Content Menu

● What is the LED SMT 460 PCB Machine?

>> Key Features of the LED SMT 460 PCB Machine

● How Does It Enhance PCB Assembly Accuracy?

>> 1. Flying Vision System

>> 2. Dual Gantry with Multiple Heads

>> 3. Smart Feeder Mechanism

>> 4. Integrated Controller

>> 5. Advanced Software Integration

● Benefits of Using the LED SMT 460 PCB Machine

>> Improved Production Efficiency

>> Enhanced Reliability

>> Cost-Effectiveness

>> Flexibility

>> Scalability

● Applications of the LED SMT 460 PCB Machine

● Challenges Addressed by the LED SMT 460 PCB Machine

● Future Trends and the LED SMT 460 PCB Machine

● Conclusion

● FAQs

>> 1. What is the placement accuracy of the LED SMT 460 PCB machine?

>> 2. Can this machine handle different component sizes?

>> 3. Is the LED SMT 460 PCB machine suitable for mass production?

>> 4. What industries benefit most from this machine?

>> 5. How does the smart feeder system improve accuracy?

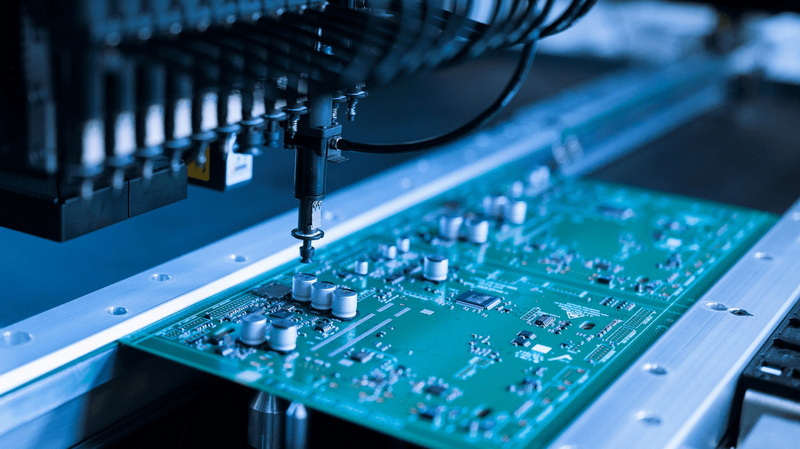

The automatic high precision LED SMT 460 PCB machine has revolutionized the PCB assembly process, particularly in the LED manufacturing industry. By combining cutting-edge technology, automation, and precision, this machine ensures high-quality production while reducing operational costs. As the demand for LED products continues to grow across industries, manufacturers are increasingly relying on advanced equipment like the LED SMT 460 PCB machine to meet stringent quality requirements and stay competitive in a rapidly evolving market.

What is the LED SMT 460 PCB Machine?

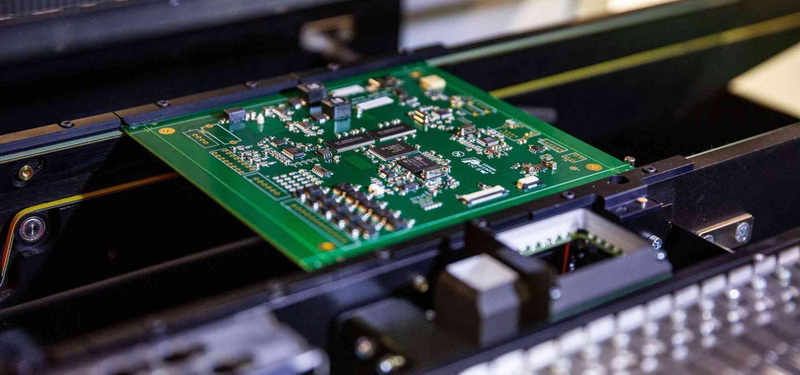

The LED SMT 460 PCB machine is a state-of-the-art automatic pick-and-place device designed for assembling printed circuit boards (PCBs) used in LED applications. It integrates advanced technologies such as flying vision systems, dual gantry heads, and smart feeders to ensure precise placement of components. This machine is particularly suitable for small to medium-sized enterprises (SMEs) and research laboratories due to its compact design, affordability, and high flexibility.

Key Features of the LED SMT 460 PCB Machine

1. High-Speed Placement: The machine boasts a placement rate of up to 18,000 components per hour (CPH), significantly boosting production efficiency.

2. Precision Alignment: Equipped with flying vision technology, it achieves placement accuracy of ±0.1mm, ensuring consistent quality.

