Content Menu

● Understanding SMD Placement Assembly Machines

● Key Factors to Consider When Choosing an SMD Placement Assembly Machine

>> 1. Production Volume and Speed Requirements

>> 2. Placement Accuracy and Component Size Capability

>> 3. Flexibility and Changeover Speed

>> 4. Equipment Stability and Maintenance

>> 5. Cost-effectiveness and Budget

>> 6. Brand Reputation and After-sales Support

● Types of SMD Placement Assembly Machines

>> High-speed Chip Shooters

>> Flexible Multi-head Machines

>> Compact Desktop Machines

● Practical Tips for Selecting the Right SMD Placement Assembly Machine

● Conclusion

● FAQ

>> 1. What is the main function of an SMD placement assembly machine?

>> 2. How important is placement accuracy in SMD machines?

>> 3. What factors affect the choice of an SMD placement machine?

>> 4. Can small businesses benefit from high-end SMD placement machines?

>> 5. How can I ensure the longevity and reliability of my SMD placement machine?

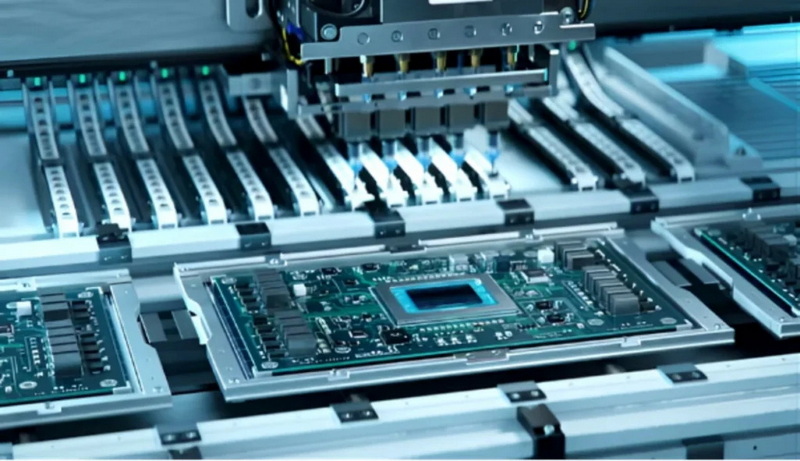

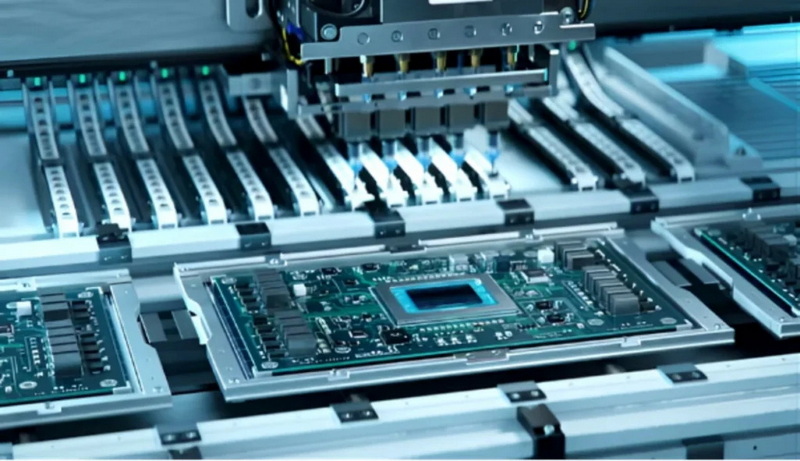

Surface Mount Device (SMD) placement assembly machines are indispensable in modern electronics manufacturing. These machines enable the precise and efficient placement of components onto printed circuit boards (PCBs), dramatically improving production speed and quality. Selecting the right SMD placement assembly machine is a critical decision that can significantly impact your manufacturing efficiency, product quality, and overall business profitability. This comprehensive guide will explore the essential factors to consider, the types of machines available, and practical tips to help you choose the best SMD placement assembly machine tailored to your business needs.

Understanding SMD Placement Assembly Machines

An SMD placement assembly machine, commonly referred to as a pick-and-place machine, automates the process of placing surface mount components onto PCBs. These machines use vacuum nozzles and advanced vision systems to pick components from feeders and place them accurately on solder-pasted PCB pads. The automation provided by these machines reduces manual labor, minimizes errors, and increases throughput, making them the backbone of Surface Mount Technology (SMT) assembly lines.

These machines vary widely in terms of speed, accuracy, flexibility, and cost. Understanding their capabilities and features is essential to making an informed purchasing decision.

Key Factors to Consider When Choosing an SMD Placement Assembly Machine

1. Production Volume and Speed Requirements

One of the primary considerations when selecting an SMD placement assembly machine is your production volume. Machines differ significantly in placement speed, typically measured in components per hour (CPH). High-end machines, such as the Panasonic NPM-W2, can place up to 77,000 components per hour, making them ideal for large-scale manufacturing. Mid-range machines like the Yamaha YSM10 offer speeds around 50,000 CPH, suitable for medium-sized production runs.

If your business produces small batches or prototypes, a high-speed machine may be unnecessary and cost-prohibitive. Conversely, if you anticipate scaling production or require continuous high-volume output, investing in a faster machine will provide better return on investment.

2. Placement Accuracy and Component Size Capability

Placement accuracy is crucial in SMT assembly to ensure components are positioned precisely on PCB pads, preventing defects such as solder bridges, tombstoning, or misalignment. High-end SMD placement assembly machines can achieve placement accuracy as fine as 22 microns (0.022 mm), which is essential when working with ultra-fine pitch components like 01005 size resistors and capacitors.

