Content Menu

● Introduction to SMT PCB Assembly

>> Key Factors Influencing SMT PCB Costs

● SMT Assembly Pricing Models

● Strategies for Reducing SMT PCB Costs

● Impact of Lead Times on SMT Assembly Costs

● The Role of Automation in SMT Assembly

● Comparison of SMT and Through-Hole Components

● Design Considerations for Cost Reduction

● Supply Chain Management

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary factors influencing SMT PCB assembly costs?

>> 2. How does PCB design complexity affect SMT assembly costs?

>> 3. What are the advantages of using SMT components over through-hole components?

>> 4. How do economies of scale impact SMT PCB assembly costs?

>> 5. What strategies can be used to reduce SMT PCB assembly costs?

● Citations:

The Surface Mount Technology (SMT) process is a cornerstone of modern electronics manufacturing, playing a pivotal role in the production of printed circuit boards (PCBs). Understanding how SMT impacts the cost of PCB production is crucial for manufacturers seeking to optimize their budgets and improve efficiency. This article delves into the key factors influencing SMT PCB costs, explores strategies for cost reduction, and discusses the various pricing models available in the industry.

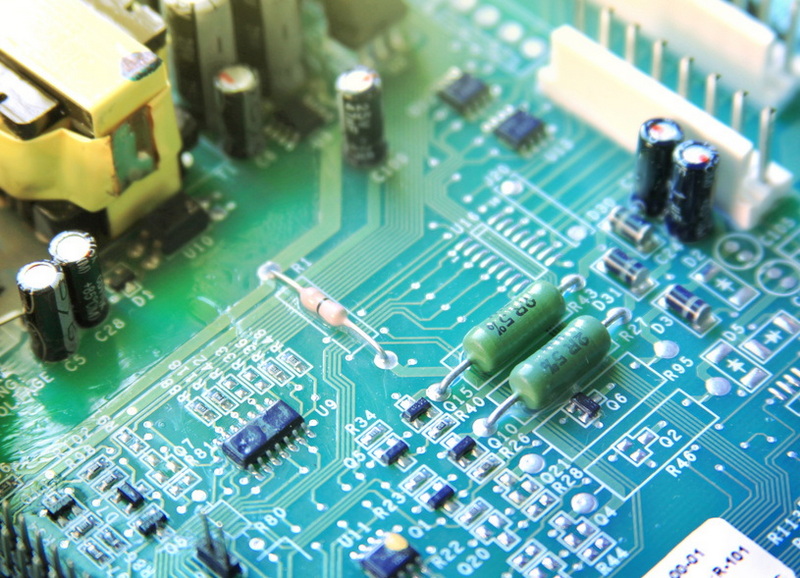

Introduction to SMT PCB Assembly

SMT assembly is a method where electronic components are mounted directly onto the surface of a PCB. This technique has become the standard in electronics manufacturing due to its efficiency, reliability, and cost-effectiveness compared to traditional through-hole technology. The SMT process involves several stages, including component placement, solder paste application, and reflow soldering. Each stage contributes to the overall cost of PCB production.

Key Factors Influencing SMT PCB Costs

The cost of SMT PCB assembly is influenced by several key factors:

