Content Menu

● Introduction to SMT Reel Racks

>> Importance of SMT Reel Racks

● Key Factors to Consider When Choosing an SMT Reel Rack

>> 1. Storage Capacity and Flexibility

>> 2. Space Efficiency

>> 3. Accessibility and Automation

>> 4. Environmental Control

>> 5. Integration with Existing Systems

● Implementing the Best SMT Reel Rack

>> Planning and Placement

>> Training and Maintenance

● Benefits of Using the Right SMT Reel Rack

● Case Studies: Successful Implementations

● The Future of SMT Reel Storage: Intelligent Systems

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using SMT reel racks in PCB assembly?

>> 2. How do SMT reel racks protect electronic components from environmental factors?

>> 3. What features should I look for in an automated SMT reel storage system?

>> 4. How can SMT reel racks improve production efficiency in PCB assembly?

>> 5. What are the long-term benefits of investing in a high-quality SMT reel rack system?

● Citations:

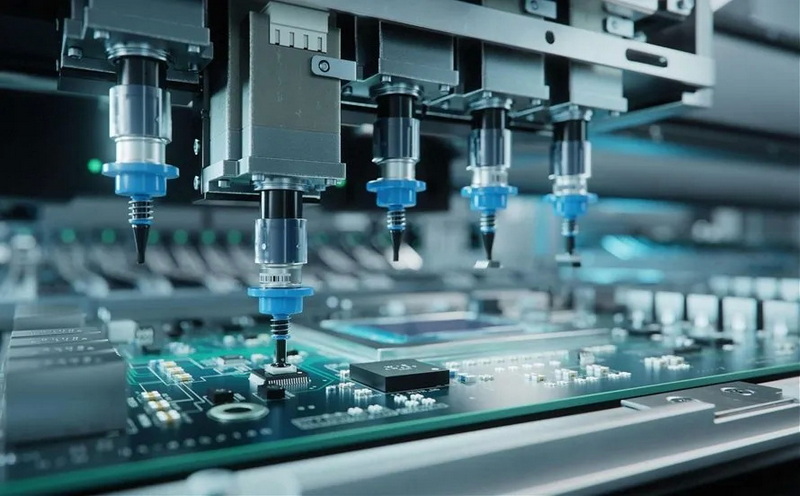

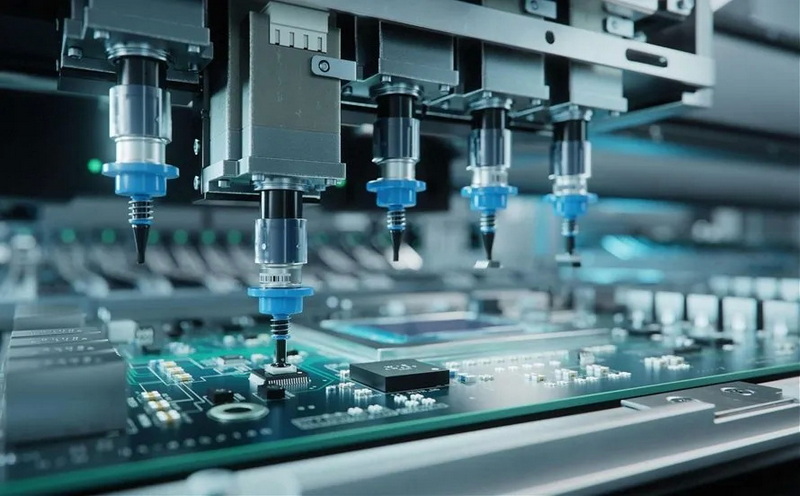

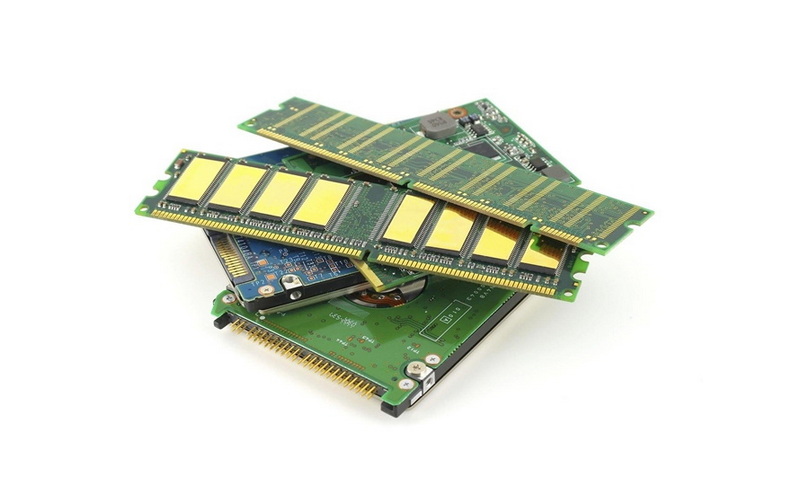

In the fast-paced world of electronics manufacturing, efficiency and organization are paramount. One crucial aspect of this industry is the storage and management of Surface Mount Technology (SMT) reels, which are used to hold and store electronic components essential for PCB assembly. Choosing the right SMT reel rack can significantly impact your factory's productivity, space utilization, and overall operational efficiency. This comprehensive guide will walk you through the essential factors to consider when selecting the best SMT reel rack for your PCB assembly needs.

Introduction to SMT Reel Racks

SMT reel racks are specialized storage solutions designed to organize, protect, and efficiently retrieve components for production processes. These systems play a vital role in maintaining the integrity of electronic components by safeguarding them against environmental factors such as humidity and electrostatic discharge (ESD). Proper storage also enables accurate tracking of component quantities and locations, reducing the risk of stockouts or overstocking.

Importance of SMT Reel Racks

