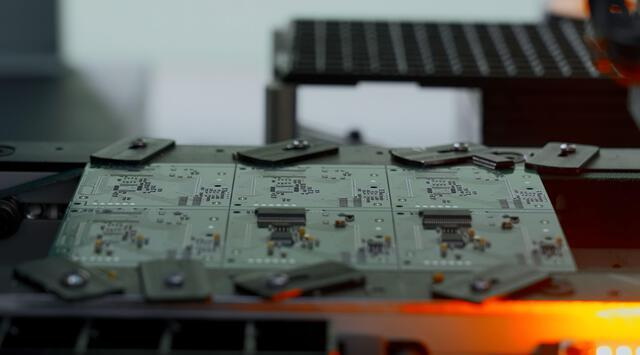

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. Panasonic's Surface Mount Technology (SMT) lines have emerged as a game-changer, offering unparalleled advantages in production efficiency. This article delves into how Panasonic's SMT lines revolutionize the manufacturing process, ensuring high-quality output and reduced operational costs.

Key Features of Panasonic SMT Lines

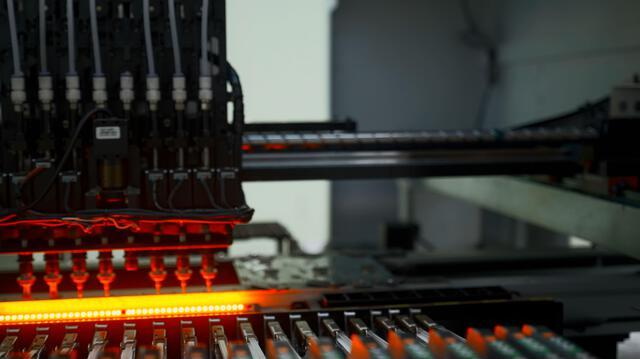

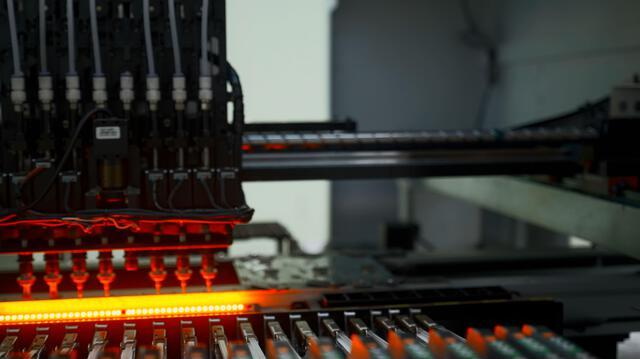

1. High-Speed Component Placement

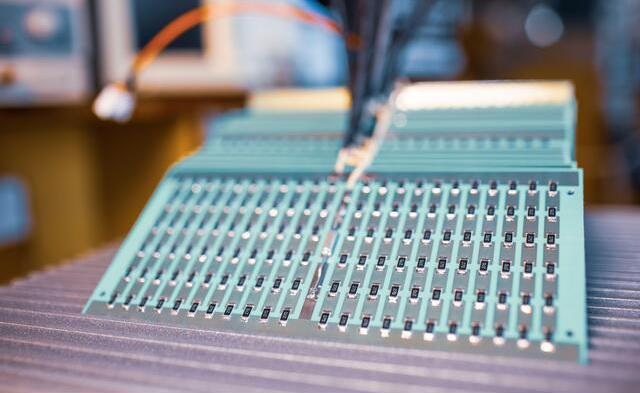

Panasonic's SMT lines, such as the NPM series, are designed for high-speed component placement, achieving speeds of up to 171,000 components per hour. This capability is crucial for meeting the demands of large-scale production runs. The rapid placement not only accelerates production but also allows manufacturers to respond swiftly to market changes.

