Content Menu

● Understanding the SMT Line Components

● Key Considerations for SMT Line Layout Design

>> 1. Workflow Optimization

>> 2. Machine Placement Strategies

>> 3. Space Utilization

● Best Practices for Designing an Efficient SMT Line Layout

>> 1. Component Sequencing

>> 2. Feeder Management

>> 3. Ergonomics and Safety

● Implementing Lean Manufacturing Principles

● Utilizing Simulation Tools

● Continuous Improvement

● Material Handling Efficiency

● Advanced Technology Integration

● Training and Workforce Development

● Monitoring Performance Metrics

● Conclusion

● FAQ

>> 1. What is an SMT line?

>> 2. Why is machine placement important in an SMT line?

>> 3. How can I ensure safety in my SMT line layout?

>> 4. What role does continuous improvement play in SMT line design?

>> 5. How can simulation tools aid in designing an SMT line?

● Citations:

Designing an efficient Surface Mount Technology (SMT) line layout is crucial for maximizing productivity and ensuring high-quality output in electronics manufacturing. The layout of an SMT line directly impacts the flow of materials, the speed of assembly, and the overall effectiveness of the production process. This article will explore key considerations, best practices, and strategies for creating the most efficient SMT line layout.

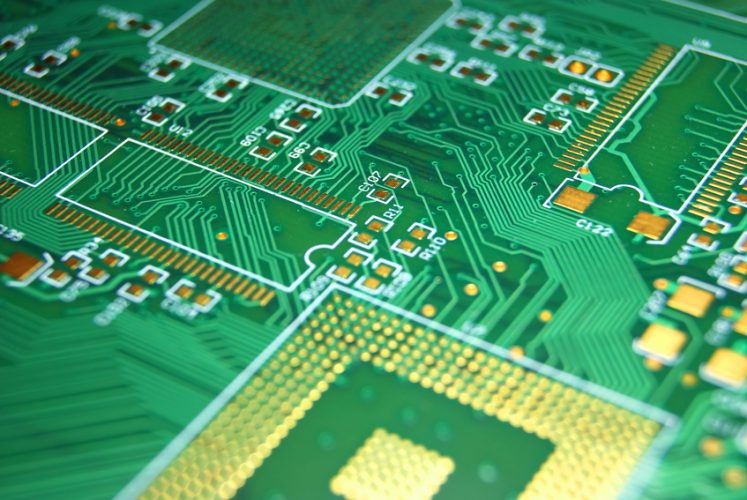

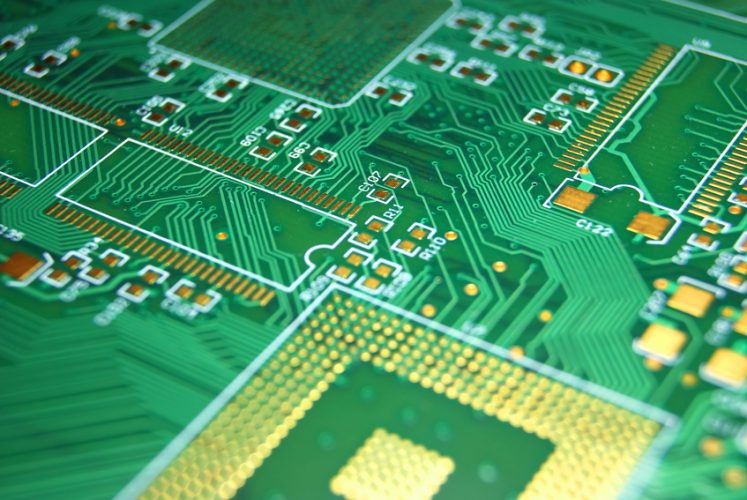

Understanding the SMT Line Components

An SMT line consists of several essential components that work together to assemble electronic components onto printed circuit boards (PCBs). These components typically include:

- Solder Paste Printer: Applies solder paste to the PCB.