1. Component Protection: Electronic components are sensitive to environmental factors. A good storage system helps protect these components from damage.

2. Inventory Management: Efficient storage systems enable accurate tracking of component quantities and locations.

3. Space Optimization: With the vast number of components used in electronics manufacturing, optimizing storage space is essential for efficient factory operations.

4. Production Efficiency: Quick and easy access to required components can significantly reduce production setup times and increase overall efficiency.

Key Factors to Consider When Choosing an SMT Reel Rack

When selecting an SMT reel rack, several factors must be considered to ensure that the chosen system meets your current and future needs.

1. Storage Capacity and Flexibility

- Reel Size Accommodation: Ensure the rack can accommodate various reel sizes, as components vary in size and type. Many modern systems can store reels ranging from 7" to 15" in diameter and 8-56mm in width[4].

- Modular Design: Opt for systems with modular designs that allow for easy expansion as your storage needs increase. This scalability can be a cost-effective solution in the long run, as it eliminates the need for complete system replacements as your business grows[4].

2. Space Efficiency

- Vertical Storage: Utilize vertical storage solutions like carousels or lift modules to maximize space, potentially saving up to 85% of floor space compared to traditional shelving systems[1][4].

- Compact Footprint: Choose racks with a compact footprint to fit into tight spaces without compromising storage capacity.

3. Accessibility and Automation

- Guided Retrieval Systems: Look for systems with guided retrieval features such as LEDs or laser pointers to speed up component access. Advanced systems can retrieve reels in less than 4 seconds and return them in less than 8 seconds[4].

- Automation Level: Consider the level of automation needed, from basic manual systems to fully automated robotic solutions. Some high-end systems can integrate with AGVs for automated material transport and connect with production planning software for seamless workflow automation[4].

