Content Menu

● Introduction

● Overview of Tape and Reel Packaging

● Benefits of Tape and Reel Packaging

● Tape and Reel Machines in SMT

● Customization and Advanced Techniques

● Applications of Tape and Reel Packaging

● Challenges and Future Developments

● Conclusion

● FAQ

>> 1. What materials are used for the carrier and cover tapes in tape and reel packaging?

>> 2. How does the tape and reel process protect components during shipping?

>> 3. What are the advantages of using automated pick-and-place machines in tape and reel packaging?

>> 4. Can tape and reel packaging handle high-volume production?

>> 5. What types of components are typically packaged using the tape and reel method?

Introduction

The tape and reel process is a crucial component of Surface Mount Technology (SMT), which is widely used in the electronics manufacturing industry. This method involves packaging electronic components, particularly surface mount devices (SMDs), onto a carrier tape with individual pockets and then sealing them with a cover tape. The components are then wound onto a reel, making it easier to transport and handle them in automated assembly systems. In this article, we will delve into the details of how the tape and reel process works in SMT, its benefits, and its applications.

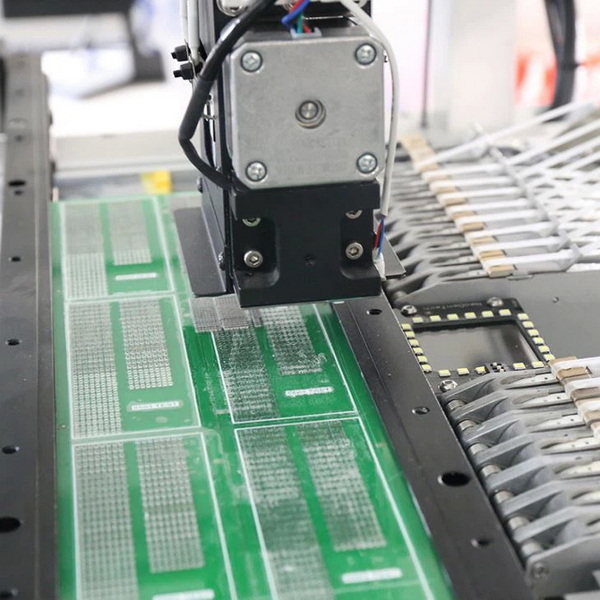

Overview of Tape and Reel Packaging

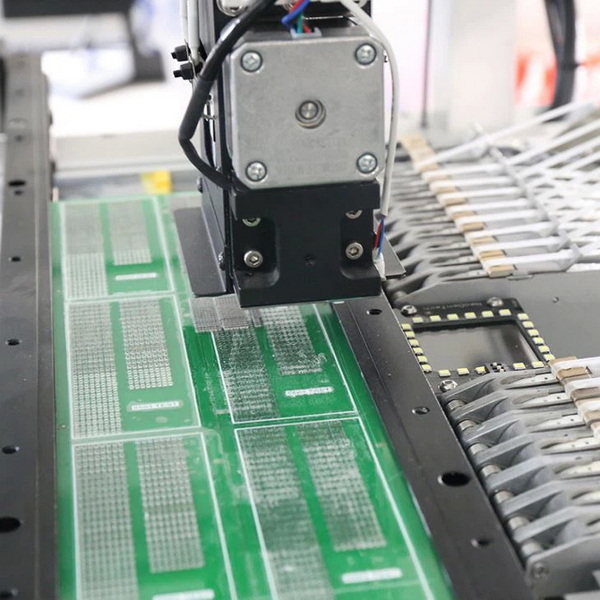

Tape and reel packaging is designed to simplify the handling of SMDs for automated circuit board assembly. The process begins with loading components onto a carrier tape, which is typically made of polycarbonate or polystyrene materials. The components are placed into thermoformed pockets on the tape at specific intervals using automated pick-and-place machines. Once the components are loaded, a cover tape, usually made of polyester, is applied over the carrier tape to secure the components in place. This cover tape uses pressure-sensitive or heat-activated adhesive to ensure that the components remain secure during shipping and handling.

The tape is then wound onto a reel, which can be either 7 inches or 13 inches in diameter, depending on the package type and customer specifications. The reels are fully compliant with industry standards such as EIA-481 and IEC 60286-3, ensuring compatibility with a wide range of automated assembly systems.

Benefits of Tape and Reel Packaging

The tape and reel packaging process offers several advantages in the electronics manufacturing industry:

1. Protection of Components: The process provides excellent protection to the components during transportation and storage. The cover tape shields the components from static electricity, moisture, and physical impact, reducing the risk of damage.

2. Efficiency in Assembly: Components packaged in tape and reel format can be easily fed into automated pick-and-place machines. This significantly reduces the time and labor required for assembly, as the machines can place components on printed circuit boards (PCBs) with high precision and speed.

