Content Menu

● Introduction

● What is an SMT Line Technician?

● Steps to Become a Skilled SMT Line Technician

>> 1. Educational Background

>> 2. Acquire Technical Skills

>> 3. Obtain Certifications

>> 4. Hands-On Training

>> 5. Stay Updated

● Skills Required for an SMT Line Technician

● Training and Resources

● Challenges and How to Overcome Them

>> 1. Keeping Up with Technological Advancements

>> 2. Troubleshooting Complex Issues

>> 3. Meeting Quality Standards

● Conclusion

● FAQ

>> 1. What is the role of an SMT line technician?

>> 2. What certifications are beneficial for SMT technicians?

>> 3. How can I gain hands-on experience in SMT?

>> 4. What skills are essential for an SMT technician?

>> 5. Where can I find training resources for SMT?

● Citations:

Introduction

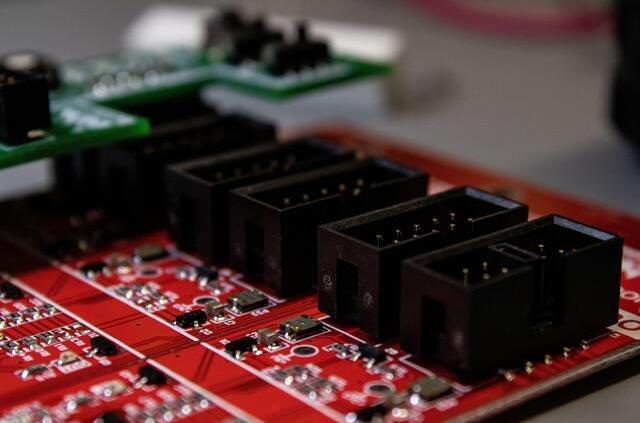

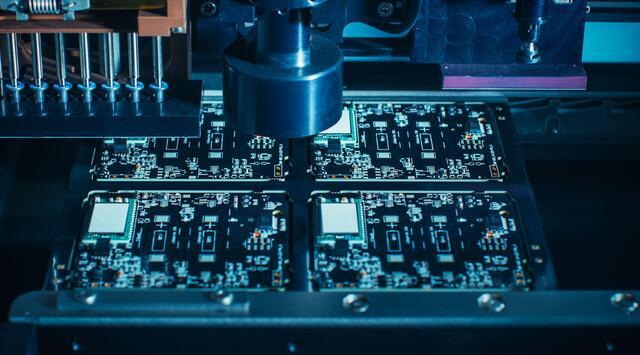

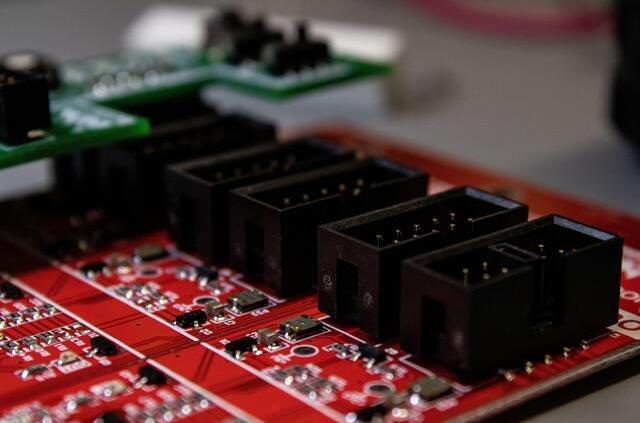

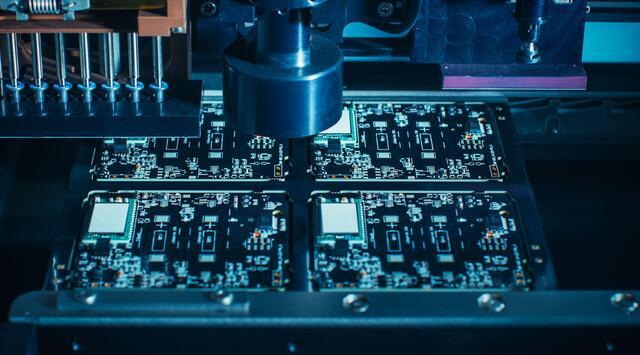

Surface Mount Technology (SMT) is a pivotal process in modern electronics manufacturing, enabling the assembly of electronic components onto printed circuit boards (PCBs) with high efficiency and precision. The role of an SMT line technician is crucial in this process, as they are responsible for operating and maintaining SMT equipment, ensuring quality control, and troubleshooting issues that arise during production. This article outlines the steps, skills, and resources necessary to become a proficient SMT line technician.

What is an SMT Line Technician?

An SMT line technician operates and maintains machines used in the assembly of electronic components onto PCBs. Their responsibilities include:

- Machine Operation: Setting up and running SMT machines such as screen printers, pick-and-place machines, and reflow ovens.

- Quality Control: Monitoring the production process to ensure that products meet quality standards.

- Troubleshooting: Identifying and resolving issues that may arise during the manufacturing process.

- Maintenance: Performing regular maintenance on machines to ensure optimal performance.

The role requires a blend of technical skills, attention to detail, and problem-solving abilities to ensure that electronic devices are manufactured reliably and efficiently.

Steps to Become a Skilled SMT Line Technician

1. Educational Background

- Minimum Requirement: A high school diploma or GED is essential for entry-level positions.

- Further Education: Pursuing a degree in electronics or a related field can provide a competitive edge. Courses in mathematics, physics, and computer science are particularly beneficial.

