Content Menu

● Understanding SMD and SMT

>> The Importance of Learning SMD and SMT Skills

● Why Use a Practice Board?

● Key Features to Look for in a Practice Board

>> 1. Component Variety

>> 2. Size of Components

>> 3. Clear Markings

>> 4. Separate Practice Areas

>> 5. Availability of Resources

● Recommended Practice Boards

>> Additional Recommendations

● Tools Needed for SMD/SMT Practice

>> Essential Accessories

● Learning Techniques

>> 1. Start with Simple Components

>> 2. Use Flux Generously

>> 3. Practice Different Techniques

>> 4. Inspect Your Work

>> 5. Seek Feedback

>> 6. Document Your Progress

● Resources for Learning

● Troubleshooting Common Issues

>> Cold Joints

>> Bridges

>> Component Misalignment

● Conclusion

● FAQ

>> 1. What is the best practice board for beginners?

>> 2. Can I use regular solder for SMD work?

>> 3. How do I know if my solder joints are good?

>> 4. What tools do I need for SMD soldering?

>> 5. Where can I find additional resources for learning?

● Citations:

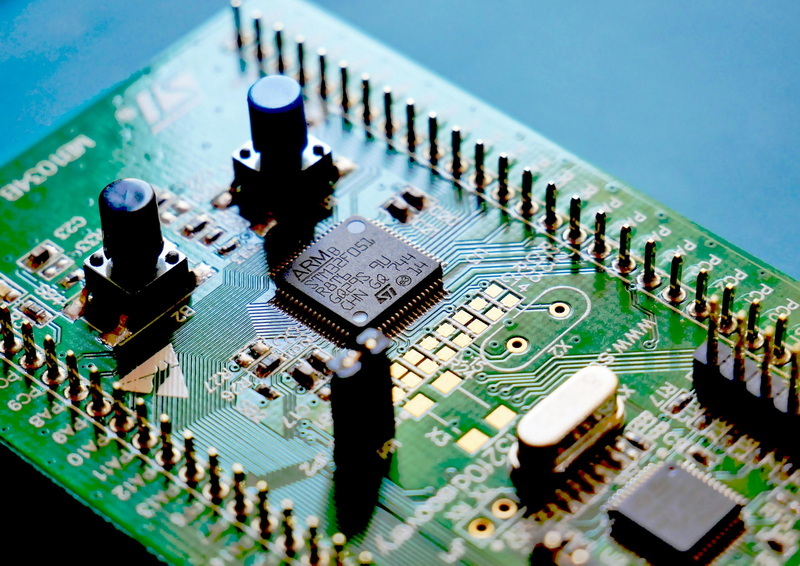

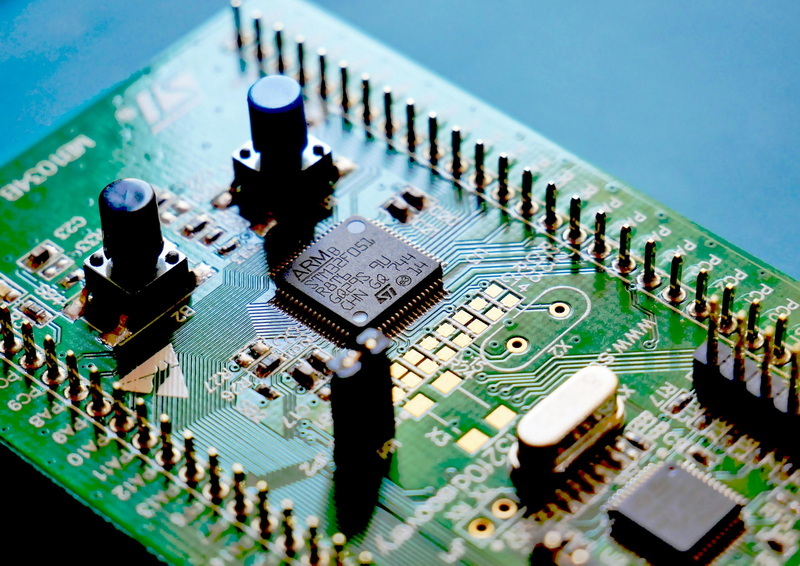

Learning Surface Mount Device (SMD) and Surface Mount Technology (SMT) soldering skills is essential for anyone interested in electronics, whether you're a hobbyist or a professional. A practice board can significantly enhance your learning experience by providing a hands-on approach to mastering these techniques. This article will guide you through the process of selecting an appropriate practice board, along with tips, resources, and frequently asked questions.

Understanding SMD and SMT

SMD refers to components that are mounted directly onto the surface of a printed circuit board (PCB), while SMT is the technology used to solder these components onto the PCB. The main advantages of SMD and SMT include:

- Compact Design: SMD components are smaller than traditional through-hole components, allowing for more compact circuit designs.

- Automated Assembly: SMT is compatible with automated assembly processes, which increases production efficiency.

- Improved Performance: SMD components typically have better electrical performance due to shorter lead lengths.

