Content Menu

● The Fundamentals of SMT Stencils in PCB Assembly

● The Advent of Laser-Cut SMT Stencils

>> Key Advantages of Laser-Cut SMT Stencils

● The Laser Cutting Process for SMT Stencils

● Impact on PCB Assembly Efficiency

>> Enhanced Solder Paste Deposition

>> Support for Miniaturization

>> Reduction in Defects and Rework

● Advancements in Laser-Cut SMT Stencil Technology

>> Nano-Coatings for Enhanced Performance

>> Integration with Industry 4.0

● Comparing Laser-Cut Stencils to Other Methods

>> Laser-Cut vs. Chemically Etched Stencils

>> Laser-Cut vs. Electroformed Stencils

● Best Practices for Using Laser-Cut SMT Stencils

● Future Trends in Laser-Cut SMT Stencil Technology

>> Even Finer Pitch Capabilities

>> Advanced Materials

>> Integration with Additive Manufacturing

>> AI-Driven Design Optimization

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of using laser-cut SMT stencils for PCB assembly?

>> 2. How do laser-cut SMT stencils compare to chemically etched stencils?

>> 3. What is the typical lifespan of a laser-cut SMT stencil?

>> 4. Can laser-cut SMT stencils be used for double-sided PCB assembly?

>> 5. What recent innovations have improved laser-cut SMT stencil performance?

● Citations:

In the ever-evolving world of electronics manufacturing, precision and efficiency are paramount. One of the most significant advancements in recent years has been the widespread adoption of laser-cut SMT (Surface Mount Technology) stencils for PCB (Printed Circuit Board) assembly. These high-precision tools have revolutionized the way we approach circuit board production, offering unparalleled accuracy and consistency in the application of solder paste. This article delves into the transformative impact of laser-cut SMT stencils on PCB assembly, exploring their benefits, manufacturing process, and the ways they're shaping the future of electronics production.

