Content Menu

● Understanding SMT Splicing Tape

>> What is SMT Splicing Tape?

>> The Role of Embossed Dots

● Benefits of Using SMT Splice Tape with Embossed Dots

● How SMT Splice Tape Works

>> The Splicing Process

● Challenges and Considerations

● Advanced Features of SMT Splice Tape

>> Material Composition

>> Size Variability

● The Impact on Production Lines

>> Continuous Production Flow

>> Cost Reduction

● Case Studies Highlighting Successful Implementations

● Conclusion

● FAQ

>> 1. What types of SMT splice tape are available?

>> 2. How do embossed dots improve splicing accuracy?

>> 3. Can SMT splice tape be used with all types of SMD components?

>> 4. What is the typical impact on production efficiency when using SMT splice tape?

>> 5. Are there any risks associated with using low-quality SMT splice tapes?

● Citations:

In the realm of electronics manufacturing, efficiency and minimal downtime are paramount. Surface Mount Technology (SMT) splicing tape, particularly those featuring embossed dots, has emerged as a crucial tool in achieving these goals. This article explores how SMT splice tape with embossed dots enhances production processes, reduces downtime, and ultimately improves efficiency in manufacturing environments.

Understanding SMT Splicing Tape

What is SMT Splicing Tape?

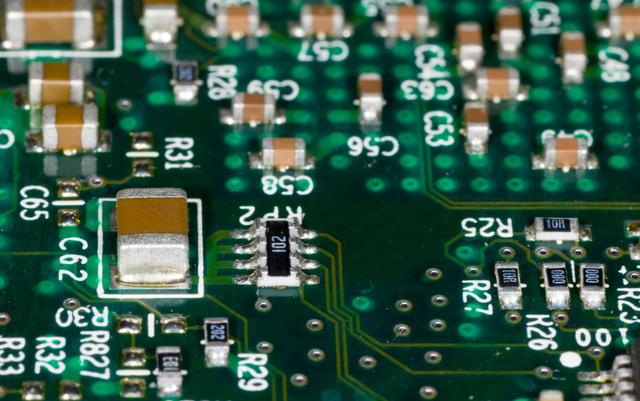

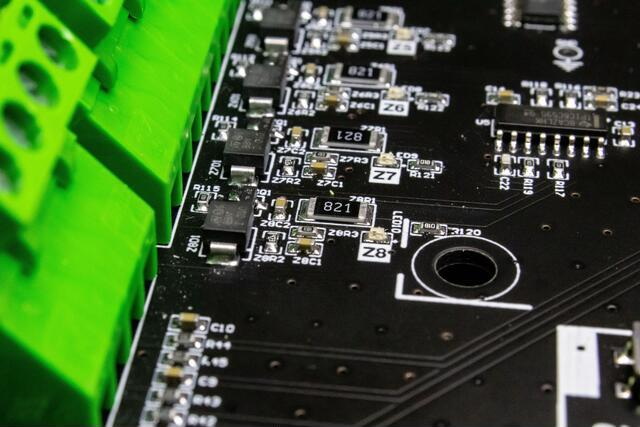

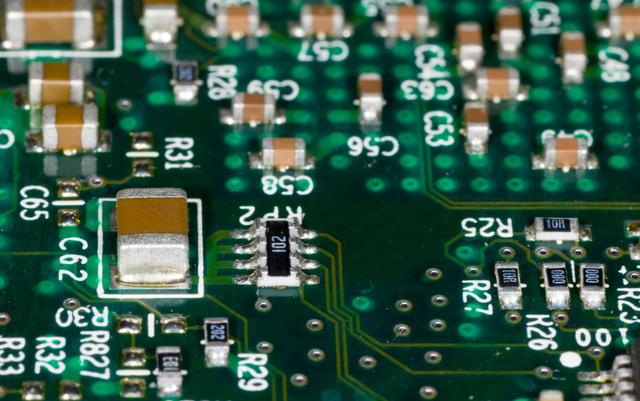

SMT splicing tape is a specialized adhesive tape used to join two reels of Surface Mount Device (SMD) components. This process is vital for ensuring a continuous feed of components during automated assembly operations. The tape is designed to securely bond the leader of a new component reel to the end of an existing reel, thus creating an uninterrupted flow necessary for high-speed production lines.

The Role of Embossed Dots

Embossed dots on SMT splice tape serve as alignment aids, allowing operators to position the tapes accurately without the need for additional tools. This feature simplifies the splicing process, making it quicker and more efficient. The design ensures that components remain aligned during transport through pick-and-place machines, which is critical for maintaining production quality.

Benefits of Using SMT Splice Tape with Embossed Dots

The integration of SMT splice tape with embossed dots into manufacturing processes offers several significant benefits:

- Reduced Downtime: By facilitating quick and accurate splicing of component reels, this type of tape minimizes the time machines are idle during reel changes. Traditional methods often involve lengthy manual adjustments and potential misalignments, leading to increased downtime.

- Increased Production Efficiency: Continuous operation is essential in high-volume production settings. SMT splice tape enables seamless transitions between component reels, allowing for uninterrupted assembly processes. This can lead to productivity increases ranging from 5% to 30%, depending on the specific application and machinery used.

- Enhanced Accuracy: The embossed dots provide visual cues that help operators align the tapes correctly every time. This precision reduces the likelihood of errors during the splicing process, which can lead to defects in the final product.

- User-Friendly Operation: The design of SMT splice tape with embossed dots eliminates the need for auxiliary tools or extensive training for operators. This ease of use contributes to faster onboarding and less reliance on specialized skills, making it accessible for various operators within a manufacturing setting.

