Content Menu

● Understanding SMD Blower Machines

● Key Features to Look for in an SMD Blower Machine

>> 1. Precise Temperature Control

>> 2. Adjustable Airflow

>> 3. Power and Wattage

>> 4. Nozzle Variety and Compatibility

>> 5. User-Friendliness and Ergonomics

>> 6. Additional Features

● Factors to Consider When Choosing an SMD Blower Machine

>> Workshop Size and Budget

>> Types of PCBs and Components

>> Frequency and Type of Use

>> Maintenance and Support

● How to Use an SMD Blower Machine Effectively

>> Apply Flux

>> Even Heating

>> Preheat the PCB

>> Maintain Tools

>> Ventilation

● Conclusion

● FAQ

>> 1. What is the ideal temperature range for an SMD blower machine?

>> 2. How important is airflow control in an SMD blower machine?

>> 3. Can I use an SMD blower machine for lead-free soldering?

>> 4. What maintenance is required for SMD blower machines?

>> 5. Are preheating plates necessary for SMD rework?

● Citations:

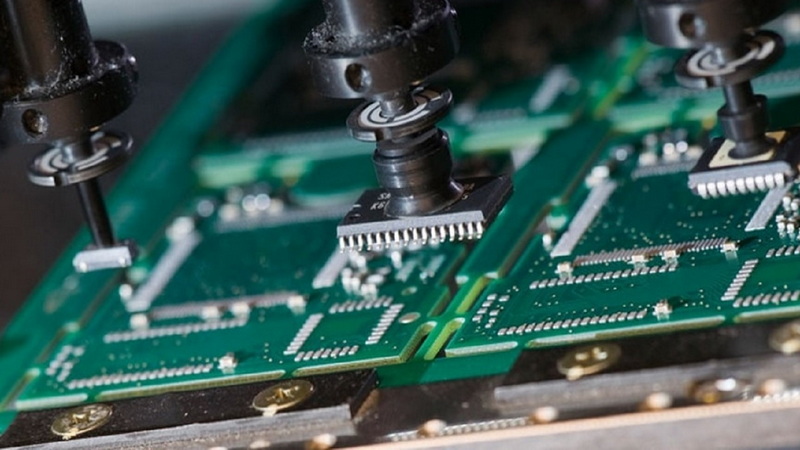

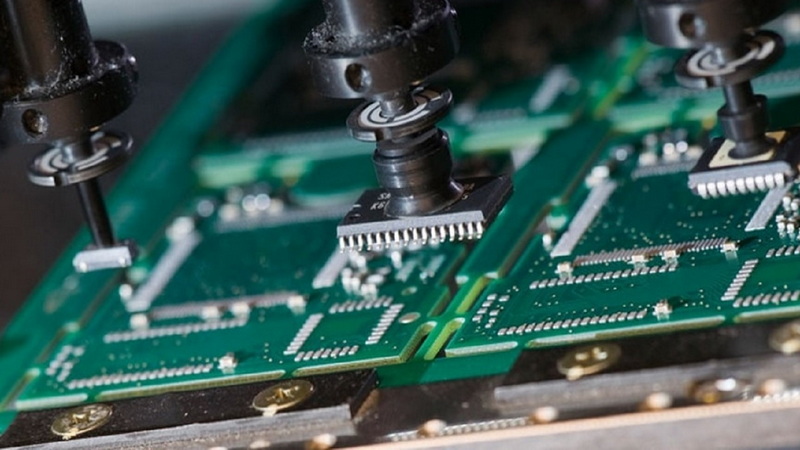

Selecting the appropriate SMD blower machine is crucial for any workshop engaged in surface-mount device (SMD) soldering and rework. The right machine not only improves efficiency but also ensures precision and safety in handling delicate electronic components. This comprehensive guide will walk you through the essential factors to consider when choosing an SMD blower machine, helping you optimize your workshop's performance.

Understanding SMD Blower Machines

An SMD blower machine is a specialized tool designed to provide controlled hot air for soldering and desoldering surface-mount components on printed circuit boards (PCBs). It typically features adjustable temperature and airflow settings, allowing technicians to heat solder joints evenly without damaging sensitive components.

