Content Menu

● Introduction to SMT Reel Counters

>> Key Features of SMT Reel Counters

● Benefits of Renting SMT Reel Counters

● The Rental Process

● Rental Providers and Their Services

● Choosing the Right Rental Provider

● Advanced Technologies in SMT Reel Counters

>> X-Ray Counters

>> AI and ML Integration

● SMT Reel Counters in Various Industries

● Case Studies and Real-World Applications

● Advanced Technologies and Their Impact

● Real-World Applications and Case Studies

● Future Developments and Trends

● Conclusion

● FAQs

>> 1. What are the primary benefits of renting SMT reel counters?

>> 2. How do SMT reel counters improve inventory accuracy?

>> 3. What types of components can SMT reel counters handle?

>> 4. What is the typical rental duration for SMT reel counters?

>> 5. Do rental providers offer training for SMT reel counter operators?

The rental process for SMT reel counters is designed to provide businesses with flexible and cost-effective solutions for managing their electronic component inventory. SMT reel counters are essential tools in the electronics manufacturing industry, used for accurately counting components on reels to ensure efficient production and inventory management. In this article, we will delve into the details of the rental process, highlighting the benefits, key features of SMT reel counters, and how they support businesses in optimizing their operations.

Introduction to SMT Reel Counters

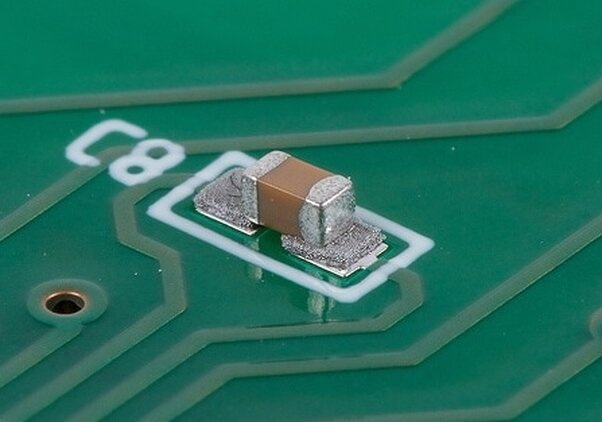

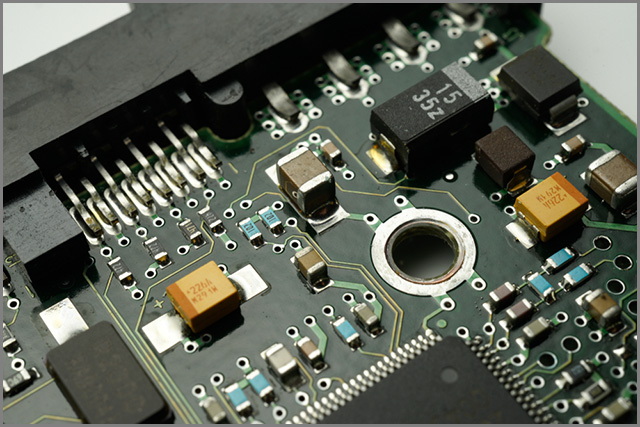

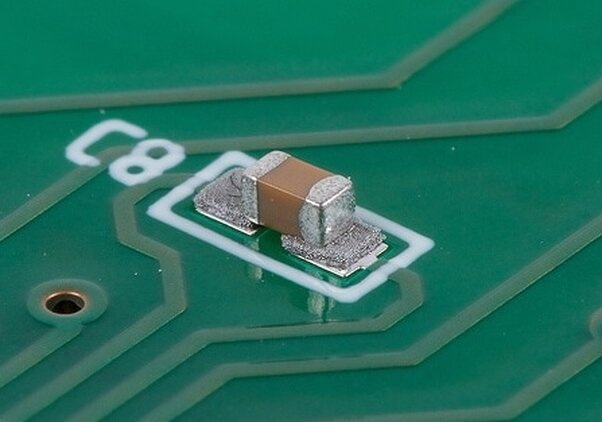

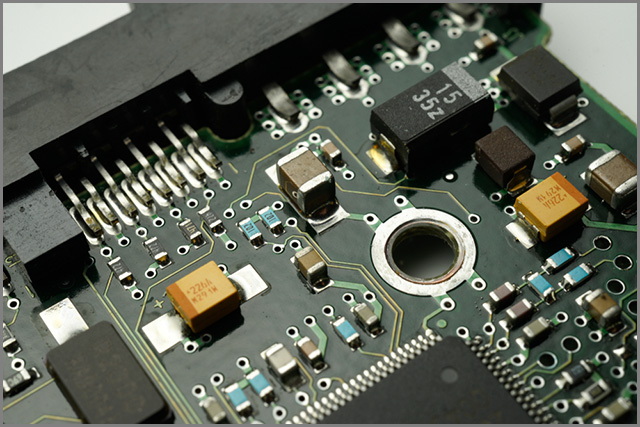

SMT reel counters are specialized machines used to count surface mount technology (SMT) components stored on reels. These components include resistors, capacitors, inductors, and integrated circuits, among others. The counters are crucial for maintaining accurate inventory levels, reducing errors in component counting, and enhancing production efficiency.

Key Features of SMT Reel Counters

1. Accuracy: Most SMT reel counters offer high accuracy levels, often up to 99.99%, ensuring reliable inventory management.

2. Speed: They can process entire reels quickly, some in as little as 90 seconds, making them ideal for high-volume production environments.

3. Missing Part Detection: Advanced models feature missing part detection, which stops the machine if a component is missing, preventing errors and improving inventory accuracy.

4. Flexibility: They can handle various reel sizes and component types, including small components like 01005s.

Benefits of Renting SMT Reel Counters

Renting SMT reel counters provides several benefits for businesses:

- Cost Savings: Renting eliminates the need for a significant upfront capital investment, allowing companies to allocate resources more efficiently.

- Flexibility: Rental options can be tailored to meet short-term or seasonal needs, providing flexibility in managing production cycles.

- Access to Latest Technology: Renting allows businesses to use the latest models without the long-term commitment of purchasing, ensuring they always have access to the most advanced technology.