3. Component Versatility: Supports a wide range of components from as small as 0603 resistors to larger components like LQFP80 ICs.

4. Smart Feeder System: Reduces feeding deviation and ensures smooth component delivery for uninterrupted operation.

5. Dual Gantry System: Features two gantries with four placement heads each, allowing simultaneous operations to reduce production time.

6. User-Friendly Interface: Offers intuitive software for programming and monitoring operations, making it accessible even for operators with minimal technical expertise.

How Does It Enhance PCB Assembly Accuracy?

The automatic high precision LED SMT 460 PCB machine incorporates several advanced features and technologies that work together to enhance accuracy in PCB assembly:

1. Flying Vision System

The flying vision system is a standout feature that inspects components during the placement process without compromising speed. Unlike traditional systems that rely on fixed cameras, flying vision uses high-speed cameras mounted on the placement heads to capture real-time images of components. This ensures that each component is perfectly aligned before being mounted on the board, minimizing placement errors.

The system's ability to detect and correct misalignments in real-time significantly reduces the likelihood of defects in the final product. It can identify issues such as component polarity, presence/absence, and even subtle variations in component dimensions that might affect the overall quality of the PCB.

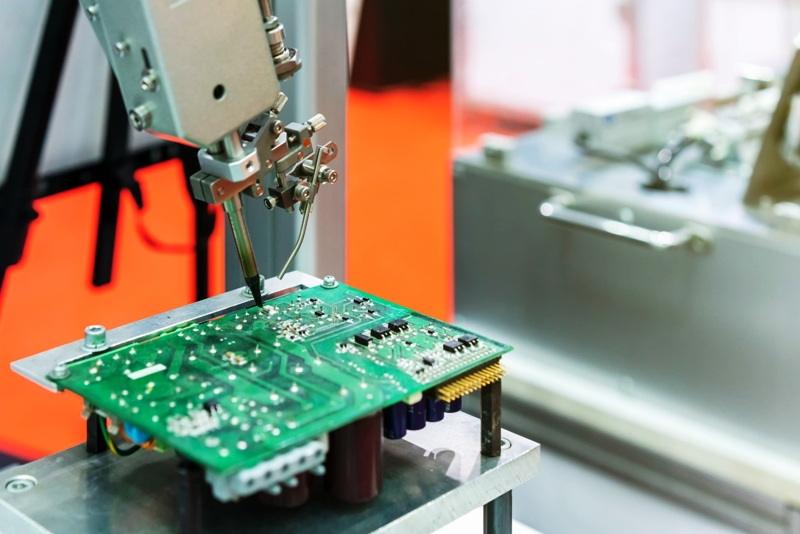

2. Dual Gantry with Multiple Heads

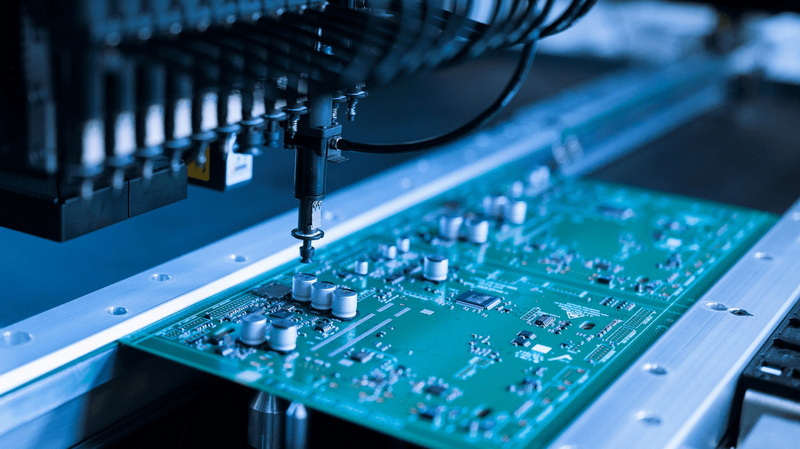

The dual gantry system is designed for simultaneous pick-and-place operations using multiple heads (four per gantry). This not only accelerates the assembly process but also ensures uniformity in component placement across all boards. By reducing manual handling and human intervention, the system virtually eliminates errors caused by fatigue or oversight.

Each gantry operates independently, allowing for optimized movement patterns that minimize travel time between component pickup and placement locations. This dual-gantry design effectively doubles the machine's throughput without compromising on accuracy.

