Content Menu

● Introduction

● A Brief History of Surface Mount Technology

● The Advantages of SMT

● Technological Advancements in SMT

● Current Applications of Surface Mount Technology

>> Telecommunications

>> Consumer Electronics

>> Automotive Electronics

>> Medical Devices

● Challenges in Surface Mount Technology

● The Future of Surface Mount Technology

● Conclusion

● Relevant Questions and Answers

>> 1. What is the difference between SMT and through-hole technology?

>> 2. How does reflow soldering work in SMT?

>> 3. What are some common applications of SMT?

>> 4. What materials are used in SMT?

>> 5. How has automation impacted SMT?

Introduction

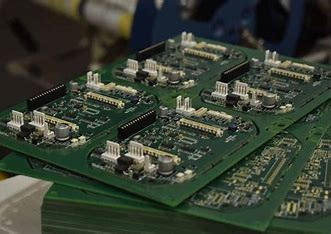

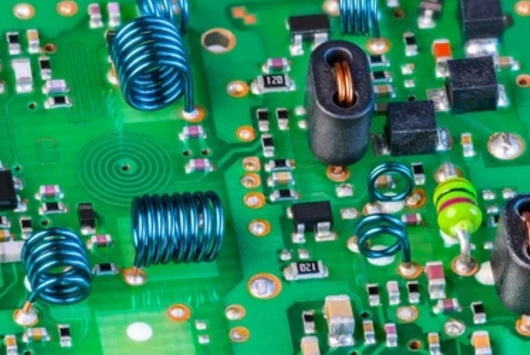

Surface Mount Technology (SMT) has transformed the electronics manufacturing landscape since its inception in the late 1960s. This technology allows for the direct attachment of electronic components to the surface of printed circuit boards (PCBs), revolutionizing the way devices are designed and produced. In this article, we will explore the evolution of Surface Mount Technology, examining its origins, advancements, and current applications.

A Brief History of Surface Mount Technology

Surface Mount Technology emerged in the late 1960s as a solution to the growing need for smaller and more efficient electronic devices. The first SMT components were larger than today's standards; however, they paved the way for significant progress. Initially, manufacturers relied on conductive adhesives to attach components to PCBs, but advancements in soldering techniques, particularly reflow soldering, have greatly improved durability and efficiency.

The Advantages of SMT

One of the key factors driving the adoption of Surface Mount Technology is its numerous advantages over traditional through-hole technology. Key benefits include:

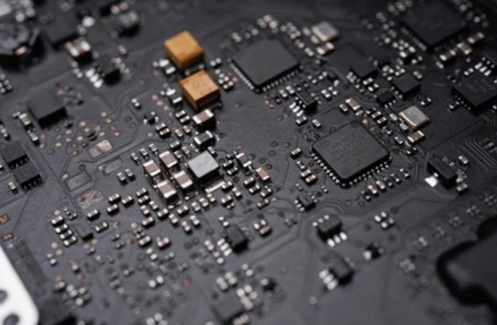

- Smaller Size: SMT allows designers to reduce the overall size of electronic devices by enabling closer placement of components.

- Higher Component Density: Surface Mount Technology can accommodate more components in a given space, optimizing performance without increasing size.

- Automated Assembly: The design of SMT components makes them ideal for automated assembly processes, which improve production speed and accuracy.

Technological Advancements in SMT

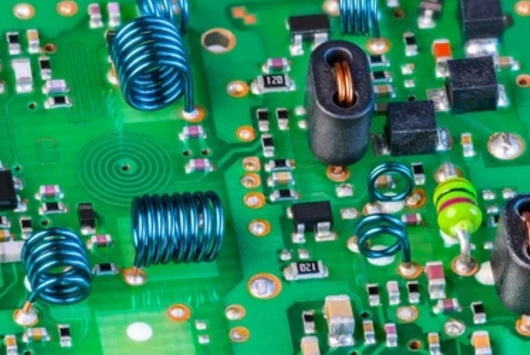

Throughout the years, numerous technological advancements have influenced the evolution of Surface Mount Technology. Some of the most notable include:

- Improved Materials: The development of new solder materials and substrates has led to increased thermal and mechanical performance of SMT assemblies.