The Fundamentals of SMT Stencils in PCB Assembly

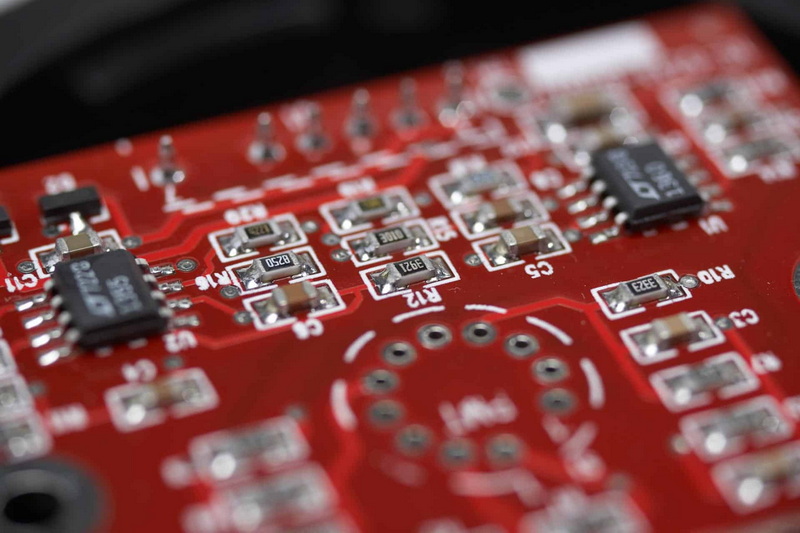

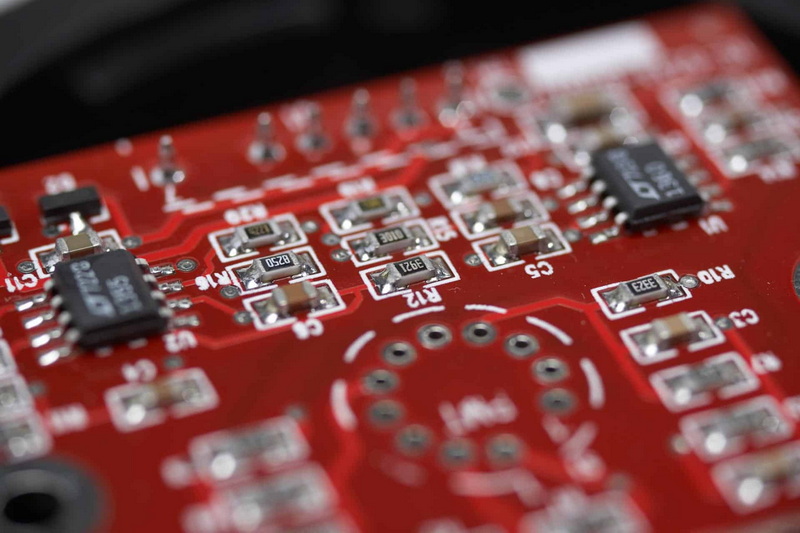

Before we dive into the specifics of laser-cut SMT stencils, it's crucial to understand the role of stencils in PCB assembly. SMT stencils are thin metal sheets, typically made from stainless steel, with precisely cut openings or apertures that correspond to the solder pad locations on a PCB[4]. These stencils serve as a template for applying solder paste to the board, ensuring that the right amount of paste is deposited in the correct locations.

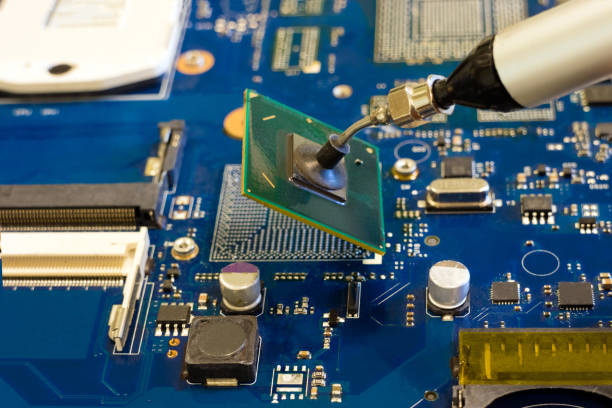

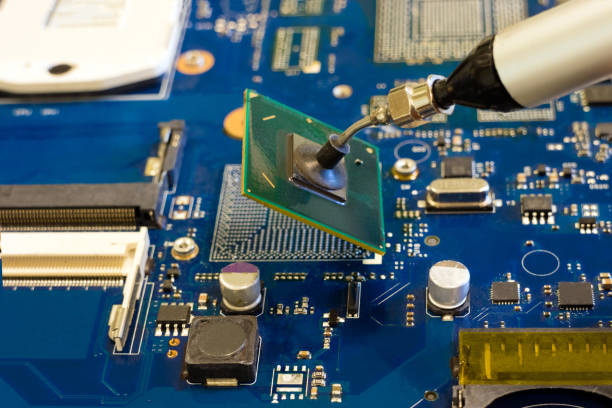

The solder paste application process is a critical step in PCB assembly. It involves placing the stencil over the PCB, applying solder paste, and then using a squeegee to force the paste through the apertures onto the board's solder pads. The accuracy of this process directly impacts the quality and reliability of the final product, making the precision of the stencil paramount.

The Advent of Laser-Cut SMT Stencils

Laser-cut SMT stencils have emerged as the gold standard in the industry, offering several advantages over traditional manufacturing methods such as chemical etching. The laser cutting process uses a high-powered laser beam to create apertures in the stencil material with exceptional precision[4].

Key Advantages of Laser-Cut SMT Stencils

1. Precision and Accuracy: Laser cutting technology can achieve tolerances as tight as ±5μm, ensuring extremely accurate aperture dimensions and positioning[5]. This level of precision is crucial for modern electronics with increasingly miniaturized components.

2. Smooth Aperture Walls: The laser cutting process results in exceptionally smooth internal pad walls, with wall geometric changes less than 3μm[2]. This smoothness contributes to superior paste release characteristics, ensuring consistent solder paste deposition.