Additionally, consider the range of component sizes your business handles. Some machines specialize in placing small passive components rapidly, while others offer the flexibility to handle a wide variety of component sizes and shapes, including odd-form components and connectors. Ensuring the machine supports your component portfolio is vital for maintaining production quality.

3. Flexibility and Changeover Speed

In today's dynamic electronics market, many manufacturers face frequent product changes and diverse component mixes. Selecting an SMD placement assembly machine with high flexibility and fast changeover capabilities can significantly reduce downtime and improve responsiveness.

Machines equipped with multiple nozzle heads and versatile feeder systems-such as tape, tray, and reel feeders-allow quick switching between different components. Models like the Europlacer iineo series are designed to handle a broad range of component sizes and shapes efficiently, making them ideal for contract manufacturers or businesses with varied product lines.

4. Equipment Stability and Maintenance

Reliable operation is essential for consistent production output. When choosing an SMD placement assembly machine, prioritize models known for robust build quality and ease of maintenance. Machines with stable mechanical structures, high-quality linear motors, and precision vision systems tend to have longer lifespans and fewer breakdowns.

Regular calibration and preventive maintenance are necessary to maintain placement accuracy and avoid common issues such as nozzle clogging, fiducial recognition errors, or component damage. Machines with user-friendly interfaces and diagnostic tools simplify maintenance tasks and reduce operator training time.

5. Cost-effectiveness and Budget

Budget constraints are always a factor in equipment selection. While high-end SMD placement assembly machines offer advanced features and faster speeds, they come with a premium price tag. For startups, small businesses, or prototyping labs, compact and affordable machines like Boarditto or Liteplacer may provide sufficient capabilities without excessive costs.

When evaluating cost, consider not only the initial purchase price but also the total cost of ownership. This includes maintenance expenses, consumables (such as nozzles and feeders), software licenses, and operator training. Investing in a reliable machine with good support can reduce long-term costs by minimizing downtime and repair expenses.

6. Brand Reputation and After-sales Support

Choosing equipment from reputable manufacturers with a proven track record is critical. Leading brands such as Panasonic, Yamaha, JUKI, and Europlacer have established themselves as industry leaders by consistently delivering high-quality SMD placement assembly machines and excellent after-sales support.

Strong technical support ensures timely repairs, software updates, and availability of spare parts, which are crucial for minimizing production interruptions. Before purchasing, research customer reviews, request references, and evaluate the manufacturer's service network in your region.

Types of SMD Placement Assembly Machines

Understanding the types of SMD placement assembly machines available helps you match the right machine to your production needs.

High-speed Chip Shooters

These machines specialize in placing small passive components such as resistors, capacitors, and inductors at extremely high speeds. They are optimized for mass production environments where throughput is critical. However, they may have limited flexibility for larger or odd-shaped components.

Flexible Multi-head Machines

Equipped with multiple placement heads and versatile feeders, these machines can handle a wide variety of component sizes and shapes. They offer a balance of speed and flexibility, making them suitable for contract manufacturers or companies with diverse product lines.

Compact Desktop Machines

Designed for prototyping, small batch production, or hobbyists, these machines emphasize ease of use and affordability. While they have lower placement speeds and limited component size ranges, they are ideal for startups or R&D departments needing quick turnaround times.

Practical Tips for Selecting the Right SMD Placement Assembly Machine

- Match machine speed and accuracy to your product requirements: Avoid overpaying for speed or precision you don't need.

- Verify compatibility with component supply formats: Ensure the machine supports your feeders' tape widths, tray sizes, and reel types.

- Check PCB size and thickness compatibility: The machine should accommodate your PCB dimensions and thickness ranges.

- Evaluate software usability and integration: Look for machines with intuitive programming interfaces and support for your PCB design data formats.

- Look for advanced features: Vision systems, fiducial recognition, automated calibration, and error detection improve placement quality and reduce operator workload.

- Plan for future scalability: Choose machines that can be upgraded or expanded as your production grows.

Conclusion

Selecting the right SMD placement assembly machine is a strategic decision that directly influences your manufacturing efficiency, product quality, and cost management. By carefully assessing your production volume, component types, accuracy needs, flexibility requirements, and budget constraints, you can identify the machine that best fits your business. Investing in reliable, well-supported equipment from reputable manufacturers will ensure smooth operations and long-term success in your SMT assembly process.

FAQ

1. What is the main function of an SMD placement assembly machine?

An SMD placement assembly machine automates the precise placement of surface mount components onto PCBs, significantly increasing production speed and reducing human error.

2. How important is placement accuracy in SMD machines?

Placement accuracy is critical to avoid defects such as misaligned components or soldering issues. High-precision machines can achieve accuracies as fine as 22 microns, essential for small and fine-pitch components.

3. What factors affect the choice of an SMD placement machine?

Key factors include production volume, placement speed, component size compatibility, machine flexibility, maintenance requirements, cost, and brand support.

4. Can small businesses benefit from high-end SMD placement machines?

Small businesses or hobbyists often benefit more from compact, affordable machines that are easy to operate and maintain rather than expensive high-speed models designed for mass production.

5. How can I ensure the longevity and reliability of my SMD placement machine?

Regular maintenance, proper calibration, using quality components, and choosing machines with good after-sales service are essential to maintain machine performance and minimize downtime.