Content Menu

● Understanding SMT Stencil Coating Technology

>> What Is SMT Stencil Coating?

>> Types of SMT Stencil Coatings

● How SMT Stencil Coating Technology Reduces Downtime

>> 1. Minimizing Stencil Cleaning Frequency

>> 2. Enhancing Paste Release and Transfer Efficiency

>> 3. Increasing Stencil Durability and Longevity

>> 4. Improving Process Consistency

● How SMT Stencil Coating Technology Improves Yield

>> 1. Higher Paste Transfer Efficiency

>> 2. Reduction of Printing Defects

>> 3. Enhanced Print Quality for Complex Designs

>> 4. Compatibility with Existing Processes

● Latest Innovations in SMT Stencil Coating Technology

>> NanoSlic Premium SMT Stencil Coating

>> StenTech BluPrint™ CVD Surface Treatment

>> Vapor Deposited Ceramic Nano-Coatings

● Benefits Summary of SMT Stencil Coating Technology

● Conclusion

● FAQ

>> 1. What is the main purpose of SMT stencil coating technology?

>> 2. How do nano-coatings differ from CVD coatings on SMT stencils?

>> 3. Can SMT stencil coatings be applied to existing stencils?

>> 4. Do SMT stencil coatings affect the compatibility with existing SMT equipment?

>> 5. What are the cost benefits of using SMT stencil coating technology?

Surface Mount Technology (SMT) stencil coating technology has become a pivotal advancement in the electronics manufacturing industry, significantly enhancing the efficiency and quality of solder paste printing on printed circuit boards (PCBs). This article explores how SMT stencil coating technology reduces downtime and improves yield, delving into the types of coatings, their benefits, and the latest innovations in this field.

