Content Menu

● Understanding SMT Technology

● Key Factors to Consider When Choosing an SMT Equipment Manufacturer

>> 1. Reputation and Experience

>> 2. Product Range and Capabilities

>> 3. Technical Support and Service

>> 4. Spare Parts Availability

>> 5. Industry Standards and Certifications

>> 6. Price vs. Value

● Evaluating Potential Manufacturers

● Additional Considerations

>> 1. Technological Advancements

>> 2. Global Reach vs Local Support

>> 3. User-Friendly Interface

>> 4. Warranty and Guarantees

● Conclusion

● FAQ

>> 1. What should I look for in an SMT machine?

>> 2. How important is technical support from an SMT manufacturer?

>> 3. Are all SMT machines customizable?

>> 4. What certifications should an SMT manufacturer have?

>> 5. How do I assess a manufacturer's reputation?

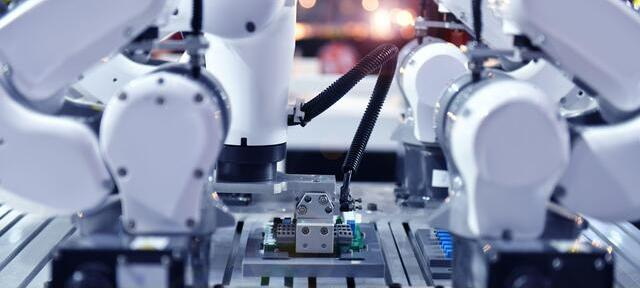

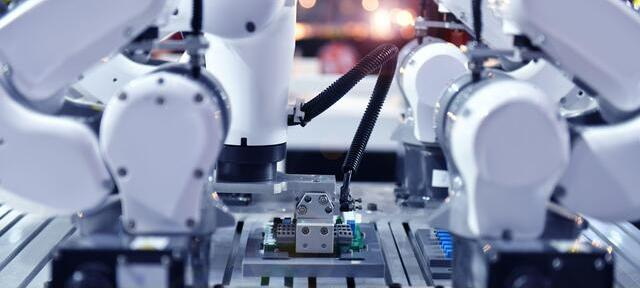

Selecting a reliable Surface Mount Technology (SMT) equipment manufacturer is crucial for electronics manufacturers aiming to enhance production efficiency and product quality. The right manufacturer can significantly impact the performance, reliability, and longevity of SMT machines, which are essential for assembling electronic components on printed circuit boards (PCBs). This article outlines key factors to consider when choosing an SMT equipment manufacturer, ensuring that your investment aligns with your production needs.

Understanding SMT Technology

Surface Mount Technology (SMT) is a method used in the electronics manufacturing industry to mount electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, SMT allows for smaller components and higher density layouts, resulting in more compact and efficient electronic devices. The process involves several critical steps, including solder paste application, component placement, and soldering.

Key Factors to Consider When Choosing an SMT Equipment Manufacturer

Choosing the right SMT equipment manufacturer involves evaluating several critical factors:

1. Reputation and Experience

The manufacturer's reputation in the industry is paramount. Look for companies with a proven track record of producing high-quality SMT machines. Consider their years of operation, customer reviews, and case studies that showcase their expertise. A reputable manufacturer typically adheres to industry standards and certifications that reflect their commitment to quality.

A well-established manufacturer often has a history of innovation and adaptation to changing technologies. They are more likely to invest in research and development, ensuring their machines incorporate the latest advancements in SMT technology.

2. Product Range and Capabilities

Assess the manufacturer's product offerings to ensure they align with your specific requirements. Key aspects to evaluate include:

- Machine Types: Ensure they offer a variety of machines suitable for your production volumes, whether low-volume prototypes or high-volume mass production.

- Specifications: Look for machines with high placement speed (measured in components per hour), accuracy, and flexibility in handling different component sizes.

- Customization Options: Determine if the manufacturer can customize machines according to your unique needs, such as feeder configurations or software interfaces.

In addition to these factors, consider the adaptability of the machines for future technological advancements. As electronic components evolve, having equipment that can accommodate new types or sizes will be beneficial.

3. Technical Support and Service

A reliable manufacturer should provide comprehensive technical support throughout the machine's lifecycle. This includes:

- Installation Services: Assistance with setting up the equipment in your facility.

- Training Programs: Ensuring your staff is well-trained on machine operation and maintenance.

