Content Menu

● Understanding SMT Production Lines

● Importance of Training in SMT Operations

● Strategies for Effective Training

>> 1. Develop a Comprehensive Training Program

>> 2. Utilize Various Training Methods

>> 3. Implement Mentorship Programs

>> 4. Focus on Safety Training

>> 5. Continuous Improvement Through Feedback

● Best Practices for Training Implementation

>> 1. Assess Skill Levels

>> 2. Standardize Procedures

>> 3. Schedule Regular Refresher Courses

>> 4. Encourage Cross-Training

>> 5. Monitor Performance Metrics

● Enhancing Efficiency Through Training

>> 1. Automation Integration

>> 2. Lean Manufacturing Principles

>> 3. Statistical Process Control (SPC) Techniques

>> 4. Quality Control Mechanisms

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. Why is employee training important in SMT operations?

>> 3. What are some effective methods for training employees on SMT?

>> 4. How often should refresher courses be conducted?

>> 5. What metrics should be monitored post-training?

● Citations:

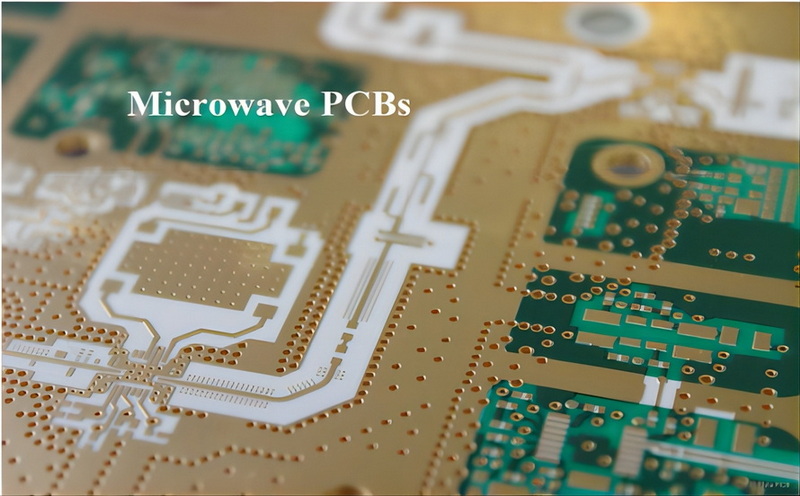

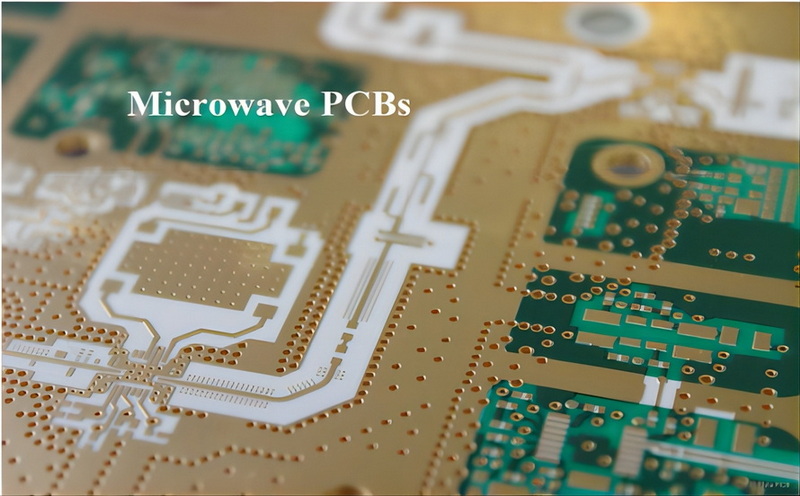

Surface Mount Technology (SMT) is a pivotal process in electronics manufacturing, where components are mounted directly onto the surface of printed circuit boards (PCBs). As the demand for high-quality electronics continues to rise, effective training for employees operating SMT production lines becomes essential. This article explores strategies, methods, and best practices for training employees on SMT production line operations.

