniques

>> 6. Functional Testing

>>> Enhancing Functional Testing

>> 7. Final Assembly and Packaging

>>> Advanced Protection Methods

● Best Practices for High-Quality Customized SMT PCB Assembly

>> 1. Partner with Experienced Manufacturers

>> 2. Follow DFM Guidelines

>> 3. Use High-Quality Components

>> 4. Invest in Advanced Inspection Tools

>> 5. Implement Continuous Improvement

>> 6. Train and Certify Personnel

>> 7. Maintain Clean Room Standards

● Challenges in Customized SMT PCB Assembly

>> Overcoming Assembly Challenges

>>> 1. Advanced Equipment Investment

>>> 2. Thermal Simulation and Design

>>> 3. Material Science Expertise

>>> 4. Lean Manufacturing Principles

● Future Trends in Customized SMT PCB Assembly

>> 1. Industry 4.0 Integration

>> 2. Additive Manufacturing

>> 3. Green Manufacturing

>> 4. Advanced Packaging Technologies

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is the difference between SMT and through-hole technology?

>> 2. How can I ensure the reliability of my customized SMT PCB assembly?

>> 3. What equipment is essential for SMT PCB assembly?

>> 4. Why is reflow soldering important in SMT assembly?

>> 5. Can I customize my SMT PCB assembly process?

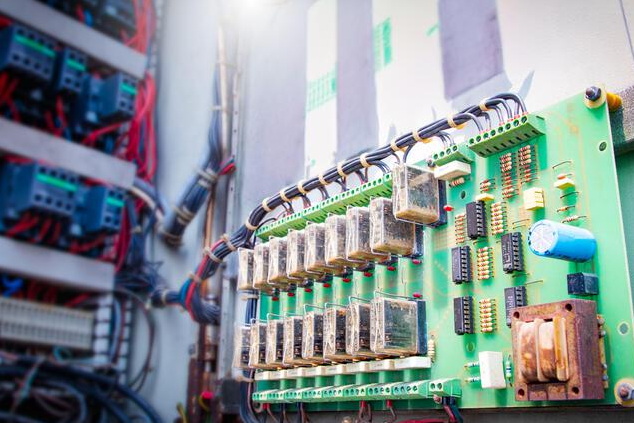

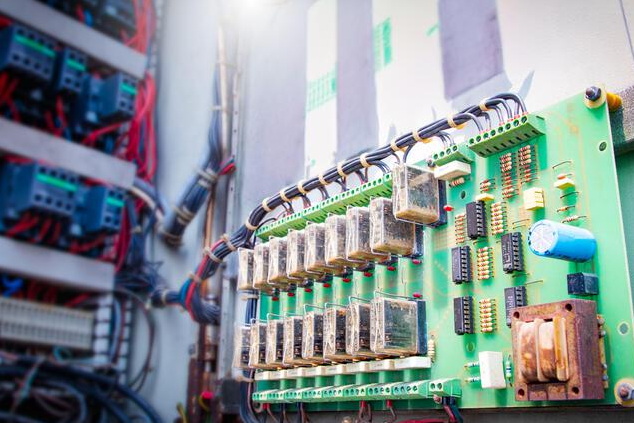

Ensuring high-quality customized SMT PCB assembly is critical for the success of modern electronic products. With the increasing demand for compact, reliable, and efficient devices, Surface Mount Technology (SMT) has become the industry standard for assembling printed circuit boards (PCBs). This article explores the essential steps, best practices, and considerations to achieve superior results in customized SMT PCB assembly.

What is Customized SMT PCB Assembly?

Customized SMT PCB assembly involves tailoring the process of mounting electronic components directly onto the surface of a PCB to meet specific product requirements. Unlike traditional through-hole technology, SMT allows for smaller components, higher component density, and automated processes, resulting in compact and high-performance PCBs.

Key Benefits of Customized SMT PCB Assembly:

- Compact Designs: Enables smaller and lighter devices.

- Improved Performance: Minimizes signal loss and interference.

- Cost Efficiency: Reduces labor costs through automation.

- Enhanced Reliability: Ensures consistent soldering and placement accuracy.