Understanding SMT Stencil Coating Technology

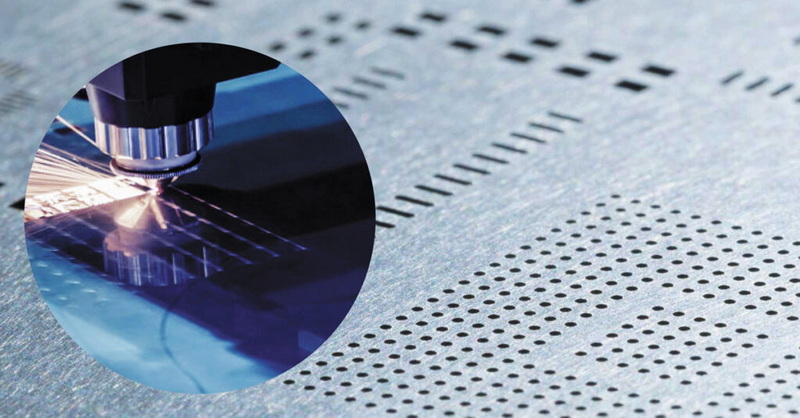

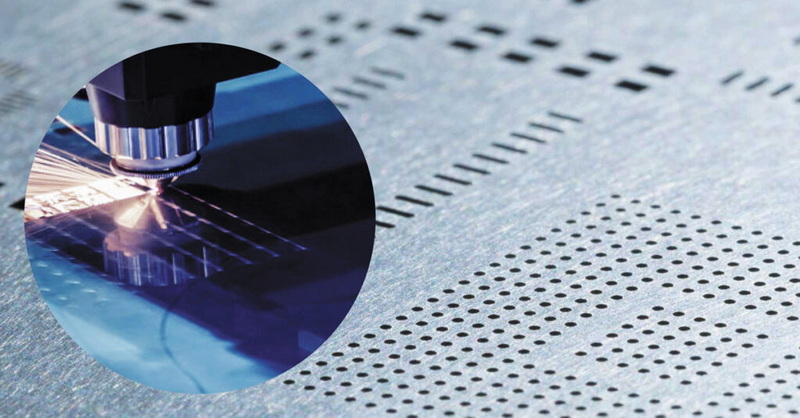

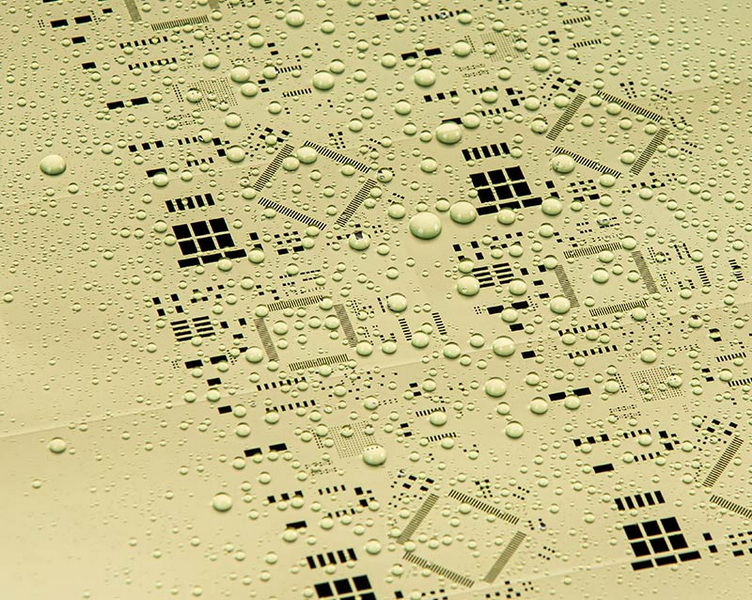

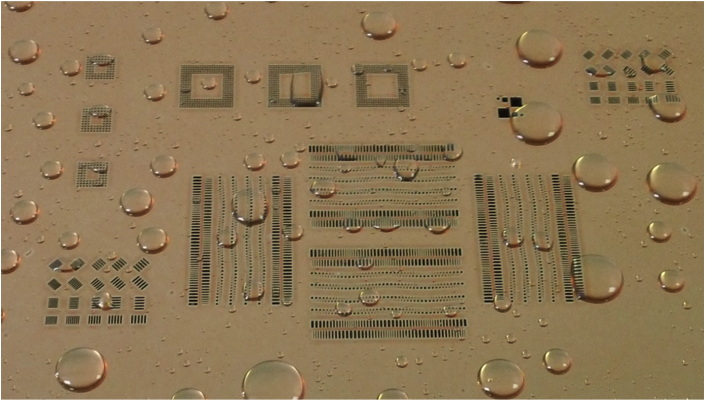

SMT stencils are thin metal sheets, typically stainless steel or nickel alloys, with laser-cut apertures that define where solder paste is applied on a PCB. The precision of solder paste deposition directly affects the quality of solder joints and overall assembly yield. SMT stencil coating technology involves applying specialized coatings to the stencil surface and aperture walls to optimize solder paste release and printing consistency.

What Is SMT Stencil Coating?

SMT stencil coating technology refers to the application of advanced materials—often nano-coatings or chemical vapor deposited (CVD) films—that create a hydrophobic and oleophobic surface on the stencil. These coatings repel solder paste, reduce paste adhesion to stencil surfaces, and improve paste transfer efficiency during printing.

The primary goal of SMT stencil coatings is to enhance the solder paste release from the stencil apertures onto the PCB pads, ensuring consistent and accurate paste deposits. This is crucial because any variation in solder paste volume or placement can lead to defects such as bridging, insufficient solder, or tombstoning, which negatively impact yield and reliability.

Types of SMT Stencil Coatings

- Nano-Coatings: Ultra-thin ceramic or polymer-based coatings typically around 3-5 nanometers thick that provide non-stick properties, reducing solder paste residue and cleaning frequency. These coatings are often applied via dip or spray processes and cure at relatively low temperatures, making them suitable for quick application and reapplication.

- Chemical Vapor Deposited (CVD) Coatings: These are advanced coatings applied via chemical vapor deposition processes, resulting in uniform, durable, and corrosion-resistant surfaces with thicknesses around 3-5 micrometers, significantly thicker and more robust than traditional nano-coatings. CVD coatings bond strongly to the stencil metal, providing long-lasting performance even under high-volume production conditions.

- Anti-Tarnish Coatings: Protect the stencil from environmental corrosion and tarnishing, extending stencil life by maintaining surface integrity and preventing oxidation that can affect paste release.

- Anti-Stick and Fluxophobic Coatings: Prevent solder paste and flux residues from adhering to stencil surfaces, reducing cleaning needs and improving print quality. These coatings are especially beneficial when working with no-clean fluxes and lead-free solder pastes, which tend to be more challenging to clean.

How SMT Stencil Coating Technology Reduces Downtime

Downtime in SMT production lines is costly, often resulting from frequent stencil cleaning, stencil damage, or printing defects that require machine stoppages. SMT stencil coating technology addresses these issues effectively.

1. Minimizing Stencil Cleaning Frequency

One of the most significant contributors to SMT line downtime is the need to clean stencils frequently to remove solder paste buildup. Coated stencils have surfaces that repel solder paste and flux residues, which drastically reduces the buildup on the stencil underside and aperture walls. This leads to fewer cleaning cycles during production runs, minimizing machine downtime and increasing throughput.

For example, studies have shown that stencils treated with durable nano-coatings can extend cleaning intervals by up to 50%, meaning production can continue longer without interruption. This is particularly valuable in high-volume manufacturing environments where even small reductions in downtime translate into substantial productivity gains.