- After-Sales Support: Access to a responsive customer service team for troubleshooting and repairs.

The importance of ongoing support cannot be overstated. In the fast-paced electronics manufacturing environment, any downtime can lead to significant losses. Manufacturers that offer proactive maintenance services can help mitigate these risks by ensuring that equipment remains in optimal working condition.

4. Spare Parts Availability

Inquire about the availability of spare parts for the machines you are considering. A good manufacturer should have a robust supply chain for spare parts to minimize downtime during repairs or maintenance. This availability is crucial for maintaining production efficiency over time.

Additionally, consider the cost and lead time associated with obtaining spare parts. Manufacturers with local distribution centers may offer faster service compared to those relying on international shipping.

5. Industry Standards and Certifications

Check if the manufacturer complies with relevant industry standards such as ISO 9001 or IPC-A-610. Certifications indicate a commitment to quality management systems and adherence to best practices in manufacturing processes.

Furthermore, certifications related to environmental management (like ISO 14001) can also be important if sustainability is a priority for your company. Manufacturers that prioritize eco-friendly practices may align better with your corporate values and customer expectations.

6. Price vs. Value

While price is an important consideration, it should not be the sole factor in your decision-making process. Compare pricing among different manufacturers while considering the features, capabilities, and support services offered. Often, investing slightly more in a reliable machine can save costs in repairs and downtime in the long run.

It's also worth considering total cost of ownership (TCO), which includes initial purchase price, operational costs (such as energy consumption), maintenance expenses, and potential resale value at the end of its lifecycle.

Evaluating Potential Manufacturers

Once you have identified potential manufacturers based on the above criteria, it's essential to conduct thorough evaluations:

- Factory Visits: If possible, arrange visits to their manufacturing facilities to assess their production processes firsthand.

- Customer References: Request references from existing customers to gain insights into their experiences regarding reliability and support.

- Trial Runs: Some manufacturers may offer trial periods for their machines or allow you to see them in operation at other facilities.

During factory visits, pay attention to cleanliness, organization, and adherence to safety protocols as these factors often reflect a company's commitment to quality manufacturing practices.

Additional Considerations

In addition to the primary factors discussed above, there are several other considerations that can influence your choice of an SMT equipment manufacturer:

1. Technological Advancements

The electronics industry is rapidly evolving with new technologies emerging regularly. Look for manufacturers that actively invest in research and development (R&D) to stay ahead of trends such as automation, artificial intelligence (AI), and Industry 4.0 solutions that integrate IoT capabilities into manufacturing processes.

2. Global Reach vs Local Support

Consider whether you prefer working with a global manufacturer or a local one. Global manufacturers may offer advanced technology but might lack personalized support due to distance or time zone differences. Local manufacturers may provide quicker response times but could have limitations regarding technology offerings.

3. User-Friendly Interface

Evaluate whether the machine's software interface is user-friendly. A complicated interface can lead to operational inefficiencies and increased training time for staff members who need to learn how to use it effectively.

4. Warranty and Guarantees

Investigate what warranties or guarantees are offered on machinery purchases. A solid warranty can provide peace of mind regarding potential defects or issues arising shortly after purchase.

Conclusion

Choosing a reliable SMT equipment manufacturer requires careful consideration of multiple factors including reputation, product range, technical support, spare parts availability, compliance with industry standards, overall value for money, technological advancements, global reach versus local support, user interface design, and warranty provisions. By conducting thorough research and evaluations based on these criteria, you can make an informed decision that aligns with your production goals while ensuring long-term satisfaction with your equipment investment.

FAQ

1. What should I look for in an SMT machine?

When selecting an SMT machine, consider placement speed, accuracy, machine repeatability, component size capability, and available technical support from the manufacturer.

2. How important is technical support from an SMT manufacturer?

Technical support is crucial as it ensures that you can effectively operate and maintain your equipment. Look for manufacturers that offer comprehensive training and responsive customer service.

3. Are all SMT machines customizable?

Not all manufacturers offer customization options; it varies by company. It's essential to discuss your specific needs with potential manufacturers to determine if they can accommodate customization requests.

4. What certifications should an SMT manufacturer have?

Look for certifications such as ISO 9001 for quality management systems or IPC-A-610 for electronics assembly quality standards as indicators of a manufacturer's commitment to quality.

5. How do I assess a manufacturer's reputation?

Research online reviews, request customer references, and check industry publications or forums where professionals discuss their experiences with various manufacturers.