Content Menu

● Understanding SMD Reel Counters

>> Key Functions of SMD Components Counting Machines

● Speed of Modern SMD Reel Counters

>> Optical and Mechanical Counting Speeds

>> X-ray Counting Technology

>> Summary of Counting Speeds

● Technology Behind High-Speed Counting

>> Photoelectric Sensing Principle

>> Motorized Tape Feeding

>> Leak Detection and Error Prevention

>> X-ray Imaging

● Advantages of Modern SMD Components Counting Machines

● Choosing the Right SMD Components Counting Machine

● Future Trends in SMD Components Counting Technology

● Conclusion

● FAQ

>> 1. How fast can an SMD components counting machine process a full reel?

>> 2. What technologies do SMD reel counters use to count components?

>> 3. Can SMD counters detect missing components on the tape?

>> 4. Are these machines compatible with different reel sizes and tape pitches?

>> 5. Is it possible to count multiple reels simultaneously?

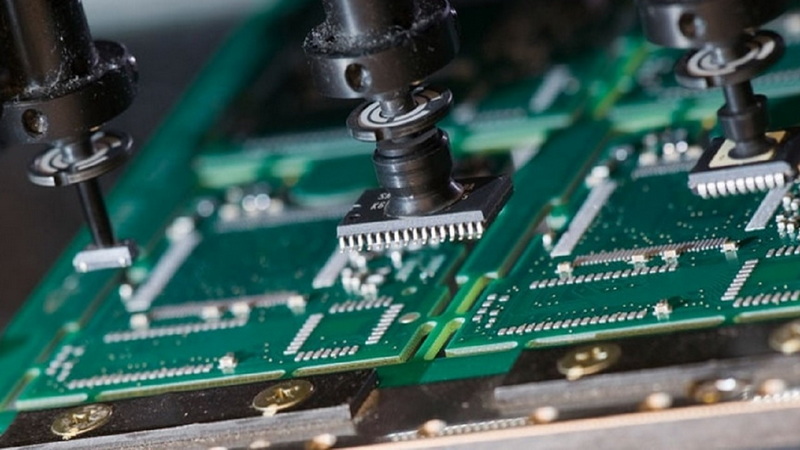

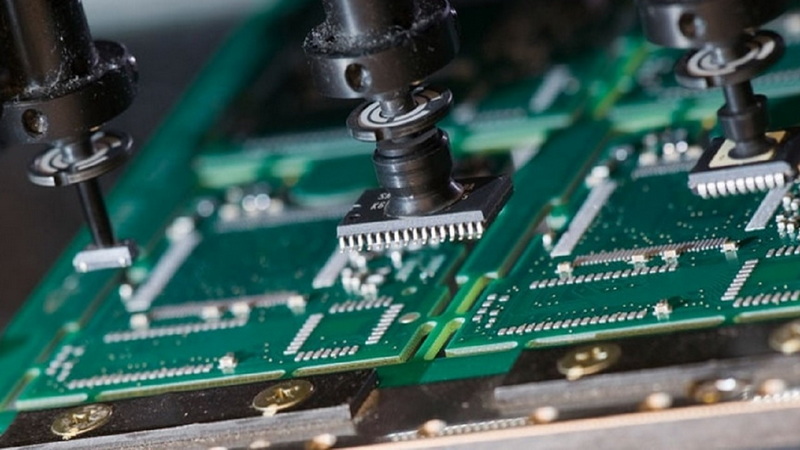

Surface Mount Device (SMD) components are fundamental in modern electronics manufacturing. Efficiently counting these components on reels is crucial for inventory management, production planning, and quality control. Modern SMD components counting machines have evolved to provide rapid, accurate, and reliable counting, significantly improving manufacturing workflows. This article explores how fast these machines can process components, the technology behind them, and their key features.

Understanding SMD Reel Counters

SMD reel counters are specialized machines designed to count electronic components packaged on reels, such as resistors, capacitors, and integrated circuits. These machines use optical sensors, photoelectric principles, or X-ray imaging to detect and count components as they pass through the device.

Key Functions of SMD Components Counting Machines

- Automatic counting with zero error tolerance.

- Forward and reverse counting capability.

- Leakage detection to identify missing components.

- Speed regulation for different component pitches.

- Compatibility with various reel sizes and tape widths.

- Data management features such as memory and barcode scanning.

These features make SMD components counting machines indispensable tools in electronics manufacturing, where precision and speed are paramount.

Speed of Modern SMD Reel Counters

Optical and Mechanical Counting Speeds

Modern SMD components counting machines can process components at remarkable speeds, often counting thousands of pieces within seconds or minutes. The speed depends on the component size, tape pitch, and the specific machine model.

- The 2000PC Automatic SMD Counter processes a full reel in about 90 seconds, counting up to 800 pieces per second for 2mm pitch components. This speed is achieved through a high-precision photoelectric sensor combined with a motorized tape feeding system.

