Content Menu

● Understanding SMT Equipment and Its Importance

>> Benefits of SMT in PCB Manufacturing

● Key Factors to Consider When Choosing Low-Cost SMT Equipment

>> 1. Production Volume

>> 2. Degree of Automation

>> 3. Equipment Compatibility

>> 4. Budget Constraints

>> 5. Flexibility and Scalability

● Top Low-Cost SMT Equipment Options

>> 1. Stencil Printers

>> 2. Pick-and-Place Machines

>> 3. Reflow Ovens

>> 4. Inspection Systems

● Best Practices for Efficient PCB Manufacturing with Low-Cost SMT Equipment

>> Optimize Process Flow

>> Prepare Components in Advance

>> Train Your Team

>> Regular Maintenance

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is low-cost SMT equipment?

>> 2. How does automation level affect SMT equipment selection?

>> 3. What are the benefits of using low-cost SMT equipment?

>> 4. How can I improve my production efficiency with low-cost SMT machines?

>> 5 What's Total Cost Ownership(TCO)?

Surface Mount Technology (SMT) equipment is the backbone of modern PCB manufacturing, offering precision, speed, and efficiency. However, selecting the right low-cost SMT equipment for your production line can be challenging, especially when balancing cost-effectiveness with performance. This article provides a comprehensive guide to help you make informed decisions.

Understanding SMT Equipment and Its Importance

SMT equipment is used to mount electronic components directly onto the surface of a PCB. Unlike through-hole technology, SMT eliminates the need for drilled holes, enabling compact and lightweight designs. The key types of SMT equipment include:

- Stencil Printers: Apply solder paste to the PCB.

- Pick-and-Place Machines: Precisely position components on the board.

- Reflow Ovens: Heat the assembly to solder components.

- Inspection Systems (AOI/SPI): Ensure assembly quality.

Benefits of SMT in PCB Manufacturing

1. Compact Designs: Enables smaller and lighter PCBs for modern devices like smartphones and IoT gadgets.

2. High Production Speed: Automated processes reduce assembly time.

3. Cost Efficiency: Minimizes material waste and labor costs.

4. Enhanced Reliability: Soldered connections improve durability and performance.

Key Factors to Consider When Choosing Low-Cost SMT Equipment

1. Production Volume

Different production scales require different equipment setups:

- Small Batch Production: Semi-automatic machines are cost-effective and suitable for prototyping or low-volume production.

- Large-Scale Production: Fully automated lines ensure high throughput and consistent quality for mass production.

Understanding your production volume is critical because over-investing in high-end equipment for small-scale operations can lead to unnecessary costs, while under-investing may result in inefficiencies during large-scale manufacturing.

2. Degree of Automation

SMT equipment ranges from manual to fully automated systems:

- Manual Systems: These are affordable but require significant operator involvement, making them ideal for small-scale or prototype production.

- Semi-Automatic Systems: These balance cost and efficiency, offering some automation features while still requiring operator input.

- Fully Automatic Systems: These are designed for high-speed, large-scale manufacturing where minimal human intervention is needed.

The degree of automation you choose should align with your production goals and budget constraints.

3. Equipment Compatibility

Ensure the equipment supports your specific PCB design requirements:

- Multi-layer PCB compatibility is essential if your designs involve complex circuits.

- Check whether the machines can handle a wide range of component sizes, from small chip resistors to larger ICs.

- Verify that the equipment can accommodate different PCB sizes and thicknesses.

Compatibility issues can lead to inefficiencies or even production errors, so it's crucial to match the capabilities of your low-cost SMT equipment with your design needs.

4. Budget Constraints

While focusing on affordability, it's important to consider the total cost of ownership (TCO), which includes:

- The initial purchase price of the equipment.

- Maintenance costs over time.

- Energy consumption during operation.

- Potential costs for upgrades or additional features.

Investing in cheap but unreliable machines may lead to higher long-term expenses due to frequent repairs or replacements. Striking a balance between upfront costs and long-term value is key when selecting low-cost SMT equipment.

