Content Menu

● Understanding SMT Nozzle Design

● Factors to Consider When Choosing SMT Nozzles

>> 1. Component Size and Shape

>> 2. Component Height

>> 3. Vacuum Pressure

>> 4. PCB Design Considerations

>> 5. Environmental Factors

● Types of SMT Nozzles

>> Standard Nozzles

>> Custom Nozzles

>> Specialized Nozzles

● Best Practices for PCB Design

>> 1. Use Larger Components When Possible

>> 2. Maintain Adequate Spacing

>> 3. Optimize Component Orientation

>> 4. Group Related Components Together

>> 5. Follow Design for Manufacturability (DFM) Guidelines

>> 6. Consider Reworkability

● Enhancing Efficiency Through Proper Nozzle Management

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is an SMT nozzle?

>> 2. How do I choose the right SMT nozzle for my PCB design?

>> 3. Can I use the same nozzle for all components?

>> 4. What are the benefits of using custom nozzles?

>> 5. How does PCB design affect nozzle selection?

● Citations:

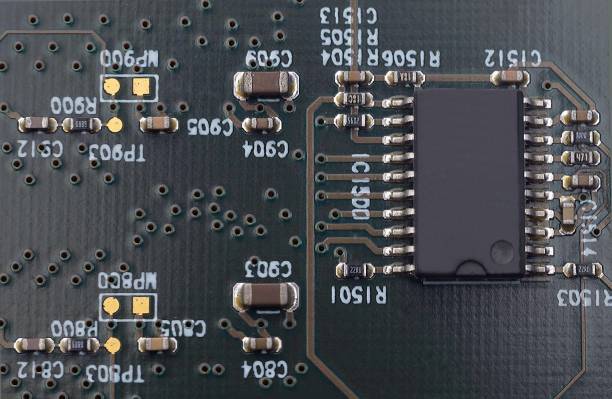

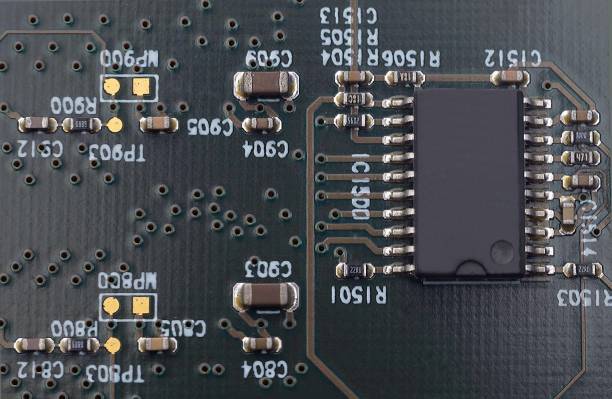

Surface Mount Technology (SMT) is a cornerstone of modern electronics manufacturing, enabling the efficient assembly of printed circuit boards (PCBs). One critical aspect of this process is selecting the right SMT nozzle for different PCB designs. The nozzle's design and compatibility with components significantly impact the accuracy, speed, and yield of the assembly process. This article delves into the factors to consider when choosing SMT nozzles, the types of nozzles available, best practices for optimizing PCB designs for SMT assembly, and practical tips to enhance overall manufacturing efficiency.

Understanding SMT Nozzle Design

SMT nozzles are specialized tools used in pick-and-place machines to handle and place components onto PCBs. The design of these nozzles varies based on the type of components, their dimensions, and the specific requirements of the assembly process. Key factors in nozzle design include:

- Material: Anti-static, abrasion-resistant materials are preferred to ensure durability and prevent component damage.

- Suction Area: The effective suction shape and area must match the component's profile to ensure a secure grip.

- Symmetry: Symmetrical suction holes ensure stability during placement, reducing the risk of misalignment.

- Nozzle Length: The length of the nozzle can affect its ability to reach components located in tight spaces on a PCB.

Factors to Consider When Choosing SMT Nozzles

1. Component Size and Shape

The size and shape of components dictate the type of nozzle required. For instance, flat chips like 0402 or 0603 require specific nozzle types to ensure accurate placement. Larger components may necessitate wider nozzles with larger suction areas.

2. Component Height

Different pick-and-place machines have height limitations. Ensuring components fit within these limits avoids manual placement and improves efficiency. Tall components should be carefully considered in relation to adjacent smaller parts to avoid interference during placement.

