Content Menu

● Understanding SMT Reel Storage Systems

>> The Importance of Proper SMT Reel Storage

● Key Factors to Consider When Choosing an SMT Reel Storage System

>> 1. Storage Capacity and Scalability

>> 2. Space Efficiency

>> 3. Accessibility and Retrieval Speed

>> 4. Inventory Management and Traceability

>> 5. Environmental Control

>> 6. Automation and Industry 4.0 Compatibility

● Types of SMT Reel Storage Systems

>> 1. Vertical Carousel Modules (VCMs)

>> 2. Vertical Lift Modules (VLMs)

>> 3. Smart Racks and Shelving Systems

>> 4. Automated Storage and Retrieval Systems (AS/RS)

● Implementing Your SMT Reel Storage System

>> 1. Planning and Layout

>> 2. Integration with Existing Systems

>> 3. Staff Training

>> 4. Establishing Standard Operating Procedures (SOPs)

>> 5. Monitoring and Optimization

● Case Studies: Successful SMT Reel Storage Implementations

>> Case Study 1: Electronics Manufacturer Improves Efficiency

>> Case Study 2: Large-Scale Production Facility Automates Storage

● Conclusion

● FAQ

>> 1. What is the average ROI for implementing an SMT reel storage system?

>> 2. How does an SMT reel storage system improve component traceability?

>> 3. Can SMT reel storage systems accommodate different reel sizes?

>> 4. How do SMT reel storage systems protect against ESD and moisture?

>> 5. What level of automation can I expect from an SMT reel storage system?

● Citations:

In the fast-paced world of electronics manufacturing, efficiency and organization are paramount. One crucial aspect of this industry is the storage and management of Surface Mount Technology (SMT) reels. Choosing the right SMT reel storage system can significantly impact your factory's productivity, space utilization, and overall operational efficiency. This comprehensive guide will walk you through the essential factors to consider when selecting the best SMT reel storage system for your factory.