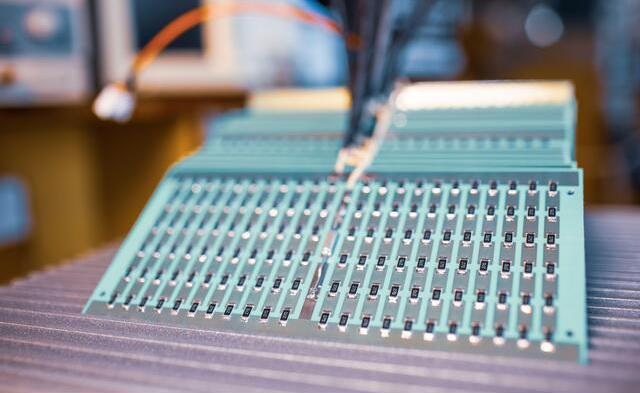

2. Advanced Inspection Systems

Integrated Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) systems ensure that every component is placed accurately, maintaining high-quality standards throughout the production process. These advanced inspection technologies help identify defects early, reducing waste and rework.

3. Modular and Scalable Design

The modular design of Panasonic SMT lines allows manufacturers to start small and scale up operations as needed, making them suitable for both small-scale and large-scale production. This flexibility is essential for businesses looking to adapt to varying production demands without significant capital investment.

4. Integration with Factory Automation

Panasonic's SMT lines are equipped with software solutions for factory automation, optimizing workflow and resource management. This integration enhances overall operational efficiency by streamlining processes from material handling to final assembly.

5. Energy Efficiency and Sustainability

Real-time intelligent machine monitoring not only enhances efficiency but also contributes to energy savings, aligning with sustainability goals. By minimizing downtime and optimizing machine performance, Panasonic's SMT solutions support environmentally friendly manufacturing practices.

Benefits of Using Panasonic SMT Lines

Enhanced Production Efficiency

By automating the assembly process, Panasonic SMT lines significantly reduce manual labor and assembly time. This automation leads to faster turnaround times and increased output, allowing manufacturers to meet tight deadlines without compromising quality.

Improved Product Quality

With advanced inspection systems, manufacturers can ensure defect-free products, enhancing customer satisfaction. The ability to detect errors in real-time means that corrective actions can be taken immediately, further improving quality control measures.

Cost-Effectiveness

The combination of reduced labor costs and increased throughput leads to substantial cost savings. Manufacturers can achieve higher profit margins by lowering operational expenses while maintaining high production levels.

Versatility

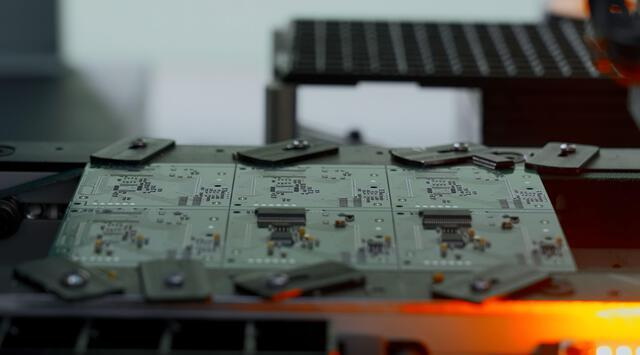

Panasonic SMT lines can handle a wide range of components, from tiny resistors to large connectors, making them versatile for various industries. This adaptability allows manufacturers to diversify their product offerings without needing multiple specialized machines.

Applications of Panasonic SMT Lines

Consumer Electronics

From smartphones to home appliances, Panasonic SMT lines are integral to assembling compact electronic devices. The efficiency and precision of these lines ensure that consumer electronics meet the high standards expected by today's consumers.

Automotive Industry

With the rise of electric vehicles and advanced driver-assistance systems (ADAS), reliable electronic components are essential. Panasonic's SMT solutions provide the speed and accuracy needed for automotive electronics manufacturing.

Medical Devices

High precision is critical in medical electronics; thus, Panasonic SMT lines are employed in producing devices like pacemakers and diagnostic equipment. The reliability and quality assurance provided by these machines are vital in this highly regulated industry.