- Reduced Maintenance Costs: Maintenance and repair responsibilities typically fall on the rental provider, reducing operational costs for the business.

The Rental Process

The rental process for SMT reel counters typically involves the following steps:

1. Initial Inquiry: Businesses contact rental providers to inquire about available models and pricing.

2. Equipment Selection: Choose the appropriate SMT reel counter model based on specific needs, such as component type and counting speed.

3. Rental Agreement: Sign a rental agreement outlining terms, including duration, cost, and any additional services like maintenance or training.

4. Delivery and Setup: The rental provider delivers and sets up the equipment, often providing training for operators.

5. Usage and Support: Use the equipment during the rental period, with support available for any technical issues.

6. Return or Renewal: At the end of the rental period, decide whether to return the equipment or renew the rental agreement.

Rental Providers and Their Services

Several companies offer SMT reel counter rental services, each providing unique benefits:

- Scienscope: Offers a rent-to-own program for their AXC-800 x-ray table top component reel counter, allowing customers to apply rental payments towards a purchase.

- Scale Services & Sales: Provides a wide range of counting scales and SMD component counters with flexible rental options and customized solutions.

- Data Weighing Systems: Offers manual and motorized reel counters for short-term needs, with customization options for specific applications.

Choosing the Right Rental Provider

When selecting a rental provider, consider the following factors:

- Equipment Variety: Ensure they offer models that meet your specific component counting needs.

- Support and Training: Look for providers that offer comprehensive training and technical support.

- Flexibility in Rental Terms: Opt for providers with flexible rental periods and options to renew or purchase.

- Cost and Value: Evaluate the cost-effectiveness of the rental service compared to purchasing.

Advanced Technologies in SMT Reel Counters

Recent advancements in SMT reel counters include the integration of X-ray technology, which provides non-destructive analysis of components. This technology is particularly beneficial for detecting internal defects and ensuring component quality without damaging them. Additionally, the use of Artificial Intelligence (AI) and Machine Learning (ML) enhances the accuracy of defect detection and reduces false positives, further improving the reliability of inspections in manufacturing processes.

X-Ray Counters

SMT reel X-ray counters leverage X-ray imaging to provide precise counts without damaging components. They are especially valuable in high-volume production environments where accuracy and speed are paramount. These counters:

- Improve Efficiency: Automate the counting process, significantly reducing labor costs and errors associated with manual counting.