Understanding SMT Reel Storage Systems

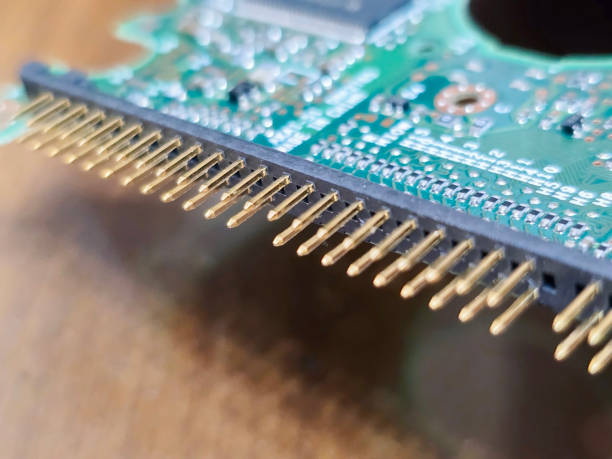

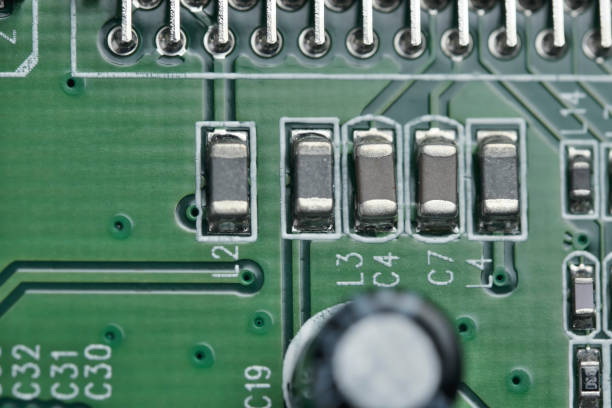

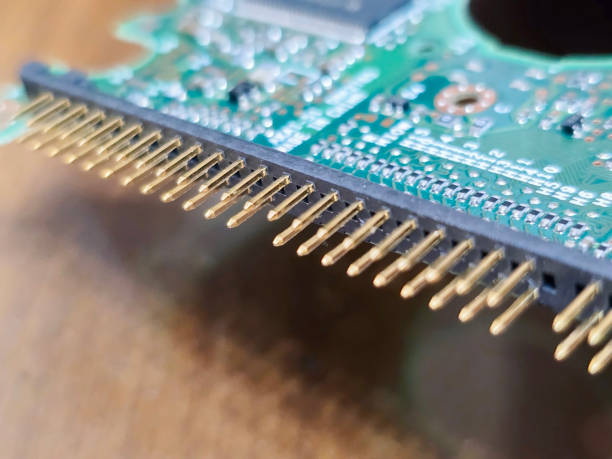

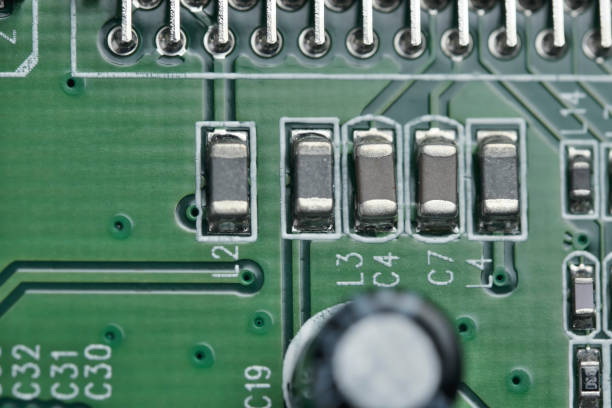

SMT reel storage systems are specialized solutions designed to store and manage the reels of electronic components used in surface mount technology manufacturing. These systems play a vital role in organizing, protecting, and efficiently retrieving components for production processes.

The Importance of Proper SMT Reel Storage

Proper storage of SMT reels is crucial for several reasons:

1. Component Protection: Electronic components are sensitive to environmental factors such as humidity and electrostatic discharge. A good storage system helps protect these components from damage.

2. Inventory Management: Efficient storage systems enable accurate tracking of component quantities and locations, reducing the risk of stockouts or overstocking.

3. Space Optimization: With the vast number of components used in electronics manufacturing, optimizing storage space is essential for efficient factory operations.

4. Production Efficiency: Quick and easy access to required components can significantly reduce production setup times and increase overall efficiency.

Key Factors to Consider When Choosing an SMT Reel Storage System

1. Storage Capacity and Scalability

When selecting an SMT reel storage system, it's crucial to consider both your current and future storage needs. Assess the number and sizes of reels you need to store and choose a system that can accommodate your requirements with room for growth.

Some systems offer modular designs that allow for easy expansion as your storage needs increase. This scalability can be a cost-effective solution in the long run, as it eliminates the need for complete system replacements as your business grows.

2. Space Efficiency

In most manufacturing environments, floor space is at a premium. Look for SMT reel storage systems that maximize vertical space utilization. Vertical carousel modules (VCMs) and vertical lift modules (VLMs) are excellent options for high-density storage, potentially saving up to 85% of floor space compared to traditional shelving systems[5].

3. Accessibility and Retrieval Speed

The speed at which components can be retrieved from storage is a critical factor in maintaining production efficiency. Advanced SMT reel storage systems offer features like:

- Guided retrieval systems using LEDs or laser pointers

- Automated carousel or lift mechanisms for quick access to stored reels

- Software-driven inventory management for locating specific components

Some systems can retrieve reels in less than 4 seconds and return them in less than 8 seconds, significantly reducing kitting time from hours to minutes[9].

4. Inventory Management and Traceability

Modern SMT reel storage systems often come with integrated inventory management software. This software can provide real-time tracking of component quantities, locations, and usage history. Look for systems that offer:

- Real-time inventory updates

- Integration with existing ERP or MES systems

- Barcode or RFID scanning capabilities for accurate tracking

- First-in, First-out (FIFO) inventory management

These features ensure accurate stock levels, reduce the risk of production delays due to component shortages, and enhance traceability throughout the manufacturing process[5].

5. Environmental Control

Electronic components can be sensitive to environmental conditions. Consider SMT reel storage systems that offer:

- Temperature control

- Humidity regulation

- ESD (Electrostatic Discharge) protection

These features help maintain the integrity and longevity of your stored components, reducing the risk of damage and ensuring consistent quality in your manufacturing processes[3].