2. Enhancing Paste Release and Transfer Efficiency

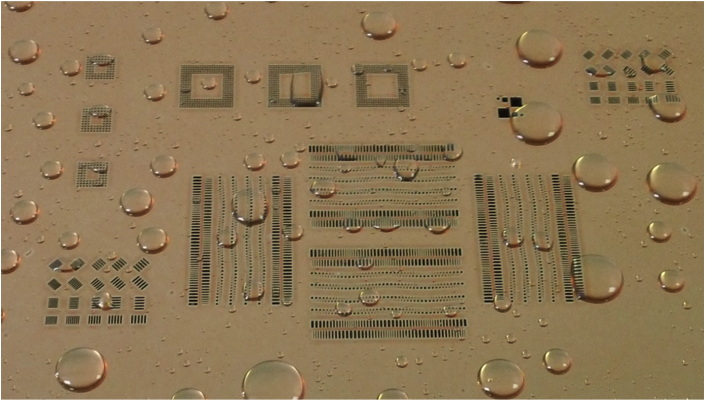

The hydrophobic and oleophobic nature of coatings ensures solder paste releases cleanly from stencil apertures onto the PCB pads. This reduces paste smearing and bridging defects, which otherwise cause production stoppages for rework and cleaning.

Improved paste release also means fewer print defects such as insufficient paste deposits or inconsistent volumes, which are common causes of rework or scrap. By reducing these defects, SMT stencil coating technology helps maintain a steady production flow and reduces the need for troubleshooting or adjustments.

3. Increasing Stencil Durability and Longevity

Advanced coatings, especially CVD treatments, provide a robust, corrosion-resistant surface that withstands repeated printing cycles without degradation. This reduces stencil replacement frequency, lowering downtime associated with stencil changes and maintenance.

Stencils are expensive consumables, and frequent replacement not only adds material costs but also causes production interruptions. Coated stencils maintain their surface finish and aperture integrity longer, enabling manufacturers to maximize stencil life and reduce operational disruptions.

4. Improving Process Consistency

Uniform coatings applied via proprietary processes ensure consistent stencil surface properties and aperture wall smoothness. This consistency reduces variability in solder paste deposition, decreasing defects and the need for production halts to adjust or troubleshoot printing issues.

Consistent paste deposition is critical for achieving high first-pass yields. Variability in stencil surface properties can lead to uneven paste release, causing defects that require line stoppages to diagnose and fix. SMT stencil coating technology provides a more stable printing process, reducing such variability.

How SMT Stencil Coating Technology Improves Yield

Yield improvement is a core objective in SMT manufacturing, as higher yields mean more functional boards per production run, reducing costs and improving profitability.

1. Higher Paste Transfer Efficiency

Coated stencils significantly improve solder paste transfer efficiency, especially for fine-pitch and small apertures. This results in more accurate and consistent solder paste volumes, which are critical for forming reliable solder joints and reducing defects like insufficient solder or bridging.

For example, the application of nano-coatings has been shown to increase paste transfer efficiency by up to 10%, which is a substantial improvement in high-precision electronics assembly.

2. Reduction of Printing Defects

By minimizing bridging, smearing, and paste residue buildup, stencil coatings reduce common printing defects that cause rejects and rework. This directly enhances first-pass yield and overall assembly quality.

Defects such as solder bridges can cause shorts, while insufficient paste can lead to open circuits or weak joints. Reducing these defects through improved stencil coating technology means fewer boards need rework or scrap, improving overall yield.

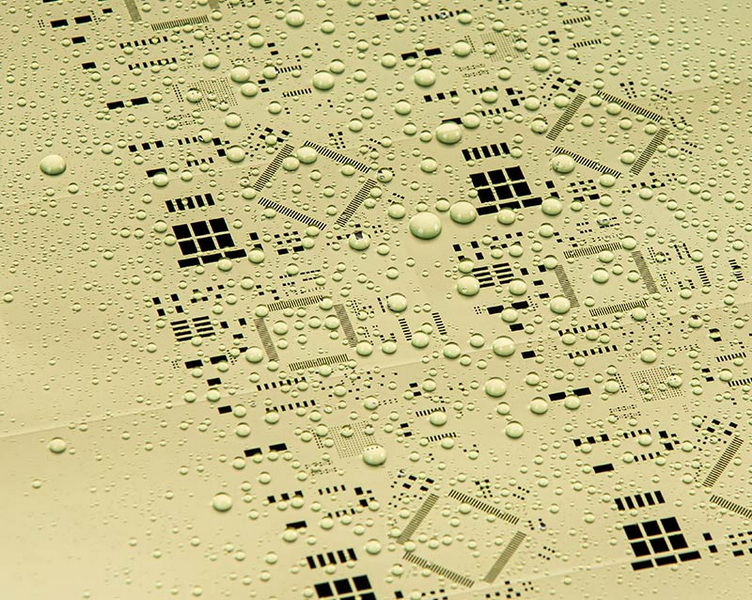

3. Enhanced Print Quality for Complex Designs

As PCB designs become more complex with smaller components and tighter pitches, stencil coatings help maintain high print quality by ensuring paste release even in challenging aperture geometries. This supports higher yields in advanced electronics manufacturing.