3. Fine-Pitch Capability: Laser-cut stencils can accommodate ultra-fine pitch patterns less than 250μm without issues, making them suitable for today's challenging very fine pitch devices[2].

4. Consistency and Repeatability: The laser cutting process ensures high consistency between stencils, which is crucial for large-scale production and repeatability in PCB assembly[6].

5. Versatility: Laser cutting technology can work with various stencil materials and thicknesses, offering flexibility in stencil design and application[6].

The Laser Cutting Process for SMT Stencils

The manufacturing process of laser-cut SMT stencils involves several steps, each contributing to the stencil's final quality and precision:

1. Data Processing: The process begins with the PCB design files, typically in Gerber format. These files are processed to create the cutting instructions for the laser machine.

2. Material Selection: High-quality stainless steel foil is selected, often with a high nickel content for improved strength and smaller surface grain structures[2].

3. Laser Cutting: A high-powered laser beam is used to cut the apertures in the stencil material. The laser's power, speed, and focus are precisely controlled to achieve the desired aperture dimensions and shape.

4. Post-Processing: After cutting, the stencil undergoes additional treatments such as polishing to ensure smooth surfaces and optimal paste release characteristics.

5. Quality Control: Rigorous inspection processes are employed to verify the accuracy of the apertures and overall stencil quality.

Impact on PCB Assembly Efficiency

The adoption of laser-cut SMT stencils has significantly improved various aspects of PCB assembly:

Enhanced Solder Paste Deposition

The precision of laser-cut stencils leads to more accurate solder paste deposition. This accuracy is crucial for several reasons:

- It ensures that components are properly secured to the PCB during the reflow process.

- It reduces the risk of solder bridges or insufficient solder joints, which can lead to assembly defects.

- It allows for consistent performance across large production runs.

Support for Miniaturization

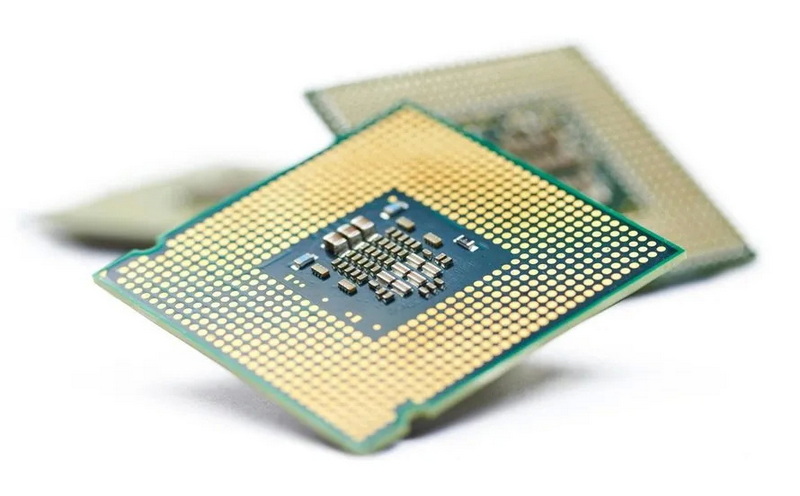

As electronic devices continue to shrink in size, PCB designs are becoming increasingly dense with smaller components. Laser-cut SMT stencils can accommodate these trends:

- They enable the accurate placement of solder paste for components with extremely fine pitches.

- The precision of laser cutting allows for the creation of complex aperture shapes necessary for advanced component packages.

Reduction in Defects and Rework

The improved accuracy of solder paste application translates directly into a reduction in assembly defects:

- Fewer instances of component misalignment due to inconsistent solder paste volumes.

- Reduced occurrence of solder bridges between closely spaced pads.

- Lower rates of component tombstoning caused by uneven solder paste distribution.

These improvements lead to a significant reduction in the need for rework, saving time and resources in the production process.

Advancements in Laser-Cut SMT Stencil Technology

The field of laser-cut SMT stencils continues to evolve, with ongoing research and development leading to new innovations:

Nano-Coatings for Enhanced Performance

Advanced coatings, such as NanoSlic, are being applied to laser-cut stencils to further improve their performance[14]. These coatings can:

- Enhance solder paste release, ensuring more consistent paste transfer to the PCB.