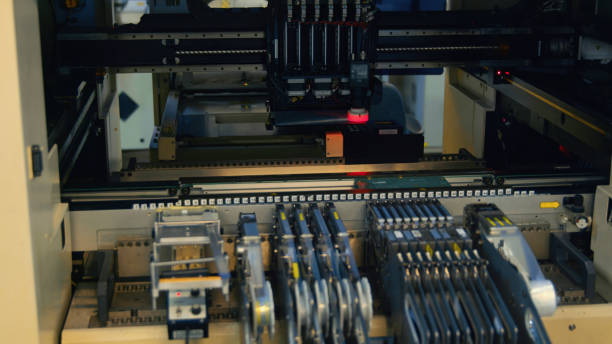

6. Automation and Industry 4.0 Compatibility

As manufacturing moves towards greater automation and Industry 4.0 principles, choosing an SMT reel storage system that aligns with these trends can future-proof your investment. Look for systems that offer:

- Integration with automated guided vehicles (AGVs) for material transport

- Compatibility with robotic picking systems

- API connectivity for seamless integration with other smart factory systems

These features can significantly enhance your factory's overall automation and efficiency[5].

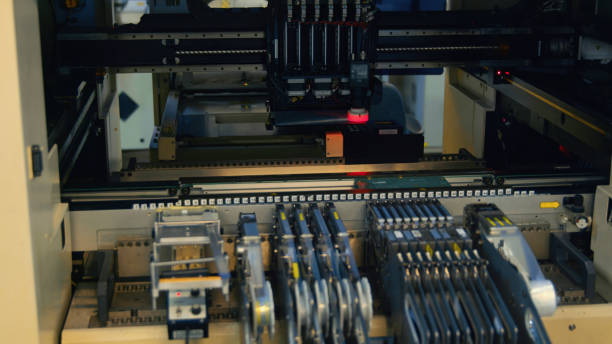

Types of SMT Reel Storage Systems

1. Vertical Carousel Modules (VCMs)

VCMs consist of a series of carriers that rotate vertically, bringing stored items to an ergonomic access point. These systems are excellent for high-density storage and quick retrieval of SMT reels.

2. Vertical Lift Modules (VLMs)

VLMs use a vertical lift mechanism to retrieve trays of stored items. They offer high storage density and can be customized to accommodate various reel sizes.

3. Smart Racks and Shelving Systems

These systems use guided light technology and sensors to assist in locating and retrieving specific reels. They can be more cost-effective than fully automated systems while still offering significant improvements in efficiency.

4. Automated Storage and Retrieval Systems (AS/RS)

AS/RS solutions are fully automated systems that use robotic mechanisms to store and retrieve reels. While more expensive, they offer the highest level of automation and efficiency for large-scale operations.

Implementing Your SMT Reel Storage System

Once you've chosen the right SMT reel storage system for your factory, proper implementation is crucial to maximize its benefits.

1. Planning and Layout

Carefully plan the placement of your storage system within your facility. Consider factors such as:

- Proximity to production lines

- Material flow patterns

- Access for maintenance and restocking

2. Integration with Existing Systems

Ensure that your new SMT reel storage system integrates smoothly with your existing inventory management and production planning software. This may require working closely with your IT department and the system vendor.

3. Staff Training

Proper training is essential to ensure that your team can effectively use the new storage system. This includes:

- Operating the physical storage and retrieval mechanisms

- Using any associated software for inventory management

- Understanding maintenance requirements

4. Establishing Standard Operating Procedures (SOPs)

Develop clear SOPs for using the new storage system, including:

- Procedures for storing and retrieving reels

- Inventory counting and reconciliation processes

- Maintenance schedules

5. Monitoring and Optimization

After implementation, continuously monitor the performance of your SMT reel storage system. Look for opportunities to optimize its use and address any issues that arise.

