Content Menu

● What is an SMD Machine for Mobile Repairing?

● Why Your Mobile Repair Business Needs an SMD Machine

● Types of SMD Machines for Mobile Repairing

>> 1. Manual SMD Rework Stations

>> 2. Semi-Automatic SMD Machines

>> 3. Fully Automatic SMD Machines

● Key Features to Consider When Choosing an SMD Machine for Mobile Repairing

>> 1. Compatibility with Mobile Phone Components

>> 2. Optical Alignment System

>> 3. Temperature Control and Range

>> 4. Heating Method

>> 5. PCB Fixture and Handling

>> 6. Ease of Use and Training

>> 7. Size and Portability

>> 8. Warranty and Support

● How to Evaluate Your Business Needs

● Popular SMD Machines for Mobile Repairing

● Tips for Using an SMD Machine Effectively

● Conclusion

● FAQ

>> 1. What types of chips can an SMD machine for mobile repairing handle?

>> 2. How important is the optical alignment system in an SMD machine?

>> 3. Can I use an SMD machine for repairing other electronics besides mobile phones?

>> 4. What is the typical temperature range for an SMD machine used in mobile repairs?

>> 5. How do I maintain my SMD machine for longevity?

In the fast-evolving mobile repair industry, having the right tools can make all the difference. One of the most critical pieces of equipment for a mobile repair business is the SMD machine for mobile repairing. This machine enables technicians to efficiently handle surface mount device (SMD) components on mobile phone motherboards and other small electronic boards, facilitating precise chip-level repairs. Choosing the right SMD machine is essential to ensure high-quality repairs, reduce labor time, and improve business profitability.

This comprehensive guide will walk you through everything you need to know about selecting the ideal SMD machine for your mobile repair business, including key features, types, and practical considerations.

What is an SMD Machine for Mobile Repairing?

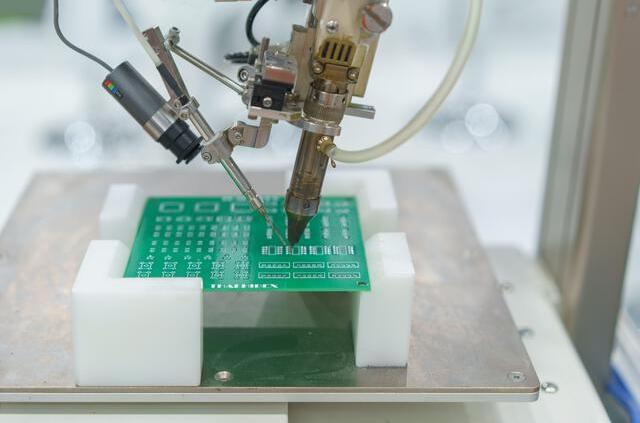

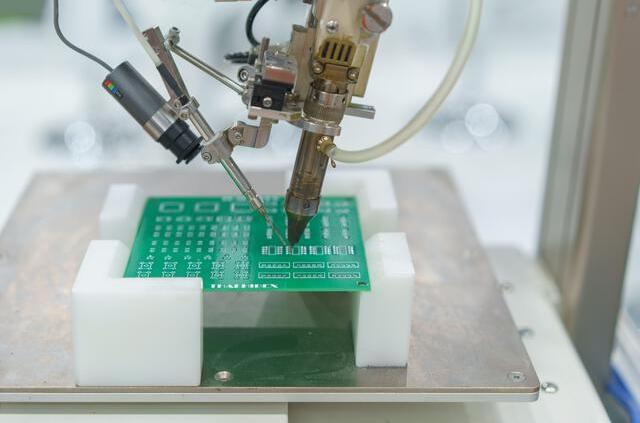

An SMD machine for mobile repairing is a specialized tool designed to work with surface mount devices-small electronic components mounted directly onto the surface of printed circuit boards (PCBs). These machines assist in soldering, desoldering, and reworking components such as BGAs, QFNs, and other chip types commonly found in mobile phone motherboards.

Typically, these machines use hot air or infrared heat to melt solder, allowing technicians to remove faulty chips and replace them with new ones accurately. Many modern SMD machines come equipped with CCD camera optical alignment systems for precise component placement.

Why Your Mobile Repair Business Needs an SMD Machine

- Precision and Efficiency: SMD machines provide accurate alignment and controlled heat, essential for delicate mobile phone components.

- Chip-Level Repair Capability: Enables repair of complex motherboard issues without replacing entire boards.

- Reduced Labor and Training Time: Automated or semi-automated functions simplify the repair process.

- Improved Repair Quality: Minimizes damage to PCBs and components, increasing customer satisfaction.

- Competitive Advantage: Offering chip-level repairs can differentiate your business in a crowded market.

