Content Menu

● What is an SMD Desoldering Machine?

● Key Features to Consider When Choosing an SMD Desoldering Machine

>> 1. Temperature Control and Range

>> 2. Airflow Control

>> 3. Vacuum Suction Capability

>> 4. Tip and Nozzle Compatibility

>> 5. ESD Safety

>> 6. Ergonomics and Usability

>> 7. Power and Wattage

>> 8. Multi-Functionality

● Types of SMD Desoldering Machines

>> Hot Air Desoldering Stations

>> Vacuum Desoldering Stations

>> Combination Rework Stations

● How to Choose the Right SMD Desoldering Machine for Your Needs

>> Step 1: Define Your Purpose and Workload

>> Step 2: Consider Your Budget

>> Step 3: Evaluate Workspace and Portability

>> Step 4: Check Consumables Availability

>> Step 5: Look for Brand Reputation and Support

● Recommended SMD Desoldering Machines

● Conclusion

● FAQ

>> 1. What is the difference between an SMD desoldering machine and a regular soldering iron?

>> 2. Why is adjustable temperature control important in an SMD desoldering machine?

>> 3. Do I need a vacuum pump for desoldering SMD components?

>> 4. What does ESD safe mean, and why is it important?

>> 5. Can I use the same machine for soldering and desoldering SMD components?

● Citations:

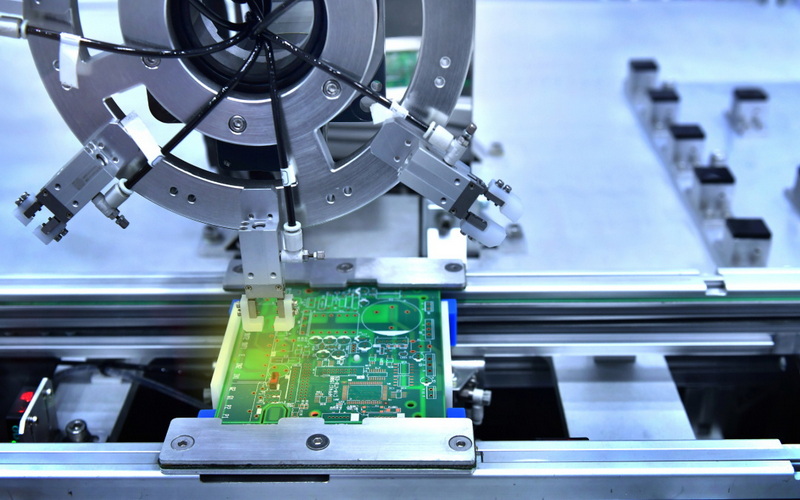

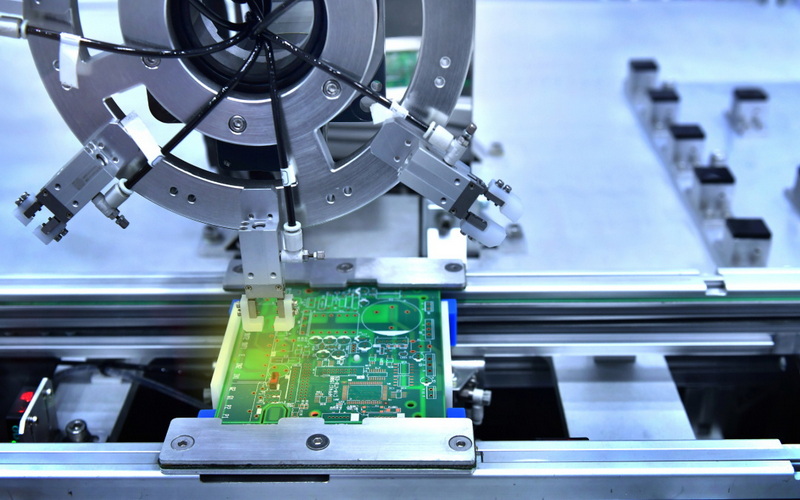

Choosing the right SMD desoldering machine is crucial for anyone involved in electronics manufacturing, repair, or hobbyist work. Surface-Mount Device (SMD) components require precision and care during soldering and desoldering to avoid damage to the delicate parts or printed circuit boards (PCBs). This comprehensive guide will help you understand what an SMD desoldering machine is, the key features to look for, and how to select the best one tailored to your specific needs.

What is an SMD Desoldering Machine?