Case Studies: Successful SMT Reel Storage Implementations

Case Study 1: Electronics Manufacturer Improves Efficiency

A medium-sized electronics manufacturer implemented a vertical carousel SMT reel storage system. The results included:

- 70% reduction in floor space used for component storage

- 50% decrease in time spent retrieving components

- 99.9% inventory accuracy

Case Study 2: Large-Scale Production Facility Automates Storage

A large electronics production facility invested in a fully automated AS/RS for SMT reel storage. The outcomes were:

- 90% reduction in manual handling of components

- 30% increase in overall production efficiency

- Zero incidents of component mix-ups or losses

Conclusion

Choosing the best SMT reel storage system for your factory is a critical decision that can significantly impact your operational efficiency and bottom line. By carefully considering factors such as storage capacity, space efficiency, accessibility, inventory management, environmental control, and automation compatibility, you can select a system that not only meets your current needs but also positions your factory for future growth and technological advancements.

Remember that the right SMT reel storage solution should seamlessly integrate with your existing processes, enhance your inventory management, and ultimately contribute to smoother, more efficient production. As the electronics manufacturing industry continues to evolve, investing in a smart, scalable storage system will help ensure that your factory remains competitive and ready for the challenges of tomorrow.

FAQ

1. What is the average ROI for implementing an SMT reel storage system?

The return on investment (ROI) for an SMT reel storage system can vary depending on the size of your operation and the specific system chosen. However, many manufacturers report an ROI within 3-6 months due to increased efficiency, reduced errors, and better inventory management. Some systems have shown to reduce kitting time from hours to minutes, which can lead to significant cost savings over time[9].

2. How does an SMT reel storage system improve component traceability?

SMT reel storage systems improve component traceability by providing real-time tracking of each reel's location, usage history, and remaining quantity. Advanced systems can record which order a component was used for, when it was used, and even analyze wasted costs. This level of detail ensures that you can trace components throughout the production process, meeting quality control standards and facilitating easier audits[5].

3. Can SMT reel storage systems accommodate different reel sizes?

Yes, most modern SMT reel storage systems are designed to accommodate various reel sizes. For example, some systems can store reels ranging from 7" to 15" in diameter and 8-56mm in width. Many systems also offer customizable storage options to fit specific needs, including storage for other component types such as tubes, trays, and mechanical parts[9].

4. How do SMT reel storage systems protect against ESD and moisture?

Advanced SMT reel storage systems often include built-in ESD protection measures to safeguard sensitive electronic components. This can include the use of ESD-safe materials in the construction of storage units and grounding mechanisms. For moisture protection, some systems incorporate climate control features that regulate temperature and humidity levels within the storage environment, ensuring that components remain in optimal condition[3].

5. What level of automation can I expect from an SMT reel storage system?

The level of automation in SMT reel storage systems can vary greatly depending on the specific solution. Basic systems may offer guided light systems for manual picking, while more advanced solutions can provide fully automated storage and retrieval with robotic systems. Some high-end systems can even integrate with AGVs for automated material transport and connect with production planning software for seamless workflow automation. The choice depends on your specific needs and budget[5].

Citations:

[1] https://www.southwestsolutions.com/ssg/material-handling/smt-reel-storage-solutions/

[2] https://global.neotel.tech/2023/01/13/boost-productivity-with-our-smt-reel-storage-system/

[3] https://global.neotel.tech/2023/01/05/what-is-smt-reel-storage-solution/

[4] https://patents.google.com/patent/CN104244605B/zh

[5] https://www.allsmt.com/automated-warehouse-systems-smt-production

[6] https://flowcleanrooms.com/super-erecta-smt-reel-shelves.html

[7] https://global.neotel.tech/2022/02/24/5-things-you-must-know-about-smt-reel/

[8] https://www.gii.co.jp/report/qyr1453327-global-intelligent-smt-reel-storage-system-market.html

[9] https://inovaxe.com/smt-reel-storage/

[10] https://metro.com/shop/super-erecta-smt-reel-shelves/

[11] https://www.youtube.com/watch?v=If9Pht8ioo4

[12] https://www.adoptsmt.com/en/reel-storage-system/

[13] https://www.orion-industry.com/smt-placement/electronics-manufacturing-smd-reels-traceability-smart-storage.html