The Step-by-Step Process of Customized SMT PCB Assembly

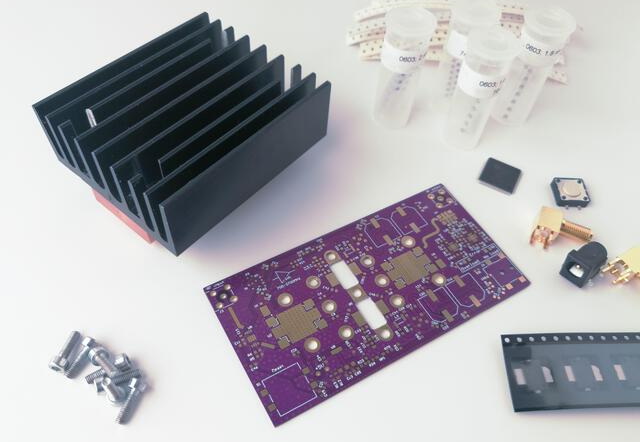

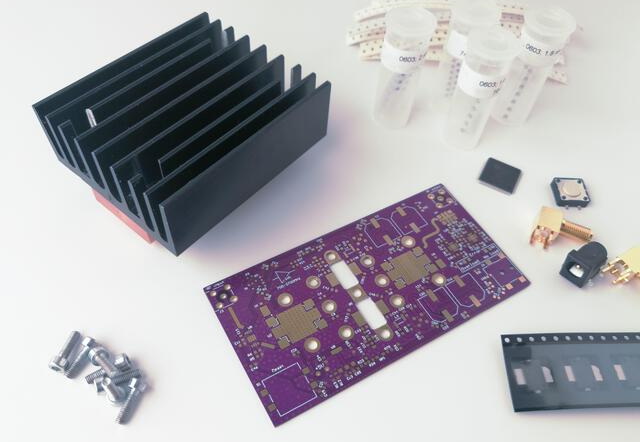

1. Design and Preparation

The foundation of a successful SMT PCB assembly lies in the design phase. A well-thought-out design ensures manufacturability and performance.

- Circuit Design: Create a schematic that meets electrical requirements.

- PCB Layout Optimization: Follow Design for Manufacturing (DFM) guidelines to ensure proper component spacing and alignment.

- Material Selection: Choose high-quality PCBs and components that match the Bill of Materials (BOM).

Advanced Design Considerations

- Thermal Management: Incorporate thermal vias and copper planes to dissipate heat effectively.

- Signal Integrity: Use controlled impedance traces for high-speed signals.

- EMI/EMC Compliance: Design with electromagnetic compatibility in mind to reduce interference.

2. Solder Paste Application

Solder paste is applied to the PCB using a stainless steel stencil. This step ensures that solder is only deposited on the pads where components will be placed.

- Use precision-cut stencils tailored to the PCB design.

- Inspect solder paste application with automated tools to avoid defects.

Optimizing Solder Paste Application

- Stencil Design: Consider step stencils for mixed component sizes.

- Paste Selection: Choose solder paste based on reflow profile and component requirements.

- Environmental Control: Maintain proper temperature and humidity in the production area.

3. Component Placement

High-speed pick-and-place machines position Surface Mount Devices (SMDs) onto the solder paste-coated pads.

- Ensure accurate placement using pre-programmed X-Y coordinates.

- Use automated systems to handle small or leadless components efficiently.

Advanced Placement Techniques

- Component Feeders: Utilize intelligent feeders for improved accuracy and speed.

- Vision Systems: Implement advanced vision systems for precise alignment.

- Traceability: Incorporate component tracking for quality control and recall management.

4. Reflow Soldering

The assembled PCBs are passed through a reflow oven where heat melts the solder paste, creating strong electrical connections.

- Maintain precise temperature profiles to prevent overheating or cold joints.

- Inspect solder joints post-reflow to ensure quality.

Reflow Profile Optimization

- Preheat Stage: Gradually increase temperature to activate flux and reduce thermal shock.

- Soak Stage: Allow time for uniform heating of components and PCB.

- Reflow Stage: Reach peak temperature for proper solder melting and wetting.

- Cooling Stage: Control cooling rate to prevent thermal stress.

5. Inspection and Quality Control

Inspection is critical to identify defects such as misaligned components or poor soldering.

- Use Automatic Optical Inspection (AOI) systems for visual checks.

- Perform X-ray inspection for multilayer PCBs or complex assemblies.

Advanced Inspection Techniques

- 3D AOI: Utilize three-dimensional imaging for improved defect detection.

- Solder Paste Inspection (SPI): Implement pre-reflow inspection of solder paste deposits.

- In-Circuit Testing (ICT): Perform electrical tests to verify component connections and values.

6. Functional Testing

Testing ensures that the assembled PCB meets all functional requirements.

- Conduct In-Circuit Testing (ICT) to verify electrical performance.

- Use Automated Test Equipment (ATE) for comprehensive testing against design specifications.

Enhancing Functional Testing

- Boundary Scan Testing: Implement JTAG testing for digital circuits.

- Environmental Stress Screening: Subject assemblies to temperature and vibration tests.

- RF Testing: Conduct specialized tests for wireless and high-frequency applications.