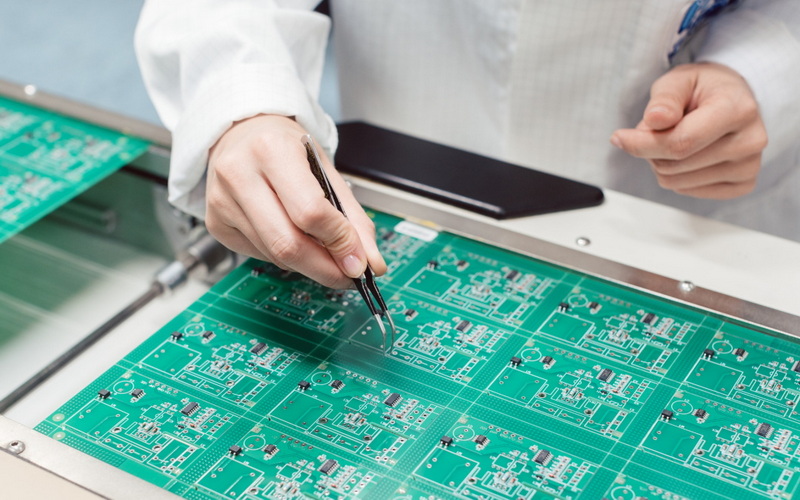

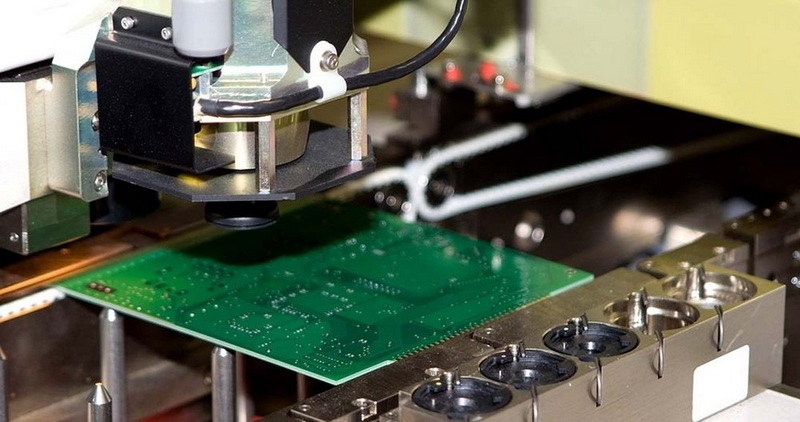

- Pick-and-Place Machine: Accurately places surface mount components onto the PCB.

- Reflow Oven: Melts solder paste to create electrical connections between components and the PCB.

- Inspection Systems: Automated Optical Inspection (AOI) and X-ray inspection systems check for defects.

Each component plays a critical role in ensuring the quality and efficiency of the assembly process. Understanding these roles is vital for optimizing the SMT line layout.

Key Considerations for SMT Line Layout Design

1. Workflow Optimization

The layout should facilitate a smooth workflow that minimizes movement and handling. Key strategies include:

- Linear Flow: Arrange machines in a straight line to promote a logical progression from solder paste application to final inspection.

- Minimize Bottlenecks: Identify potential bottlenecks in the production process and adjust machine placement accordingly.

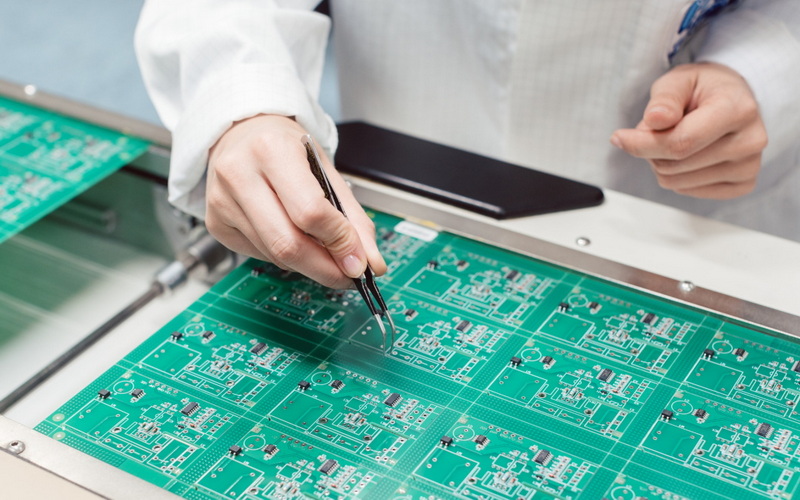

2. Machine Placement Strategies

Proper placement of machines is essential for efficiency:

- Group Technology: Place similar machines or processes close together to reduce transportation time between stages.

- Parallel Placement: For high-volume production, consider parallel configurations of pick-and-place machines or reflow ovens.

3. Space Utilization

Efficient use of space can significantly impact productivity:

- Adequate Spacing: Ensure there is enough space between machines for operators to move freely and perform maintenance without disrupting production.

- Future Expansion: Design the layout with future growth in mind, allowing for easy reconfiguration or addition of new machines.

Best Practices for Designing an Efficient SMT Line Layout

1. Component Sequencing

Arrange components in the order they will be placed on the PCB. This reduces machine setup time and improves overall throughput.

2. Feeder Management

Maintain organized feeders stocked with components to minimize changeover times and prevent shortages during production runs.

3. Ergonomics and Safety

Design workstations with operator comfort in mind:

- Ensure that controls are easily accessible without awkward reaching or straining.

- Implement safety measures such as proper lighting, ventilation, and clearly marked emergency exits.

Implementing Lean Manufacturing Principles

Applying lean manufacturing principles can help eliminate waste and improve efficiency:

- Value Stream Mapping: Analyze each step in the production process to identify areas for improvement.

- 5S Methodology: Sort, set in order, shine, standardize, and sustain to maintain an organized workspace that promotes efficiency.

