Content Menu

● Understanding BGA PCB SMT Assembly

● Key Factors to Consider

>> 1. Technical Expertise and Experience

>> 2. Equipment and Technology

>> 3. Quality Control Measures

>> 4. Production Capacity and Flexibility

>> 5. Design for Manufacturing (DFM) Support

● The BGA PCB SMT Assembly Process

>> 1. PCB Preparation

>> 2. Component Placement

>> 3. Reflow Soldering

>> 4. Cooling and Inspection

>> 5. Additional Processes

● Evaluating Manufacturer Capabilities

>> Stencil Creation and Inspection

>> BGA Placement Precision

>> Reflow Soldering Expertise

>> Inspection and Testing Capabilities

● Considering Cost and Value

● The Importance of Communication

● Environmental Considerations

● Industry Certifications and Standards

● Prototyping and Small-Batch Production

● Global Supply Chain Management

● Post-Assembly Services

● Intellectual Property Protection

● Continuous Improvement and Innovation

● Conclusion

● FAQ

>> 1. What is BGA PCB SMT assembly?

>> 2. Why is BGA PCB SMT assembly challenging?

>> 3. What equipment is essential for BGA PCB SMT assembly?

>> 4. How can I ensure the quality of BGA PCB SMT assembly?

>> 5. What are the advantages of BGA PCB SMT assembly?

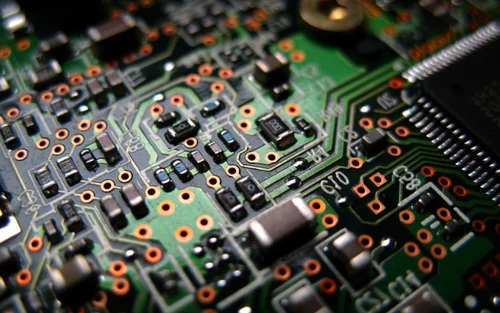

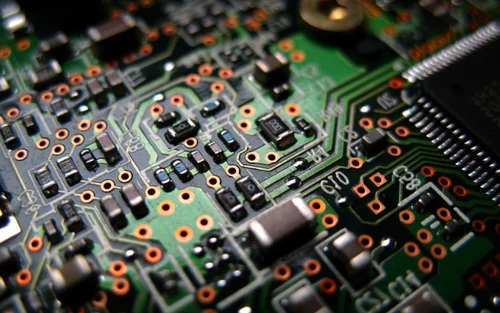

In today's rapidly evolving electronics industry, choosing the right manufacturer for BGA PCB SMT assembly is crucial for ensuring the quality, reliability, and efficiency of your electronic products. Ball Grid Array (BGA) components, combined with Surface Mount Technology (SMT) assembly processes, have become increasingly popular due to their high-density packaging and improved performance. This article will guide you through the essential factors to consider when selecting a manufacturer for your BGA PCB SMT assembly needs.

Understanding BGA PCB SMT Assembly

Before delving into the selection process, it's important to understand what BGA PCB SMT assembly entails. BGA (Ball Grid Array) is a type of surface-mount packaging used for integrated circuits. It's characterized by a grid of solder balls on the underside of the package, which are used to conduct electrical signals between the integrated circuit and the PCB. SMT (Surface Mount Technology) is the method used to mount these components directly onto the surface of printed circuit boards (PCBs).

The combination of BGA components and SMT assembly offers several advantages:

1. Higher component density

2. Improved electrical performance

3. Better heat dissipation

4. Reduced board size

However, BGA PCB SMT assembly also presents unique challenges, such as the need for precise alignment and the difficulty of visual inspection of solder joints. Therefore, choosing a manufacturer with expertise in this area is crucial.

Key Factors to Consider

1. Technical Expertise and Experience

When selecting a manufacturer for BGA PCB SMT assembly, their technical expertise and experience should be your primary consideration. Look for a company with a proven track record in handling BGA components and SMT assembly processes.

Key points to evaluate:

- Years of experience in BGA PCB SMT assembly

- Types of BGA packages they can handle (e.g., micro-BGA, QFN)

- Familiarity with different PCB materials and designs

- Knowledge of industry standards and certifications

2. Equipment and Technology

The quality of BGA PCB SMT assembly heavily depends on the equipment and technology used. A reputable manufacturer should have state-of-the-art equipment for each stage of the assembly process.

Essential equipment includes:

- Advanced pick-and-place machines for accurate component placement

- Reflow ovens with precise temperature control

- X-ray inspection systems for checking BGA solder joints

- Automated Optical Inspection (AOI) systems

3. Quality Control Measures

Given the complexity of BGA PCB SMT assembly, robust quality control measures are essential. The manufacturer should have a comprehensive quality management system in place.