- Vocational Training: Consider enrolling in vocational programs that focus on electronics or SMT technology.

2. Acquire Technical Skills

To excel as an SMT technician, one must develop various technical skills:

- Operating SMT Machines: Gain hands-on experience with screen printers, pick-and-place machines, and reflow ovens.

- Soldering Skills: Learn proper soldering techniques, which are vital for assembling components onto PCBs.

- PCB Handling: Understand how to handle PCBs safely to avoid damage during the assembly process.

- Measurement Tools: Familiarize yourself with hand tools like calipers and rulers for precise measurements.

3. Obtain Certifications

Certifications can enhance your qualifications and demonstrate your expertise:

- IPC Certifications: Certifications such as IPC-A-610 (Acceptability of Electronic Assemblies), J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies), and IPC-7711/7721 (Rework and Repair) are highly regarded in the industry.

- Training Programs: Attend training programs offered by organizations like the Surface Mount Technology Association (SMTA) or Circuit Technology Training to gain practical knowledge and certification.

4. Hands-On Training

Practical experience is crucial for mastering SMT processes:

- Participate in Workshops: Engage in hands-on training sessions where you can work directly with SMT equipment.

- Internships: Seek internships or entry-level positions in electronics manufacturing companies to gain real-world experience.

- Troubleshooting Practice: Work on identifying common defects and optimizing machine settings during training sessions.

5. Stay Updated

The field of SMT is constantly evolving:

- Continuous Learning: Keep abreast of the latest advancements in SMT technology through workshops, webinars, and industry conferences.

- Professional Organizations: Join organizations like SMTA to network with industry professionals and access valuable resources.

Skills Required for an SMT Line Technician

To be successful in this role, technicians should possess the following skills:

- Technical Proficiency: Ability to operate hand tools and SMT machines effectively.

- Quality Assurance Knowledge: Understanding of PCB assembly processes and quality standards.

- Problem-Solving Skills: Strong analytical skills to troubleshoot issues that arise during production.

- Attention to Detail: Precision is critical in ensuring high-quality assembly.

- Manual Dexterity: Good hand-eye coordination for tasks such as soldering.

- Safety Awareness: Knowledge of ESD precautions and safety protocols to prevent damage to sensitive components.