5. Flexibility and Scalability

Choose equipment that can adapt to future production needs:

- Modular designs allow you to upgrade specific components instead of replacing entire systems.

- Scalable systems can accommodate increasing production volumes as your business grows.

Flexibility ensures that your investment remains relevant even as your manufacturing requirements evolve over time.

Top Low-Cost SMT Equipment Options

When selecting low-cost SMT equipment, it's essential to evaluate each type of machine based on its role in the assembly process. Below are some popular options:

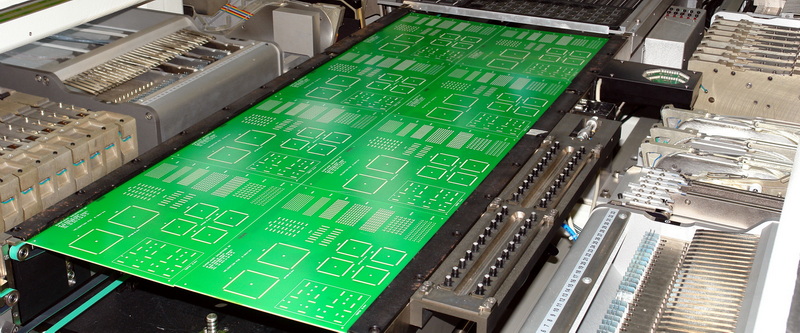

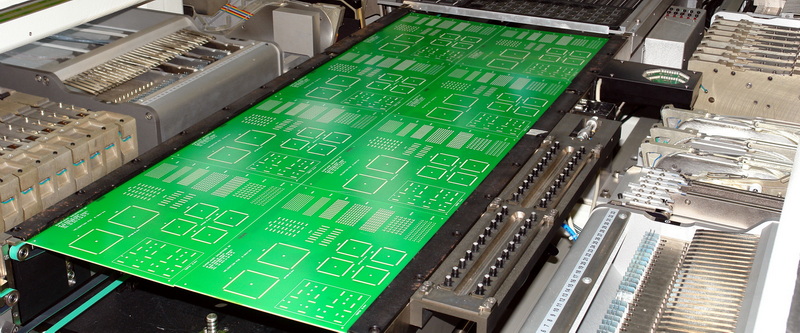

1. Stencil Printers

Stencil printers apply solder paste with precision, ensuring proper adhesion of components during reflow soldering. Features to look for include:

- Adjustable alignment systems for accurate paste application.

- Compatibility with various stencil sizes and PCB dimensions.

- Ease of cleaning and maintenance.

For low-cost options, consider semi-automatic stencil printers that offer a good balance between affordability and precision.

