Content Menu

● Introduction to SMT PCB Loaders

>> Role of Vacuum Technology

● Working Principle of Vacuum Technology

● Features of SMT Automatic Vacuum PCB Loaders

● Applications and Benefits

>> Benefits

● Advanced Technologies in SMT Production

>> Future Developments

● Integration with Other SMT Equipment

>> Compatibility and Flexibility

● Maintenance and Upkeep

>> Best Practices for Maintenance

● Conclusion

● FAQ

>> 1. How does the vacuum technology in SMT PCB loaders ensure PCB safety?

>> 2. What are the typical air pressure requirements for SMT vacuum loaders?

>> 3. Can SMT vacuum loaders handle PCBs of different sizes and thicknesses?

>> 4. What is the role of PLC control in SMT vacuum loaders?

>> 5. How do SMT vacuum loaders integrate with other equipment in the production line?

● Citations:

Vacuum technology plays a crucial role in SMT automatic vacuum PCB loaders, which are essential components in the surface mount technology (SMT) production line. These loaders utilize vacuum absorption to handle printed circuit boards (PCBs) efficiently and accurately. In this article, we will delve into the working principle of vacuum technology in SMT PCB loaders, their features, applications, and benefits.

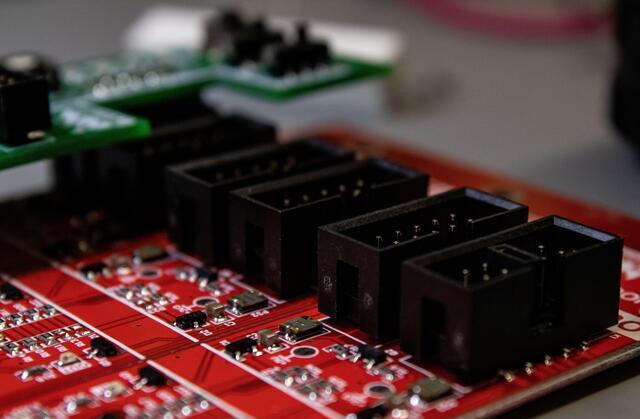

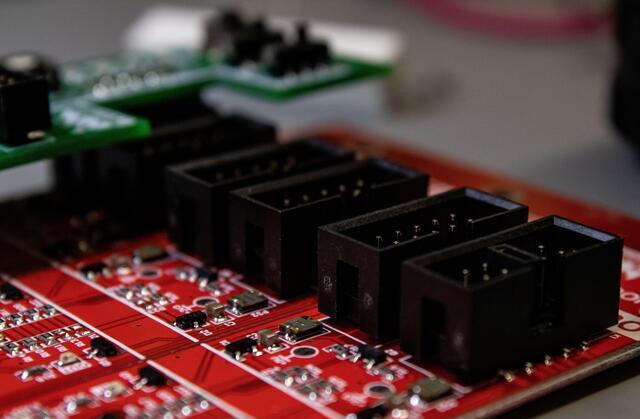

Introduction to SMT PCB Loaders

SMT PCB loaders are designed to automate the process of loading PCBs onto the production line. They are typically used at the beginning of the SMT assembly process, where bare PCBs are fed into the system for further processing, such as solder paste printing, component placement, and soldering. The use of vacuum technology in these loaders ensures precise control over the PCBs, minimizing damage and improving production efficiency.