Understanding SMT Production Lines

Before delving into training methodologies, it is crucial to understand the components and processes involved in SMT production lines. The typical SMT process includes:

- Solder Paste Printing: Applying solder paste to the PCB using a stencil.

- Component Placement: Using pick-and-place machines to position components accurately on the PCB.

- Reflow Soldering: Heating the assembled PCB in a reflow oven to melt the solder and create electrical connections.

- Inspection: Utilizing Automated Optical Inspection (AOI) and other methods to ensure quality control.

Each of these stages requires specific skills and knowledge, making comprehensive training imperative.

Importance of Training in SMT Operations

Training employees effectively on SMT operations is vital for several reasons:

- Quality Assurance: Well-trained employees can significantly reduce errors that lead to defects in electronic products.

- Operational Efficiency: Proper training enhances productivity by minimizing downtime and ensuring smooth operations.

- Safety Compliance: Employees must be aware of safety protocols when handling machinery and materials.

- Adaptation to Technology: With rapid advancements in SMT technology, continuous training helps employees stay updated with the latest practices and equipment.

Strategies for Effective Training

1. Develop a Comprehensive Training Program

A well-structured training program should encompass both theoretical knowledge and practical skills. Key elements include:

- Curriculum Design: Create a curriculum that covers all aspects of SMT operations, including equipment handling, process control, troubleshooting, and quality assurance.

- Hands-On Training: Incorporate practical sessions where employees can operate machinery under supervision. This helps reinforce theoretical concepts.

2. Utilize Various Training Methods

Different employees have different learning styles; thus, employing a mix of training methods can enhance learning outcomes:

- Instructor-Led Training: Conduct workshops led by experienced trainers who can provide insights and answer questions.

- E-Learning Modules: Develop online courses that employees can complete at their own pace, allowing for flexibility.

- Simulation Training: Use simulation software or virtual reality tools to create realistic training environments without the risks associated with live equipment.

3. Implement Mentorship Programs

Pairing new employees with experienced mentors can facilitate knowledge transfer and provide guidance during the initial stages of their training. Mentors can offer real-world insights and help troubleshoot problems as they arise.

4. Focus on Safety Training

Safety is paramount in manufacturing environments. Ensure that all training programs include comprehensive safety protocols related to:

- Equipment operation

- Handling hazardous materials

- Emergency procedures

Regular safety drills should also be conducted to reinforce these practices.

5. Continuous Improvement Through Feedback

Establish mechanisms for collecting feedback from trainees about the training process. This can include surveys or informal discussions. Use this feedback to refine training programs continuously.

Best Practices for Training Implementation

1. Assess Skill Levels

Before initiating training, assess the current skill levels of employees to tailor the program accordingly. This ensures that each employee receives relevant training based on their existing knowledge and experience.

2. Standardize Procedures

Develop standardized operating procedures (SOPs) for each stage of the SMT process. These documents should be part of the training materials to ensure consistency across operations.

3. Schedule Regular Refresher Courses

Technology and processes evolve; therefore, regular refresher courses are necessary to keep all employees updated on best practices and new technologies in SMT manufacturing.

4. Encourage Cross-Training

Cross-training employees on different roles within the SMT production line can enhance flexibility and improve overall team performance. This approach also prepares the workforce for unexpected absences or changes in staffing.

5. Monitor Performance Metrics

After training, monitor performance metrics such as defect rates, production speed, and equipment downtime. Analyzing these metrics helps identify areas where further training may be needed.

Enhancing Efficiency Through Training

In addition to basic operational training, enhancing efficiency in SMT production lines is critical for maintaining competitiveness in the electronics industry. Here are some strategies:

1. Automation Integration

The integration of automation technologies into SMT processes can significantly enhance efficiency. Automated machines reduce manual labor requirements while improving precision and speed in various stages of production. Employees should be trained not only on how to operate these machines but also on how to troubleshoot common issues that may arise during automated operations[1][4].

