Content Menu

● Introduction to SMD LED Machines

>> Key Components of SMD LED Machines

● Factors to Consider When Choosing an SMD LED Machine

>> 1. Production Volume and Speed

>> 2. Component Handling Capability

>> 3. Precision and Accuracy

>> 4. Cost and Budget

>> 5. Compatibility with Existing Infrastructure

● Benefits of Using SMD LED Machines

● Challenges and Considerations

● Future Trends in SMD LED Machines

● Market Outlook for SMD LEDs

● Selecting the Right SMD LED Modules

● Industry Applications of SMD LED Machines

● Conclusion

● FAQ

>> 1. What is the primary function of a pick and place machine in an SMD LED assembly line?

>> 2. How does an SMD LED machine improve product quality?

>> 3. What are the key factors to consider when selecting an SMD LED machine for a small-scale business?

>> 4. How does the use of SMD LED machines affect production costs?

>> 5. What maintenance is required for SMD LED machines?

Choosing the right SMD LED machine is crucial for businesses involved in the production of LED-based products. SMD (Surface Mount Device) LEDs are widely used in various applications due to their compact size, energy efficiency, and versatility. This article will guide you through the key considerations and steps to select an appropriate SMD LED machine for your business needs.

Introduction to SMD LED Machines

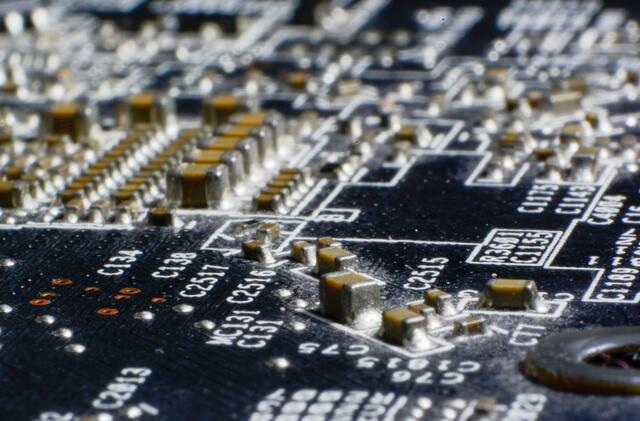

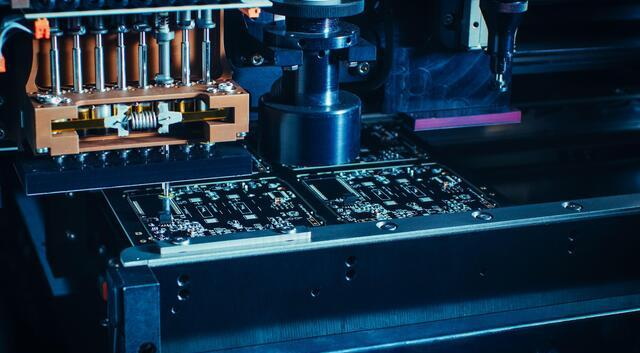

SMD LED machines are designed to handle the assembly and manufacturing of SMD LEDs onto printed circuit boards (PCBs). These machines are essential for automating the process of placing and soldering SMD LEDs, ensuring high precision and efficiency in production. The choice of an SMD LED machine depends on several factors, including production volume, product complexity, and budget constraints.

Key Components of SMD LED Machines

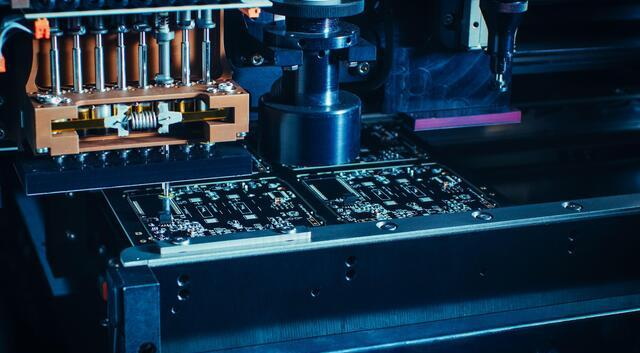

1. Pick and Place Machines: These are the core components of SMD LED machines, responsible for picking up SMD LEDs from reels and placing them accurately onto the PCB. The precision and speed of these machines are critical for high-volume production. For example, some advanced machines can handle components ranging from 0201 to 10mm tape reel packages, offering high mounting speeds of up to 120,000 components per hour (CPH) under optimal conditions.