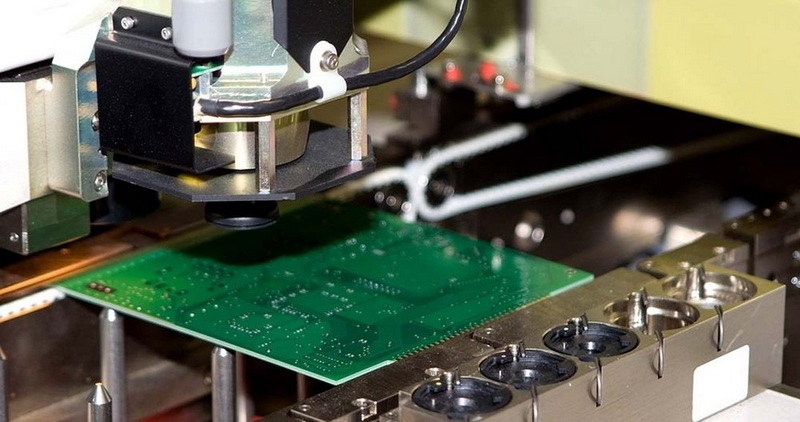

Utilizing Simulation Tools

Simulation tools can be invaluable when designing SMT line layouts. These tools allow manufacturers to create virtual models of their production lines and test various configurations before implementation. This helps identify potential issues early on and avoids costly mistakes during actual setup.

Continuous Improvement

Designing an efficient SMT line layout is not a one-time task but an ongoing process:

- Regularly review performance metrics to identify areas for optimization.

- Solicit feedback from operators to address any challenges they face on the line.

Material Handling Efficiency

Efficient material handling is crucial for maintaining a smooth SMT production line setup. Implementing systems that facilitate just-in-time (JIT) inventory can help reduce waste and ensure that materials are available when needed. Proper storage solutions, such as climate-controlled environments for sensitive components, are also essential.

Automated material handling systems, such as conveyors and feeders, can streamline processes and reduce manual handling errors. This automation not only speeds up operations but also minimizes human error, leading to higher quality outputs.

Advanced Technology Integration

Integrating advanced technologies into your SMT line can significantly enhance efficiency:

- Implement Automated Optical Inspection (AOI) systems to detect defects early in the production process.

- Use machine learning algorithms for predictive maintenance, which can anticipate equipment failures before they disrupt production.

By leveraging these technologies, manufacturers can achieve higher precision in assembly processes and reduce downtime caused by equipment malfunctions.

Training and Workforce Development

A skilled workforce is essential for maintaining an efficient SMT line. Regular training programs ensure that operators are familiar with the latest technologies and best practices. Investing in personnel development not only improves operational efficiency but also fosters a culture of continuous improvement within the organization.

Training should cover various aspects, including machine operation, troubleshooting techniques, quality control measures, and safety protocols. This comprehensive approach ensures that employees are well-equipped to handle challenges on the production floor effectively.

Monitoring Performance Metrics

To optimize your SMT line continuously, it's essential to monitor key performance indicators (KPIs). These metrics might include:

- Cycle time

- First-pass yield

- Equipment utilization rates

- Downtime incidents

By analyzing these metrics regularly, manufacturers can identify trends, pinpoint inefficiencies, and make data-driven decisions that enhance overall productivity.

Conclusion

Creating an efficient SMT line layout requires careful planning, consideration of workflow dynamics, proper machine placement, adherence to best practices, effective material handling strategies, advanced technology integration, workforce training, and continuous monitoring of performance metrics. By focusing on these elements and implementing lean manufacturing principles, manufacturers can optimize their production lines for maximum efficiency and quality output. As technology evolves, continuous improvement will remain essential in adapting layouts to meet changing demands and enhance productivity.

FAQ

1. What is an SMT line?

An SMT line refers to a sequence of machines and processes used to assemble electronic components onto printed circuit boards (PCBs) using surface mount technology.

2. Why is machine placement important in an SMT line?

Proper machine placement minimizes idle time, reduces transportation delays between processes, and enhances overall workflow efficiency.

3. How can I ensure safety in my SMT line layout?

Implement ergonomic designs for workstations, ensure proper lighting and ventilation, and clearly mark emergency exits to enhance safety on the production floor.

4. What role does continuous improvement play in SMT line design?

Continuous improvement allows manufacturers to regularly assess performance metrics, identify inefficiencies, and implement changes based on operator feedback to enhance productivity over time.

5. How can simulation tools aid in designing an SMT line?

Simulation tools enable manufacturers to create virtual models of their production lines, allowing them to test various configurations and identify potential issues before actual implementation.

Citations:

[1] https://www.smtfactory.com/Strategic-SMT-Production-Line-Layout-Design-id40117676.html

[2] https://txjpcb.com/the-best-practices-for-smt-line-balancing-and-optimization/

[3] https://www.linkedin.com/pulse/perfect-layout-analysis-design-smt-electronics-factory-mia-feng-vxw6c

[4] https://www.smthelp.com/smt-manufacturability-design-guidelines

[5] https://www.smtfactory.com/Perfecting-Your-SMT-Line-Layout-for-Efficiency-id47017676.html

[6] https://core-emt.com/blog/smt-news-1/identifying-addressing-smt-line-bottlenecks-to-plan-line-upgrades-smartly-119

[7] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[8] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[9] https://www.raypcb.com/line-efficiency/

[10] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html