Training and Resources

Several resources can help you gain the necessary skills for an SMT technician role:

- CORE-emt Training Courses: Offers comprehensive training on SMT equipment and software tailored for new technicians.

- Circuit Technology Training: Provides detailed courses covering all aspects of SMT assembly from basic principles to advanced techniques.

- Online Learning Platforms: Utilize platforms like YouTube for tutorials on specific processes or troubleshooting techniques related to SMT operations.

Challenges and How to Overcome Them

1. Keeping Up with Technological Advancements

The rapid evolution of technology can be overwhelming.

*Solution*: Regularly attend training sessions and industry events to stay informed about new techniques and equipment.

2. Troubleshooting Complex Issues

Diagnosing problems within the production line can be challenging due to the complexity of modern machines.

*Solution*: Develop a systematic approach to troubleshooting by utilizing manuals, online forums, and peer support when faced with difficult issues.

3. Meeting Quality Standards

Ensuring compliance with rigorous quality standards is essential but can be demanding.

*Solution*: Familiarize yourself with relevant standards (e.g., IPC-A-610) and implement best practices consistently throughout your work processes.

Conclusion

Becoming a skilled SMT line technician is a rewarding journey that combines education, training, and continuous learning. By following the outlined steps—gaining educational qualifications, acquiring technical skills, obtaining certifications, participating in hands-on training, and staying updated—you can build a successful career in the electronics manufacturing industry. The role not only involves operating machinery but also ensuring the quality and reliability of products that power our modern world.

FAQ

1. What is the role of an SMT line technician?

An SMT line technician operates and maintains SMT equipment while ensuring efficient production processes and quality control measures are met.

2. What certifications are beneficial for SMT technicians?

Certifications such as IPC-A-610, J-STD-001, and IPC-7711/7721 are highly recommended for those looking to advance their careers in this field.

3. How can I gain hands-on experience in SMT?

Participating in training programs or internships at electronics manufacturing companies provides practical experience working with real SMT equipment.

4. What skills are essential for an SMT technician?

Key skills include troubleshooting abilities, soldering proficiency, PCB handling knowledge, attention to detail, and understanding quality standards.

5. Where can I find training resources for SMT?

Organizations like CORE-emt provide comprehensive courses on SMT technologies; additionally, online resources such as webinars from SMTA can be beneficial.

Citations:

[1] https://core-emt.com/training-courses-on-smt-equipment-smt-software-training

[2] https://www.zippia.com/smt-operator-jobs/skills/

[3] https://smtnet.com/products/index.cfm?fuseaction=browse_products&cat_id=5

[4] https://www.ziprecruiter.com/career/Smt-Operator/What-Is-How-to-Become

[5] https://www.velvetjobs.com/job-descriptions/smt-machine-operator

[6] https://www.circuittechnology.com/Training-ID/49/Training-Category/

[7] https://www.youtube.com/watch?v=Z0Nl4Sc9nyo

[8] https://www.tsscindia.com/App_Files/Documents/1c98b9ba-f100-434c-ac3b-92c693245796TEL_Q2501_Telecom%20SMT%20Technician_v2.0.pdf

[9] https://education.ipc.org/product/ipc-j-std-001-operators

[10] https://www.youtube.com/watch?v=8z3X99iReJM

[11] https://www.psdc.org.my/index.php/academy/jobs/smt-technician-season-malaysia-manufacturing-sdn-bhd

[12] https://www.prideindustries.com/our-stories/smta-certification

[13] https://www.controltek.com/sites/www.controltek.com/files/job-opportunity-documents/SMT%20Machine%20Operator%20I%20(1).pdf

[14] https://careersinelectronics.com/smt-engineer/

[15] https://www.vadatech.com/media/pdf_SMT_Rework_Tech_website_posting_USA_5-18.pdf

[16] https://www.linkedin.com/pulse/smt-engineer-how-become-process-echo-lee-9limc

[17] https://www.ziprecruiter.com/career/SMT-Operator/Resume-Keywords-and-Skills