Content Menu

● Understanding SMT Technology

● Key Factors to Consider When Choosing SMT Equipment

>> 1. Production Volume and Flexibility

>> 2. PCB Complexity and Component Mix

>> 3. Accuracy and Quality

>> 4. Software Integration and Industry 4.0 Compatibility

>> 5. Vendor Reputation and Future Development

>> 6. Scalability and Future-Proofing

● Types of SMT Equipment

● Common Mistakes When Choosing SMT Equipment

● Evaluating Total Cost of Ownership (TCO)

● Case Studies of Successful SMT Implementations

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How do I determine my production volume needs?

>> 3. What are key features to look for in pick-and-place machines?

>> 4. Why is software integration important in SMT equipment?

>> 5. How can I ensure my SMT line is future-proof?

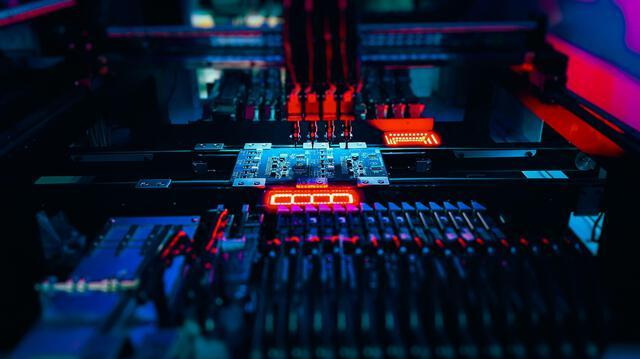

Choosing the best Surface Mount Technology (SMT) equipment line for your factory is crucial for optimizing production efficiency, ensuring product quality, and maintaining cost-effectiveness. This article provides a comprehensive guide on how to select the right SMT equipment line tailored to your specific manufacturing needs, covering essential factors such as production volume, equipment capabilities, vendor reputation, and future scalability.

Understanding SMT Technology

Surface Mount Technology (SMT) is a method used in electronic assembly that allows components to be mounted directly onto the surface of printed circuit boards (PCBs). This technology has revolutionized the electronics manufacturing industry by enabling the production of smaller, more complex, and highly efficient PCBs. The SMT assembly process typically involves several key steps:

- Solder Paste Printing: Applying solder paste to PCB pads using a stencil.

- Component Placement: Positioning surface mount devices (SMDs) onto the solder paste.

- Reflow Soldering: Heating the assembly to melt the solder, creating electrical connections.

Key Factors to Consider When Choosing SMT Equipment

1. Production Volume and Flexibility

Assess your current and projected production volumes. Different types of SMT equipment cater to varying production scales:

- High-volume production: Requires faster, automated machines capable of handling large batches efficiently.

- Low-volume production: May benefit from flexible, multi-purpose machines that allow for quick changeovers between different product runs.

Consider throughput rates of pick-and-place machines and their ability to handle various component sizes and types.

2. PCB Complexity and Component Mix

Evaluate the complexity of your PCBs and the variety of components involved:

- Component Sizes: Ensure that your chosen equipment can accommodate a range of sizes from large ICs to tiny 01005 components.

- Mixed Technology Requirements: If you need to handle both through-hole and surface mount components, select equipment that supports mixed technology.

The ability to handle diverse component types will not only streamline your production process but also reduce downtime associated with machine adjustments.

3. Accuracy and Quality

Precision is paramount in SMT assembly. Look for equipment that offers:

- High Placement Accuracy: Aim for ±0.05mm or better for fine-pitch components.

- Advanced Vision Systems: These systems enhance component recognition and alignment.

- Closed-loop Feedback Systems: These systems help maintain continuous accuracy improvements.

Quality assurance mechanisms should be integrated into every stage of the SMT process to minimize defects and rework costs.

4. Software Integration and Industry 4.0 Compatibility

Modern SMT equipment should seamlessly integrate with existing systems:

- MES Compatibility: Ensure compatibility with your Manufacturing Execution System for better data management.

- Data Collection Capabilities: Choose machines that can collect and analyze production data for performance optimization.

Industry 4.0 principles emphasize connectivity and data-driven decision-making, making software integration a critical factor in modern manufacturing environments.

5. Vendor Reputation and Future Development

Selecting a reputable vendor is essential:

- Proven Track Record: Look for manufacturers with a history of reliability in the SMT industry.

- Ongoing R&D Commitment: Vendors should demonstrate a commitment to innovation and product improvements.

Researching customer reviews and case studies can provide insights into a vendor's reliability and service quality.