The Importance of Learning SMD and SMT Skills

As technology advances, the demand for skilled technicians who can work with SMD and SMT components continues to grow. Proficiency in these skills opens up numerous opportunities in various fields, including:

- Consumer Electronics: From smartphones to laptops, most modern devices utilize SMD technology.

- Automotive Industry: Many vehicles now feature advanced electronics that require SMT assembly.

- Medical Devices: Precision and reliability are crucial in medical electronics, making SMD skills highly valuable.

Why Use a Practice Board?

A practice board offers several benefits for beginners learning SMD and SMT skills:

- Hands-On Experience: Provides practical experience in soldering techniques.

- Error Correction: Allows you to make mistakes without the fear of damaging valuable components.

- Skill Development: Helps build confidence in handling small components and using soldering tools.

Key Features to Look for in a Practice Board

When choosing a practice board, consider the following features:

1. Component Variety

A good practice board should include a range of SMD components such as resistors, capacitors, diodes, and integrated circuits (ICs). This variety will help you learn different soldering techniques.

2. Size of Components

Look for boards that feature various sizes of components (e.g., 0805, 0603). Starting with larger components can ease the learning curve before moving on to smaller ones.

3. Clear Markings

Ensure that the practice board has clear markings for component placement and polarity. This will help you understand where each component goes and how to orient them correctly.

4. Separate Practice Areas

Some boards have designated areas for practice that do not affect the working circuit. This feature allows you to hone your skills without compromising the integrity of your projects.

5. Availability of Resources

Choose boards that come with instructional materials or links to online tutorials. These resources can provide valuable guidance as you learn.

Recommended Practice Boards

Here are some popular practice boards that cater to beginners:

| Board Name | Features | Price Range |

| SMD Rotating LED Skill Training Kit | Includes various SMD components; clear markings | $10 - $20 |

| Gikfun DIY SMD SMT Welding Practice Board | Multiple component sizes; good instructional support | $5 - $15 |

| Electrodragon SMD Soldering Skills Training Board | Affordable; includes various SMDs for practice | $1 - $3 |

Additional Recommendations

Apart from the boards listed above, consider exploring custom or DIY practice boards available from various online platforms. These often allow you to design your own layout with specific components tailored to your learning goals.

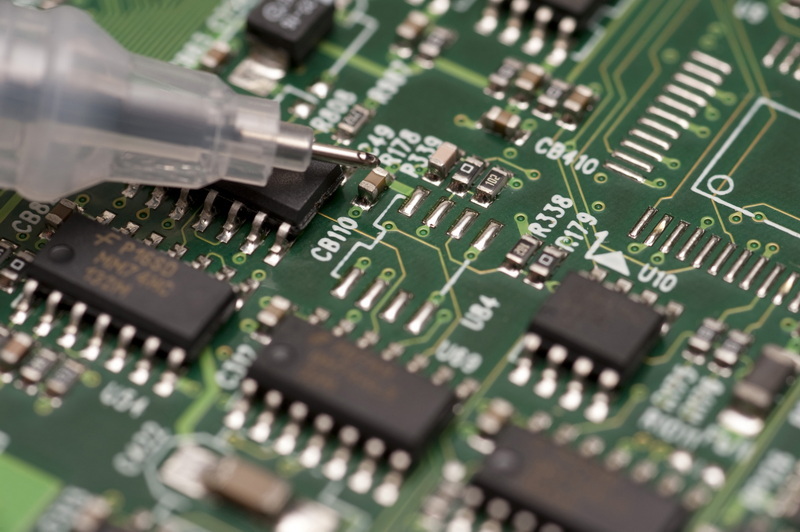

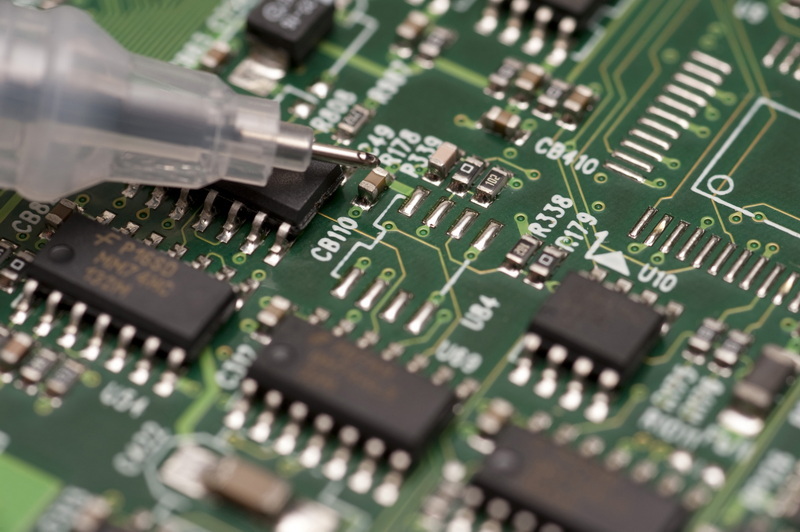

Tools Needed for SMD/SMT Practice

To effectively use a practice board, you'll need some essential tools:

- Soldering Iron: A fine-tipped soldering iron is crucial for precision work.