Role of Vacuum Technology

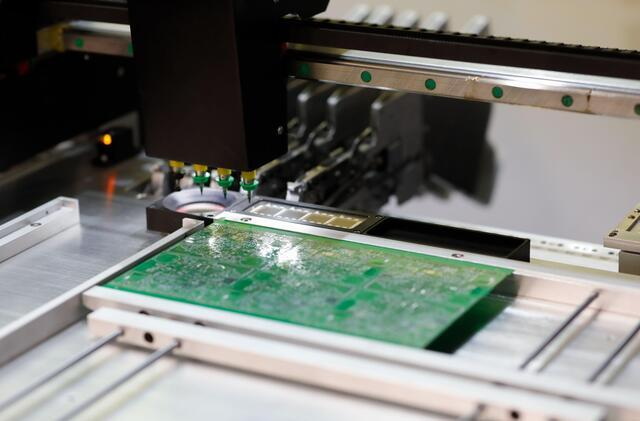

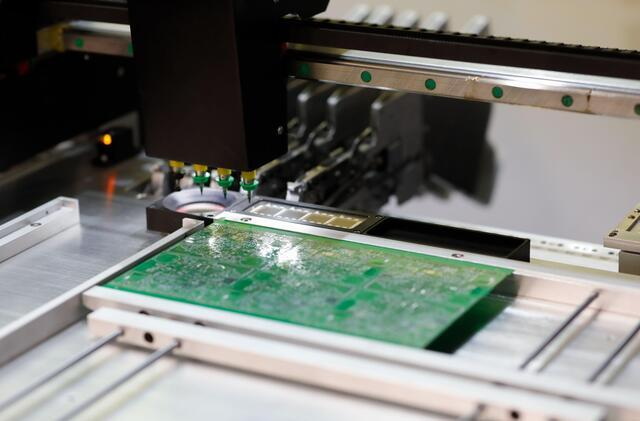

Vacuum technology in SMT PCB loaders works by creating a vacuum environment that securely grips the PCBs. This is achieved through a suction head that applies gentle yet firm pressure to lift and transport the boards. The vacuum system is designed to handle PCBs of various sizes and thicknesses, ensuring that they are placed accurately on the conveyor belt for further processing.

Working Principle of Vacuum Technology

The working principle of vacuum technology in SMT PCB loaders involves several key components:

1. Vacuum Generation: A vacuum pump or blower generates the necessary vacuum pressure to lift the PCBs. The pressure is typically in the range of 0.4 to 0.6 MPa, depending on the specific requirements of the loader[1].

2. Suction Head: The suction head is the part that comes into contact with the PCB. It is designed to be flexible and adjustable, allowing it to accommodate different PCB sizes and shapes.

3. PCB Lifting and Transport: Once the suction head creates a vacuum seal with the PCB, it lifts the board from the stack and transports it to the conveyor belt. This process is highly controlled to prevent any damage to the PCB.

4. Conveyor System: The conveyor belt is usually made of ESD (Electrostatic Discharge) material to prevent static damage to the PCBs. It transports the PCBs to the next stage of the production line.

Features of SMT Automatic Vacuum PCB Loaders

SMT automatic vacuum PCB loaders come with several features that enhance their functionality and efficiency:

- PLC Control System: Most loaders are equipped with a programmable logic controller (PLC) that allows for customizable settings and automated operations. This includes touch screen interfaces for easy operation and monitoring[1][6].

- Adjustable Lifting Step: The lifting step can be adjusted according to the thickness of the PCBs, ensuring that boards of different sizes are handled correctly[1].

- Safety Features: Many loaders include safety features such as safety door locks and emergency shutdowns to protect operators and prevent accidents[1][6].

- SMEMA Compatibility: The loaders often support standard SMEMA interfaces, allowing them to integrate seamlessly with other equipment in the SMT production line[1][6].

Applications and Benefits

SMT automatic vacuum PCB loaders are widely used in the electronics manufacturing industry due to their ability to improve production efficiency and reduce labor costs. They are particularly beneficial for high-volume production lines where precision and speed are crucial.

Benefits

1. Improved Efficiency: By automating the PCB loading process, these loaders significantly reduce manual labor and increase production throughput.

2. Enhanced Precision: The use of vacuum technology ensures that PCBs are handled gently and accurately, minimizing the risk of damage during transport.

3. Cost Savings: Reduced labor costs and lower risk of PCB damage contribute to overall cost savings in the production process.

4. Flexibility: These loaders can handle a wide range of PCB sizes and thicknesses, making them versatile for different production needs.

Advanced Technologies in SMT Production

In addition to vacuum loaders, other advanced technologies are being integrated into SMT production lines to enhance efficiency and quality. For example, vacuum modules are used in reflow convection soldering systems to ensure void-free soldering, which is critical for reliable assemblies[2]. Similarly, vapour phase soldering systems utilize vacuum-compatible designs to optimize the soldering process[2].