- Improve the stencil's resistance to wear, extending its usable lifespan.

- Facilitate easier cleaning, reducing downtime between production runs.

Integration with Industry 4.0

As manufacturing moves towards greater automation and data exchange, laser-cut SMT stencils are being integrated into smart factory systems:

- Stencils can be equipped with RFID tags for tracking and inventory management.

- Data from stencil usage can be collected and analyzed to optimize the production process.

- Automated stencil cleaning and inspection systems are being developed to maintain consistent performance.

Comparing Laser-Cut Stencils to Other Methods

While laser cutting has become the preferred method for SMT stencil production, it's worth comparing it to alternative techniques to understand its advantages fully:

Laser-Cut vs. Chemically Etched Stencils

Chemical etching was once the primary method for producing SMT stencils. However, laser cutting offers several advantages:

- Precision: Laser cutting achieves tighter tolerances and more consistent aperture sizes compared to chemical etching[13].

- Speed: The laser cutting process is generally faster, allowing for quicker turnaround times on stencil orders[13].

- Environmental Impact: Laser cutting is a cleaner process, avoiding the use of harsh chemicals required in etching.

Laser-Cut vs. Electroformed Stencils

Electroformed stencils are known for their high quality but come with limitations:

- Cost: Laser-cut stencils are typically more cost-effective, especially for smaller production runs.

- Flexibility: Laser cutting allows for easier modifications and quicker production of prototype stencils.

- Durability: While electroformed stencils can offer excellent performance, laser-cut stencils made from high-quality materials can match or exceed their durability.

Best Practices for Using Laser-Cut SMT Stencils

To maximize the benefits of laser-cut SMT stencils in PCB assembly, consider the following best practices:

1. Proper Storage: Store stencils in a clean, dry environment to prevent contamination and maintain their precision.

2. Regular Cleaning: Implement a thorough cleaning regimen to remove solder paste residue and maintain optimal performance.

3. Stencil Tension: Ensure proper tension when mounting the stencil in the printer to maintain flatness and prevent warping.

4. Aperture Design: Work closely with stencil manufacturers to optimize aperture designs for specific component requirements.

5. Quality Control: Implement regular inspections of both the stencils and the resulting solder paste deposits to catch any issues early.

Future Trends in Laser-Cut SMT Stencil Technology

As the electronics industry continues to advance, we can expect further developments in laser-cut SMT stencil technology:

Even Finer Pitch Capabilities

As components continue to shrink, stencil manufacturers will push the boundaries of laser cutting technology to create even finer apertures with tighter tolerances.

Advanced Materials

Research into new stencil materials that offer improved durability and paste release characteristics will likely continue, potentially leading to stencils that can handle an even greater number of print cycles.

Integration with Additive Manufacturing

There may be opportunities to combine laser cutting technology with additive manufacturing techniques to create hybrid stencils with unique properties or features.

AI-Driven Design Optimization

Artificial intelligence and machine learning algorithms could be employed to optimize stencil designs based on historical performance data and specific PCB requirements.

Conclusion

Laser-cut SMT stencils have undeniably revolutionized PCB assembly, bringing unprecedented levels of precision, consistency, and efficiency to the solder paste application process. Their ability to accommodate the demands of modern electronics manufacturing, from ultra-fine pitch components to complex board designs, has made them an indispensable tool in the industry.

As we look to the future, the continued evolution of laser-cut SMT stencil technology promises to keep pace with the relentless miniaturization and increasing complexity of electronic devices. By enabling more precise and reliable PCB assembly, these stencils play a crucial role in advancing the capabilities of consumer electronics, medical devices, aerospace systems, and countless other applications that rely on high-quality circuit boards.

The impact of laser-cut SMT stencils extends beyond just improved product quality. Their efficiency contributes to reduced waste, lower production costs, and faster time-to-market for new electronic products. As the technology continues to mature and integrate with broader Industry 4.0 initiatives, we can expect even greater optimizations in the PCB assembly process.