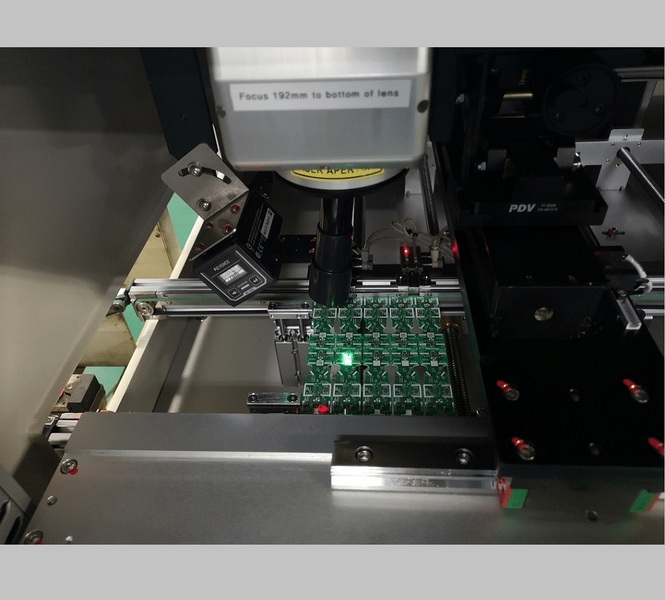

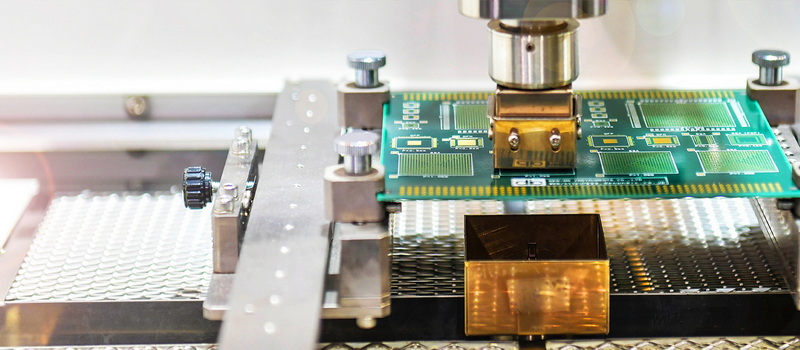

2. Pick-and-Place Machines

Pick-and-place machines are responsible for positioning components on the PCB. Key considerations include:

- Placement speed (measured in components per hour).

- Accuracy and repeatability to ensure consistent results.

- Feeder capacity to handle multiple component types simultaneously.

Low-cost pick-and-place machines often come in desktop models suitable for small-scale operations, while mid-range options cater to medium-sized businesses.

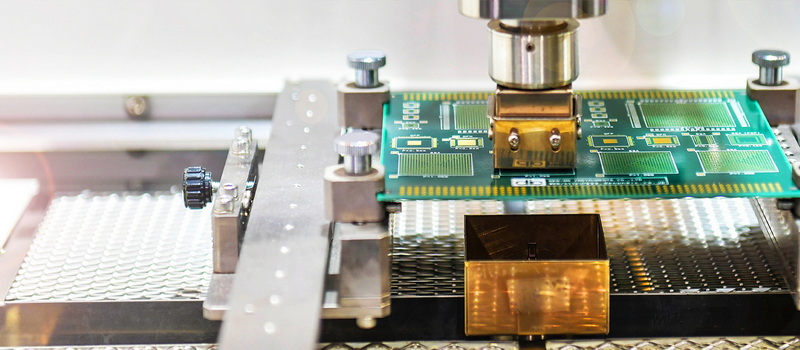

3. Reflow Ovens

Reflow ovens solder components by heating the entire assembly through controlled temperature profiles. When choosing a low-cost reflow oven:

- Decide between infrared or convection heating systems based on your budget and production needs.

- Ensure uniform temperature distribution across the PCB for reliable solder joints.

- Look for compact designs if space is limited in your facility.

Entry-level reflow ovens are suitable for prototyping or small-batch production, while mid-tier models support higher throughput at a reasonable cost.

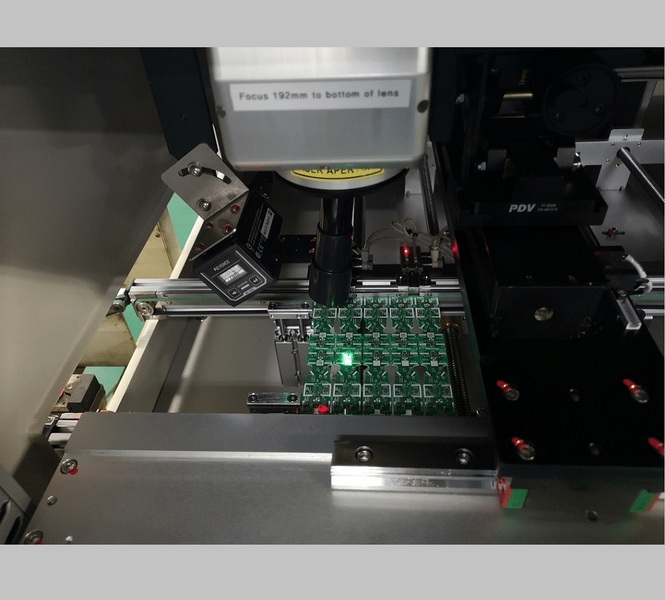

4. Inspection Systems

Inspection systems play a critical role in maintaining quality control during PCB assembly:

- Automated Optical Inspection (AOI) systems check component placement, polarity, and solder joints.