- Tweezers: Use ceramic-tipped tweezers to handle small components without causing damage.

- Solder: Choose lead-free solder for a more environmentally friendly option.

- Flux: Flux helps improve solder flow and adhesion.

- Magnifying Glass or Microscope: Useful for inspecting small joints and ensuring quality.

- Desoldering Tools: A desoldering pump or wick can help correct mistakes by removing excess solder.

Essential Accessories

In addition to the primary tools mentioned above, consider investing in accessories such as:

- Soldering Mat: A heat-resistant mat protects your work surface while providing a non-slip area for your board and tools.

- ESD Wrist Strap: An electrostatic discharge wrist strap can prevent damage to sensitive electronic components during handling.

- Lighting: Good lighting is essential when working with small parts; consider using a bright LED lamp or a magnifying lamp with built-in illumination.

Learning Techniques

Once you have your practice board and tools ready, here are some techniques to enhance your learning:

1. Start with Simple Components

Begin by practicing with larger components like resistors before moving on to smaller ones like capacitors and ICs. This gradual progression helps build confidence.

2. Use Flux Generously

Applying flux before soldering can help improve the flow of solder and make it easier to position components accurately.

3. Practice Different Techniques

Experiment with various soldering techniques such as drag soldering or using solder paste for surface mount applications.

4. Inspect Your Work

After soldering each component, inspect your work under magnification to identify any issues such as cold joints or bridges between pads.

5. Seek Feedback

Join online forums or local electronics clubs where you can share your work and receive constructive feedback from experienced hobbyists or professionals.

6. Document Your Progress

Keep a journal of your practice sessions, noting what techniques worked well and what challenges you faced. This documentation can help track your improvement over time.

Resources for Learning

There are numerous online resources available to aid your learning process:

- YouTube Tutorials: Channels dedicated to electronics often provide step-by-step guides on SMD soldering techniques.

YouTube Tutorials

- Online Courses: Websites like Udemy or Coursera offer courses specifically focused on electronics and soldering skills.

Online Courses

- Forums: Communities like Reddit's r/soldering provide a platform for asking questions and sharing experiences with fellow learners.

Forums

Troubleshooting Common Issues

As you practice, you may encounter common issues while soldering SMD components. Here are some troubleshooting tips:

Cold Joints

Cold joints occur when the solder does not melt properly, leading to poor electrical connections. To fix this issue:

- Reheat the joint until the solder flows smoothly.

- Ensure that both the pad and component lead are heated adequately before applying solder.

Bridges

Bridges happen when excess solder creates an unintended connection between two pads. To resolve this:

- Use a desoldering pump or wick to remove excess solder carefully.

- Reapply solder only where necessary after correcting the bridge.

Component Misalignment

If a component is misaligned during placement:

- Use tweezers to gently reposition it before applying heat from the soldering iron.

Conclusion

Choosing the right practice board is crucial for mastering SMD and SMT skills effectively. By considering factors like component variety, size, markings, and available resources, you can select a board that meets your learning needs. Remember to equip yourself with the necessary tools and adopt effective learning techniques to enhance your soldering skills. With dedication and practice, you'll be well on your way to becoming proficient in SMD and SMT technology.

FAQ

1. What is the best practice board for beginners?

The best practice board varies by individual preference but boards like the Gikfun DIY SMD SMT Welding Practice Board are popular due to their affordability and variety of components.

2. Can I use regular solder for SMD work?

While you can use regular solder, it's recommended to use lead-free solder as it is more environmentally friendly and commonly used in professional settings.

3. How do I know if my solder joints are good?

Good solder joints should be shiny, smooth, and have a concave shape. Inspect them under magnification for cold joints or bridges between pads.

4. What tools do I need for SMD soldering?

Essential tools include a fine-tipped soldering iron, tweezers, flux, lead-free solder, and a magnifying glass or microscope.

5. Where can I find additional resources for learning?

YouTube tutorials, online courses on platforms like Udemy, and forums such as Reddit's r/soldering are excellent resources for further learning.

Citations:

[1] https://www.instructables.com/SMD-Soldering-Practice-Kit-or-How-I-Learned-to-Sto/

[2] https://www.youtube.com/watch?v=OXDhn-Q34SE

[3] https://www.reddit.com/r/soldering/comments/19aqrml/i_got_an_smd_practice_kit_easiest_place_to_start/

[4] https://shopee.sg/product/135054553/25304434558

[5] https://www.eevblog.com/forum/beginners/solder-practice-kits-for-technicians/

[6] https://www.ebay.com.sg/itm/262711878482

[7] https://forum.arduino.cc/t/smd-soldering-training-pcbs/184901

[8] https://kaisertech.co.uk/mixed-technology-soldering-practice-boards-smd-kits

[9] https://www.electrodragon.com/product/smd-soldering-skills-training-board/