3. Smart Feeder Mechanism

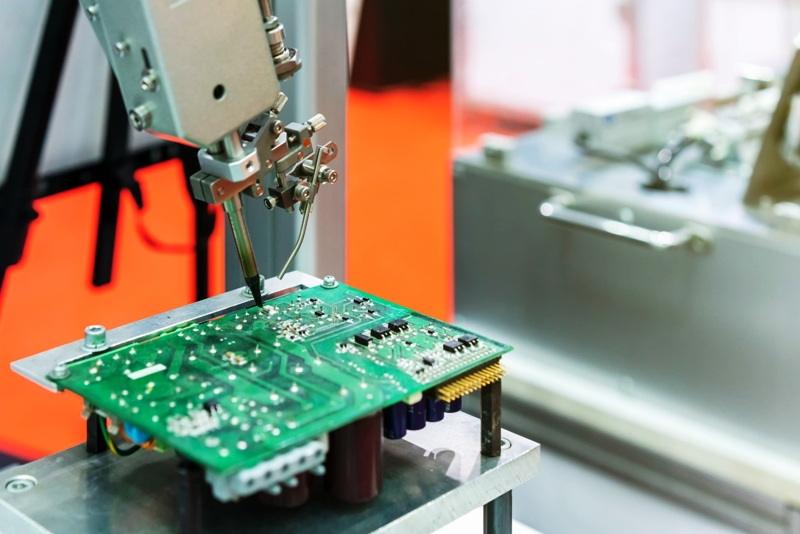

Feeding errors are one of the most common causes of misalignment in PCB assembly. The smart feeder mechanism of the LED SMT 460 PCB machine uses electronic actuation for ultra-smooth tape advancement. This minimizes feeding deviations and ensures that components are delivered accurately and consistently to the placement heads.

The smart feeders are also equipped with sensors that detect low tape levels, misfeeds, or jams, alerting operators before these issues can affect production quality. This proactive approach to component management significantly reduces downtime and improves overall efficiency.

4. Integrated Controller

An integrated controller manages all aspects of the machine's operation, from component alignment to placement speed and pressure. This centralized control system ensures stability and precision throughout the production cycle, even during high-speed operations.

The controller continuously monitors and adjusts various parameters in real-time, compensating for factors such as temperature fluctuations or slight variations in component dimensions. This adaptive control mechanism maintains consistent accuracy across long production runs.

5. Advanced Software Integration

The machine's software supports various file formats such as CSV and TXT for easy programming. It also offers online and offline programming capabilities, enabling manufacturers to fine-tune placement parameters for different types of PCBs. This level of customization ensures that every board meets exact specifications.

The software also includes features for production planning, inventory management, and quality control, providing a comprehensive solution for PCB assembly operations. It can generate detailed reports on machine performance, component usage, and production statistics, allowing managers to optimize processes and identify areas for improvement.

Benefits of Using the LED SMT 460 PCB Machine

The adoption of the automatic high precision LED SMT 460 PCB machine offers numerous benefits that go beyond just accuracy:

Improved Production Efficiency

With its high-speed placement capabilities and automated processes, this machine significantly reduces production time while maintaining consistent quality across batches. The dual gantry system and multiple placement heads allow for parallel operations, further accelerating the assembly process.

Enhanced Reliability

The precision alignment systems ensure consistent performance by minimizing defects such as misaligned components or soldering issues. This reliability translates into fewer reworks and higher customer satisfaction. The machine's ability to maintain accuracy over long production runs also contributes to improved product consistency.

Cost-Effectiveness

Automation reduces labor costs by minimizing manual intervention during the assembly process. Additionally, features like smart feeders reduce material wastage, further lowering production costs. The high accuracy of placement also reduces the need for post-assembly inspections and rework, saving both time and resources.

Flexibility

The machine's ability to handle various component sizes and types makes it suitable for diverse applications across industries such as consumer electronics, automotive lighting, and industrial LED solutions. This versatility allows manufacturers to adapt quickly to changing market demands without investing in multiple specialized machines.

Scalability

Whether you're producing small prototype batches or scaling up for mass production, the LED SMT 460 PCB machine can adapt to your needs without compromising on quality or efficiency. Its modular design allows for easy upgrades and modifications to meet future production requirements.

Applications of the LED SMT 460 PCB Machine

The versatility of the LED SMT 460 PCB machine makes it an invaluable asset across multiple industries:

- LED Lighting: Perfect for assembling PCBs used in LED strips, bulbs, panels, and other lighting solutions. The machine's precision is crucial for creating uniform and efficient LED products.