- The CNSMT-801 SMD Reel Counter Machine can count up to 5000 pieces in approximately 10 to 30 seconds, depending on the model and settings. It supports forward and reverse counting, making it versatile for different production needs.

- The QH902N SMD component counting machine counts 5000 pieces in about 24 seconds per disk, with multi-speed regulation for different tape pitches. This feature allows the machine to adapt to a variety of component sizes and tape formats without compromising speed.

X-ray Counting Technology

X-ray based counters provide another level of speed and accuracy, especially for reels with dense or opaque packaging. This technology is particularly useful for components that are difficult to detect optically due to their color, shape, or packaging material.

- The Quad Count Pro machine can count a single reel or up to four 7-inch reels simultaneously within 8 seconds using X-ray and barcode scanning technology. This multi-reel counting capability significantly increases throughput in high-volume manufacturing environments.

- The Assure X-ray Component Counter processes a single reel in approximately 10 seconds and four reels in around 15 seconds. Its advanced imaging technology ensures zero error counting even with complex component arrangements.

Summary of Counting Speeds

| Machine Model | Counting Speed | Counting Volume | Special Features |

| 2000PC Automatic SMD Counter | 800 pcs/second (2mm pitch) | Full reel in 90 sec | Verification, rewind function |

| CNSMT-801 SMD Reel Counter | Up to 5000 pcs in 10-30 seconds | -99999 to 99999 pcs | Leak detection, forward/reverse count |

| QH902N SMD Counting Machine | 5000 pcs in 24 seconds per disk | -99999 to 99999 pcs | Leak detection, multi-speed regulation |

| Quad Count Pro (X-ray) | 1 reel or 4 reels in 8 seconds | Varies | X-ray counting, barcode scanning |

| Assure X-ray Counter | 1 reel in ~10 sec, 4 reels in 15s | Varies | X-ray technology, high accuracy |

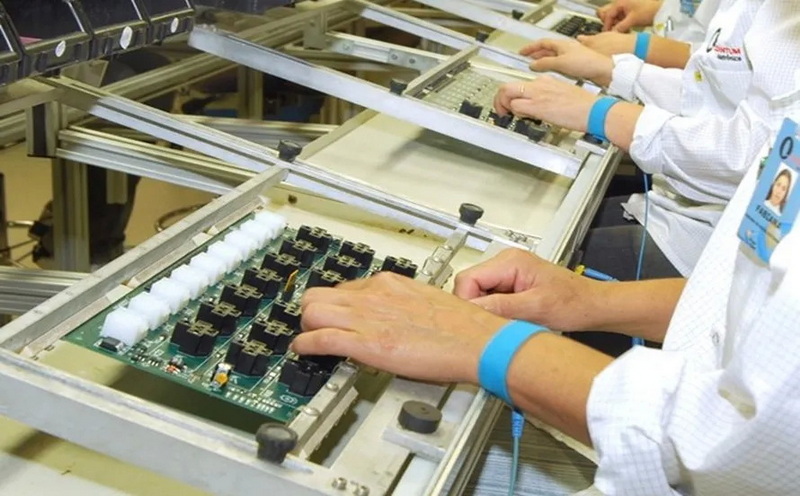

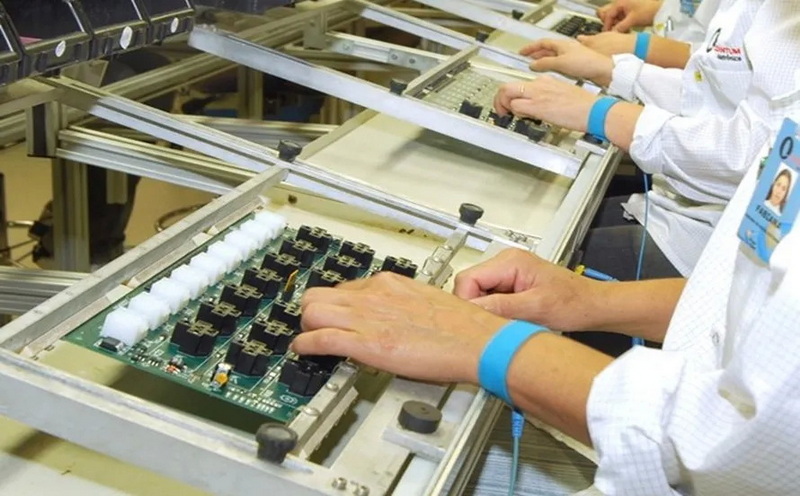

Technology Behind High-Speed Counting

Photoelectric Sensing Principle

Most optical SMD counters use photoelectric sensors that detect the presence of components based on light interruption or reflection. This method allows for high-speed counting with zero error, as the sensor counts each component passing through the guide hole on the tape. The sensor's sensitivity and the precision of the light beam ensure that even the smallest components are accurately detected.