- Solder Paste Inspection (SPI) systems verify proper solder paste application before component placement.

Low-cost AOI systems often use simple cameras and software algorithms but can still detect common defects effectively. Investing in inspection tools helps reduce rework costs and ensures product reliability.

Best Practices for Efficient PCB Manufacturing with Low-Cost SMT Equipment

Implementing best practices can maximize the efficiency of your low-cost SMT equipment while maintaining high-quality output:

Optimize Process Flow

Streamline your assembly process by arranging equipment logically to minimize bottlenecks. For example:

- Position stencil printers near pick-and-place machines to reduce handling time.

- Place inspection systems at key points in the process flow for early defect detection.

A well-organized layout improves productivity and reduces downtime.

Prepare Components in Advance

Ensure all components are prepared before starting production:

- Organize feeders based on component types and placement order.

- Verify component quantities to avoid shortages during assembly runs.

Proper preparation minimizes delays and keeps the production line running smoothly.

Train Your Team

Invest in training programs to enhance operator skills:

- Teach operators how to set up and calibrate machines correctly.

- Provide troubleshooting guides for common issues with low-cost SMT equipment.

Skilled operators can maximize machine performance while reducing errors that lead to rework or scrap materials.

Regular Maintenance

Routine maintenance prevents unexpected downtime and extends the lifespan of your equipment:

- Clean stencil printers regularly to avoid solder paste residue buildup.

- Inspect pick-and-place nozzles for wear or blockages.

- Calibrate reflow ovens periodically to maintain consistent temperature profiles.

Preventive maintenance ensures that your low-cost SMT equipment operates reliably over time.

Conclusion

Choosing the right low-cost SMT equipment involves evaluating your production needs, budget constraints, and future scalability requirements. Whether you're investing in stencil printers, pick-and-place machines, reflow ovens, or inspection tools, each piece of equipment plays a vital role in ensuring efficient PCB manufacturing. By following best practices such as optimizing process flow, preparing components in advance, training operators, and conducting regular maintenance, you can achieve high-quality results without overspending on expensive machinery.

Investing wisely in low-cost SMT solutions not only reduces initial expenses but also enhances operational efficiency—allowing you to stay competitive in today's fast-paced electronics industry. With careful planning and strategic choices, even budget-conscious manufacturers can achieve professional-grade results in their PCB assembly processes.

Frequently Asked Questions (FAQ)

1. What is low-cost SMT equipment?

Low-cost SMT equipment refers to affordable machines used in Surface Mount Technology processes designed for small-to-medium-scale PCB manufacturing while maintaining efficiency. These machines provide essential functions like solder paste application, component placement, reflow soldering, and quality inspection at a lower price point compared to high-end industrial models.

2. How does automation level affect SMT equipment selection?

The degree of automation impacts cost, speed, labor requirements, and scalability:

- Manual systems are cheaper but slower due to heavy operator involvement.

- Semi-Automatic systems strike a balance by automating certain tasks while requiring some manual input.

- Fully Automatic systems offer high-speed operation with minimal labor but come at a higher cost upfront—ideal for large-scale production environments where throughput is critical.

3. What are the benefits of using low-cost SMT equipment?

Low-cost SMT equipment offers several advantages:

1. Reduces upfront investment compared to premium models.

2. Enables efficient small-batch or medium-scale production without sacrificing quality.

3. Provides flexibility for startups or businesses transitioning from manual assembly methods.

4. Minimizes operational costs through energy-efficient designs tailored for smaller workloads.

4. How can I improve my production efficiency with low-cost SMT machines?

To improve efficiency when using low-cost SMT machines:

1. Optimize process flow by arranging machines logically within your workspace.

2. Prepare all components beforehand (e.g., organize feeders).

3. Train operators thoroughly on machine setup/operation techniques specific-to-models purchased!

4 Conduct routine preventive maintenance schedules ensuring smooth operation avoiding costly downtime/errors!

5 What's Total Cost Ownership(TCO)?

TCO = Purchase Price + Operational Costs(Maintenance/Energy)+ Long Term Upgrades