Content Menu

● Introduction to SMT PCB Fasteners

>> Advantages of SMT PCB Fasteners

>> Types of SMT PCB Fasteners

● Applications of SMT PCB Fasteners

● Selection Criteria for SMT PCB Fasteners

● Common Challenges with SMT PCB Fasteners

● Best Practices for Using SMT PCB Fasteners

● Advanced Considerations for SMT PCB Fasteners

>> Thermal Management

>> Environmental Considerations

>> Design for Manufacturability

>> Cost Considerations

● Future Trends in SMT PCB Fasteners

>> Integration with Emerging Technologies

>> Sustainability and Environmental Impact

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using SMT PCB fasteners?

>> 2. How do I ensure the reliability of SMT PCB fasteners?

>> 3. What are common challenges associated with SMT PCB fasteners?

>> 4. Can SMT PCB fasteners be used in high-temperature applications?

>> 5. How do I select the right material for SMT PCB fasteners?

Choosing the right SMT (Surface Mount Technology) PCB fasteners is crucial for ensuring the reliability, efficiency, and longevity of electronic devices. SMT PCB fasteners play a vital role in securing components, managing wires, and maintaining the structural integrity of printed circuit boards (PCBs). In this article, we will delve into the world of SMT PCB fasteners, exploring their types, applications, and selection criteria.