6. Scalability and Future-Proofing

Anticipate future needs by considering:

- Upgradeability: Machines should allow for software and hardware upgrades as technology evolves.

- Emerging Component Technologies: Ensure compatibility with new component types that may arise in the future.

Investing in scalable solutions will save costs in the long run by reducing the need for frequent replacements or major overhauls as your production demands change.

Types of SMT Equipment

Understanding the various types of SMT equipment available is crucial in making an informed decision:

- Solder Paste Printers: Essential for applying solder paste accurately to PCB pads. Look for printers that offer high precision and adjustable speed settings.

- Pick-and-Place Machines: The heart of any SMT line; these machines place components onto PCBs with high speed and precision. Consider machines with multi-nozzle heads for increased efficiency.

- Reflow Ovens: Used for melting solder paste to create electrical connections between components and PCB pads. Evaluate temperature profiles and heating methods (convection vs. infrared) based on your specific solder paste requirements.

- Automated Optical Inspection (AOI): Ensures quality control by inspecting PCB assemblies for defects before they proceed further in the manufacturing process. Invest in AOI systems that utilize advanced imaging technologies for higher defect detection rates.

Common Mistakes When Choosing SMT Equipment

Avoid these common pitfalls during your selection process:

- Overemphasis on Price: While budget is important, focusing solely on cost can lead to suboptimal choices that affect productivity and quality.

- Neglecting After-Sales Service: Ensure that vendors offer robust support services post-purchase, including training, maintenance, and troubleshooting assistance.

- Blindly Pursuing High Performance: Consider whether high-speed equipment aligns with your actual production needs rather than just choosing the fastest option available.

Additionally, failing to involve key stakeholders in the decision-making process can lead to equipment choices that do not meet operational requirements or employee capabilities.

Evaluating Total Cost of Ownership (TCO)

When selecting SMT equipment, it's essential to evaluate not just the initial purchase price but also the total cost of ownership (TCO). TCO encompasses all costs associated with acquiring, operating, maintaining, and disposing of equipment over its lifespan. Key factors include:

- Initial Purchase Price: The upfront cost of acquiring the machinery.

- Operating Costs: Energy consumption, labor costs associated with operation, and materials required for maintenance.

- Maintenance Costs: Regular maintenance schedules can incur additional costs over time; factor these into your TCO analysis.

By understanding TCO, manufacturers can make more informed decisions about which machines provide long-term value rather than just short-term savings.

Case Studies of Successful SMT Implementations

To illustrate how careful selection of SMT equipment can lead to successful outcomes, consider these case studies:

1. Electronics Manufacturer A faced challenges with slow production rates due to outdated pick-and-place machines. By investing in high-speed pick-and-place technology with advanced vision systems, they increased their output by 40% while reducing defect rates significantly thanks to improved placement accuracy.

2. Consumer Electronics Company B needed flexibility due to varying product lines. They opted for modular SMT equipment that allowed quick changeovers between different products without extensive downtime. This adaptability led to a 30% reduction in lead times across their manufacturing processes.

3. Automotive Supplier C implemented an integrated MES solution alongside new SMT machinery. This combination enabled real-time monitoring of production metrics, leading to data-driven decisions that improved overall efficiency by 25% within six months post-installation.

These examples highlight how strategic investments in modern SMT equipment can yield significant operational improvements when aligned with specific business objectives.

Conclusion

Choosing the best SMT equipment line for your factory requires careful consideration of multiple factors including production volume, PCB complexity, accuracy requirements, software integration, vendor reputation, scalability, total cost of ownership (TCO), and real-world case studies demonstrating successful implementations. By following these guidelines, manufacturers can optimize their production capabilities while ensuring high-quality outputs in a competitive market landscape.

FAQ

1. What is Surface Mount Technology (SMT)?

SMT is an assembly method where electronic components are mounted directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs and automated manufacturing processes.

2. How do I determine my production volume needs?

Assess your current output levels alongside projected growth based on market demands or new product introductions to choose appropriate equipment configurations.

3. What are key features to look for in pick-and-place machines?

Key features include placement speed, accuracy (±0.05mm), component size capabilities (supporting sizes like 0402), and advanced vision systems for alignment.

4. Why is software integration important in SMT equipment?

Software integration facilitates seamless communication between machines, enhances data collection for analysis, and supports remote monitoring which improves overall efficiency.

5. How can I ensure my SMT line is future-proof?

Select machines that allow upgrades in software/hardware, ensure compatibility with emerging technologies, and choose vendors committed to ongoing research and development efforts.