Content Menu

● Understanding SMT Stencils

>> What is an SMT Stencil?

>> Importance of Choosing the Right SMT Stencil

● Factors to Consider When Choosing an SMT Stencil

>> 1. Stencil Material

>> 2. Stencil Thickness

>> 3. Aperture Design

>> 4. Framed vs. Frameless Stencils

>> 5. Production Volume

>> 6. Component Types and Sizes

>> 7. Solder Paste Type

● Best Practices for Using SMT Stencils

>> 1. Cleaning and Maintenance

>> 2. Storage

>> 3. Inspection Before Use

>> 4. Alignment with PCB

>> 5. Solder Paste Selection

>> 6. Temperature and Humidity Control

>> 7. Training and Skill Development

● Advanced Considerations for SMT Stencil Selection

>> 1. Laser-Cut vs. Electroformed Stencils

>> 2. Custom Stencil Designs

>> 3. Technology Integration

>> 4. Cost vs. Quality

>> 5. Supplier Reputation and Support

● Conclusion

● FAQ

>> 1. What is the difference between framed and frameless SMT stencils?

>> 2. How do I clean an SMT stencil?

>> 3. What material is best for SMT stencils?

>> 4. How thick should an SMT stencil be?

>> 5. Why is aperture design important in SMT stencils?

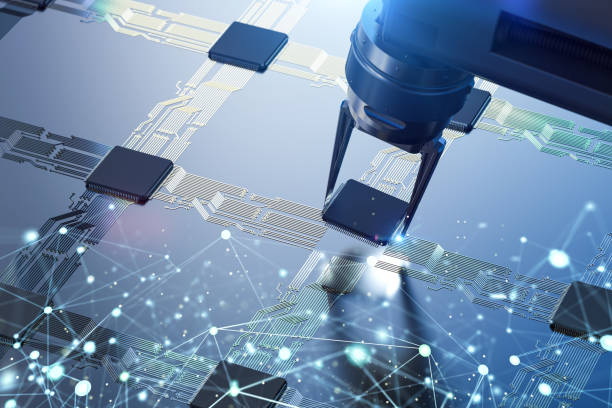

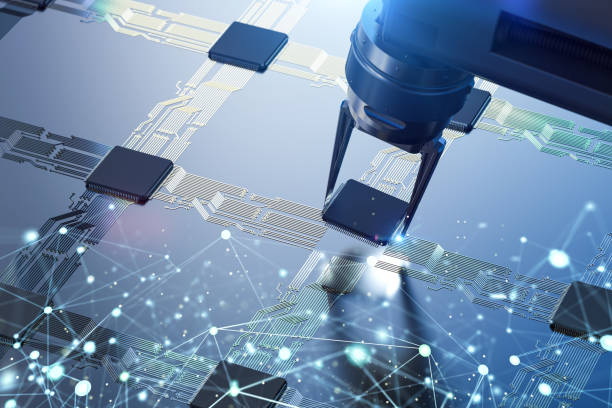

Surface Mount Technology (SMT) stencils play a crucial role in the PCB assembly process, particularly in the application of solder paste. Choosing the right SMT stencil is essential for ensuring high-quality assembly, reducing defects, and improving efficiency. This article will guide you through the factors to consider when selecting an SMT stencil, the types available, and best practices for use.

Understanding SMT Stencils

What is an SMT Stencil?

An SMT stencil, also known as a solder paste stencil, is a thin sheet, typically made of stainless steel or other materials, with openings (apertures) that correspond to the pads on a PCB. These stencils are used to apply solder paste to the PCB before components are placed and soldered. The precision of the stencil directly affects the quality of the solder application, which is critical for the performance of the final product.

Importance of Choosing the Right SMT Stencil

Selecting the appropriate SMT stencil is vital for several reasons:

- Accuracy: A well-designed stencil ensures that the right amount of solder paste is applied to each pad, which is crucial for the reliability of the solder joints.

- Consistency: Using the correct stencil helps maintain uniformity across multiple assemblies, reducing the risk of defects.

- Efficiency: The right stencil can speed up the assembly process, allowing for faster production times and lower costs.