3. Vacuum Pressure

The vacuum pressure settings must align with the component's weight and size to prevent misplacement or damage. Too much vacuum can cause delicate components to deform, while too little can lead to dropping or misalignment during placement.

4. PCB Design Considerations

Spacing between components is crucial; overcrowding can lead to difficulties in placement and soldering. Avoid placing tall components near small ones, as this can complicate nozzle selection and increase error rates.

5. Environmental Factors

Consideration must be given to the environment in which the PCB will operate. For example, if a board will be exposed to high temperatures or humidity, selecting a nozzle that can withstand these conditions is essential.

Types of SMT Nozzles

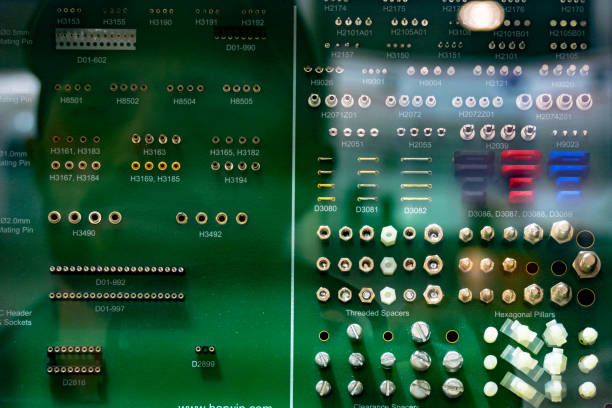

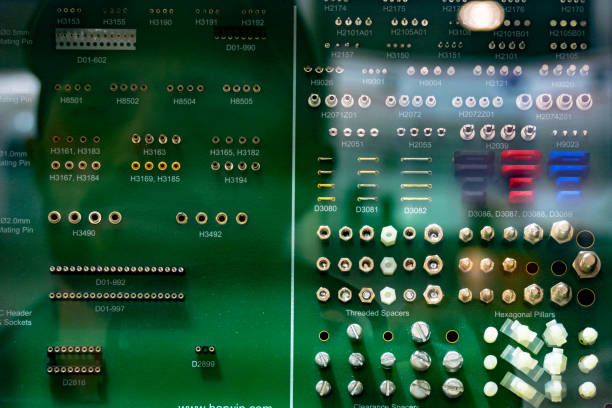

Standard Nozzles

Standard nozzles are versatile and suitable for most applications. They are categorized by numbers (e.g., 1xx, 2xx) based on their compatibility with specific machine models.

Custom Nozzles

For non-standard components, custom nozzles are designed to meet unique requirements. These are often used for irregularly shaped or delicate components where standard nozzles would not suffice.

Specialized Nozzles

Some applications may require specialized nozzles designed for specific tasks, such as high-speed assembly or handling sensitive electronic parts that require gentle handling.

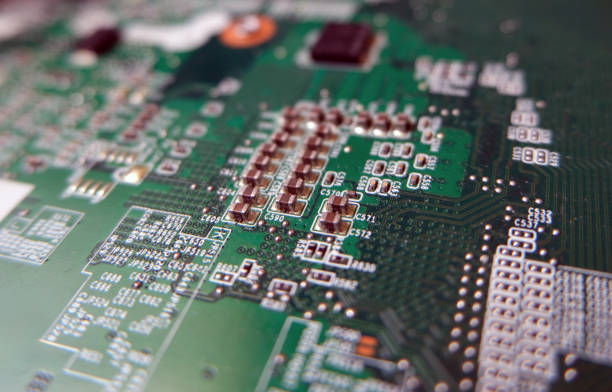

Best Practices for PCB Design

1. Use Larger Components When Possible

Larger components are easier to handle and place, reducing the risk of errors. Choosing a 0402 package size or larger will make your contract manufacturer happy as it simplifies assembly processes.

