Content Menu

● Introduction

● The Role of LED SMT Nozzles in SMT

>> Importance of Precision

>> Enhanced Compatibility

● Advantages of LED SMT Nozzles

>> Increased Precision and Efficiency

>> Cost-Effectiveness

>> Impact on Production Speed and Quality

● Challenges and Solutions

>> Nozzle Wear and Tear

>> Handling Different LED Sizes

>> Solutions Through Material Innovation

● Future Trends in LED SMT Nozzles

>> Smart Nozzle Technology

>> Increased Demand for Customization

>> Integration with Industry 4.0

● The Impact on Various Industries

>> Consumer Electronics

>> Automotive Industry

>> Medical Devices

● Environmental Considerations

>> Reducing Waste

>> Supporting Energy Efficiency

● Conclusion

● FAQ

>> 1. What are LED SMT nozzles?

>> 2. How do LED SMT nozzles improve manufacturing?

>> 3. What are the cost implications of using LED SMT nozzles?

>> 4. Are there any drawbacks to using LED SMT nozzles?

>> 5. What is the future of LED SMT nozzles in the industry?

● Citations:

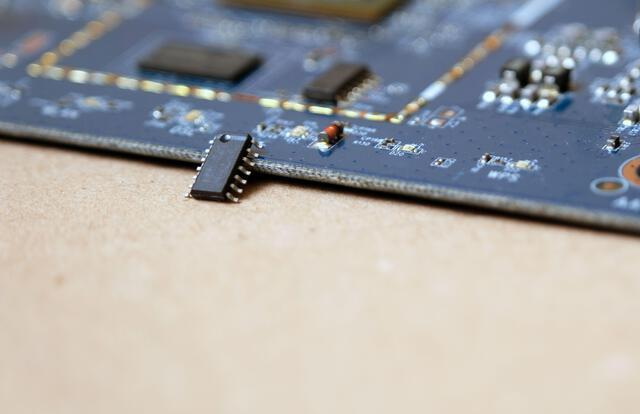

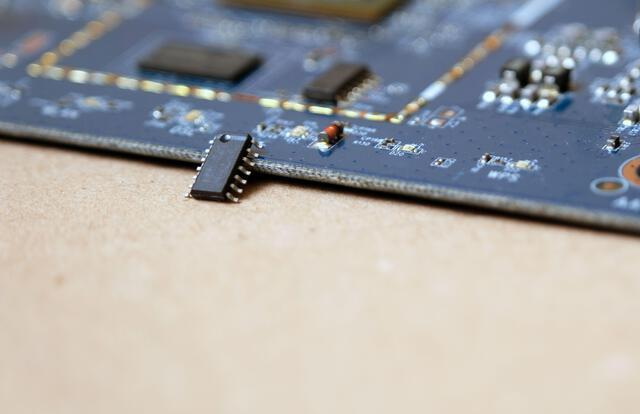

Introduction

Surface-Mount Technology (SMT) has fundamentally transformed the electronics manufacturing industry, enabling components to be mounted directly onto the surface of printed circuit boards (PCBs). This innovative method has largely replaced traditional through-hole technology, offering numerous advantages such as reduced weight, increased component density, and improved performance under shock and vibration conditions. In recent years, LED SMT nozzles have emerged as a critical innovation within SMT, further enhancing its capabilities and efficiency.

LED SMT nozzles are specialized tools used in pick-and-place machines that position LEDs onto PCBs. These nozzles are designed to handle the unique requirements of LEDs, which are often more delicate and require precise placement compared to other components. The introduction of LED SMT nozzles has revolutionized the way LEDs are integrated into electronic devices, offering significant improvements in efficiency and precision.

