Content Menu

● The Rise of Chinese SMT Equipment Manufacturing

● Key Features of Modern Chinese SMT Glue Dispensers

>> High Precision and Accuracy

>> Advanced Vision Systems

>> Versatility in Dispensing Materials

>> Automated Cleaning Systems

>> User-Friendly Software

● Reliability Factors of Chinese SMT Glue Dispensing Machines

>> Manufacturing Standards and Quality Control

>> Component Quality

>> Technological Innovation

>> After-Sales Support and Service

● Comparative Analysis: Chinese vs. Western Manufacturers

>> Cost-Effectiveness

>> Technological Gap

>> Customization and Flexibility

>> Long-Term Reliability

● Case Studies and User Experiences

>> LED Manufacturer in Tajikistan

>> Global Adoption of Chinese Dispensing Machines

● Challenges and Areas for Improvement

>> Perception Issues

>> Intellectual Property Concerns

>> Consistency Across Manufacturers

● Future Outlook for Chinese SMT Glue Dispensing Machine Manufacturers

>> Continued Technological Advancement

>> Industry 4.0 Integration

>> Expansion of Global Service Networks

>> Focus on Sustainability

● Conclusion

● FAQ

>> 1. Are Chinese-made SMT glue dispensing machines as accurate as Western models?

>> 2. What types of adhesives can Chinese SMT glue dispensing machines handle?

>> 3. How do Chinese manufacturers ensure the quality of their SMT glue dispensing machines?

>> 4. What after-sales support can I expect from Chinese SMT glue dispensing machine manufacturers?

>> 5. How do Chinese SMT glue dispensing machines compare in terms of cost-effectiveness?

● Citations:

In the rapidly evolving world of electronics manufacturing, Surface Mount Technology (SMT) has become the cornerstone of efficient and high-quality production. Among the critical processes in SMT, glue dispensing plays a pivotal role in ensuring the stability and reliability of components on Printed Circuit Boards (PCBs). As China continues to dominate the global manufacturing landscape, it's essential to examine the reliability of SMT PCB glue dispensing machines produced by Chinese manufacturers.

The Rise of Chinese SMT Equipment Manufacturing

China has emerged as a powerhouse in the production of SMT equipment, including glue dispensing machines. This rise can be attributed to several factors:

1. Cost-effectiveness

2. Rapid technological advancements

3. Vast manufacturing infrastructure

4. Growing domestic and international demand

Chinese manufacturers have invested heavily in research and development, aiming to close the gap with their Western counterparts in terms of quality and innovation. This effort has resulted in a new generation of SMT PCB glue dispensing machines that boast impressive features and capabilities.

Key Features of Modern Chinese SMT Glue Dispensers

High Precision and Accuracy

Modern SMT glue dispensing machines manufactured in China offer remarkable precision. Many models can achieve a dispensing accuracy of ±0.02mm and a repeated accuracy of ±0.01mm[6]. This level of precision is crucial for the increasingly miniaturized components used in modern electronics.

Advanced Vision Systems

Chinese manufacturers have integrated sophisticated vision systems into their dispensing machines. These systems, often utilizing CCD cameras, ensure accurate placement and quality control throughout the dispensing process[5].

Versatility in Dispensing Materials

The latest machines are designed to handle a wide range of adhesives, including:

- Silicone

- Epoxy resin

- UV adhesive

- Conductive adhesive

- AB adhesive[4]

This versatility allows manufacturers to use a single machine for various applications, increasing efficiency and reducing equipment costs.

Automated Cleaning Systems

To maintain consistent performance, many Chinese-made dispensers feature automatic cleaning systems. These systems help prevent clogging and ensure uniform dispensing over extended production runs[5].

User-Friendly Software

Chinese manufacturers have made significant strides in developing intuitive operating software. For instance, the UFD operating software used in some models ensures system stability and reliability, making it easier for operators to manage complex dispensing tasks[5].

Reliability Factors of Chinese SMT Glue Dispensing Machines

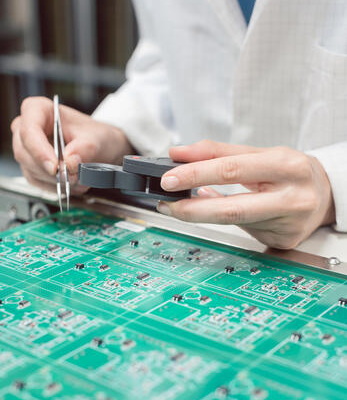

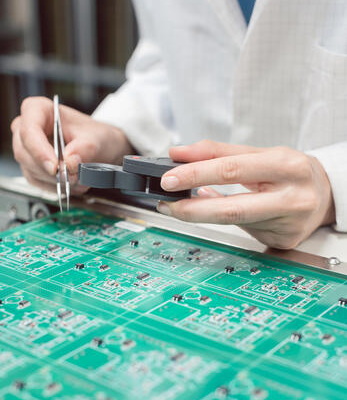

Manufacturing Standards and Quality Control

Leading Chinese manufacturers have adopted international quality standards and implemented rigorous quality control measures. Many machines are CE certified, indicating compliance with European safety standards[3]. This adherence to global standards has significantly improved the overall reliability of Chinese-made dispensing equipment.