Future Developments

The future of SMT production involves further integration of automation and advanced technologies. This includes the development of high-temperature vacuum inline reflow soldering systems that offer improved zone segmentation and reduced heat overflow[5]. Such advancements are expected to enhance production efficiency and product quality in the electronics manufacturing industry.

Integration with Other SMT Equipment

SMT automatic vacuum PCB loaders are designed to work seamlessly with other equipment in the production line. They support SMEMA interfaces, which enable them to communicate effectively with downstream machines such as printers, pick-and-place machines, and reflow ovens. This integration ensures a smooth workflow and minimizes downtime during production.

Compatibility and Flexibility

The compatibility of these loaders with various PCB sizes and production environments makes them highly versatile. They can be easily integrated into different production setups, whether it's for SMT, THT (Through-Hole Technology), or conformal coating assembly lines[3][4].

Maintenance and Upkeep

Regular maintenance is crucial for ensuring the optimal performance of SMT automatic vacuum PCB loaders. This includes checking the vacuum system for leaks, cleaning the suction heads, and updating software for PLC control systems. Proper maintenance helps extend the lifespan of the equipment and maintains production efficiency.

Best Practices for Maintenance

1. Regular Cleaning: Regularly clean the suction heads and conveyor belts to prevent dust accumulation and ensure smooth operation.

2. Vacuum System Checks: Periodically check the vacuum system for leaks or blockages to maintain optimal suction power.

3. Software Updates: Keep the PLC control system updated with the latest software to ensure compatibility with other equipment and to access new features.

Conclusion

In conclusion, the vacuum technology in SMT automatic vacuum PCB loaders is a critical component that enhances the efficiency, precision, and reliability of the PCB loading process. By understanding how this technology works and the benefits it offers, manufacturers can optimize their SMT production lines for better performance and productivity.

FAQ

Here are some frequently asked questions about SMT automatic vacuum PCB loaders:

1. How does the vacuum technology in SMT PCB loaders ensure PCB safety?

The vacuum technology ensures PCB safety by providing a gentle yet firm grip on the boards, minimizing the risk of damage during handling and transport.

2. What are the typical air pressure requirements for SMT vacuum loaders?

The typical air pressure requirements for SMT vacuum loaders range from 0.4 to 0.6 MPa, depending on the specific model and application[1].

3. Can SMT vacuum loaders handle PCBs of different sizes and thicknesses?

Yes, SMT vacuum loaders are designed to handle PCBs of various sizes and thicknesses. They often feature adjustable lifting steps to accommodate different board thicknesses[1].

4. What is the role of PLC control in SMT vacuum loaders?

PLC control in SMT vacuum loaders allows for automated operations, customizable settings, and easy monitoring through touch screen interfaces[1][6].

5. How do SMT vacuum loaders integrate with other equipment in the production line?

SMT vacuum loaders typically integrate with other equipment through standard SMEMA interfaces, facilitating smooth communication and operation within the production line[1][6].

Citations:

[1] https://www.hayawin.com/product-vacuum-loader.html

[2] https://www.rehm-group.com/en/news/blog/details/rehm-presents-vacuum-technologies-at-smart-smt-pcb-assembly-in-korea.html

[3] https://www.jwide-smt.com/products/smt-pcb-magazine-loader/

[4] https://www.smtglobe.com/product/pcb-vacuum-loader.html

[5] https://www.productronicachina.com.cn/en/unlocking-diverse-challenges-in-the-pcb-industry-how-smt-soldering-technology-enhances-the-upgrade-of-electronic-manufacturing

[6] https://www.smtfactory.com/I-C-T-VL-M-SMT-Automatic-PCB-Translational-Vacuum-Loader-pd41931364.html

[7] https://www.youtube.com/watch?v=lKe810Kd29g

[8] https://www.jt-int.com/smt-vacuum-reflow-oven-revolutionizing-smt-assembly-technology/