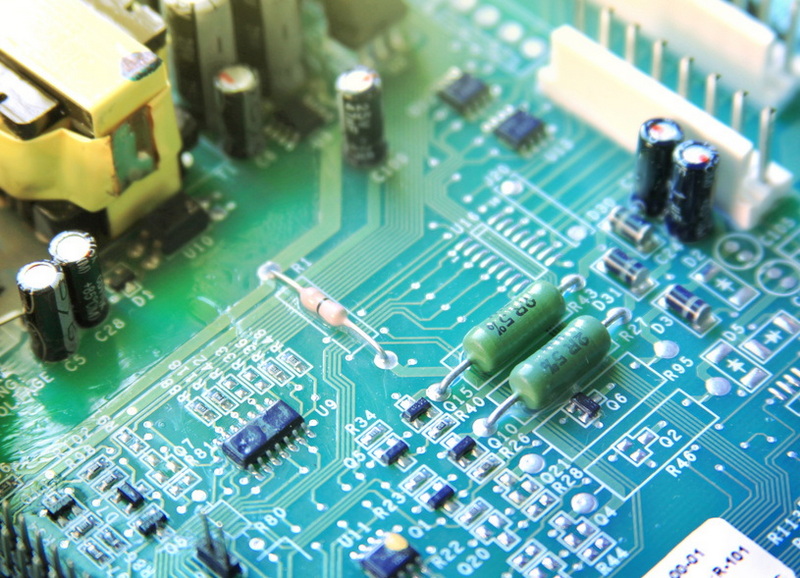

1. Material Costs: The cost of the PCB itself, including the type of substrate (e.g., FR-4, Aluminum), thickness, copper weight, and surface finish, significantly impacts the overall cost. Additionally, the bill of materials (BOM), which includes all components such as resistors, capacitors, and integrated circuits, plays a crucial role in determining the final assembly cost.

2. Labor Expenses: Labor costs encompass not only assembly workers but also engineers, quality control personnel, and setup technicians. The level of automation in the assembly process affects these costs, with more automated processes generally reducing labor expenses.

3. Equipment Utilization: The type and efficiency of machinery used, along with their operating and maintenance costs, influence assembly pricing. Advanced equipment often results in higher costs due to increased precision and speed.

4. Design Complexity: The complexity of the PCB design, including factors such as the number of layers, component density, and specialized design requirements (e.g., vias, impedance control), directly affects assembly costs. More complex designs require more precise assembly techniques and specialized equipment, increasing costs.

5. Production Volume: Economies of scale play a significant role in SMT PCB assembly. Larger production volumes typically lead to lower per-unit costs due to the distribution of fixed costs over more units.

SMT Assembly Pricing Models

Understanding the different pricing models for SMT assembly is essential for effective cost management. The most common models include:

- Per-Pad Pricing: Costs are calculated based on the number of solder pads on the PCB. This model is transparent and suitable for simpler designs but can become costly for complex PCBs with many pads.

- Per-Component Pricing: Costs are determined by the number of components placed on the PCB. This model reflects the complexity of part placement and is beneficial for designs with a high variety of component types.

- Turnkey Pricing: This comprehensive model covers all aspects from component sourcing to assembly, and sometimes testing. It offers convenience and reduces supply chain management overhead but may be more expensive overall.

Strategies for Reducing SMT PCB Costs

Minimizing SMT PCB costs requires a strategic approach that focuses on optimizing design, material selection, and supply chain management. Here are some practical tips:

1. Optimize PCB Design: Simplifying PCB designs can reduce costs by minimizing the number of layers and using standard footprints. This approach also reduces material usage and manufacturing complexity.

2. Component Selection: Choosing standard, readily available components can lower material costs. Consolidating component values and utilizing multi-function components can further reduce the BOM size and simplify procurement.

3. Panelization and Order Quantity: Panelizing PCBs maximizes manufacturing efficiency, and larger order quantities often yield lower per-unit costs due to volume discounts.

4. Effective Supplier Management: Establishing strong relationships with reliable suppliers who offer competitive pricing and high-quality services is crucial. Regularly reviewing pricing and considering multi-sourcing can mitigate price increases and supply chain risks.

5. Design for Manufacturability (DFM): Implementing DFM principles early in the design process reduces manufacturing challenges and rework, improving yield and reducing assembly time and costs.

Impact of Lead Times on SMT Assembly Costs

Lead times in SMT assembly are not just about delivery timelines; they significantly impact production costs. Short lead times can lead to rushed production, resulting in overtime and increased operational expenses. Conversely, extending lead times can help reduce costs by avoiding expedited processes and improving quality.

The Role of Automation in SMT Assembly

Automation plays a crucial role in reducing SMT assembly costs. By leveraging advanced machinery such as pick-and-place machines and automated inspection systems, manufacturers can significantly decrease labor costs and improve production efficiency. Full automation of the SMT process, from PCB printing to assembly and inspection, offers great opportunities for optimizing production costs while maintaining high-quality standards[3][5].

Comparison of SMT and Through-Hole Components

SMT components generally offer a cost advantage over through-hole components due to their automated assembly process, which reduces labor costs and improves efficiency. In contrast, through-hole techniques require more manual labor, increasing costs and reducing production speed[7]. However, through-hole components can be beneficial in certain applications where mechanical strength is crucial.

Design Considerations for Cost Reduction

Several design considerations can help reduce PCB assembly costs:

1. Component Placement: Keeping SMT components on one side of the PCB simplifies assembly and reduces costs. Avoiding arbitrary angles for component placement ensures compatibility with automated assembly machines[1].