2. Reflow Ovens: After the placement of SMD LEDs, reflow ovens are used to melt the solder paste, securing the components to the PCB. The quality of the reflow oven affects the reliability and durability of the final product.

3. Inspection Systems: Automated optical inspection (AOI) systems are integrated into SMD LED machines to inspect the PCBs for defects or misplacements. This ensures quality control and reduces the need for manual inspection.

Factors to Consider When Choosing an SMD LED Machine

1. Production Volume and Speed

The production volume and speed requirements of your business are crucial in selecting an SMD LED machine. High-speed machines are ideal for large-scale production, while smaller businesses may opt for more cost-effective, lower-speed options. For instance, a small-scale operation might consider a mini 4-head SMD pick and place machine, which offers a balance between cost and efficiency.

2. Component Handling Capability

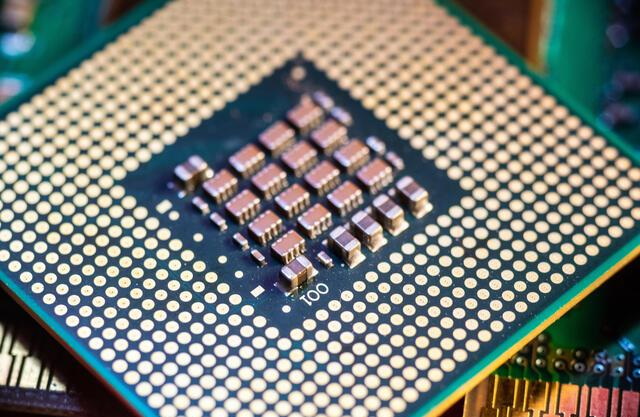

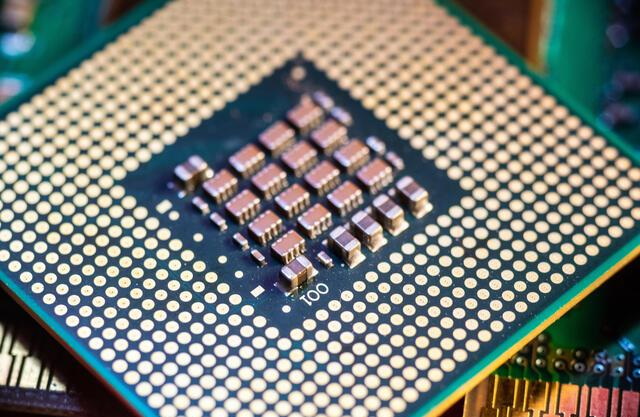

Ensure the machine can handle the specific types and sizes of SMD LEDs you plan to use. Different machines may specialize in handling different component sizes, such as 0805, 1206, or 3528. SMD LEDs come in various sizes, each suited for different applications based on brightness and energy efficiency.

3. Precision and Accuracy

The precision of the pick and place mechanism is vital for ensuring that SMD LEDs are placed correctly on the PCB. High accuracy reduces defects and improves overall product quality. Machines with advanced vision systems can achieve placement accuracy of ±0.05mm or better.

4. Cost and Budget

The cost of the SMD LED machine is a significant factor. Businesses must balance the need for high-quality equipment with budget constraints. Consider both the initial purchase cost and ongoing maintenance expenses.

5. Compatibility with Existing Infrastructure

Ensure that the SMD LED machine is compatible with your existing manufacturing setup, including PCB design software and other production equipment.

Benefits of Using SMD LED Machines

1. Increased Efficiency: SMD LED machines automate the assembly process, significantly reducing production time and increasing output.

2. Improved Quality: Automated processes minimize human error, leading to higher quality products with fewer defects.

3. Cost Savings: While the initial investment in machinery may be high, long-term savings come from reduced labor costs and improved efficiency.