Factors to Consider When Choosing an SMT Stencil

1. Stencil Material

The most common materials for SMT stencils are stainless steel and polymer. Each material has its advantages:

- Stainless Steel: Offers durability and precision, making it ideal for high-volume production. It can withstand multiple uses and cleaning cycles.

- Polymer: Generally less expensive and suitable for low-volume or prototype runs. However, it may not provide the same level of precision as stainless steel.

2. Stencil Thickness

The thickness of the stencil affects the volume of solder paste that can be deposited. Common thicknesses range from 0.1 mm to 0.2 mm. Thicker stencils can hold more paste, which is beneficial for larger components, while thinner stencils are better for fine-pitch components.

3. Aperture Design

The design of the apertures is critical. Factors to consider include:

- Size: The aperture size should match the pad size on the PCB. Oversized apertures can lead to excess solder, while undersized ones can result in insufficient solder.

- Shape: Different components may require different aperture shapes. For example, a round aperture may be suitable for a standard pad, while a rectangular one may be better for a fine-pitch component.

4. Framed vs. Frameless Stencils

- Framed Stencils: These stencils are mounted in a frame, providing stability and ease of handling. They are ideal for high-volume production.

- Frameless Stencils: These are more flexible and can be used for smaller runs or prototypes. They are easier to store and transport but may require more careful handling.

5. Production Volume

Consider the volume of production when selecting a stencil. For high-volume production, investing in a high-quality stainless steel stencil may be worthwhile. For low-volume or prototype runs, a polymer stencil may suffice.

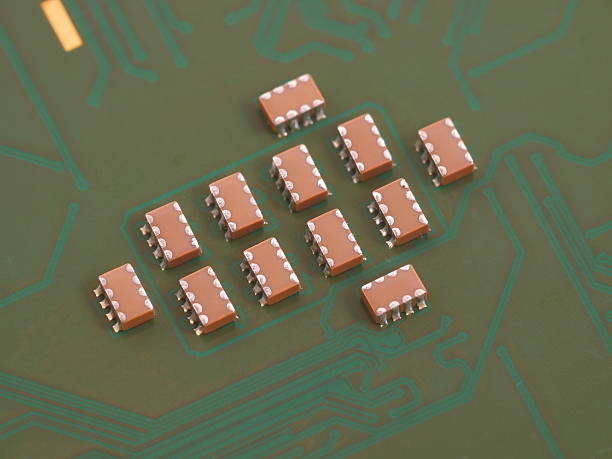

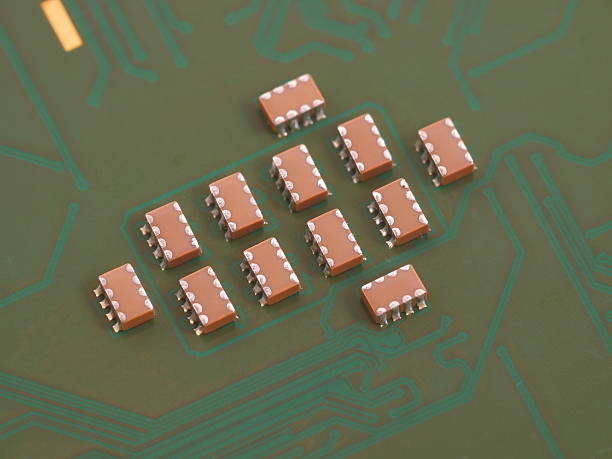

6. Component Types and Sizes

Different components require different solder paste applications. For instance, larger components like connectors may need larger apertures, while smaller, fine-pitch components require more precise, smaller apertures. Understanding the types and sizes of components you will be using is essential in determining the appropriate stencil design.

7. Solder Paste Type

The type of solder paste used can also influence the choice of stencil. Different solder pastes have varying viscosities and particle sizes, which can affect how well they flow through the stencil apertures. It's important to match the stencil design with the specific solder paste characteristics to ensure optimal performance.

Best Practices for Using SMT Stencils

1. Cleaning and Maintenance

Proper cleaning and maintenance of SMT stencils are essential to ensure their longevity and performance. After each use, stencils should be cleaned to remove any residual solder paste. This can be done using a stencil cleaning solution and a lint-free cloth. Regular maintenance helps prevent contamination and ensures consistent solder paste application.