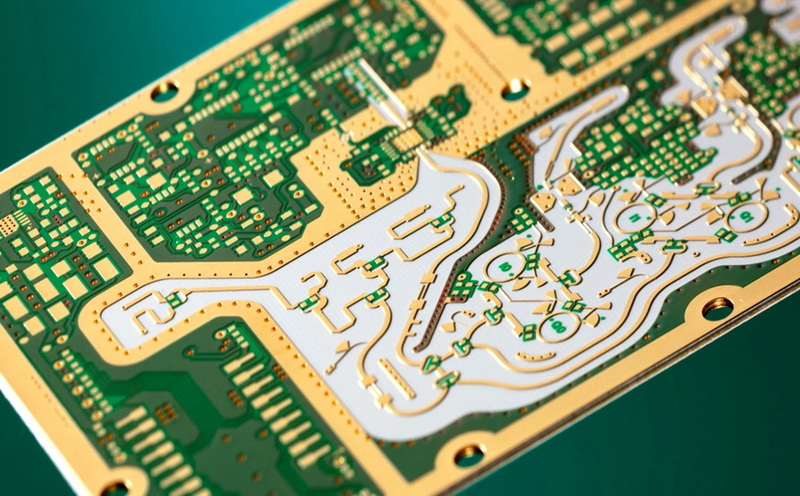

4. Environmental Control

- ESD Protection: Ensure the rack provides adequate ESD protection to safeguard sensitive electronic components. This can include the use of ESD-safe materials in the construction of storage units and grounding mechanisms[4].

- Climate Control: Opt for systems that maintain stable temperature and humidity conditions to prevent component degradation. Some systems incorporate climate control features that regulate temperature and humidity levels within the storage environment[4].

5. Integration with Existing Systems

- Software Compatibility: Ensure the storage system integrates seamlessly with your existing inventory management and production planning software. Modern SMT reel storage systems often come with integrated inventory management software that provides real-time tracking of component quantities, locations, and usage history[4].

- Real-time Tracking: Choose systems that offer real-time tracking of reel movements and provide accurate stock information. This eliminates the risk of human errors in manual record-keeping and ensures that manufacturers have up-to-date inventory data[3].

Implementing the Best SMT Reel Rack

Once you've chosen the right SMT reel rack, proper implementation is crucial to maximize its benefits.

Planning and Placement

- Proximity to Production Lines: Place the storage system close to production lines to reduce material handling time. This proximity can significantly enhance production efficiency by minimizing travel distances and reducing the time spent on retrieving components[4].

- Material Flow Patterns: Consider the flow of materials to ensure smooth operations. Understanding how components move through your facility can help optimize the placement of storage systems, reducing bottlenecks and improving overall workflow efficiency.

Training and Maintenance

- Operational Training: Ensure your team is trained to operate the storage and retrieval mechanisms effectively. Proper training can reduce errors and enhance the efficiency of component retrieval.

- Maintenance Schedules: Establish clear maintenance schedules to prevent system downtime. Regular maintenance ensures that the storage system operates smoothly and efficiently, minimizing the risk of mechanical failures.

Benefits of Using the Right SMT Reel Rack

Choosing the right SMT reel rack can lead to significant improvements in operational efficiency and cost savings.

- Increased Efficiency: Automated systems can reduce kitting time from hours to minutes, enhancing production speed. For instance, a medium-sized electronics manufacturer saw a 50% decrease in time spent retrieving components after implementing a vertical carousel SMT reel storage system[4].

- Reduced Errors: Guided retrieval systems minimize errors in component selection, ensuring that the correct components are used in production. This accuracy is crucial for maintaining high-quality products and reducing rework.

- Cost Savings: Improved inventory management and reduced labor costs contribute to overall cost savings. Many manufacturers report an ROI within 3-6 months due to increased efficiency, reduced errors, and better inventory management[4].

Case Studies: Successful Implementations

Several companies have seen significant benefits from implementing advanced SMT reel storage systems:

1. Electronics Manufacturer: A medium-sized electronics manufacturer improved efficiency by 70% in floor space usage and reduced component retrieval time by 50% after implementing a vertical carousel system. They also achieved 99.9% inventory accuracy[4].