2. Component Spacing: Ensuring adequate spacing between components and the PCB edge facilitates easier assembly and reduces the risk of component damage during handling[1].

3. Visible Leads: Including components with visible leads in the design can reduce inspection costs by avoiding the need for X-ray inspections, which are typically required for components like BGAs and QFNs[1].

4. Standardization: Using industry-standard component sizes and PCB dimensions simplifies manufacturing and reduces setup times[1].

5. Panelization: Panelizing PCBs makes it easier and less time-consuming for assembly houses to work with large panels, reducing overall assembly costs[1].

Supply Chain Management

Effective supply chain management is essential for controlling SMT PCB costs. This includes sourcing components from reliable suppliers, maintaining a flexible BOM to accommodate component availability and pricing fluctuations, and ensuring timely delivery of components to meet production schedules.

Conclusion

The SMT process significantly impacts the cost of PCB production through various factors such as material costs, labor expenses, equipment utilization, design complexity, and production volume. Understanding these factors and implementing strategies for cost reduction, such as optimizing PCB design and effective supplier management, are crucial for manufacturers seeking to optimize their budgets. By leveraging the right pricing models and managing lead times effectively, businesses can achieve cost-effective PCB assembly without compromising quality or performance.

Frequently Asked Questions

1. What are the primary factors influencing SMT PCB assembly costs?

- The primary factors include material costs (PCB and components), labor expenses, equipment utilization, design complexity, and production volume.

2. How does PCB design complexity affect SMT assembly costs?

- Complex designs with multiple layers, dense component placement, and specialized requirements increase costs due to the need for precise assembly techniques and advanced machinery.

3. What are the advantages of using SMT components over through-hole components?

- SMT components offer a cost advantage due to automated assembly processes, which reduce labor costs and improve efficiency compared to through-hole techniques.

4. How do economies of scale impact SMT PCB assembly costs?

- Larger production volumes lead to lower per-unit costs by distributing fixed costs over more units, reducing labor and component costs through bulk purchasing and automation.

5. What strategies can be used to reduce SMT PCB assembly costs?

- Strategies include optimizing PCB design, selecting cost-effective components, panelizing PCBs, managing suppliers effectively, and implementing design for manufacturability principles.

Citations:

[1] https://camptechii.com/14-actionable-ways-to-lower-your-pcb-assembly-cost-and-make-your-boards-easier-to-test/

[2] https://www.anypcba.com/blogs/pcb-assembly-knowledge/understanding-smt-assembly-cost-a-comprehensive-guide.html

[3] https://vectorbluehub.com/smt-assembly

[4] https://www.wellpcb.com/blog/pcb-manufacturing/reducing-pcb-cost/

[5] https://arkcircuits.com/blog/impact-of-smt-on-modern-pcb-design/

[6] https://www.pcbpower.us/blog/the-definitive-guide-to-reducing-pcb-assembly-costs-and-enhancing-efficiency

[7] https://reprosupplies.co.za/what-factors-influence-the-cost-of-an-smt-assembly-project/

[8] https://jlcpcb.com/blog/the-definitive-guide-to-reducing-pcb-assembly-costs-and-enhancing-efficiency

[9] https://www.atmwa.com.au/the-different-pcb-assembly-methods-and-how-they-impact-cost-savings/

[10] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[11] https://www.7pcb.com/blog/factors-affecting-cost-pcb-production

[12] https://www.andwinpcb.com/advancements-in-smt-assembly-techniques-for-modern-manufacturing/

[13] https://resources.altium.com/p/simple-strategies-reach-10-pcb-cost-reduction

[14] https://www.prideindustries.com/our-stories/smt-process

[15] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction

[16] https://www.pcbcart.com/article/content/cut-pcba-cost-without-sacrificing-qualit.html

[17] https://emsginc.com/resources/how-to-reduce-pcb-costs-and-turnaround-times/

[18] https://www.linkedin.com/pulse/smt-assembly-capabilities-advancing-modern-kfotc

[19] https://www.reddit.com/r/PCB/comments/12k56m8/what_steps_are_taken_to_reduce_the_cost_of_a/

[20] https://www.andwinpcb.com/understanding-smt-assembly-quotes-for-efficient-manufacturing/