Content Menu

● Understanding Reflow Ovens

>> Key Components of a Reflow Oven

● Factors to Consider When Choosing a Wholesale Reflow Oven

>> 1. Production Volume and Throughput Requirements

>> 2. Component Types

>> 3. Heating Zone Configuration

>> 4. Budget Considerations

>> 5. Technical Support and Warranty

>> 6. Space Requirements

>> 7. Energy Efficiency

>> 8. Advanced Features

● Types of Reflow Ovens

● Evaluating Manufacturer Options

● Real-world Applications

● Conclusion

● FAQ

>> 1. What is a reflow oven used for?

>> 2. How many heating zones should my reflow oven have?

>> 3. What are the benefits of convection over infrared reflow ovens?

>> 4. How do I maintain my reflow oven?

>> 5. Can I use a reflow oven for lead-free soldering?

Selecting the right wholesale reflow oven for your Surface Mount Technology (SMT) production line is a critical decision that can significantly impact the quality and efficiency of your electronic assembly processes. With numerous options available in the market, understanding the key factors and features of reflow ovens is essential for making an informed choice. This comprehensive guide will walk you through the considerations necessary to choose the best reflow oven tailored to your specific needs.

Understanding Reflow Ovens

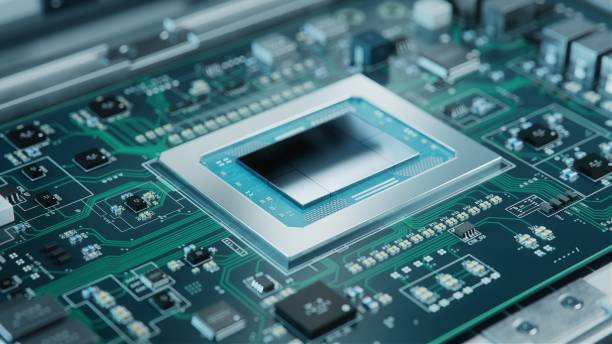

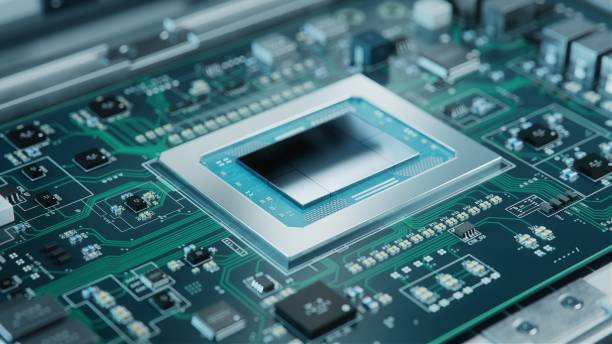

A reflow oven is an essential piece of equipment in SMT processes, designed to melt solder paste and bond electronic components to printed circuit boards (PCBs). The reflow process typically consists of several stages: preheat, soak, reflow, and cooling. Each stage plays a crucial role in achieving high-quality solder joints.

Key Components of a Reflow Oven

- Heating Zones: The number of heating zones affects temperature control and uniformity. More zones allow for better thermal management across various components on the PCB.

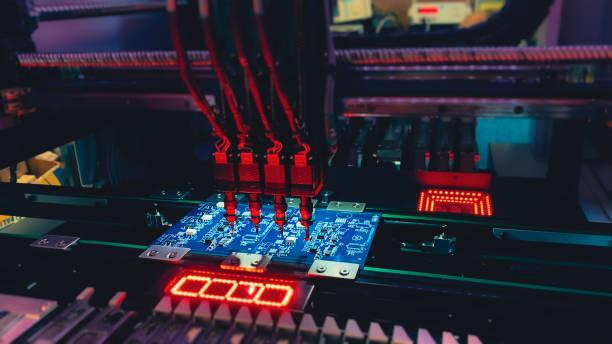

- Conveyor System: A reliable conveyor system ensures smooth transportation of PCBs through the oven without causing damage or misalignment.

- Temperature Control: Accurate temperature control is vital for maintaining optimal soldering conditions and preventing defects.

- Cooling System: An effective cooling system is essential for rapidly bringing down the temperature after the reflow process, which helps solidify solder joints quickly and reduces thermal stress on components.

Factors to Consider When Choosing a Wholesale Reflow Oven

1. Production Volume and Throughput Requirements

Assess your production needs to determine the appropriate capacity. If you're producing large volumes of PCBs, consider a high-capacity reflow oven that can handle increased throughput without compromising quality. For instance, if your production line operates continuously with multiple shifts, investing in a robust oven with high throughput capabilities will pay off in efficiency.

2. Component Types

Different electronic components require specific soldering techniques and temperature profiles. Ensure that the reflow oven you choose can accommodate the types of components you frequently use, especially if they are sensitive to high temperatures. For example, if your production involves fine-pitch components or multi-layer boards, you may need an oven capable of precise temperature control to avoid damaging these delicate parts.

3. Heating Zone Configuration

The configuration of heating zones is crucial for achieving consistent results during the soldering process. Look for a reflow oven that offers multiple heating zones, allowing for different temperature profiles across the PCB. A typical configuration might include separate zones for preheating, soaking, reflow, and cooling, which can be independently controlled to optimize the soldering process.