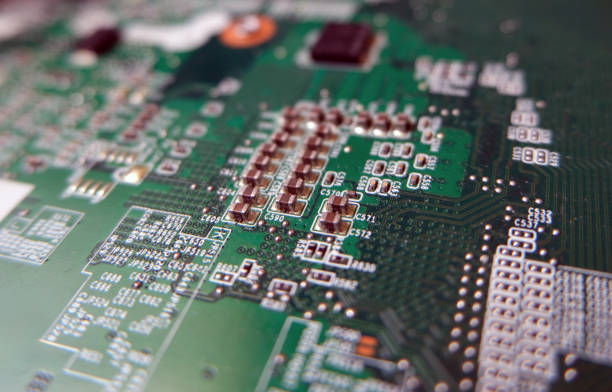

2. Maintain Adequate Spacing

Leave at least 1mm between components to avoid collisions during placement. This spacing is crucial for ensuring that nozzles can operate effectively without interference from adjacent parts.

3. Optimize Component Orientation

Ensure that all surface mount components are placed in the same orientation (for example, with the same polarity or pin direction). This practice simplifies assembly and reduces errors during machine inspection.

4. Group Related Components Together

Logical component placement can significantly ease the assembly process. Group related components together and arrange them to minimize trace lengths, which reduces chances of errors during assembly and enhances signal integrity.

5. Follow Design for Manufacturability (DFM) Guidelines

Consult DFM guidelines provided by your PCB manufacturer. These guidelines often include recommendations for component spacing, solder pad sizes, and other critical design elements that improve manufacturing yield and reduce defect risks.

6. Consider Reworkability

Design PCBs with reworkability in mind; include test points for easy troubleshooting after assembly. Test points should be easily accessible and clearly marked.

Enhancing Efficiency Through Proper Nozzle Management

Choosing the right nozzle is only part of ensuring an efficient SMT process; managing nozzles effectively throughout production is equally important:

- Regular Maintenance: Ensure that nozzles are regularly cleaned and maintained to prevent clogs that could lead to misplacement or damage during assembly.

- Inventory Management: Keep an organized inventory of different types of nozzles so that operators can quickly access the correct nozzle type as needed.

- Training Operators: Provide thorough training for operators on how to select and change nozzles properly based on component requirements.

Conclusion

Choosing the right SMT nozzle is a critical step in optimizing the PCB assembly process. By understanding the factors that influence nozzle selection and adhering to best practices in PCB design, manufacturers can achieve higher yields, lower costs, and improved efficiency. Whether using standard or custom nozzles, aligning the nozzle's capabilities with specific requirements ensures successful assembly outcomes.

Investing time in proper design considerations not only enhances productivity but also contributes significantly to product reliability and performance in today's competitive electronics market.

Frequently Asked Questions (FAQ)

1. What is an SMT nozzle?

An SMT nozzle is a tool used in pick-and-place machines to handle and place components onto PCBs. It is designed specifically to match each component's size, shape, and weight requirements.

2. How do I choose the right SMT nozzle for my PCB design?

Consider factors such as component size, shape, height, vacuum pressure required, and ensure compatibility with your pick-and-place machine specifications.

3. Can I use the same nozzle for all components?

While standard nozzles are versatile enough for many applications, some non-standard components may require custom-designed nozzles for accurate placement.

4. What are the benefits of using custom nozzles?

Custom nozzles are tailored specifically for unique component geometries or sizes, ensuring precise placement while minimizing damage risks during handling.

5. How does PCB design affect nozzle selection?

PCB design impacts nozzle selection by influencing factors such as component spacing, height variations among components, footprint designs, and overall layout complexity which can dictate suitable nozzle types.

Citations:

[1] https://smtnet.com/library/files/upload/Design-Rules-Selective-Soldering

[2] https://pubs.aip.org/aip/acp/article/2607/1/120004/2892462/Design-of-nozzles-for-surface-mount-technologies

[3] https://novaenginc.com/best-practices-for-designing-circuit-boards-for-assembly/

[4] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[5] https://www.analog.com/en/resources/design-notes/smt-assembly-and-pcb-design-guidelines-for-leaded-packages.html

[6] https://www.rhsmt.com/news/the-integral-role-of-smt-nozzles-in-modern-electronics-assembly/

[7] https://jlcpcb.com/blog/design-process-of-a-surface-mount-pcb

[8] https://wellerpcb.com/pcb-layout-guidelines-for-smt-assembly-process-limits

[9] https://www.smthelp.com/smt-manufacturability-design-guidelines

[10] https://www.protoexpress.com/blog/tips-pcb-design-for-assembly/