2. Lean Manufacturing Principles

Implementing lean manufacturing principles can help minimize waste and optimize workflows within SMT production lines. Employees should be trained in identifying bottlenecks, streamlining processes, and applying continuous improvement methodologies such as Kaizen[1][4].

3. Statistical Process Control (SPC) Techniques

Training employees in SPC techniques allows them to monitor production processes actively, identifying variations before they lead to defects[2]. Key tools include control charts and capability analysis which help maintain stability in production quality.

4. Quality Control Mechanisms

Incorporating robust quality control mechanisms into employee training ensures that workers understand how to detect defects early in the process[2]. Techniques such as Poka-Yoke (error-proofing) can prevent common assembly mistakes through systematic checks at various stages of production[2].

Conclusion

Training employees effectively on SMT production line operations is critical for maintaining high-quality standards and operational efficiency in electronics manufacturing. By developing comprehensive training programs that incorporate various teaching methods, emphasizing safety, fostering a culture of continuous improvement, and integrating advanced technologies like automation, organizations can ensure their workforce is well-equipped to handle the complexities of modern SMT processes.

As technology continues to advance, ongoing education will remain essential for keeping pace with industry changes and meeting customer expectations. Investing in employee development not only enhances individual skills but also contributes significantly to organizational success by fostering a knowledgeable workforce capable of driving innovation and efficiency within SMT operations.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole technology.

2. Why is employee training important in SMT operations?

Employee training is crucial in SMT operations as it ensures quality assurance, enhances operational efficiency, promotes safety compliance, and helps workers adapt to new technologies effectively.

3. What are some effective methods for training employees on SMT?

Effective methods include instructor-led workshops, e-learning modules, hands-on practical sessions, simulation training, and mentorship programs that facilitate knowledge transfer from experienced workers to newcomers.

4. How often should refresher courses be conducted?

Refresher courses should be scheduled regularly—at least once a year or whenever significant changes occur in technology or processes—to keep employees updated on best practices in SMT operations.

5. What metrics should be monitored post-training?

Post-training metrics include defect rates, production speed, equipment downtime, employee engagement levels during training sessions, and overall productivity improvements within the SMT line operations.

Citations:

[1] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[2] https://www.raypcb.com/effective-measures-to-improve-smt-assembly-quality/

[3] https://www.blackfox.com/hands-on-vs-online-electronic-assembly-training-which-is-right-for-you/

[4] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[5] https://core-emt.com/training-courses-on-smt-equipment-smt-software-training

[6] https://electronicsgroup.co.uk/importance-of-becoming-ipc-certified/

[7] https://hawkerrichardson.com.au/blog/smt-line-efficiency-and-training/

[8] https://ecelectronics.com/news/how-training-and-education-is-shaping-the-future-of-electronics

[9] https://faroads.com/start-smt-line-guide-2024/

[10] https://www.blackfox.com/workforce-development-bridging-the-skills-gap-in-electronics-manufacturing/

[11] https://itmconsulting.com/workshops/

[12] https://www.circuittechnology.com/Training-ID/49/Training-Category/

[13] https://www.ipc.org/better-electronics-start-better-training

[14] https://www.viasion.com/blog/smt-manufacturing-process-step-by-step-guide/

[15] https://www.youtube.com/watch?v=yaSQpqxZ-TA

[16] https://www.tysongroup.com/post/10-ways-sales-training-can-elevate-teams-in-the-electronics-manufacturing-industry

[17] https://asselems.com/en/best-practices-in-smt-assembly

[18] https://www.linkedin.com/advice/0/what-best-practices-training-employees-electronics-nidhe

[19] https://www.linkedin.com/pulse/essential-practices-long-lived-smt-lines-hawker-richardson

[20] https://praxie.com/electronic-training-management/

[21] https://www.scientific-management.com/skills-training-programs/process-control-training/

[22] https://www.scientific-management.com/skills-training-programs/