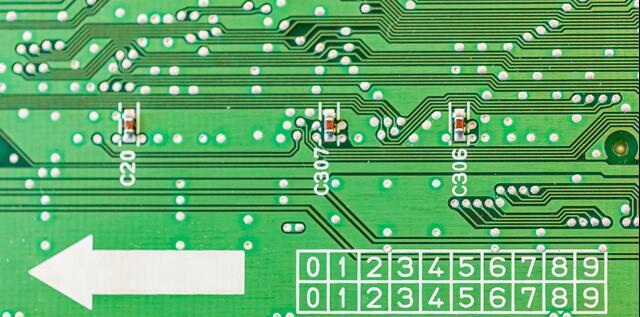

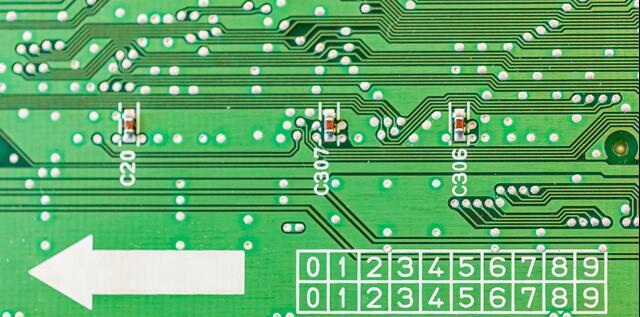

The Role of LED SMT Nozzles in SMT

LED SMT nozzles play a crucial role in the SMT process by ensuring that LEDs are accurately placed on PCBs. Unlike traditional nozzles, which may struggle with the unique shape and size of LEDs, LED SMT nozzles are specifically engineered to accommodate these components. This specialization allows for more reliable and efficient placement, reducing the risk of damage to the LEDs and improving the overall quality of the assembly.

Importance of Precision

Precision is paramount in electronics assembly. The ability of LED SMT nozzles to provide accurate placement minimizes misalignment issues that can lead to defects in the final product. This is particularly important as electronic devices become smaller and more complex, necessitating tighter tolerances in component placement.

Enhanced Compatibility

The design of LED SMT nozzles also enhances compatibility with various types of LED packages. Manufacturers can customize nozzle designs to suit specific LED shapes and sizes, which is crucial for maintaining high production rates without sacrificing quality.

Advantages of LED SMT Nozzles

The adoption of LED SMT nozzles offers several advantages that significantly impact production processes:

Increased Precision and Efficiency

One of the primary advantages of LED SMT nozzles is their ability to increase precision and efficiency in the manufacturing process. By providing a more secure grip and precise alignment, these nozzles minimize errors and reduce the need for rework. This not only speeds up production but also lowers costs by reducing waste and improving yield.

Cost-Effectiveness

In addition to enhancing precision, LED SMT nozzles contribute to cost-effectiveness by improving production speed and quality. The improved accuracy and reliability of these nozzles mean that manufacturers can produce high-quality products at a faster rate, meeting the growing demand for LED-based technologies across various industries.

Impact on Production Speed and Quality

The integration of LED SMT nozzles into manufacturing processes has been shown to increase throughput significantly. With the ability to place thousands of components per hour while maintaining high accuracy levels, manufacturers can meet market demands more effectively than ever before.

Challenges and Solutions

Despite their benefits, the use of LED SMT nozzles is not without challenges. Some common issues include:

Nozzle Wear and Tear

One significant challenge is nozzle wear over time, which can affect performance. To address this issue, manufacturers have developed durable materials and coatings that extend the lifespan of the nozzles, ensuring consistent performance throughout their operational life.

Handling Different LED Sizes

Another challenge relates to handling different LED sizes and shapes effectively. Innovations in nozzle design have helped overcome these challenges by introducing adjustable and interchangeable nozzle tips that allow for greater flexibility. This adaptability enables manufacturers to accommodate a wide range of LED specifications without compromising on quality.

Solutions Through Material Innovation

Recent advancements in materials used for nozzles have led to improved performance when handling sensitive components like LEDs. For example, silicone-based materials can provide better grip without damaging delicate surfaces, thus enhancing overall handling capabilities during assembly processes.

Future Trends in LED SMT Nozzles

The future of LED SMT nozzles looks promising as ongoing advancements in technology drive further improvements:

Smart Nozzle Technology

Emerging trends include the development of smart nozzles equipped with sensors and feedback systems that enhance precision and reduce errors. These innovations are expected to streamline the SMT process even further, making it more efficient and reliable.