Unlike traditional soldering irons, which apply heat through direct contact, SMD blower machines use hot air to reflow solder. This method is especially useful for components that are too small or fragile for direct soldering, such as tiny resistors, capacitors, and integrated circuits. The hot air gently melts the solder, allowing components to be removed or repositioned without damaging the PCB or surrounding parts.

Key Features to Look for in an SMD Blower Machine

1. Precise Temperature Control

Temperature control is the most critical feature of an SMD blower machine. Different components and solder types require specific temperature ranges to avoid damage. Look for machines with:

- Digital temperature displays: These provide real-time feedback, allowing you to monitor and adjust the heat precisely.

- Adjustable temperature settings: Machines that offer a wide range, often from 100°C to 500°C, accommodate various solder alloys and component sensitivities.

- Stable temperature maintenance: A machine that maintains consistent temperature throughout the operation prevents overheating or underheating, which can cause poor solder joints or component damage.

Proper temperature control is essential for working with both leaded and lead-free solder. Lead-free solder generally requires higher temperatures, so ensure your machine can safely reach and maintain these levels.

2. Adjustable Airflow

Airflow control allows you to regulate the volume of hot air blown onto the PCB. This feature is essential because:

- Too much airflow can blow away small components or cause uneven heating.

- Too little airflow may result in insufficient heat transfer, leading to incomplete solder melting.

Look for blower machines with variable airflow settings, often controlled by a knob or digital interface. This flexibility allows you to tailor the heat distribution to your specific task, whether you are working on tiny chips or larger components.

3. Power and Wattage

The power rating of the blower machine affects how quickly and effectively it heats up. Higher wattage machines:

- Heat up faster, reducing wait times.

- Maintain consistent temperatures under load, even during prolonged use.

- Are better suited for larger components or multilayer boards that require more heat.

For typical workshop use, a blower machine with 600W to 1000W power is usually sufficient. However, if your work involves large PCBs or heavy-duty rework, consider machines with higher wattage for better performance.

4. Nozzle Variety and Compatibility

Different SMD components require different nozzle shapes and sizes to focus heat precisely. Ensure the blower machine comes with:

- Multiple interchangeable nozzles: These allow you to concentrate the hot air on specific components without affecting others.

- Nozzles designed for various component sizes and layouts: Narrow nozzles for small ICs and wider nozzles for larger components or areas.

Having a variety of nozzles improves rework accuracy and reduces the risk of damaging adjacent parts. Some machines also offer specialty nozzles for unique applications, such as corner or edge heating.

5. User-Friendliness and Ergonomics

Ease of use affects productivity and reduces operator fatigue. Consider machines that offer:

- Intuitive controls: Knobs, buttons, or touch screens that are easy to navigate.

- Comfortable, lightweight handpieces: Reduces strain during extended use.

- Automatic features: Such as standby modes or auto shutoff for safety and energy efficiency.

A user-friendly design also reduces training time for your staff and minimizes errors during operation.

6. Additional Features

Some advanced SMD blower machines include:

- Preheating plates: These plates evenly warm the PCB before rework, reducing thermal stress and preventing warping.

- Vacuum pickup tools: Integrated vacuum systems help safely handle tiny components without manual tweezers.

- Digital microscopes: For inspection and precision work, allowing you to monitor solder joints closely.

While these features can enhance your workshop's capabilities, they often come with a higher price tag. Evaluate whether these extras align with your specific needs and budget.

Factors to Consider When Choosing an SMD Blower Machine

Workshop Size and Budget

- Budget: Prices vary widely, from around $50 for basic models to over $1000 for professional-grade machines. Determine your budget based on your workshop's needs and expected usage intensity.

- Space: Consider the physical size of the machine and the available workspace. Compact models are better for small benches, while larger setups may accommodate more advanced equipment.

Balancing cost and functionality is key. While inexpensive machines may suffice for occasional repairs, high-volume or professional workshops benefit from investing in durable, feature-rich blowers.