- Enhanced Equipment: The rise of sophisticated pick-and-place machines and reflow ovens has streamlined the SMT process, enabling more precise manufacturing.

- Design Software: Advances in design software have facilitated the layout process for SMT, allowing engineers to optimize designs for manufacturability.

Current Applications of Surface Mount Technology

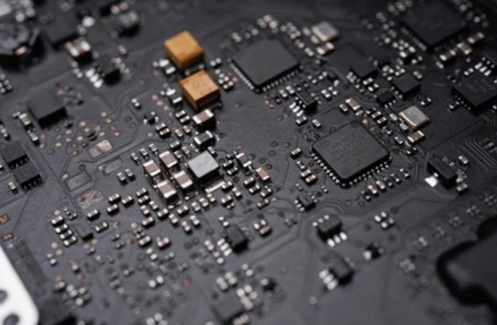

Surface Mount Technology is widely used in various industries, including telecommunications, consumer electronics, automotive, and medical devices. Examples of SMT applications range from smartphones to automotive control systems, emphasizing its versatility. The ability to miniaturize components and integrate them into complex systems is crucial for modern electronics.

Telecommunications

In telecommunications, SMT is used in devices such as routers and switches where compactness and performance are essential. The ability to place numerous components on a small PCB allows for advanced features without increasing device size.

Consumer Electronics

Consumer electronics like smartphones and tablets heavily rely on SMT due to its ability to support miniaturization. As consumers demand thinner and lighter devices with more functionality, SMT plays a pivotal role in meeting these expectations.

Automotive Electronics

Automotive applications benefit from SMT's reliability and compactness. Modern vehicles utilize numerous electronic systems for safety features, navigation, and entertainment; thus, SMT enables efficient use of space within tight confines.

Medical Devices

In the medical field, precision is critical. SMT is employed in devices such as pacemakers and diagnostic equipment where reliability and performance are paramount. The technology ensures that these vital devices can be both compact and efficient.

Challenges in Surface Mount Technology

As impressive as SMT advancements have been, several challenges continue to affect its growth and implementation:

- Thermal Management: Managing heat generation in densely packed SMT assemblies can be difficult, requiring advanced thermal management solutions.

- Reliability Issues: Ensuring long-term reliability in SMT components can pose challenges, particularly in high-stress environments.

- Reworkability: The need for precision in placing components can complicate rework processes if components must be replaced or adjusted.

The Future of Surface Mount Technology

Looking ahead, the future of Surface Mount Technology appears promising, with several trends shaping its evolution:

- Miniaturization: As consumer demand for smaller devices continues to grow, SMT will evolve further to enable even tinier components.

- 3D Integration: Advances in three-dimensional (3D) integration technology hold the potential to revolutionize SMT, allowing for vertically stacked components and further enhancing performance.

- Sustainability: The push for sustainable manufacturing practices is likely to influence the materials and processes used in SMT.

Conclusion

Surface Mount Technology has come a long way since its introduction in the late 1960s. Its evolution demonstrates how innovation can meet the demands of an ever-advancing technological landscape. With its many advantages, current applications across various industries, and future trends pointing towards continued growth, SMT will remain at the forefront of electronics manufacturing.

Relevant Questions and Answers

1. What is the difference between SMT and through-hole technology?

SMT uses solder pads on the surface of PCBs for component placement, resulting in smaller, more densely packed assemblies compared to through-hole technology, which involves inserting leads through holes in the PCB.

2. How does reflow soldering work in SMT?

Reflow soldering involves applying solder paste to the PCB, placing components on the paste, and then heating the assembly to melt the solder, solidifying it upon cooling.

3. What are some common applications of SMT?

SMT is used in various industries including consumer electronics (smartphones, tablets), automotive electronics (control systems), and medical devices (patient monitoring equipment).

4. What materials are used in SMT?

Common materials include various types of solder (tin-lead, lead-free), PCBs made of FR-4 and other compounds, and components designed specifically for surface mounting.

5. How has automation impacted SMT?

Automation has significantly improved the speed and accuracy of SMT production, enabling higher throughput, reduced labor costs, and enhanced quality control.