- Consumer Electronics: Widely used in devices requiring compact PCBs with high component density, such as smartphones, tablets, and wearable technology.

- Automotive Industry: Essential for assembling PCBs used in automotive lighting systems such as headlights, taillights, and interior lighting. The machine's reliability is particularly important in this safety-critical sector.

- Industrial Equipment: Ideal for manufacturing PCBs used in industrial-grade LED displays, control systems, and IoT devices. The machine's ability to handle a wide range of component sizes is particularly beneficial in this diverse field.

- Research & Development: A preferred choice for prototyping and small-scale production in R&D labs due to its flexibility and ease of use. The machine's quick setup and changeover capabilities make it ideal for experimental work.

Challenges Addressed by the LED SMT 460 PCB Machine

Modern manufacturing faces several challenges that can impact productivity and quality. The LED SMT 460 PCB machine effectively addresses these issues:

1. Manual Errors: Human errors during manual assembly can lead to misaligned components or defective boards. Automation eliminates these risks, ensuring consistent quality across all produced PCBs.

2. High Component Density: As PCBs become more compact with higher component density, manual assembly becomes impractical. The precision capabilities of this machine ensure accurate placement even on densely packed boards, meeting the demands of modern electronics design.

3. Time Constraints: Tight deadlines often compromise quality in manual assembly processes. The high-speed operation of this machine ensures timely delivery without sacrificing accuracy, helping manufacturers meet market demands efficiently.

4. Material Wastage: Feeding errors or misplacements can lead to significant material wastage in traditional processes. The smart feeder system minimizes such losses, contributing to cost savings and environmental sustainability.

5. Quality Consistency: Maintaining consistent quality across large production runs can be challenging with manual or less advanced systems. The LED SMT 460 PCB machine's integrated control and monitoring systems ensure uniform quality from the first board to the last.

6. Traceability: In industries with strict quality control requirements, traceability is crucial. The machine's software provides detailed logs of each assembly process, making it easier to track and resolve any issues that may arise.

Future Trends and the LED SMT 460 PCB Machine

As the electronics industry continues to evolve, the LED SMT 460 PCB machine is well-positioned to adapt to future trends:

- Miniaturization: The ongoing trend towards smaller, more compact electronic devices will require even greater precision in PCB assembly. The machine's high accuracy and ability to handle small components make it future-proof for this trend.

- Industry 4.0 Integration: With its advanced software and connectivity features, the LED SMT 460 PCB machine can easily integrate into smart factory setups, contributing to the Industry 4.0 revolution.

- Sustainability: As environmental concerns grow, the machine's efficiency and material-saving features align well with the push for more sustainable manufacturing practices.

- Customization and Flexibility: The trend towards product customization and shorter product lifecycles demands flexible manufacturing solutions. The LED SMT 460 PCB machine's adaptability makes it ideal for these changing market dynamics.

Conclusion

The automatic high precision LED SMT 460 PCB machine has set new standards in the field of PCB assembly by combining speed, accuracy, and automation into a single compact device. Its advanced features—such as flying vision systems, dual gantry heads, smart feeders, and integrated controllers—ensure unparalleled accuracy while boosting production efficiency and reducing costs.

For manufacturers aiming to produce high-quality LED products efficiently while staying competitive in an ever-evolving market, investing in this technology is not just an option but a necessity. The LED SMT 460 PCB machine addresses current manufacturing challenges and is well-equipped to meet future industry demands, making it a valuable asset for any electronics manufacturing operation.

FAQs

1. What is the placement accuracy of the LED SMT 460 PCB machine?

The machine achieves a placement accuracy of ±0.1mm due to its advanced flying vision system, ensuring precise component positioning on PCBs.

2. Can this machine handle different component sizes?

Yes, it supports components ranging from small sizes like 0603 resistors to larger ones like LQFP80 ICs, providing versatility for various PCB designs.

3. Is the LED SMT 460 PCB machine suitable for mass production?

Yes, with a placement rate of up to 18,000 CPH (components per hour), it is ideal for mass production while maintaining consistent quality across large batches.

4. What industries benefit most from this machine?

Industries such as LED lighting, automotive electronics (e.g., lighting systems), consumer electronics (e.g., compact devices), industrial equipment (e.g., displays), and R&D labs benefit significantly from this technology due to its precision and flexibility.

5. How does the smart feeder system improve accuracy?

The smart feeder system minimizes feeding deviations through ultra-smooth electronic actuation and tape advancement mechanisms, ensuring precise delivery of components during assembly and reducing the risk of misplacements or component damage.