Look for:

- ISO 9001 certification

- IPC standards compliance

- In-process quality checks

- Final inspection and testing procedures

4. Production Capacity and Flexibility

Consider the manufacturer's production capacity and their ability to handle your current and future needs. They should be able to accommodate both small prototype runs and large-scale production.

Evaluate:

- Number of SMT lines

- Production volume capabilities

- Turnaround times for different order sizes

- Ability to handle rush orders

5. Design for Manufacturing (DFM) Support

A good manufacturer should offer Design for Manufacturing (DFM) support. This service can help optimize your PCB design for BGA SMT assembly, potentially reducing costs and improving reliability.

Look for manufacturers that offer:

- PCB design review

- Component selection advice

- Layout optimization suggestions

- Thermal management recommendations

The BGA PCB SMT Assembly Process

Understanding the assembly process can help you better evaluate potential manufacturers. The typical BGA PCB SMT assembly process includes the following steps:

1. PCB Preparation

The process begins with preparing the PCB. This involves applying solder paste to the pads where BGA components will be mounted. The solder paste is a mixture of tiny solder particles and flux, which aids in the soldering process.

2. Component Placement

Next, the BGA components are precisely placed onto the prepared PCB. This is typically done using automated pick-and-place machines, which ensure accurate positioning.

3. Reflow Soldering

The PCB with placed components then goes through a reflow oven. The oven heats the board to a specific temperature profile, melting the solder paste and creating electrical connections between the BGA solder balls and the PCB pads.

4. Cooling and Inspection

After reflow, the PCB is cooled to solidify the solder joints. The assembly is then inspected for defects such as misalignment, shorts, or open connections. This often involves the use of X-ray inspection due to the hidden nature of BGA solder joints.

5. Additional Processes

Depending on the specific requirements, additional processes such as cleaning, testing, and conformal coating may be performed to ensure the reliability and quality of the finished product.

Evaluating Manufacturer Capabilities

When assessing potential manufacturers for your BGA PCB SMT assembly needs, consider the following aspects:

Stencil Creation and Inspection

The manufacturer should have capabilities for creating and inspecting solder stencils. This is crucial for ensuring proper solder paste application, which is particularly important for BGA components.

BGA Placement Precision

Inquire about the manufacturer's capabilities in terms of BGA placement accuracy. The pick-and-place machines should be capable of placing BGAs with high precision to avoid misalignment issues.

Reflow Soldering Expertise

The manufacturer should have expertise in reflow soldering, particularly for BGA components. They should be able to develop and maintain appropriate temperature profiles for different BGA types and PCB designs.

Inspection and Testing Capabilities

Look for manufacturers with advanced inspection and testing capabilities. This should include X-ray inspection for BGA solder joints, as well as electrical testing and functional testing capabilities.

Considering Cost and Value

While cost is always a factor, it's important to consider the overall value when choosing a manufacturer for BGA PCB SMT assembly. The cheapest option may not always provide the best quality or reliability.

Factors affecting cost include:

- Component sourcing

- Assembly complexity

- Production volume

- Turnaround time

- Quality assurance measures

Consider these factors in relation to your project requirements and budget constraints.

The Importance of Communication

Effective communication is crucial when working with a BGA PCB SMT assembly manufacturer. Look for a manufacturer that:

- Responds promptly to inquiries

- Provides clear and detailed quotes

- Offers regular updates on project status

- Has English-speaking staff (if you're working internationally)

Good communication can help prevent misunderstandings, ensure your requirements are met, and facilitate smooth project execution.

Environmental Considerations

In today's environmentally conscious world, it's worth considering a manufacturer's environmental policies and practices. Look for manufacturers that:

- Comply with RoHS and REACH regulations

- Have waste reduction and recycling programs

- Use energy-efficient equipment

- Offer lead-free soldering options

Choosing an environmentally responsible manufacturer can help reduce your product's environmental impact and may be important for regulatory compliance in certain markets.

Industry Certifications and Standards

When selecting a manufacturer for BGA PCB SMT assembly, it's crucial to consider their adherence to industry certifications and standards. These certifications demonstrate a manufacturer's commitment to quality and their ability to meet specific industry requirements.

Key certifications to look for include:

- ISO 9001: This certification ensures that the manufacturer has a robust quality management system in place.

- IPC Standards: Compliance with IPC standards, such as IPC-A-610 for acceptability of electronic assemblies, is essential for ensuring high-quality BGA PCB SMT assembly.

- AS9100: For aerospace applications, this certification is crucial as it builds on ISO 9001 with additional quality requirements specific to the aerospace industry.