Introduction to SMT PCB Fasteners

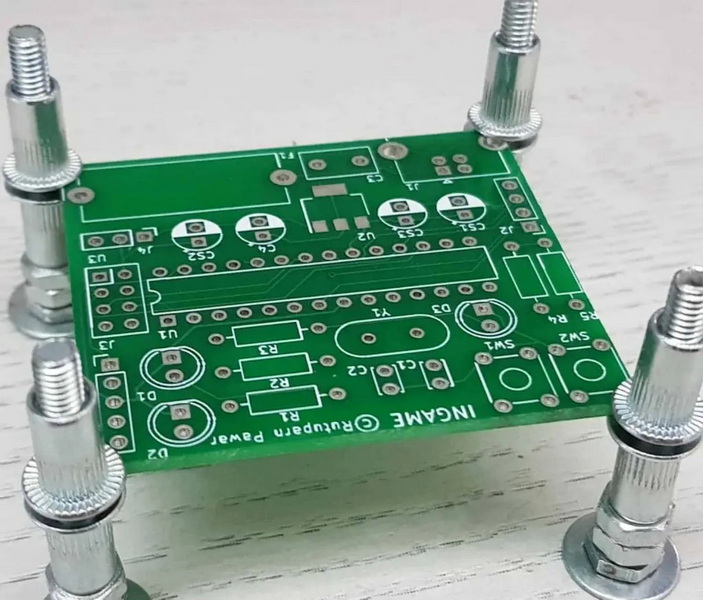

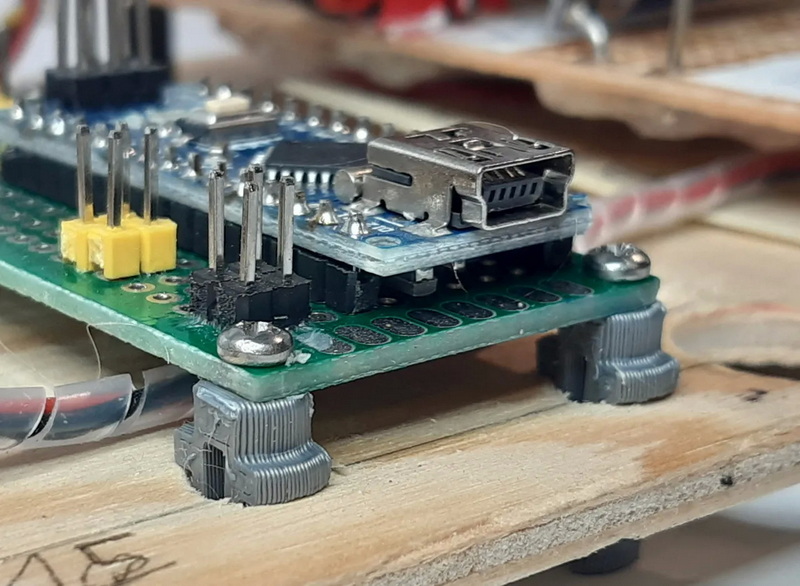

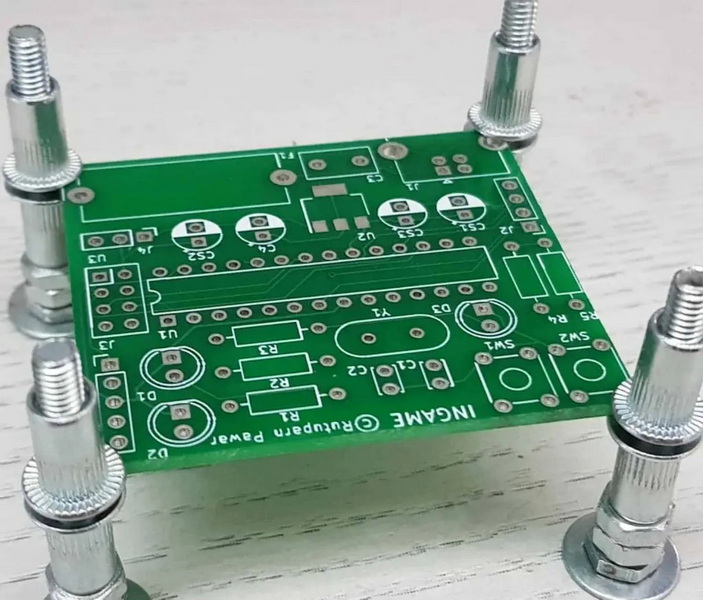

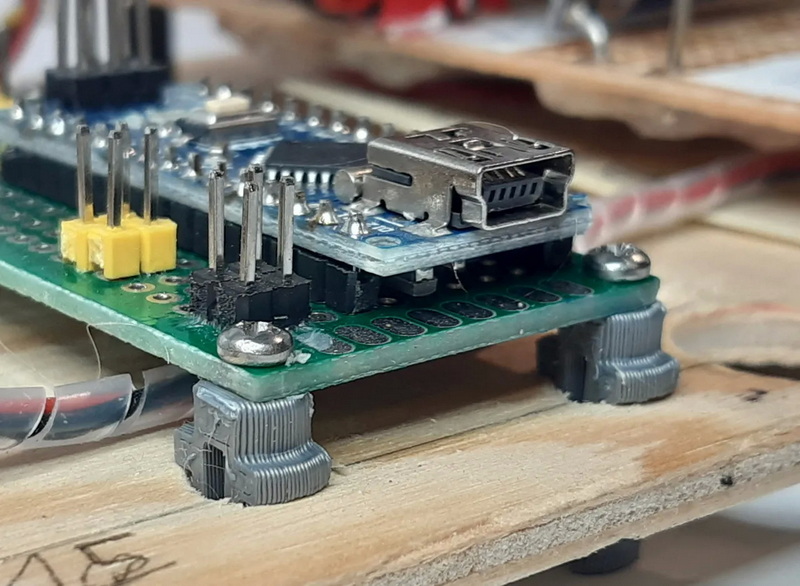

SMT PCB fasteners are designed to be mounted directly onto the surface of a PCB using reflow soldering. This technology eliminates the need for through-holes, allowing for more compact designs and increased component density. SMT fasteners include standoffs, nuts, studs, and other specialized components that are essential for modern electronic devices.

Advantages of SMT PCB Fasteners

1. Compact Design: SMT fasteners enable more compact PCB designs by eliminating the need for through-holes, which can increase the density of components on a board.

2. Efficient Production: The use of reflow soldering simplifies the assembly process, reducing production time and costs.

3. Improved Reliability: SMT fasteners provide strong mechanical bonds, enhancing the overall reliability of electronic systems.

Types of SMT PCB Fasteners

- Standoffs: These are used to elevate PCBs from their mounting surfaces, preventing electrical shorts and improving heat dissipation.

- Nuts: Available in various types, such as clinch nuts and floating nuts, they provide secure fastening solutions.

- Studs: Often used for locating and aligning components.

- Captivated Screws: Include simple screws, spring-loaded screws, and knob cap screws for different applications.

Applications of SMT PCB Fasteners

SMT PCB fasteners are widely used in various industries, including electronics, telecommunications, automotive, and aerospace. They are essential for:

- PCB Mounting: Securing PCBs in enclosures and ensuring proper alignment.

- Wire Management: Helping to organize cables and wires within electronic systems.

- Component Support: Providing structural support for components to prevent damage from vibrations.

Selection Criteria for SMT PCB Fasteners

When choosing SMT PCB fasteners, several factors must be considered:

1. Material: The choice of material depends on the application's environmental conditions, such as temperature, humidity, and exposure to chemicals.

2. Size and Shape: The fastener must fit the available space on the PCB and match the component's design requirements.

3. Strength and Durability: The fastener should withstand mechanical stresses and vibrations without compromising the PCB's integrity.