7. Final Assembly and Packaging

After successful testing, additional steps like conformal coating or encapsulation may be applied to protect the PCB from environmental factors.

Advanced Protection Methods

- Conformal Coating: Apply thin protective films to guard against moisture and contaminants.

- Potting: Encapsulate sensitive components in resin for extreme environments.

- Underfill: Use epoxy underfill for BGA components to improve mechanical strength.

Best Practices for High-Quality Customized SMT PCB Assembly

1. Partner with Experienced Manufacturers

Select a manufacturer with expertise in customized SMT PCB assembly and advanced equipment.

2. Follow DFM Guidelines

Optimize your design for manufacturability by adhering to industry standards for component placement, spacing, and orientation.

3. Use High-Quality Components

Ensure that all components meet quality standards and are compatible with your design specifications.

4. Invest in Advanced Inspection Tools

Leverage AOI, X-ray inspection, and functional testing to detect defects early in the process.

5. Implement Continuous Improvement

Regularly review and update assembly processes based on data analysis and industry advancements.

6. Train and Certify Personnel

Invest in ongoing training for operators and engineers to maintain high skill levels and stay current with technology.

7. Maintain Clean Room Standards

Establish and maintain appropriate clean room conditions to minimize contamination risks.

Challenges in Customized SMT PCB Assembly

Despite its advantages, customized SMT PCB assembly comes with challenges:

1. Miniaturization: Handling extremely small components requires precision equipment.

2. Thermal Management: Ensuring proper heat dissipation in densely packed designs.

3. Material Compatibility: Matching solder paste and components with specific operating conditions.

4. Cost Management: Balancing customization with cost efficiency.

Overcoming Assembly Challenges

1. Advanced Equipment Investment

- Utilize state-of-the-art pick-and-place machines capable of handling ultra-fine pitch components.

- Implement advanced reflow ovens with precise temperature control and multiple heating zones.

2. Thermal Simulation and Design

- Use thermal modeling software to predict and optimize heat distribution.

- Incorporate heat sinks and thermal management materials into the PCB design.

3. Material Science Expertise

- Collaborate with material suppliers to select compatible solder pastes and flux formulations.

- Conduct extensive testing to validate material performance under various conditions.

4. Lean Manufacturing Principles

- Implement Just-In-Time (JIT) inventory management to reduce carrying costs.

- Optimize production flows to minimize waste and improve efficiency.

Future Trends in Customized SMT PCB Assembly

As technology continues to evolve, several trends are shaping the future of customized SMT PCB assembly:

1. Industry 4.0 Integration

- Implement smart factory concepts with interconnected machines and real-time data analysis.

- Utilize artificial intelligence for predictive maintenance and process optimization.

2. Additive Manufacturing

- Explore 3D printing technologies for prototyping and small-scale production of PCBs.

- Investigate printed electronics for flexible and wearable device applications.

3. Green Manufacturing

- Adopt lead-free and halogen-free materials to comply with environmental regulations.

- Implement energy-efficient processes and equipment to reduce carbon footprint.

4. Advanced Packaging Technologies

- Incorporate System-in-Package (SiP) and 3D packaging techniques for higher integration.

- Explore embedded component technologies to further miniaturize designs.

Conclusion

Achieving high-quality customized SMT PCB assembly requires meticulous planning, advanced technology, and strict quality control measures. By following best practices such as optimizing designs for manufacturability, using high-quality materials, and partnering with experienced manufacturers, businesses can produce reliable and efficient PCBs tailored to their needs. As the industry continues to evolve, staying informed about emerging trends and technologies will be crucial for maintaining a competitive edge in the rapidly advancing field of electronics manufacturing.

Frequently Asked Questions (FAQs)

1. What is the difference between SMT and through-hole technology?

SMT mounts components directly onto the surface of a PCB without drilling holes, while through-hole technology involves inserting component leads into pre-drilled holes before soldering. SMT offers higher component density and automation capabilities.

2. How can I ensure the reliability of my customized SMT PCB assembly?

To ensure reliability:

- Follow DFM guidelines during design.

- Use high-quality materials.

- Perform rigorous inspections such as AOI and X-ray testing.

3. What equipment is essential for SMT PCB assembly?

Key equipment includes:

- Solder paste printers.

- Pick-and-place machines.

- Reflow ovens.

- Inspection tools like AOI systems.

4. Why is reflow soldering important in SMT assembly?

Reflow soldering creates strong electrical connections by melting solder paste under controlled heat conditions. It ensures durable joints between components and PCBs.

5. Can I customize my SMT PCB assembly process?

Yes, customization allows you to tailor designs, materials, and processes to meet specific product requirements, enhancing performance and reliability.