3. High-Volume Production: Tape and reel packaging supports high-volume production by allowing components to be stored and transported in a compact and organized manner. This reduces inventory management challenges and minimizes the risk of misplacement or damage to components.

4. Cost-Effectiveness: The efficiency and precision of automated assembly processes reduce production costs. Additionally, the compact storage of components on reels saves space and reduces handling errors.

5. Environmental Benefits: By minimizing packaging waste and optimizing storage, tape and reel packaging contributes to more sustainable manufacturing practices.

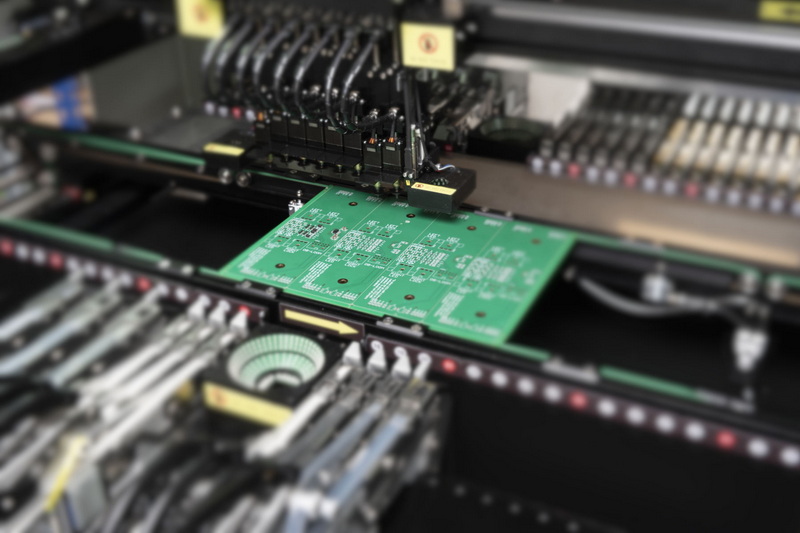

Tape and Reel Machines in SMT

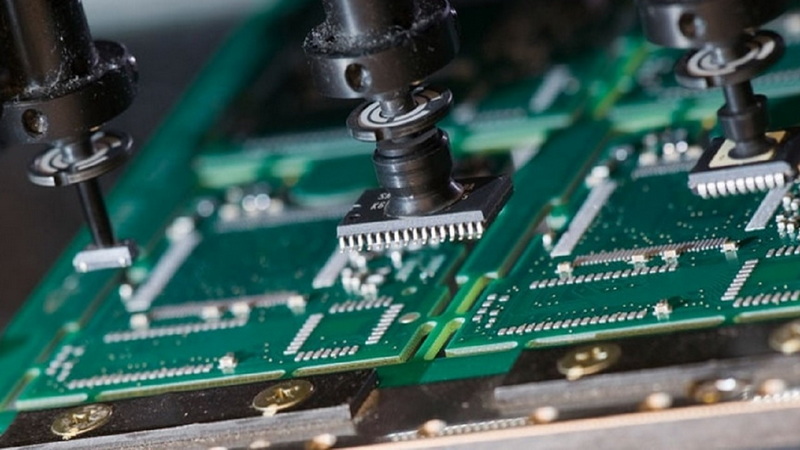

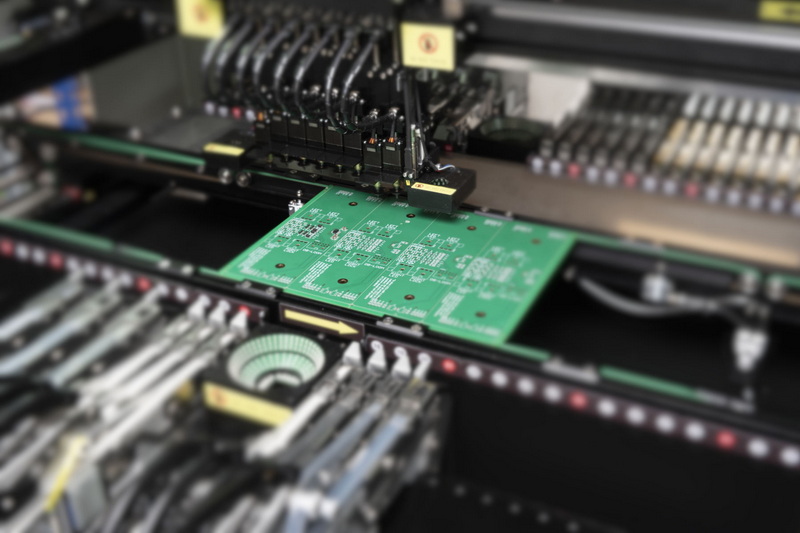

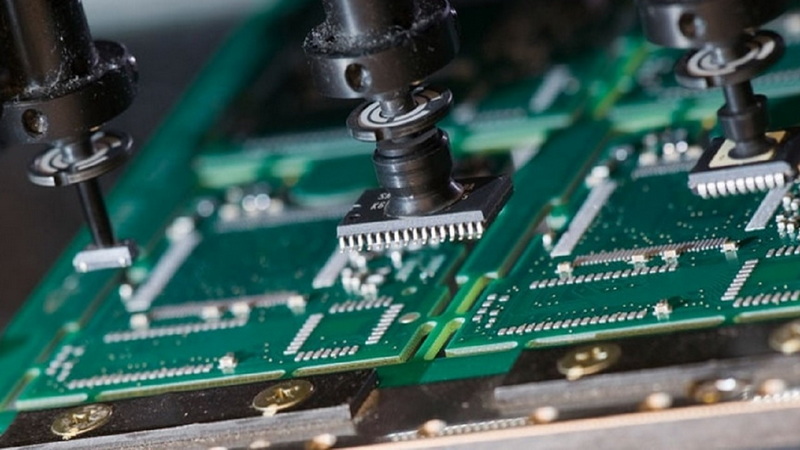

Tape and reel machines play a critical role in the SMT assembly process. These machines are designed to handle the tape and reel packaging efficiently, ensuring that components are accurately placed on PCBs. The machines typically include:

- Pick-and-Place Mechanisms: These mechanisms use vacuum nozzles to pick components from the tape and place them on the PCB with high precision. Advanced machines often include vision systems to verify component placement and detect any errors.

- Reel Handling Systems: These systems manage the reels, unwinding the tape as needed and feeding it into the pick-and-place mechanism. They ensure smooth and continuous operation, minimizing downtime and maximizing production throughput.

- Tape Cutting and Splicing: Some machines are equipped with features to cut and splice the tape, allowing for seamless transitions between reels and minimizing production interruptions.

Customization and Advanced Techniques

To meet the unique needs of different customers, companies like Rowley Spring and Stamping Corp. offer customized tape and reel solutions. They design and build specialized pick-and-place equipment that integrates advanced vision systems to ensure accurate placement and compliance with industry standards.

Additionally, some manufacturers use continuous reel-to-reel methods, where components are stamped from raw material into a continuous strip and loaded onto a reel. This method allows for efficient production and assembly of components without the need for individual pockets on the tape.

Applications of Tape and Reel Packaging

Tape and reel packaging is widely used across various sectors of the electronics industry, including:

- Consumer Electronics: Components for smartphones, laptops, and other consumer devices are often packaged in tape and reel format to facilitate high-volume production and efficient assembly.