2. Large Production Facility: A large electronics production facility invested in a fully automated AS/RS for SMT reel storage. The results included a 90% reduction in manual handling of components, a 30% increase in overall production efficiency, and zero incidents of component mix-ups or losses[4].

The Future of SMT Reel Storage: Intelligent Systems

The SMT reel storage industry is evolving with the introduction of intelligent systems that leverage advanced technologies like IoT, AI, and machine learning to optimize inventory management and streamline production processes[3]. These systems provide real-time inventory visibility, enabling manufacturers to make informed decisions about procurement and inventory management. By integrating barcode or RFID technology, intelligent SMT reel storage systems offer accurate tracking of reel movements, reducing the risk of stockouts or excess inventory[3].

Conclusion

Selecting the best SMT reel rack for your PCB assembly needs involves careful consideration of storage capacity, space efficiency, accessibility, environmental control, and integration with existing systems. By choosing a system that meets these criteria, you can significantly enhance your factory's productivity, reduce operational costs, and position your business for future growth and technological advancements.

Frequently Asked Questions

1. What are the primary benefits of using SMT reel racks in PCB assembly?

The primary benefits include improved component protection, enhanced inventory management, optimized space utilization, and increased production efficiency. SMT reel racks also help reduce errors and costs associated with manual handling and storage.

2. How do SMT reel racks protect electronic components from environmental factors?

SMT reel racks protect components by providing ESD protection and maintaining stable temperature and humidity conditions. This ensures that sensitive electronic components remain in optimal condition, reducing the risk of damage during storage.

3. What features should I look for in an automated SMT reel storage system?

When selecting an automated SMT reel storage system, look for features such as guided retrieval systems, real-time inventory tracking, and integration with existing software systems. Also, consider the level of automation needed, from manual to fully automated solutions.

4. How can SMT reel racks improve production efficiency in PCB assembly?

SMT reel racks improve production efficiency by providing quick and easy access to components, reducing setup times, and minimizing errors in component selection. Automated systems can also retrieve components rapidly, significantly speeding up the production process.

5. What are the long-term benefits of investing in a high-quality SMT reel rack system?

Investing in a high-quality SMT reel rack system can lead to long-term benefits such as increased operational efficiency, reduced costs, and improved inventory management. It also positions your business for future growth by enhancing scalability and adaptability to changing production needs.

Citations:

[1] https://www.southwestsolutions.com/ssg/material-handling/smt-reel-storage-solutions/

[2] https://vohrum.com/unlocking-the-full-potential-of-surface-mount-technology-tips-and-techniques-for-efficient-implementation/

[3] https://pmarketresearch.com/auto/intelligent-smt-reel-storage-system-market/

[4] https://www.gssmt-parts.com/how-to-choose-the-best-smt-reel-storage-system-for-your-factory.html

[5] https://global.neotel.tech/2023/01/05/what-is-smt-reel-storage-solution/

[6] https://smtmachineline.com/smd-reel-storage-solution-vs-storage-rack/

[7] https://www.abelwomack.com/take-your-pick-efficiency-accuracy-or-reel-disorganization-blog/

[8] https://www.infismash.com/smt-reel-storage/

[9] https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

[10] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[11] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[12] https://www.epsprogramming.com/blog/challenges-component-packaging-assembly-line/

[13] https://www.smthelp.com/sir7000b-intelligent-smt-reel-rack-7inch.html

[14] https://global.neotel.tech/2023/01/02/how-to-implement-intelligent-storage-system-in-smt-industry/

[15] https://groupdiy.com/threads/diy-storage-of-smt-reels.34948/

[16] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[17] https://www.riverpublishers.com/downloadchapter.php?file=RP_9788770228282C17.pdf

[18] https://johnnyjigs.com/blogs/news/basic-slow-pitch-jigging-reel-storage-and-maintenance-tips

[19] https://kicthermal.com/wp-content/uploads/2012/11/Process-Guidelines-to-Ensure-Optimal-SMT-Electronics-Assembly-98776-R0.pdf.pdf

[20] https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html