Increased Demand for Customization

As the demand for LED technology continues to grow across various sectors—from consumer electronics to automotive applications—the role of LED SMT nozzles in the industry is likely to expand. Manufacturers are investing heavily in research and development to create nozzles that can handle increasingly complex LED designs.

Integration with Industry 4.0

The integration of Industry 4.0 principles into manufacturing processes will also influence future developments in nozzle technology. Automation, data exchange, and real-time monitoring will enhance production efficiency while allowing for greater customization based on specific manufacturing needs.

The Impact on Various Industries

The influence of LED SMT nozzles extends beyond just manufacturing efficiencies; they are reshaping various industries by enabling new applications:

Consumer Electronics

In consumer electronics, products such as smartphones, tablets, and smart home devices increasingly rely on LEDs for displays and indicators. The precise placement capabilities offered by LED SMT nozzles ensure that these components function optimally within compact designs.

Automotive Industry

The automotive industry is experiencing a significant shift towards incorporating more advanced lighting systems using LEDs. From interior lighting to headlights, precise assembly facilitated by LED SMT nozzles ensures reliability and performance under varying conditions.

Medical Devices

In medical devices where accuracy is critical—such as diagnostic equipment—LEDs play a vital role in functionality. The use of specialized nozzles ensures that these components are placed correctly without compromising device integrity or performance.

Environmental Considerations

As industries evolve towards sustainability, so too must their manufacturing processes. The use of LED SMT nozzles aligns with environmental goals by:

Reducing Waste

By improving precision during assembly processes, manufacturers can significantly reduce material waste associated with misaligned or damaged components. This contributes not only to cost savings but also supports sustainability initiatives within organizations.

Supporting Energy Efficiency

LED technology itself is known for its energy efficiency compared to traditional lighting solutions. By facilitating better integration of LEDs into products through advanced nozzle technology, manufacturers contribute indirectly to energy conservation across multiple sectors.

Conclusion

In conclusion, LED SMT nozzles have revolutionized surface-mount technology by providing enhanced precision, efficiency, and cost-effectiveness. Their ability to handle the unique requirements of LEDs has made them an indispensable tool in the electronics manufacturing industry. As technology continues to evolve, LED SMT nozzles will undoubtedly play a key role in shaping the future landscape of surface-mount technology across various applications—from consumer electronics to automotive systems—while supporting sustainability goals through reduced waste and improved energy efficiency.

FAQ

1. What are LED SMT nozzles?

LED SMT nozzles are specialized tools used in pick-and-place machines to position LEDs onto PCBs. They are designed specifically for handling LEDs' unique requirements, ensuring precise placement during assembly.

2. How do LED SMT nozzles improve manufacturing?

LED SMT nozzles improve manufacturing by increasing precision and efficiency during component placement. They provide a secure grip and precise alignment that minimizes errors and reduces rework needs.

3. What are the cost implications of using LED SMT nozzles?

Using LED SMT nozzles can lead to significant cost savings by enhancing production speed and quality while reducing waste through improved accuracy—ultimately lowering overall manufacturing costs.

4. Are there any drawbacks to using LED SMT nozzles?

While they offer numerous benefits, potential drawbacks include wear over time due to frequent use; however, advancements in materials have mitigated these issues significantly.

5. What is the future of LED SMT nozzles in the industry?

The future looks bright for LED SMT nozzles as ongoing technological advancements lead to smarter designs with integrated sensors for enhanced precision—making them essential for modern manufacturing processes.

Citations:

[1] https://en.wikipedia.org/wiki/Surface-mount_technology

[2] https://www.intel.sg/content/dam/www/public/us/en/documents/packaging-databooks/packaging-chapter-07-databook.pdf

[3] https://www.circuitinsight.com/pdf/led_pick_place_challenge_ipc.pdf

[4] https://www.ledsmagazine.com/manufacturing-services-testing/assembly-contract-manufacturing/article/16699893/led-component-assembly-benefits-from-smt-processes

[5] https://www.raypcb.com/surface-mount-technology/