Coatings that reduce paste sticking and facilitate clean release are especially important for fine-pitch BGAs, CSPs, and other miniaturized components where paste volume control is critical.

4. Compatibility with Existing Processes

Modern SMT stencil coatings are compatible with current assembly equipment and processes, allowing manufacturers to adopt them without costly process changes while still benefiting from yield improvements.

This compatibility means that companies can implement stencil coating technology with minimal disruption, leveraging existing investments in SMT lines while gaining yield and downtime benefits.

Latest Innovations in SMT Stencil Coating Technology

The SMT stencil coating field is rapidly evolving, with new materials and application methods driving continuous improvements.

NanoSlic Premium SMT Stencil Coating

NanoSlic offers a thermally cured, permanent coating that is highly hydrophobic and oleophobic, applied to both the stencil underside and aperture walls. This coating improves paste transfer efficiency, reduces bridging, and minimizes cleaning requirements, leading to higher yields and less rework.

NanoSlic's coating is notable for its durability and ability to maintain performance over thousands of print cycles, making it ideal for high-volume manufacturing.

StenTech BluPrint™ CVD Surface Treatment

StenTech's BluPrint™ is a cutting-edge CVD coating applied after plasma polishing the stencil surface and aperture walls. It creates a smooth, high-gloss, corrosion-resistant surface with a thickness about 1000 times less than traditional coatings but with superior durability and transfer efficiency. This technology is particularly effective for high-volume production and fine-pitch applications.

BluPrint™ treatment also improves stencil flatness and aperture wall smoothness, further enhancing print quality and reducing defects.

Vapor Deposited Ceramic Nano-Coatings

Recent studies confirm that ceramic nano-coatings applied via vapor deposition improve transfer efficiency and reduce variability better than other coatings. These coatings offer a balance of durability and performance, making them a preferred choice for many SMT manufacturers.

Vapor deposited coatings are also environmentally friendly and compatible with lead-free solder pastes, supporting sustainable manufacturing practices.

Benefits Summary of SMT Stencil Coating Technology

- Reduced cleaning frequency and downtime: Coatings repel solder paste and flux residues, extending cleaning intervals.

- Improved solder paste transfer efficiency and print quality: Enhanced release characteristics reduce defects.

- Lower defect rates such as bridging and smearing: Consistent paste volumes and clean release minimize common printing issues.

- Increased stencil lifespan and reduced maintenance costs: Durable coatings resist corrosion and wear.

- Enhanced process consistency and repeatability: Uniform coatings reduce variability in paste deposition.

- Compatibility with existing SMT assembly lines: Easy integration without costly equipment changes.

Conclusion

SMT stencil coating technology is a transformative advancement that significantly reduces downtime and improves yield in surface mount assembly processes. By applying durable, hydrophobic, and oleophobic coatings—ranging from nano-coatings to advanced CVD treatments—manufacturers achieve superior solder paste transfer efficiency, minimize defects, and extend stencil life. These improvements lead to higher first-pass yields, lower operational costs, and streamlined production workflows. As electronics continue to evolve with finer pitches and more complex designs, adopting advanced SMT stencil coating technology becomes essential for maintaining competitive manufacturing performance.

FAQ

1. What is the main purpose of SMT stencil coating technology?

SMT stencil coating technology primarily aims to improve solder paste transfer efficiency by creating a non-stick surface on the stencil, reducing defects and cleaning frequency, thereby enhancing overall yield and reducing downtime.

2. How do nano-coatings differ from CVD coatings on SMT stencils?

Nano-coatings are ultra-thin (around 3-5 nanometers) ceramic or polymer layers that provide non-stick properties, while CVD coatings are thicker (3-5 micrometers), more durable, and corrosion-resistant films applied via chemical vapor deposition, offering superior longevity and consistent performance.

3. Can SMT stencil coatings be applied to existing stencils?

Yes, many nano-coatings can be applied to previously used stencils even on the production line, improving their performance without needing new stencil purchases.

4. Do SMT stencil coatings affect the compatibility with existing SMT equipment?

No, modern SMT stencil coatings are designed to be fully compatible with current SMT assembly equipment and processes, allowing easy integration without costly changes.

5. What are the cost benefits of using SMT stencil coating technology?

By reducing cleaning frequency, minimizing stencil replacements, and improving yield through fewer defects, SMT stencil coatings lower operational costs and increase production efficiency, resulting in significant cost savings over time.