2. Storage

Stencils should be stored flat in a clean, dry environment to prevent warping or damage. Avoid stacking heavy objects on top of stencils to maintain their shape. Proper storage conditions can significantly extend the life of the stencil.

3. Inspection Before Use

Before using a stencil, inspect it for any damage or defects. Ensure that the apertures are clear and that there are no obstructions that could affect solder paste application. Regular inspections can help identify issues before they impact production.

4. Alignment with PCB

Accurate alignment of the stencil with the PCB is crucial for effective solder paste application. Use alignment tools or fiducial marks on the PCB to ensure proper placement. Misalignment can lead to solder paste being applied to the wrong pads, resulting in defects.

5. Solder Paste Selection

Choose the right solder paste for your application. The viscosity and particle size of the solder paste can affect how well it flows through the stencil apertures. Consult with your solder paste supplier to select a paste that complements your stencil design and production requirements.

6. Temperature and Humidity Control

Environmental factors such as temperature and humidity can affect solder paste performance. Ensure that the assembly area is controlled for temperature and humidity to maintain the quality of the solder paste and the effectiveness of the stencil.

7. Training and Skill Development

Investing in training for your assembly team can significantly improve the quality of the solder paste application. Ensure that operators understand the importance of stencil handling, cleaning, and alignment. Skilled operators can make a substantial difference in the overall quality of the PCB assembly process.

Advanced Considerations for SMT Stencil Selection

1. Laser-Cut vs. Electroformed Stencils

When selecting an SMT stencil, consider whether to use laser-cut or electroformed stencils. Laser-cut stencils are typically less expensive and suitable for low to medium volume production. They offer good precision but may not be as durable as electroformed stencils. Electroformed stencils, on the other hand, are more expensive but provide superior precision and durability, making them ideal for high-volume production runs.

2. Custom Stencil Designs

In some cases, standard stencil designs may not meet specific requirements. Custom stencils can be designed to accommodate unique component layouts or specific solder paste application needs. Working with a stencil manufacturer to create a custom design can enhance the efficiency and quality of your PCB assembly process.

3. Technology Integration

Consider integrating technology into your stencil application process. Automated stencil printers can improve accuracy and speed, reducing the potential for human error. Additionally, some advanced printers offer features like vision systems that ensure proper alignment and paste application.

4. Cost vs. Quality

While it may be tempting to choose the least expensive option, consider the long-term implications of your stencil choice. Investing in high-quality stencils can lead to fewer defects, reduced rework, and ultimately lower costs in the production process. Evaluate the total cost of ownership, including maintenance and replacement, when making your decision.

5. Supplier Reputation and Support

When selecting a stencil supplier, consider their reputation in the industry and the level of support they offer. A reliable supplier can provide valuable insights into stencil selection and maintenance, helping you make informed decisions that enhance your production process.

Conclusion

Choosing the right SMT stencil is a critical step in the PCB assembly process. By considering factors such as material, thickness, aperture design, production volume, and component types, you can select a stencil that meets your specific needs. Proper maintenance and handling of the stencil will further enhance its performance and longevity, leading to higher quality assemblies and reduced defects. Additionally, staying informed about advancements in stencil technology and best practices can help you continuously improve your PCB assembly process.

FAQ

1. What is the difference between framed and frameless SMT stencils?

Framed stencils are mounted in a rigid frame for stability, making them suitable for high-volume production. Frameless stencils are more flexible and easier to handle, ideal for low-volume or prototype runs.

2. How do I clean an SMT stencil?

SMT stencils should be cleaned with a stencil cleaning solution and a lint-free cloth after each use to remove residual solder paste.

3. What material is best for SMT stencils?

Stainless steel is preferred for high-volume production due to its durability and precision, while polymer stencils are suitable for low-volume or prototype runs.

4. How thick should an SMT stencil be?

Common thicknesses range from 0.1 mm to 0.2 mm. Thicker stencils hold more paste, while thinner stencils are better for fine-pitch components.

5. Why is aperture design important in SMT stencils?

Aperture design affects the volume and accuracy of solder paste application. Properly sized and shaped apertures ensure the right amount of solder is deposited on each pad.