Component Quality

While early Chinese machines were often criticized for using lower-quality components, many manufacturers now use internationally renowned components in their dispensing machines. This shift has led to improved durability and performance consistency[3].

Technological Innovation

Chinese manufacturers have invested heavily in research and development, leading to innovative features such as:

- Non-contact jet valves for smaller dispensing diameters

- Chip edge identification for more accurate dispensing

- ID identification and automatic program calling for smart manufacturing[6]

These advancements have enhanced the reliability and efficiency of their dispensing machines.

After-Sales Support and Service

Recognizing the importance of after-sales support, many Chinese manufacturers have established global service networks. For example, some companies provide comprehensive process solutions for development, manufacturing, and product innovation to their customers worldwide[5].

Comparative Analysis: Chinese vs. Western Manufacturers

When comparing Chinese-made SMT glue dispensing machines to those from Western manufacturers, several factors come into play:

Cost-Effectiveness

Chinese manufacturers generally offer more competitive pricing without significantly compromising on quality. This cost advantage has made their machines an attractive option for many electronics manufacturers, especially small to medium-sized enterprises.

Technological Gap

While the technological gap between Chinese and Western manufacturers has narrowed considerably, some industry experts still consider Western machines to have a slight edge in cutting-edge technologies. However, this gap continues to shrink as Chinese manufacturers invest more in R&D.

Customization and Flexibility

Chinese manufacturers often demonstrate greater flexibility in customizing their machines to meet specific customer requirements. This adaptability can be a significant advantage for manufacturers with unique production needs.

Long-Term Reliability

While the long-term reliability of Chinese-made machines has improved dramatically, some users still perceive Western machines as having a slight edge in this area. However, this perception is changing as more success stories emerge from users of Chinese equipment.

Case Studies and User Experiences

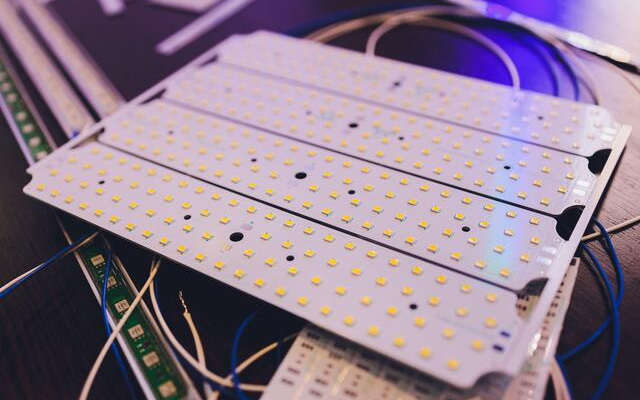

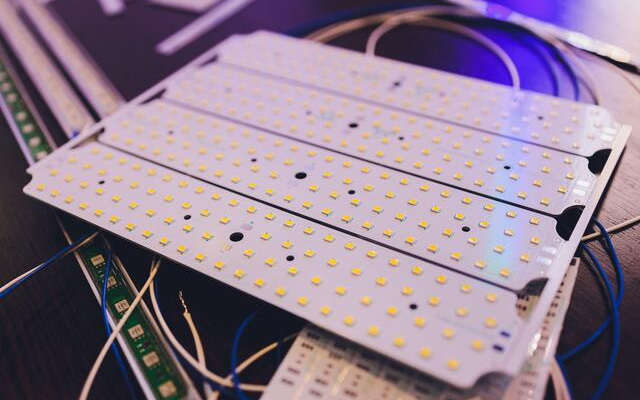

LED Manufacturer in Tajikistan

A LED manufacturer in Tajikistan purchased two complete SMT lines, including dispensing equipment, from a Chinese manufacturer. The lines were capable of producing most LED products, demonstrating the versatility and reliability of Chinese-made equipment in real-world applications[2].

Global Adoption of Chinese Dispensing Machines

Chinese SMT equipment manufacturers have reported successful implementations of their dispensing machines in over 35 countries worldwide. This global adoption indicates growing trust in the reliability of Chinese-made equipment[5].

Challenges and Areas for Improvement

Despite significant advancements, Chinese manufacturers still face some challenges:

Perception Issues

Some potential customers still harbor doubts about the reliability of Chinese-made equipment, based on outdated perceptions or past experiences with lower-quality products.

Intellectual Property Concerns

There have been instances of intellectual property disputes involving Chinese manufacturers, which can impact trust in the industry.

Consistency Across Manufacturers

While leading Chinese manufacturers produce highly reliable equipment, there can be significant quality variations among different manufacturers. Buyers need to research and choose reputable suppliers carefully.