- Automotive Electronics: The automotive industry relies on tape and reel packaging for components used in vehicle systems, such as navigation and safety systems.

- Industrial Electronics: Industrial control systems and machinery often require components packaged in tape and reel format for efficient assembly and reliability.

- Medical Devices: In the medical sector, tape and reel packaging is used for components in medical devices, ensuring precision and reliability in assembly.

Challenges and Future Developments

Despite its advantages, the tape and reel process faces challenges such as maintaining component quality during long-term storage and ensuring compatibility with evolving automated assembly systems. To address these challenges, manufacturers are investing in advanced materials and technologies that enhance component protection and improve machine efficiency.

Future developments in tape and reel packaging include the integration of smart materials that can monitor environmental conditions and alert manufacturers to potential risks. Additionally, advancements in automation and robotics are expected to further enhance the precision and speed of component placement.

Conclusion

The tape and reel process is a vital component of Surface Mount Technology, offering numerous benefits in terms of efficiency, cost-effectiveness, and component protection. As technology advances, the demand for tape and reel packaging is expected to continue, driven by its ability to support high-volume production and precise automated assembly.

FAQ

1. What materials are used for the carrier and cover tapes in tape and reel packaging?

The carrier tape is typically made from polycarbonate or polystyrene materials, while the cover tape is made from polyester.

2. How does the tape and reel process protect components during shipping?

The process protects components by sealing them between the carrier and cover tapes, shielding them from static electricity, moisture, and physical impact.

3. What are the advantages of using automated pick-and-place machines in tape and reel packaging?

Automated pick-and-place machines offer high precision, speed, and efficiency in component placement, reducing labor costs and assembly time.

4. Can tape and reel packaging handle high-volume production?

Yes, tape and reel packaging supports high-volume production by allowing components to be stored and transported in a compact and organized manner, reducing inventory management challenges.

5. What types of components are typically packaged using the tape and reel method?

The tape and reel method is commonly used for surface mount devices (SMDs), including resistors, capacitors, integrated circuits, and connectors.