Motorized Tape Feeding

Motorized reels feed the tape steadily through the counting gears, ensuring consistent speed and preventing damage to the tape or components. The feeding mechanism is designed to handle various tape widths and reel sizes, maintaining smooth operation at high speeds. Some machines also support manual feeding with a rewind function to verify counts or correct errors.

Leak Detection and Error Prevention

Advanced counters include leak detection systems using optical fibers or sensors that stop the machine automatically if missing components or tape damage are detected. This feature ensures accuracy and prevents counting errors that could lead to inventory discrepancies or production delays. Leak detection is vital in maintaining quality control in electronics manufacturing.

X-ray Imaging

X-ray counters use imaging technology to see through tape packaging and count components without physical contact. This method is faster and more accurate for dense reels and can count multiple reels simultaneously. The X-ray technology also helps in detecting hidden defects or missing components that optical sensors might miss.

Advantages of Modern SMD Components Counting Machines

- High Speed: Machines can count thousands of components in seconds, significantly reducing manual labor and time.

- Accuracy: Zero error tolerance and leak detection ensure reliable inventory data.

- Versatility: Compatible with various reel sizes, tape pitches, and component types.

- Ease of Use: User-friendly interfaces, preset functions, and memory storage simplify operation.

- Integration: Barcode scanning and printing options facilitate inventory management and traceability.

- Reduced Labor Costs: Automation of counting processes reduces the need for manual counting, minimizing human error and labor costs.

- Improved Inventory Management: Accurate counts help maintain optimal stock levels, preventing shortages or overstocking.

These advantages make SMD components counting machines essential in modern electronics manufacturing, where efficiency and accuracy directly impact production success.

Choosing the Right SMD Components Counting Machine

When selecting an SMD reel counter, consider the following factors:

- Counting Speed: Match the machine's speed with your production volume to ensure efficiency.

- Component Size and Tape Pitch: Ensure compatibility with your component specifications; some machines offer adjustable speed settings for different pitches.

- Accuracy Requirements: Look for leak detection and verification features to maintain zero error tolerance.

- Budget: Balance cost with features such as X-ray technology or multi-reel counting capabilities.

- Ease of Operation: Consider machines with intuitive controls, preset functions, and good customer support.

- Maintenance and Durability: Choose machines with robust construction and easy maintenance to ensure long-term reliability.

- Data Management Needs: Machines with memory storage, barcode scanning, and connectivity options can integrate seamlessly into your inventory management system.

By carefully evaluating these factors, manufacturers can select the most suitable SMD components counting machine to optimize their production line.

Future Trends in SMD Components Counting Technology

As electronics manufacturing continues to evolve, SMD components counting machines are expected to incorporate even more advanced technologies:

- AI and Machine Learning: Future machines may use AI algorithms to improve counting accuracy, detect anomalies, and predict maintenance needs.

- IoT Connectivity: Integration with Internet of Things (IoT) platforms will enable real-time inventory tracking and remote monitoring.

- Enhanced Imaging: Improved X-ray and optical imaging technologies will allow for faster counting and better defect detection.

- Automation Integration: Counting machines will increasingly integrate with automated pick-and-place systems and warehouse management software for seamless workflow.

- Miniaturization Support: As components become smaller, counting machines will adapt to handle ultra-fine pitch tapes with higher precision.

These innovations will further increase the speed, accuracy, and efficiency of SMD components counting, supporting the growing demands of the electronics industry.

Conclusion

Modern SMD components counting machines have revolutionized the electronics manufacturing process by enabling ultra-fast, accurate, and reliable counting of components on reels. With speeds ranging from hundreds to thousands of components per second, and advanced features like leak detection and X-ray imaging, these machines ensure smooth production flow and precise inventory management. Choosing the right machine depends on your specific needs, but the technology available today offers solutions for nearly every scale of operation. As technology advances, we can expect even faster, smarter, and more integrated counting solutions to support the future of electronics manufacturing.

FAQ

1. How fast can an SMD components counting machine process a full reel?

Modern machines can count a full reel in as little as 8 to 90 seconds depending on the technology used, with speeds up to 800 pieces per second for optical counters and simultaneous multi-reel counting via X-ray in under 10 seconds.

2. What technologies do SMD reel counters use to count components?

They primarily use photoelectric sensing, motorized tape feeding, and advanced X-ray imaging for fast and accurate counting. Leak detection and barcode scanning are common additional features.

3. Can SMD counters detect missing components on the tape?

Yes, many modern counters have leak detection systems that automatically stop counting if missing components or tape damage are detected, ensuring zero error tolerance.

4. Are these machines compatible with different reel sizes and tape pitches?

Yes, most machines support a wide range of reel diameters (e.g., 7-13 inches) and tape pitches from 2mm up to 56mm or more, making them versatile for various component types.

5. Is it possible to count multiple reels simultaneously?

Yes, specialized X-ray counting machines like the Quad Count Pro can count up to four reels simultaneously within seconds, greatly increasing throughput.