Future Outlook for Chinese SMT Glue Dispensing Machine Manufacturers

The future looks promising for Chinese manufacturers of SMT PCB glue dispensing machines. Several factors contribute to this positive outlook:

Continued Technological Advancement

Chinese manufacturers are likely to continue investing heavily in R&D, further narrowing any remaining technological gaps with Western competitors.

Industry 4.0 Integration

Many Chinese manufacturers are at the forefront of integrating Industry 4.0 concepts into their machines, including features like:

- Smart manufacturing capabilities

- IoT connectivity

- Data analytics for predictive maintenance

Expansion of Global Service Networks

As Chinese manufacturers expand their global presence, they are likely to strengthen their international service and support networks, addressing one of the key concerns of potential customers.

Focus on Sustainability

With growing global emphasis on sustainable manufacturing, Chinese manufacturers are expected to develop more energy-efficient and environmentally friendly dispensing solutions.

Conclusion

The reliability of SMT PCB glue dispensing machines manufactured in China has improved dramatically in recent years. Leading Chinese manufacturers now produce equipment that can compete with Western counterparts in terms of precision, features, and overall quality. While some challenges remain, the continuous investment in technology, adherence to international standards, and focus on customer needs have positioned Chinese manufacturers as strong contenders in the global SMT equipment market.

For electronics manufacturers considering Chinese-made dispensing equipment, it's crucial to research thoroughly, choose reputable suppliers, and consider factors beyond just price. With careful selection, users can benefit from cost-effective, high-quality dispensing solutions that meet the demands of modern electronics production.

As the electronics manufacturing industry continues to evolve, Chinese SMT equipment manufacturers are poised to play an increasingly significant role in shaping its future. Their ability to combine innovation, quality, and cost-effectiveness makes them a force to be reckoned with in the global market for SMT PCB glue dispensing machines.

FAQ

1. Are Chinese-made SMT glue dispensing machines as accurate as Western models?

Many Chinese-made SMT glue dispensing machines now offer accuracy levels comparable to Western models. For instance, some machines achieve a dispensing accuracy of ±0.02mm and a repeated accuracy of ±0.01mm[6]. However, it's important to note that accuracy can vary between manufacturers and models, so it's crucial to check the specifications of individual machines.

2. What types of adhesives can Chinese SMT glue dispensing machines handle?

Modern Chinese SMT glue dispensing machines are designed to work with a wide range of adhesives. These typically include silicone, epoxy resin, UV adhesive, conductive adhesive, and AB adhesive[4]. This versatility allows manufacturers to use a single machine for various applications, increasing efficiency and reducing equipment costs.

3. How do Chinese manufacturers ensure the quality of their SMT glue dispensing machines?

Chinese manufacturers have implemented several measures to ensure quality:

- Adoption of international quality standards

- Rigorous quality control processes

- Use of high-quality, internationally sourced components

- Compliance with safety standards (e.g., CE certification)

- Continuous investment in R&D to improve product performance and reliability[3]

4. What after-sales support can I expect from Chinese SMT glue dispensing machine manufacturers?

Many Chinese manufacturers have recognized the importance of after-sales support and have established global service networks. Some companies offer comprehensive process solutions, including support for development, manufacturing, and product innovation. However, the level of support can vary between manufacturers, so it's advisable to inquire about specific after-sales services when considering a purchase[5].

5. How do Chinese SMT glue dispensing machines compare in terms of cost-effectiveness?

Chinese-made SMT glue dispensing machines generally offer a more competitive price point compared to Western counterparts, often without significantly compromising on quality. This cost advantage has made them an attractive option for many electronics manufacturers, especially small to medium-sized enterprises. However, it's important to consider the total cost of ownership, including factors like reliability, maintenance needs, and after-sales support, rather than just the initial purchase price.

Citations:

[1] https://www.hct-smt.com/products/glue-dispenser

[2] https://www.smtfactory.com/I-C-T-SMT-automated-Glue-dispensing-systems-Dispenser-machine-pd42601860.html

[3] https://smtnet.com/index.cfm?fuseaction=search_submit&searchstring=glue&collection=full_site&start_at=11

[4] https://www.pcbdepanelingrouter.com/supplier-4193635-smt-glue-dispenser-machine

[5] https://m.smt11.com/product/PCBA-Dispensing-Machine/High-Efficiency-Automatic-SMT-PCB-Dispensing-Machine-ETA-D4-175331.html

[6] https://www.smtfactory.com/I-C-T-Automatic-Epoxy-Resin-AB-Glue-Doming-Machine-Dispensing-Machine-for-SMT-Field-pd42071624.html

[7] https://www.smtfactory.com/products/Ab-Glue-Dispensing-Machine.html

[8] https://www.neodensmt.com/news/discussion-on-dispensing-technology-of-smt-32635020.html

[9] https://www.nano-di.com/resources/whitepapers/process-capabilities-smt-glue