An SMD desoldering machine is a specialized tool designed to remove solder from surface-mounted electronic components on PCBs. Unlike traditional soldering irons, these machines often combine hot air, vacuum suction, and precise temperature control to safely detach SMD parts without harming the board or adjacent components. They are essential in rework stations used for repairing or replacing defective chips, resistors, capacitors, and other micro-components.

Typically, an SMD desoldering machine is part of a larger SMD rework station that includes soldering and hot air functions, allowing for comprehensive PCB repair and assembly tasks[1][5].

Key Features to Consider When Choosing an SMD Desoldering Machine

1. Temperature Control and Range

Precise temperature control is vital for effective desoldering. The machine should allow adjustable temperature settings, typically ranging from about 100°C to 600°C or higher, to accommodate different solder types and component sensitivities. Consistent heat prevents damage caused by overheating or insufficient melting of solder[1][2][3].

2. Airflow Control

Many SMD desoldering machines use hot air to melt solder. Adjustable airflow control is important to ensure the heat is directed accurately without disturbing nearby components. Machines with fine-tuned airflow settings help avoid overheating and improve precision during desoldering[1].

3. Vacuum Suction Capability

A built-in vacuum pump or suction system is essential for removing molten solder efficiently. Some machines come with integrated vacuum pumps, while others require an external air compressor. For hobbyists or small workshops, machines with built-in pumps are often more convenient[1][6].

4. Tip and Nozzle Compatibility

The shape and size of the desoldering tip or nozzle should match the components you work with. Tips that are too large can damage the PCB, while those too small may not transfer enough heat. Having interchangeable tips and nozzles enhances versatility for different SMD sizes and layouts[4][5].

5. ESD Safety

Electrostatic discharge (ESD) can damage sensitive electronic components. An ESD-safe desoldering machine is designed to prevent static buildup and protect your devices during rework operations. This feature is especially important in professional and industrial environments[2][3].

6. Ergonomics and Usability

Comfortable design reduces user fatigue during long repair sessions. Features like lightweight handpieces, intuitive controls, and clear displays (LCD screens) improve the overall user experience and accuracy[1][5].

7. Power and Wattage

Higher wattage machines provide more stable and consistent heat output, which is beneficial for medium to heavy workloads. Typical wattage ranges from 40W to 80W or more. Choosing the right wattage depends on the volume and complexity of your work[2].

8. Multi-Functionality

Some advanced SMD desoldering machines are part of multi-functional rework stations that combine soldering, desoldering, and hot air rework capabilities. These integrated systems can save workspace and cost while enhancing repair flexibility[1][5].

Types of SMD Desoldering Machines

Hot Air Desoldering Stations

These use a stream of hot air to melt solder around the SMD components. They are excellent for removing and replacing chips without risking damage to neighboring parts. Hot air stations often come with adjustable temperature and airflow for precision[7].

Vacuum Desoldering Stations

These machines combine heat with vacuum suction to remove molten solder immediately. They are especially useful for through-hole and some SMD components, ensuring clean removal without solder bridges or residue[6].

Combination Rework Stations

Integrated systems like the Hakko FM-206 or the Thermaltronics TMT-9000S offer soldering, desoldering, and hot air functions in one unit. These are ideal for professionals handling a variety of repair tasks and require high precision and efficiency[1][5].

How to Choose the Right SMD Desoldering Machine for Your Needs

Step 1: Define Your Purpose and Workload

- Hobbyist or occasional use: A basic desoldering station with built-in vacuum pump and adjustable temperature might suffice.

- Professional or industrial use: Invest in high-end multi-functional rework stations with advanced temperature and airflow control, ESD safety, and durable construction.

Step 2: Consider Your Budget

Prices vary widely based on features and brand. Entry-level machines may cost under $500, while professional-grade stations can exceed $700 or more. Balance your budget with the features you need to avoid overspending on unnecessary capabilities[6][8].

Step 3: Evaluate Workspace and Portability

If you have limited bench space, compact and multi-port stations are preferable. For fieldwork or mobile repair, lightweight and portable units with battery or low power consumption are beneficial[8].

Step 4: Check Consumables Availability

Ensure that replacement tips, nozzles, and filters are readily available and affordable for your chosen machine. This will reduce downtime and maintenance costs[6].

Step 5: Look for Brand Reputation and Support

Brands like Hakko are known for reliability and quality in SMD rework equipment. Choosing a reputable brand often means better customer support, warranty, and availability of spare parts[1][3].