4. Flexibility: Modern SMD LED machines can handle a variety of components and PCB designs, offering flexibility in product development.

Challenges and Considerations

1. Initial Investment: The cost of purchasing and setting up SMD LED machines can be substantial.

2. Maintenance and Upgrades: Regular maintenance is necessary to ensure optimal performance, and upgrades may be required to keep up with technological advancements.

3. Training and Expertise: Operators need training to effectively use and maintain the machinery.

Future Trends in SMD LED Machines

The future of SMD LED machines involves advancements in automation, AI integration, and improved precision. These developments will further enhance production efficiency and product quality. For instance, advancements in SMD screen technology are leading to thinner, more energy-efficient displays with higher pixel densities.

In addition to advancements in machine technology, SMD LED modules themselves are evolving. New developments include thinner designs, improved energy efficiency, and enhanced durability. For example, the P5 SMD LED module offers a 40% thinner design, improving installation speed and transportability. These advancements are crucial for applications where space and energy efficiency are paramount, such as in automotive and consumer electronics.

Market Outlook for SMD LEDs

The market for SMD LEDs is growing rapidly, driven by their energy efficiency and compact size. The global SMD LED market is expected to reach USD 9.88 billion by 2030, with a compound annual growth rate (CAGR) of 7.14% from 2024 to 2030. This growth is fueled by increasing demand for energy-efficient lighting solutions across various industries, including automotive, consumer electronics, and industrial lighting.

The growing demand for SMD LEDs is not only driven by their technical advantages but also by environmental concerns. As consumers and businesses seek more sustainable lighting solutions, the market for SMD LEDs continues to expand. This trend is expected to continue, with significant growth projected in the coming years.

Selecting the Right SMD LED Modules

When choosing SMD LED modules for your products, several factors must be considered:

- Brightness and Luminous Flux: Ensure the module provides the required brightness for your application. Higher lumens mean brighter light, which is crucial for applications like LED screens or high-output lighting.

- Color and Wavelength: Select modules based on the desired color output. SMD LEDs are available in a range of colors, including RGB options for customizable lighting effects.

- Beam Angle: The beam angle affects how light is distributed. A smaller beam angle is ideal for precise lighting applications, while a larger angle provides broader coverage.

- Working Voltage and Current: Ensure the module's electrical requirements match your system's specifications to avoid damage or inefficiency.

Industry Applications of SMD LED Machines

SMD LED machines are used across various industries, including automotive, consumer electronics, and industrial lighting. In the automotive sector, SMD LEDs are used for dashboard lighting and exterior lights due to their compact size and energy efficiency. In consumer electronics, they are found in smartphones, tablets, and laptops, enhancing display quality and reducing power consumption.

Conclusion

Choosing the right SMD LED machine for your business involves careful consideration of production needs, budget, and compatibility with existing infrastructure. By understanding the key factors and benefits of SMD LED machines, businesses can optimize their manufacturing processes, improve product quality, and increase efficiency.

FAQ

1. What is the primary function of a pick and place machine in an SMD LED assembly line?

- The primary function of a pick and place machine is to accurately pick up SMD LEDs from reels and place them onto the PCB. This process is crucial for ensuring high precision and efficiency in production.

2. How does an SMD LED machine improve product quality?

- An SMD LED machine improves product quality by automating the assembly process, which minimizes human error and ensures consistent placement of components. This results in fewer defects and higher reliability of the final product.

3. What are the key factors to consider when selecting an SMD LED machine for a small-scale business?

- For a small-scale business, key factors include production volume, budget constraints, and the ability of the machine to handle specific SMD LED sizes. It's also important to consider the machine's compatibility with existing infrastructure.

4. How does the use of SMD LED machines affect production costs?

- While the initial investment in SMD LED machines can be high, they offer long-term cost savings by reducing labor costs and improving production efficiency. This leads to lower overall production costs over time.

5. What maintenance is required for SMD LED machines?

- Regular maintenance of SMD LED machines includes cleaning, software updates, and calibration of the pick and place mechanism. This ensures optimal performance and extends the lifespan of the equipment.