4. Budget Considerations

While investing in quality equipment is essential, it's equally important to find a balance between performance and cost. Consider both initial purchase costs and long-term operational expenses when evaluating options. This includes energy consumption, maintenance costs, and potential downtime due to equipment failure. A slightly higher upfront investment in a reliable model may lead to significant savings over time through reduced energy costs and increased productivity.

5. Technical Support and Warranty

After-sales support is crucial in maintaining the longevity of your equipment. Choose a manufacturer that offers robust local support and warranty options to ensure minimal downtime in case of equipment failure. A good warranty should cover not only parts but also labor costs associated with repairs.

6. Space Requirements

Consider the physical space available in your facility. Ensure that the reflow oven can fit comfortably within your production layout, allowing for easy access and maintenance. Additionally, think about the layout of your entire SMT line; proper spacing can facilitate smoother workflows and reduce bottlenecks during production.

7. Energy Efficiency

Look for energy-efficient models that can help reduce operational costs over time while maintaining performance standards. Energy-efficient ovens often come with advanced features such as insulation technologies or variable speed fans that optimize energy use without sacrificing performance.

8. Advanced Features

Modern reflow ovens come equipped with advanced features such as programmable settings, real-time monitoring systems, and compatibility with various types of soldering processes. These features can significantly enhance your production efficiency and product quality. For example:

- Programmable Profiles: The ability to program multiple profiles allows you to switch between different products quickly.

- Data Logging: Many ovens now come with data logging capabilities that enable you to track temperature profiles over time, which is invaluable for quality control.

- Remote Monitoring: Some advanced models offer remote monitoring capabilities via cloud-based systems, allowing operators to check on production status from anywhere.

Types of Reflow Ovens

When selecting a wholesale reflow oven for your SMT production line, it's important to understand the different types available:

- Convection Reflow Ovens: These ovens use heated air to transfer heat to the PCB. They are suitable for various applications, especially those requiring uniform heating across complex assemblies. Convection ovens are known for their versatility and ability to handle a wide range of component sizes.

- Infrared Reflow Ovens: Infrared ovens use radiant heat to warm up components quickly but may not provide as uniform heating as convection ovens. They are often preferred for applications where speed is critical but may require careful calibration to avoid overheating sensitive components.

- Vapor Phase Ovens: These ovens utilize vaporized liquid to transfer heat, offering precise temperature control suitable for sensitive components. Vapor phase technology provides excellent thermal uniformity but may have higher operational costs due to the need for specialized fluids.

Evaluating Manufacturer Options

When looking for wholesale suppliers of reflow ovens, consider reputable manufacturers known for their innovation and quality in SMT machinery:

- BTU International: A leading supplier focusing on advanced thermal processing technology known for its reliability and performance.

- Heller Industries: Known for high-performance reflow ovens tailored for various manufacturing needs; they offer both standard models and customizable solutions.

- KIC: Specializes in thermal profiling solutions that enhance soldering quality; their systems integrate well with existing manufacturing setups.

- SEHO Systems: Offers a range of reflow ovens equipped with advanced features aimed at improving efficiency and reducing energy consumption.

Real-world Applications

Understanding how different businesses utilize wholesale reflow ovens can provide valuable insights into selecting the right model:

- Consumer Electronics: Companies producing smartphones or tablets often require high-volume production with precise thermal profiles due to densely packed components.

- Automotive Electronics: Manufacturers in this sector prioritize reliability; thus they often opt for robust models capable of handling lead-free solder processes under stringent quality standards.

- Medical Devices: Precision is paramount in medical device manufacturing; thus these companies typically invest in high-end reflow ovens equipped with advanced monitoring systems to ensure compliance with regulatory standards.

Conclusion

Choosing the best wholesale reflow oven for your SMT production line requires careful consideration of various factors such as production volume, component types, heating zone configuration, budget, technical support, space requirements, energy efficiency, and advanced features. By thoroughly evaluating these aspects and understanding the different types of reflow ovens available in the market, you can make an informed decision that enhances your manufacturing capabilities and ensures high-quality solder joints in your electronic assemblies.

Investing time in researching manufacturers and understanding their offerings will pay off significantly in terms of productivity gains and product quality improvements over time. A well-chosen reflow oven will not only streamline your production processes but also contribute positively to your bottom line by reducing defects and increasing throughput.

FAQ

1. What is a reflow oven used for?

A reflow oven is used in electronics manufacturing to melt solder paste on printed circuit boards (PCBs) during surface mount technology (SMT) assembly processes.

2. How many heating zones should my reflow oven have?

The number of heating zones depends on your production needs; more zones provide better temperature control across complex assemblies but may not be necessary for simpler boards.

3. What are the benefits of convection over infrared reflow ovens?

Convection ovens provide more uniform heating compared to infrared ovens, making them suitable for complex assemblies with densely packed components.

4. How do I maintain my reflow oven?

Regular maintenance includes cleaning heating elements, checking temperature sensors, calibrating controls, and ensuring proper airflow through the conveyor system.

5. Can I use a reflow oven for lead-free soldering?

Yes, many modern reflow ovens are designed to accommodate lead-free soldering processes by providing precise temperature control necessary for melting lead-free solder alloys effectively.