Recommended SMD Desoldering Machines

- Hakko 851 SMD Rework Station: Offers adjustable temperature from 100°C to 540°C, ultra-light air volume control, and is ESD safe by design. Ideal for small SMD components and precise desoldering tasks[3].

- Hakko FM-206: A multi-port professional station combining soldering, desoldering, and hot air with a built-in vacuum pump. Features power thermal recovery and energy-saving modes, perfect for complex PCB repairs[1].

- Thermaltronics TMT-9000S: Advanced station with instant power adjustment, LCD display, and multiple tip options for different soldering and desoldering needs[5].

Conclusion

Selecting the right SMD desoldering machine depends on your specific needs, workload, and budget. Key factors include precise temperature and airflow control, vacuum suction capability, tip compatibility, ESD safety, and ergonomic design. Whether you are a hobbyist or a professional technician, investing in a quality machine enhances your repair accuracy, efficiency, and component longevity. Consider multi-functional rework stations for versatility and space-saving benefits. Always prioritize brands with strong reputations and support to ensure long-term satisfaction with your purchase.

FAQ

1. What is the difference between an SMD desoldering machine and a regular soldering iron?

An SMD desoldering machine uses hot air and vacuum suction to safely remove surface-mounted components without damaging the PCB, while a regular soldering iron applies direct heat and is less precise for delicate SMD work[1][5].

2. Why is adjustable temperature control important in an SMD desoldering machine?

Different solder types and components require specific temperatures to melt solder effectively without overheating. Adjustable control ensures precision and prevents damage to sensitive parts[1][2].

3. Do I need a vacuum pump for desoldering SMD components?

Yes, a vacuum pump helps remove molten solder quickly and cleanly, reducing the risk of solder bridges and ensuring efficient component removal. Some machines have built-in pumps, while others require external compressors[1][6].

4. What does ESD safe mean, and why is it important?

ESD safe means the machine is designed to prevent electrostatic discharge, which can damage sensitive electronic components during soldering or desoldering. This is crucial for protecting high-value or delicate devices[2][3].

5. Can I use the same machine for soldering and desoldering SMD components?

Many modern SMD rework stations combine soldering, desoldering, and hot air functions in one unit, allowing you to perform all tasks with one machine, improving efficiency and saving space[1][5].

Citations:

[1] https://sumitron.com/choosing-the-best-smd-rework-station-for-precision-repairs-rework/

[2] https://www.qsource.com/blog/653/guide-to-the-best-smd-rework-stations-of-2021

[3] https://hakkousa.com/products/rework/hakko-851-smd-rework-station.html

[4] https://www.hakko.com/english/support/maintenance/detail.php?seq=171

[5] https://scanditronictech.com/resources/smd-soldering-rework-stations/

[6] https://electronics.stackexchange.com/questions/24603/what-to-look-for-in-desoldering-rework-equipment

[7] https://www.aixuntech.com/newsinfo/choosing-the-right-soldering-station-for-smd-work/

[8] https://aixuntech.com/newsinfo/what-is-smd-soldering-station-and-how-to-choose/

[9] https://www.electronicsforyou.biz/important-sectors/electronics-manufacturing-equipment-consumables/select-right-solderingdesoldering-station/

[10] https://www.reddit.com/r/soldering/comments/s4vi3r/do_i_really_need_smd_rework_station/

[11] https://www.youtube.com/watch?v=PucPg-5YHuE

[12] https://www.youtube.com/watch?v=CORLzDxDV4w

[13] https://www.gordakelec.com/news/a-comprehensive-guide-to-choosing-the-right-rework-station-for-your-workshop.html

[14] https://forum.kicad.info/t/loking-for-smd-soldering-station-recommendations/52339

[15] https://www.eevblog.com/forum/testgear/vacuum-desoldering-gun-vs-hot-air-station/

[16] https://www.reddit.com/r/soldering/comments/164k2mx/smd_desolderingresoldering_which_nozzle/

[17] https://www.reddit.com/r/soldering/comments/svry4t/how_to_choose_a_desoldering_pump/

[18] https://forum.arduino.cc/t/picking-out-a-smd-gun/421190

[19] https://www.reddit.com/r/synthdiy/comments/pkpjml/which_hot_air_rework_station_do_you_guys_recommend/

[20] https://eleshop.eu/knowledgebase/tips-smd-soldering/