- ISO 13485: If your product is for medical applications, this certification ensures the manufacturer meets quality standards for medical devices.

Prototyping and Small-Batch Production

Before committing to full-scale production, it's often beneficial to work with a manufacturer that offers prototyping and small-batch production services. This allows you to:

- Verify the design and functionality of your BGA PCB assembly

- Identify and resolve any issues early in the development process

- Refine manufacturing processes before scaling up production

Look for manufacturers that offer flexible prototyping services and can seamlessly transition from prototype to full production.

Global Supply Chain Management

In today's interconnected world, a manufacturer's ability to manage a global supply chain can be a significant advantage. Consider manufacturers that:

- Have established relationships with component suppliers

- Can source hard-to-find or obsolete components

- Offer inventory management services

- Have strategies in place to mitigate supply chain disruptions

Effective supply chain management can help ensure consistent quality, reduce costs, and minimize production delays.

Post-Assembly Services

Some manufacturers offer additional services beyond BGA PCB SMT assembly. These can add value to your project and streamline your overall product development process. Look for manufacturers that provide:

- Functional testing

- Burn-in testing for reliability

- Conformal coating for environmental protection

- Product packaging and shipping services

These additional services can save you time and resources by providing a more comprehensive solution.

Intellectual Property Protection

When working with a manufacturer, especially for proprietary designs, intellectual property (IP) protection is crucial. Ensure that the manufacturer:

- Has robust data security measures in place

- Is willing to sign non-disclosure agreements (NDAs)

- Has a track record of respecting client IP

Protecting your intellectual property is essential for maintaining your competitive edge in the market.

Continuous Improvement and Innovation

The field of BGA PCB SMT assembly is constantly evolving, with new technologies and techniques emerging regularly. Choose a manufacturer that demonstrates a commitment to continuous improvement and innovation. This might include:

- Regular investments in new equipment and technologies

- Ongoing staff training and development programs

- Participation in industry conferences and research initiatives

- A track record of implementing process improvements

A forward-thinking manufacturer can help keep your products at the cutting edge of technology and manufacturing capabilities.

Conclusion

Choosing the right manufacturer for BGA PCB SMT assembly is a critical decision that can significantly impact the quality, reliability, and success of your electronic products. By carefully evaluating factors such as technical expertise, equipment capabilities, quality control measures, and production capacity, you can select a manufacturer that best meets your needs.

Remember to consider not just the immediate requirements of your current project, but also your potential future needs. A manufacturer that can grow with your business and adapt to changing technologies can be a valuable long-term partner.

Ultimately, the goal is to find a manufacturer that can consistently deliver high-quality BGA PCB SMT assemblies, meeting your specifications, timeline, and budget. By following the guidelines outlined in this article, you'll be well-equipped to make an informed decision and choose a manufacturer that can help drive your product's success.

FAQ

1. What is BGA PCB SMT assembly?

BGA PCB SMT assembly refers to the process of mounting Ball Grid Array (BGA) components onto a Printed Circuit Board (PCB) using Surface Mount Technology (SMT). This assembly method involves placing BGA components, which have an array of solder balls on their underside, onto a PCB and then using reflow soldering to create electrical connections.

2. Why is BGA PCB SMT assembly challenging?

BGA PCB SMT assembly is challenging due to several factors:

- The solder joints are hidden beneath the component, making visual inspection difficult

- It requires precise alignment during placement

- The reflow process needs careful control to ensure proper solder joint formation

- BGA components are sensitive to thermal stress and can be damaged if not handled correctly

3. What equipment is essential for BGA PCB SMT assembly?

Essential equipment for BGA PCB SMT assembly includes:

- Advanced pick-and-place machines for accurate component placement

- Reflow ovens with precise temperature control capabilities

- X-ray inspection systems for checking BGA solder joints

- Automated Optical Inspection (AOI) systems for overall assembly quality control

4. How can I ensure the quality of BGA PCB SMT assembly?

To ensure the quality of BGA PCB SMT assembly:

- Choose a manufacturer with proven expertise in BGA assembly

- Ensure they have advanced inspection equipment, including X-ray systems

- Look for robust quality control processes throughout the assembly

- Consider manufacturers offering Design for Manufacturing (DFM) support

- Request sample runs or prototypes before full production

5. What are the advantages of BGA PCB SMT assembly?

The advantages of BGA PCB SMT assembly include:

- Higher component density, allowing for more compact designs

- Improved electrical performance due to shorter connection paths

- Better heat dissipation compared to other package types

- Reduced overall board size

- Increased reliability when properly assembled