4. Compatibility with PCB Material: Ensure that the fastener is compatible with the PCB's material to avoid damage during soldering or operation.

Common Challenges with SMT PCB Fasteners

Despite their advantages, SMT PCB fasteners present some challenges:

- Inspection and Reparability: Soldered joints can be difficult to inspect visually, and repairing them may require specialized tools.

- Mechanical Failure: Failure can lead to damage to the PCB or components, necessitating replacement.

Best Practices for Using SMT PCB Fasteners

1. Use Appropriate Solder Paste: Ensure the solder paste is suitable for the application to achieve reliable solder joints.

2. Follow Manufacturer Guidelines: Adhere to the thermal profiles and assembly procedures recommended by the manufacturer.

3. Test and Validate: Conduct thorough testing to validate the performance of the fasteners under various conditions.

Advanced Considerations for SMT PCB Fasteners

Thermal Management

In applications where heat dissipation is critical, SMT PCB fasteners can play a role in thermal management. Standoffs, for example, can help improve airflow around PCBs, reducing thermal stress on components. Additionally, selecting materials with high thermal conductivity can enhance heat transfer away from sensitive components.

Environmental Considerations

For devices exposed to harsh environments, such as high humidity or corrosive substances, selecting fasteners with appropriate coatings or materials is essential. This ensures that the fasteners do not degrade over time, compromising the system's integrity. Coatings like zinc or chrome plating can provide corrosion resistance, while materials like stainless steel offer durability in extreme conditions.

Design for Manufacturability

When designing PCBs with SMT fasteners, consider the manufacturability of the assembly. Ensure that the placement of fasteners does not interfere with other components or assembly processes, such as pick-and-place operations. This can help streamline production and reduce costs by minimizing manual intervention.

Cost Considerations

While SMT PCB fasteners offer many benefits, their cost can be a factor in budget-sensitive projects. Balancing the need for reliability and performance with cost constraints requires careful selection of materials and designs. Economies of scale can also be achieved by standardizing fastener types across different projects.

Future Trends in SMT PCB Fasteners

As technology advances, there is a growing demand for smaller, more reliable, and versatile SMT PCB fasteners. Innovations in materials and designs are expected to address challenges such as thermal management and environmental durability. Additionally, advancements in automation and robotics will further streamline the assembly process, making SMT PCB fasteners even more integral to modern electronics manufacturing.

Integration with Emerging Technologies

The integration of SMT PCB fasteners with emerging technologies like IoT devices and 5G infrastructure will require fasteners that can meet new performance standards. This includes fasteners capable of withstanding high-frequency vibrations and extreme environmental conditions. Moreover, the use of smart materials and nanotechnology could lead to the development of fasteners with enhanced properties, such as self-healing capabilities or adaptive thermal management.

Sustainability and Environmental Impact

As concerns about environmental sustainability grow, manufacturers are focusing on reducing waste and using eco-friendly materials in their products. SMT PCB fasteners can contribute to this effort by being designed with recyclable materials and minimizing the use of hazardous substances. This not only helps reduce environmental impact but also aligns with regulatory requirements and consumer preferences.

Conclusion

Choosing the right SMT PCB fasteners is critical for the success of electronic devices. By understanding the types, applications, and selection criteria for these fasteners, manufacturers can ensure reliable, efficient, and compact electronic systems. As technology continues to evolve, the role of SMT PCB fasteners will remain vital in advancing the electronics industry.

Frequently Asked Questions

1. What are the primary benefits of using SMT PCB fasteners?

SMT PCB fasteners offer several benefits, including compact design, efficient production, and improved reliability. They allow for more dense component placement and simplify the assembly process by eliminating the need for through-holes.

2. How do I ensure the reliability of SMT PCB fasteners?

To ensure reliability, use appropriate solder paste, follow manufacturer guidelines for thermal profiles and assembly, and conduct thorough testing under various conditions.

3. What are common challenges associated with SMT PCB fasteners?

Common challenges include difficulties in inspecting solder joints and potential mechanical failures that can damage PCBs or components.

4. Can SMT PCB fasteners be used in high-temperature applications?

Yes, SMT PCB fasteners can be used in high-temperature applications if the materials and solder paste are chosen to withstand those conditions. It's essential to select components rated for the expected temperature range.

5. How do I select the right material for SMT PCB fasteners?

Selecting the right material involves considering the environmental conditions of the application, such as temperature, humidity, and exposure to chemicals. The material should be compatible with the PCB and capable of withstanding mechanical stresses.