Types of PCBs and Components

- Board Size: Larger PCBs may require blowers with higher power and larger nozzles to ensure even heating.

- Component Sensitivity: Some components, such as microcontrollers or sensors, are highly sensitive to heat. Machines with precise temperature and airflow control help protect these parts.

- Multilayer Boards: Preheating plates or higher wattage machines help prevent warping during rework on multilayer PCBs, which are more prone to thermal stress.

Understanding the types of PCBs and components you commonly work with will guide you in selecting an SMD blower machine that meets your technical requirements.

Frequency and Type of Use

- Repair vs. Production: Frequent, high-volume use demands durable, high-performance machines with robust components.

- Skill Level: For beginners, simpler machines with safety features and easy controls are preferable to reduce the risk of mistakes.

If your workshop handles both repair and small-scale production, consider a versatile machine that balances ease of use with advanced features.

Maintenance and Support

- Choose machines with readily available replacement parts (nozzles, heating elements).

- Consider brands with good customer support and warranty services.

Regular maintenance ensures consistent performance and extends the lifespan of your SMD blower machine. Machines from reputable manufacturers often come with better support and longer warranties.

How to Use an SMD Blower Machine Effectively

Apply Flux

Flux improves solder flow and joint quality by cleaning oxidation and enhancing wetting. Always apply flux before heating to ensure smooth solder reflow.

Even Heating

Move the hot air nozzle evenly across the solder joints to avoid overheating any single spot. Uneven heating can cause component damage or poor solder joints.

Preheat the PCB

Use a preheating plate if available to warm the PCB before applying hot air. This reduces thermal shock and prevents warping, especially on multilayer boards.

Maintain Tools

Regularly clean nozzles and replace worn parts for consistent performance. Residue buildup can affect airflow and heating efficiency.

Ventilation

Work in a well-ventilated area or use fume extraction to avoid inhaling solder fumes, which can be harmful over time.

Conclusion

Choosing the right SMD blower machine for your workshop involves balancing power, temperature and airflow control, nozzle compatibility, ease of use, and budget considerations. By carefully evaluating your specific needs—such as PCB size, component sensitivity, and production volume—you can select a machine that enhances precision, efficiency, and safety in your SMD soldering and rework tasks. Investing in a quality blower machine will ultimately improve your workshop's output and reduce the risk of damage to delicate electronic components.

FAQ

1. What is the ideal temperature range for an SMD blower machine?

The ideal temperature range typically spans from 100°C to 500°C, allowing flexibility to work with various solder types and components safely.

2. How important is airflow control in an SMD blower machine?

Adjustable airflow is crucial to prevent blowing away small components and to ensure even heat distribution, which protects the PCB and components during rework.

3. Can I use an SMD blower machine for lead-free soldering?

Yes, but ensure the machine can reach higher temperatures (usually above 250°C) required for lead-free solder alloys without damaging the PCB.

4. What maintenance is required for SMD blower machines?

Regular cleaning of nozzles and soldering iron tips, replacing worn heating elements, and ensuring proper storage to avoid damage will keep the machine in optimal condition.

5. Are preheating plates necessary for SMD rework?

Preheating plates are highly beneficial for multilayer boards or large components as they reduce thermal stress and warping during soldering processes.

Citations:

1.https://rossmanngroup.com/buy-hot-air-station-laptop-cellphone-repair/

2.https://www.pcb-repair.com/resources/choose-bga/

3.https://www.mpja.com/download/34737tlman.pdf

4.https://www.gordakelec.com/news/a-comprehensive-guide-to-smb-rework-stations.html

5.https://scanditronictech.com/resources/smd-soldering-rework-stations/

6.https://www.instructables.com/SMD-SOLDERING-101-USING-HOT-PLATE-HOT-AIR-BLOWER-S/

7.https://patents.google.com/patent/CN217258299U/en

8.https://www.instructables.com/DIY-SMD-REWORK-STATION/

9.https://www.youtube.com/watch?v=CORLzDxDV4w

10.https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345

11.https://finetech.de/rework-equipment/