Types of SMD Machines for Mobile Repairing

Understanding the different types of SMD machines available helps you choose the one that best fits your business needs.

1. Manual SMD Rework Stations

- Use hot air guns or infrared heat.

- Require skilled operation for soldering and desoldering.

- Suitable for small-scale or entry-level repair shops.

- Typically more affordable but slower and less automated.

2. Semi-Automatic SMD Machines

- Combine manual operation with automated features like temperature control and component alignment.

- Offer better precision and repeatability.

- Ideal for growing mobile repair businesses needing higher throughput.

3. Fully Automatic SMD Machines

- Computer-controlled with programmable placement and soldering.

- Include features like feeding systems, optical alignment, and inspection.

- Suitable for high-volume repair centers or manufacturing environments.

- Higher initial investment but maximize speed and accuracy.

Key Features to Consider When Choosing an SMD Machine for Mobile Repairing

1. Compatibility with Mobile Phone Components

Ensure the machine supports the types of chips commonly found in mobile phones, such as BGA, QFN, TQFP, and others. Machines designed specifically for mobile motherboard repair often come with a variety of nozzles and fixtures to handle different chip sizes and shapes.

2. Optical Alignment System

A high-definition CCD camera system is crucial for precise component placement, especially for small and complex chips. This feature reduces errors and increases repair success rates.

3. Temperature Control and Range

The machine should offer adjustable temperature settings, typically ranging from 200°C to 480°C, to handle different solder types and components safely without damaging the PCB.

4. Heating Method

Common heating methods include hot air, infrared, or a combination. Hot air is widely used for its even heat distribution and effectiveness in mobile repair.

5. PCB Fixture and Handling

Look for machines with movable universal fixtures that prevent PCB damage during repairs. This is especially important for fragile mobile phone motherboards.

6. Ease of Use and Training

Machines that are easy to operate reduce training time and labor costs. Some models come with user-friendly interfaces and software for programming repair tasks.

7. Size and Portability

Consider the available workspace and whether you need a portable machine for mobile repair services or a fixed station for a workshop.

8. Warranty and Support

Reliable after-sales service, warranty, and availability of spare parts are important for minimizing downtime.

How to Evaluate Your Business Needs

Before investing in an SMD machine, analyze your business model and repair volume:

- Repair Volume: High-volume shops benefit from fully automatic machines with faster placement speeds.

- Repair Types: If you focus on complex chip-level repairs, prioritize machines with advanced optical alignment and precise temperature control.

- Budget: Balance the initial cost with long-term benefits like speed, accuracy, and reduced labor.

- Skill Level: For less experienced technicians, machines with automation and user-friendly interfaces are preferable.

- Space Constraints: Choose compact models if workspace is limited.

Popular SMD Machines for Mobile Repairing

Some well-known models and brands to consider include:

- Dinghua DH-G730: Known for its HD CCD optical alignment and movable fixtures, ideal for mobile motherboard repairs.

- Quick 861DW SMD Rework Station: Popular for its adjustable temperature and reliability.

- MAXX PAMMA 850A: Features autocut and inverter technology for precise soldering.

Tips for Using an SMD Machine Effectively

- Always calibrate the machine before use to ensure accuracy.

- Use the correct nozzle size for the component.

- Adjust temperature and airflow carefully to avoid PCB damage.

- Follow safety guidelines to prevent burns or equipment damage.

- Regularly maintain and clean the machine for optimal performance.

Conclusion

Choosing the right SMD machine for mobile repairing is a pivotal decision that can significantly impact the efficiency, quality, and profitability of your mobile repair business. By understanding the types of machines available, key features, and aligning them with your business needs, you can invest in equipment that enhances your service capabilities and customer satisfaction. Whether you opt for a manual, semi-automatic, or fully automatic SMD machine, prioritize precision, ease of use, and support to ensure your business thrives in the competitive mobile repair market.

FAQ

1. What types of chips can an SMD machine for mobile repairing handle?

An SMD machine can handle various chip types including BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, and LED chips commonly found on mobile phone motherboards.

2. How important is the optical alignment system in an SMD machine?

The optical alignment system, usually a CCD camera, is crucial for precise placement of tiny components, reducing errors and improving repair success rates.

3. Can I use an SMD machine for repairing other electronics besides mobile phones?

Yes, many SMD machines are versatile and can be used for repairing small control boards, tiny motherboards, and other electronic devices beyond mobile phones.

4. What is the typical temperature range for an SMD machine used in mobile repairs?

The temperature range generally spans from 200°C to 480°C, allowing safe soldering and desoldering of various components without damaging the PCB.

5. How do I maintain my SMD machine for longevity?

Regular cleaning, calibration, using proper nozzles, and following manufacturer maintenance guidelines help ensure the machine operates efficiently and lasts longer.