- Enhance Quality Control: Use X-ray imaging to inspect the internal structure of components, detecting defects such as soldering issues.

- Integrate with Management Systems: Seamlessly integrate with ERP, MES, and WMS systems for real-time inventory updates.

AI and ML Integration

The integration of AI and ML in SMT reel counters enables real-time data analysis, improving the accuracy of defect detection and reducing false positives. AI-driven systems can learn from historical data, adapting their detection criteria based on patterns and anomalies, which significantly enhances the reliability of inspections in manufacturing processes.

SMT Reel Counters in Various Industries

SMT reel counters are widely used across different industries, including:

- Electronics Manufacturing: Critical for SMT production lines where component accuracy is vital.

- Automotive Industry: Used for counting and quality control of automotive electronic components.

- Inventory Management: Essential for maintaining accurate stock levels and optimizing supply chains.

Case Studies and Real-World Applications

In real-world applications, SMT reel counters have been instrumental in improving production efficiency and quality control. For instance, in the automotive industry, these counters are used to ensure the accuracy and reliability of electronic components, which is critical for safety and performance. Similarly, in consumer electronics, they help maintain high-quality standards by detecting defects early in the manufacturing process.

Advanced Technologies and Their Impact

The integration of advanced technologies such as X-ray imaging and AI/ML in SMT reel counters has revolutionized the electronics manufacturing industry. These technologies not only improve counting accuracy but also enhance quality control by detecting internal defects in components. The use of X-ray counters allows for non-destructive testing, ensuring that components remain undamaged during the inspection process. This is particularly important for fragile or sensitive components, where manual handling could lead to damage.

Moreover, the integration of AI and ML enables these systems to learn from historical data, improving their ability to detect anomalies and defects over time. This adaptive capability significantly enhances the reliability of inspections, reducing false positives and ensuring that only high-quality components are used in production.

Real-World Applications and Case Studies

In real-world applications, SMT reel counters have proven to be indispensable for maintaining high production standards. For example, in the automotive industry, these counters are used to ensure the accuracy and reliability of electronic components. This is critical for safety and performance, as faulty components can lead to serious issues in vehicles. Similarly, in consumer electronics, SMT reel counters help maintain high-quality standards by detecting defects early in the manufacturing process, ensuring that products meet stringent quality requirements.

By adopting SMT reel counters, businesses can significantly improve their production efficiency and quality control. These counters enable real-time inventory management, allowing companies to adjust production schedules and inventory levels promptly. This flexibility is crucial in today's fast-paced electronics manufacturing environment, where demand can fluctuate rapidly.

Future Developments and Trends

Looking ahead, the future of SMT reel counters is promising, with ongoing advancements in technology expected to enhance their capabilities further. The integration of Industry 4.0 principles, such as IoT connectivity, will enable real-time monitoring and remote diagnostics, enhancing operational efficiency and reducing downtime. Additionally, advancements in X-ray imaging techniques, such as phase-contrast X-ray imaging, will provide a more detailed view of the internal structures of components, offering superior contrast and resolution compared to traditional X-ray imaging.

Conclusion

The rental process for SMT reel counters offers businesses a flexible and cost-effective way to manage their electronic component inventory. By leveraging advanced technologies and understanding the benefits of these counters, companies can optimize their production processes, reduce costs, and stay competitive in the electronics manufacturing sector.

FAQs

1. What are the primary benefits of renting SMT reel counters?

- Renting SMT reel counters offers cost savings, flexibility in managing production cycles, access to the latest technology, and reduced maintenance costs.

2. How do SMT reel counters improve inventory accuracy?

- SMT reel counters improve inventory accuracy by providing precise component counts, often with missing part detection features that prevent errors and ensure accurate inventory levels.

3. What types of components can SMT reel counters handle?

- SMT reel counters can handle a variety of components, including resistors, capacitors, inductors, and integrated circuits, as well as small components like 01005s.

4. What is the typical rental duration for SMT reel counters?

- Rental durations can vary, but common terms range from a few months to several years, depending on the provider and specific business needs.

5. Do rental providers offer training for SMT reel counter operators?

- Yes, many rental providers offer training for operators to ensure they can effectively use the equipment and maximize its benefits.