Case Studies Highlighting Efficiency Improvements

Ionics EMS Inc., Philippines

The introduction of Panasonic's latest SMT solutions at Ionics EMS resulted in a significant increase in production capacity and efficiency. By reducing the number of assembly lines from 65 to 37 while tripling production capacity, Ionics exemplified how Panasonic's integrated hardware and software can transform operations into a smart factory environment[2].

Incap UK's Upgrade

Incap UK upgraded its production line with advanced Panasonic SMT machinery, resulting in a 33% increase in overall production efficiency[3][10]. The integration of high-precision printers and placement machines allowed for quicker setups and improved material control while reducing environmental impact through intelligent monitoring systems.

Shimane Fujitsu Limited

Shimane Fujitsu Limited utilized Panasonic's hardware and software solutions to transition into high-mix low-volume production efficiently. They achieved a reduction in staff by 40% while improving productivity by 30%[5]. This case demonstrates how Panasonic's technology can adapt to diverse manufacturing needs while maintaining quality standards.

Future Trends in SMT Technology

As industries evolve towards more automated processes, the future of SMT technology will likely focus on:

- Artificial Intelligence Integration: AI will play a crucial role in predictive maintenance and real-time decision-making processes within manufacturing environments.

- Increased Customization: Manufacturers will demand more flexible systems that can quickly adapt to changing product designs without extensive reconfiguration.

- Sustainability Initiatives: Future SMT lines will emphasize energy efficiency and waste reduction as part of broader corporate social responsibility goals.

- Enhanced Connectivity: The Internet of Things (IoT) will facilitate better communication between machines on the factory floor, leading to smarter operations overall.

Conclusion

Panasonic SMT lines represent the pinnacle of innovation in electronics manufacturing. Their combination of speed, precision, scalability, and integration with advanced software makes them an invaluable asset for companies aiming to enhance their production capabilities. As industries continue to evolve towards automation and sustainability, Panasonic's advanced SMT solutions will undoubtedly play a pivotal role in shaping the future of manufacturing.

FAQ

1. What is an SMT line?

An SMT line is a series of interconnected machines used to assemble electronic components onto printed circuit boards (PCBs) with high speed and precision.

2. How does the Panasonic SMT line improve production efficiency?

Panasonic SMT lines enhance efficiency through high-speed component placement, advanced inspection systems, modular design for scalability, integration with factory automation software, and energy-efficient operations.

3. Can Panasonic SMT lines handle different types of components?

Yes, they are designed to accommodate a wide range of components from tiny resistors to large connectors.

4. Are Panasonic SMT lines suitable for small-scale production?

Yes, their modular design allows for scalability, making them ideal for both small-scale and large-scale production.

5. What industries benefit from Panasonic SMT lines?

Industries such as consumer electronics, automotive, medical devices, telecommunications, and industrial equipment benefit significantly from Panasonic SMT lines.

Citations:

[1] https://ap.connect.panasonic.com/my/en/smart-factory-smt-tht-fatp-and-beyond

[2] https://connect.panasonic.com/en/products-servicesfa/solutions/case-studies/ionics

[3] https://incapcorp.com/panasonic-highlights-incap-uk-in-new-case-study-on-advanced-smt-machinery/

[4] https://eu.connect.panasonic.com/gb/en/products/smart-factory-smt-tht-fatp-and-beyond

[5] https://connect.panasonic.com/en/products-servicesfa/solutions/case-studies/shimane-fujitsu

[6] https://bwmarketingworld.com/article/panasonic-smart-factory-solutions-india-introduces-advanced-npm-g-series-smt-machines--491718

[7] https://ap.connect.panasonic.com/id/en/about-panasonic-factory-solutions-asia-pacific-pte-ltd

[8] https://eu.connect.panasonic.com/gb/en/news/panasonic-increases-operational-efficiency-production-capacity-incap-uk

[9] https://www.eletimes.com/panasonic-launches-new-npm-g-series-smt-machines-in-india-for-a-fully-automated-production-line

[10] https://incapcorp.com/incap-uk-invests-in-state-of-the-art-smt-line-upgrades/