Content Menu

● Understanding Surface Mount Technology (SMT)

>> Key Features of SMT

● Advantages of SMT in PCB Assembly

>> Increased Production Speed

>> Cost Efficiency

>> Enhanced Reliability

>> Flexibility in Design

>> Improved Thermal Management

● The Role of SMT in China's Electronics Industry

>> Challenges and Considerations

● Conclusion

● Related Questions

>> 1. What is the difference between SMT and through-hole technology?

>> 2. How does SMT affect the design of electronic devices?

>> 3. What are the common applications of SMT?

>> 4. What are the challenges associated with SMT?

>> 5. How does SMT improve the reliability of electronic devices?

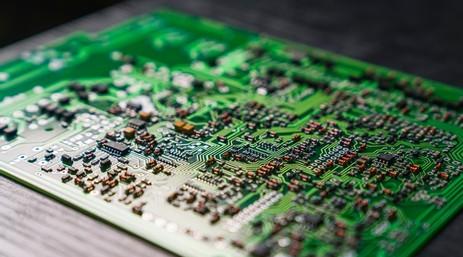

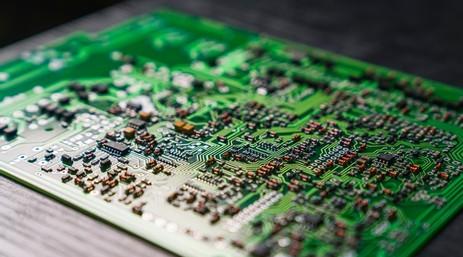

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). This method offers numerous advantages over traditional through-hole technology, making it a preferred choice in modern electronics manufacturing. In this article, we will explore how SMT improves the efficiency of PCB assembly, particularly in the context of China surface mount assembly, and discuss its impact on the electronics industry.

Understanding Surface Mount Technology (SMT)

Surface Mount Technology is a method where electronic components are mounted directly onto the surface of a PCB. Unlike through-hole technology, which requires components to be inserted into holes drilled in the board, SMT allows for a more compact design. Components used in SMT, known as Surface Mount Devices (SMDs), include resistors, capacitors, and integrated circuits, which are designed to be soldered onto the PCB surface.

Key Features of SMT

1. Compact Design: SMT enables a higher density of components on a PCB, allowing for smaller and lighter devices.

2. Automated Assembly: SMT processes are highly automated, which increases production speed and reduces labor costs.

3. Improved Performance: The shorter electrical paths in SMT can lead to better performance and reduced signal interference.

Advantages of SMT in PCB Assembly

Increased Production Speed

One of the most significant advantages of SMT is the speed at which PCBs can be assembled. Automated pick-and-place machines can quickly position components on the board, followed by reflow soldering, which melts solder paste to secure the components. This automation reduces the time required for manual assembly, allowing manufacturers to produce more units in less time.

Cost Efficiency

The use of SMT can lead to significant cost savings. The reduction in labor costs due to automation, combined with the ability to use smaller components that require less material, results in lower overall production costs. Additionally, the compact nature of SMT allows for more efficient use of PCB space, which can reduce material costs further.

Enhanced Reliability

SMT provides a more reliable connection between components and the PCB. The solder joints created during the reflow process are typically stronger and more resistant to mechanical stress compared to traditional through-hole solder joints. This reliability is crucial for devices that will be subjected to vibration or thermal cycling.

Flexibility in Design

SMT allows for greater flexibility in PCB design. Engineers can create more complex circuits with a higher component density, which is essential for modern electronic devices that require advanced functionality in a compact form factor. This flexibility is particularly beneficial in industries such as consumer electronics, telecommunications, and automotive.

Improved Thermal Management

The design of SMT components often includes features that enhance thermal management. For example, many SMDs have a larger surface area for heat dissipation, which can help prevent overheating and improve the overall performance of the device. This is especially important in high-power applications where thermal management is critical.

The Role of SMT in China's Electronics Industry

China has become a global leader in electronics manufacturing, and SMT plays a crucial role in this success. The country's advanced manufacturing capabilities and investment in automation technologies have made it a hub for SMT PCB assembly. Chinese manufacturers leverage SMT to produce high-quality electronic products at competitive prices, catering to both domestic and international markets.

Challenges and Considerations

While SMT offers numerous advantages, it is not without challenges. The initial setup costs for SMT equipment can be high, and the technology requires skilled personnel to operate and maintain the machinery. Additionally, the smaller size of SMDs can make handling and placement more challenging, necessitating precise automation and quality control measures.

Conclusion

Surface Mount Technology has significantly improved the efficiency of PCB assembly by enhancing production speed, reducing costs, and increasing reliability. Its impact on the electronics industry, particularly in China, cannot be overstated. As technology continues to evolve, SMT will likely play an even more critical role in the future of electronics manufacturing.

Related Questions

1. What is the difference between SMT and through-hole technology?

SMT mounts components directly on the PCB surface, while through-hole technology requires components to be inserted into holes drilled in the board. SMT allows for a more compact design and is generally faster and more cost-effective.

2. How does SMT affect the design of electronic devices?

SMT enables higher component density and more complex circuit designs, allowing for smaller and more functional electronic devices.

3. What are the common applications of SMT?

SMT is widely used in consumer electronics, telecommunications, automotive, and medical devices due to its efficiency and reliability.

4. What are the challenges associated with SMT?

Challenges include high initial setup costs, the need for skilled personnel, and the difficulty of handling smaller components.

5. How does SMT improve the reliability of electronic devices?

SMT creates stronger solder joints that are more resistant to mechanical stress, enhancing the overall reliability of the device.