In conclusion, laser-cut SMT stencils represent a significant leap forward in PCB assembly technology. Their adoption has not only solved many of the challenges faced by electronics manufacturers but has also opened up new possibilities for innovation in product design and manufacturing processes. As the electronics industry continues to evolve, laser-cut SMT stencils will undoubtedly remain at the forefront, enabling the next generation of technological advancements.

Frequently Asked Questions (FAQ)

1. What are the main advantages of using laser-cut SMT stencils for PCB assembly?

Laser-cut SMT stencils offer several key advantages for PCB assembly:

- Exceptional precision with tolerances as tight as ±5μm

- Smooth aperture walls for superior solder paste release

- Ability to accommodate ultra-fine pitch patterns below 250μm

- Consistency and repeatability in production

- Versatility in handling various stencil materials and thicknesses

These advantages contribute to improved solder paste deposition, reduced defects, and overall higher quality in PCB assembly.

2. How do laser-cut SMT stencils compare to chemically etched stencils?

Laser-cut SMT stencils outperform chemically etched stencils in several ways:

- Higher precision and tighter tolerances

- Faster production times

- Cleaner manufacturing process without harsh chemicals

- Better consistency between stencils

- Ability to create more complex aperture shapes

While chemically etched stencils may be suitable for less demanding applications, laser-cut stencils are the preferred choice for high-precision PCB assembly.

3. What is the typical lifespan of a laser-cut SMT stencil?

The lifespan of a laser-cut SMT stencil can vary depending on several factors, but generally:

- High-quality laser-cut stencils can typically achieve 800+ prints

- Some stencils may last for 2000+ prints with proper care and maintenance

- Factors affecting lifespan include stencil material, thickness, usage frequency, and cleaning practices

Proper storage, regular cleaning, and careful handling can significantly extend the useful life of a laser-cut SMT stencil.

4. Can laser-cut SMT stencils be used for double-sided PCB assembly?

Yes, laser-cut SMT stencils can be effectively used for double-sided PCB assembly:

- Separate stencils are typically used for each side of the board

- The high precision of laser-cut stencils ensures accurate alignment for both sides

- Some manufacturers offer special features like fiducial marks to aid in alignment for double-sided assembly

When using laser-cut stencils for double-sided PCBs, it's important to consider the order of assembly and any potential issues with component interference.

5. What recent innovations have improved laser-cut SMT stencil performance?

Recent innovations in laser-cut SMT stencil technology include:

- Advanced nano-coatings like NanoSlic for enhanced solder paste release

- Integration with RFID technology for better tracking and inventory management

- Improved laser cutting techniques allowing for even finer apertures and more complex shapes

- Development of new stencil materials with improved durability and performance characteristics

- AI-driven design optimization to enhance stencil performance based on specific PCB requirements

These innovations continue to push the boundaries of what's possible in PCB assembly, enabling manufacturers to produce increasingly complex and miniaturized electronic devices.

Citations:

[1] https://www.pentalogix.com/products/prototype-smt-stencils

[2] https://www.soldertools.net/smt-stencil/

[3] https://www.pcbonline.com/blog/guide-to-smt-stencils.html

[4] https://www.fs-pcba.com/pcb-stencil/

[5] https://smartsmttools.com/product-item/laser-cut-smt-stencils-2/

[6] https://www.findtop.com/7-benefits-of-laser-cut-stencils-for-optimal-results/

[7] https://www.lioncircuits.com/faq/pcb-assembly/what-is-a-smt-stencil-and-why-is-it-needed-for-assembly

[8] https://www.elecrow.com/blog/what-is-a-pcb-stencil-and-how-to-use-it.html

[9] https://www.stencilsunlimited.com/t/smt-stencils

[10] https://rigidflexpcb.org/comprehensive-guide-to-smt-stencils/

[11] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[12] https://www.pcbunlimited.com/t/smt-stencils

[13] https://www.raypcb.com/laser-cut-stencils-and-chemical-etching-stencils/

[14] https://blueringstencils.com