How SMT Splice Tape Works

The Splicing Process

1. Preparation: Begin by cutting the leader of the new component reel to an appropriate length.

2. Alignment: Use the embossed dots on the splice tape to align the end of the current reel with the beginning of the new reel accurately.

3. Application: Place the SMT splice tape over the joint where both reels meet, ensuring full coverage.

4. Pressure Application: Apply firm pressure to secure the bond between the two reels, ensuring they are held together tightly without gaps.

5. Verification: Check alignment and ensure that there are no obstructions that could impede movement through automated machinery.

This straightforward process allows manufacturers to maintain high levels of productivity while minimizing errors associated with manual splicing techniques.

Challenges and Considerations

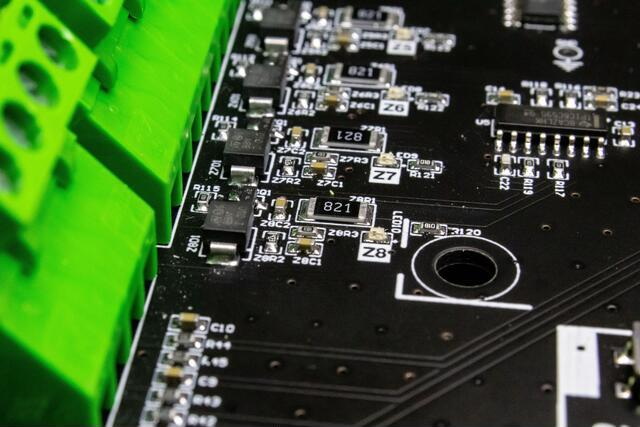

While SMT splice tapes offer numerous advantages, there are challenges that manufacturers must consider:

- Quality Control: Not all SMT splice tapes are created equal. Investing in high-quality tapes is crucial to avoid issues such as blockages and misfeeds during production.

- Training: Although these tapes are user-friendly, proper training on their application can further enhance efficiency and reduce errors in splicing.

- Compatibility: Ensure that the selected splice tape is compatible with existing equipment and meets specific operational requirements.

Advanced Features of SMT Splice Tape

Material Composition

SMT splice tapes are typically made from high-quality adhesive materials designed to provide strong bonds while maintaining flexibility. The most common materials used include:

- Polyethylene Terephthalate (PET): Known for its durability and resistance to heat, PET is often used as a backing material for splice tapes. It provides excellent adhesion properties while remaining lightweight.

- Acrylic Adhesives: These adhesives offer superior bonding strength and resistance to temperature fluctuations, making them ideal for use in various manufacturing environments.

Size Variability

SMT splice tapes come in various sizes and thicknesses to accommodate different types of carrier tapes used in electronics manufacturing:

- Common widths include 8mm, 12mm, 16mm, 24mm, 32mm, and larger dimensions depending on specific manufacturing needs.

- Availability in multiple colors can also enhance visibility during application, aiding operators in aligning components correctly.

The Impact on Production Lines

Continuous Production Flow

One of the most significant advantages of using SMT splice tape with embossed dots is its ability to facilitate continuous production flow. By reducing reel change times significantly—often by up to 50%—manufacturers can keep their pick-and-place machines running longer without interruptions. This continuous operation not only boosts output but also enhances overall profitability by maximizing machine utilization.

Cost Reduction

Reducing downtime directly correlates with cost savings in manufacturing environments. When production lines stop due to manual splicing or reel changes, costs accrue rapidly due to lost labor hours and potential delays in meeting delivery schedules. By implementing efficient splicing techniques using high-quality SMT splice tapes, manufacturers can minimize these costs significantly.

Case Studies Highlighting Successful Implementations

Several companies have successfully integrated SMT splice tapes into their production lines with remarkable results:

- Company A: A leading electronics manufacturer reduced downtime by 30% after integrating automatic splicing machines alongside high-quality SMT splice tapes into their production line. This change resulted in increased output rates without compromising quality.

- Company B: By adopting high-quality splice tapes and training their workforce on best practices, this company improved their defect rate by 15%. The enhanced accuracy achieved through proper splicing techniques led to significant cost savings associated with rework and waste reduction.

Conclusion

In conclusion, SMT splice tape with embossed dots represents a significant advancement in electronics manufacturing technology. By reducing downtime and improving efficiency through simplified splicing processes, these tapes have become indispensable tools in modern production environments. Their user-friendly design combined with enhanced accuracy makes them suitable for various applications within SMT assembly lines.

As manufacturers continue to seek ways to optimize their operations, investing in high-quality SMT splice tapes will undoubtedly contribute to achieving greater efficiency and productivity. With ongoing advancements in technology and materials used in these products, staying informed about innovations will be crucial for maintaining competitive advantages in an ever-evolving market.

FAQ

1. What types of SMT splice tape are available?

There are several types of SMT splice tape available including single-sided and double-sided options, each designed for specific applications within surface mount technology.

2. How do embossed dots improve splicing accuracy?

Embossed dots provide visual alignment aids that help operators position tapes correctly without additional tools, enhancing overall accuracy during the splicing process.

3. Can SMT splice tape be used with all types of SMD components?

Yes, most SMT splice tapes are designed to be compatible with various SMD component sizes and types; however, it's essential to verify compatibility with specific equipment used in production.

4. What is the typical impact on production efficiency when using SMT splice tape?

Using SMT splice tape can increase production efficiency by 5% to 30%, depending on factors such as machine type and operational practices.

5. Are there any risks associated with using low-quality SMT splice tapes?

Yes, low-quality tapes can lead to issues such as blockages, misfeeds, and ultimately increased downtime due to production interruptions caused by inadequate bonding between reels.

Citations:

[1] https://tlycleanroom.com/product-item/smt-splice-tape/

[2] https://www.szsmt.com/shop/m05-series-double-splice-tape

[3] https://www.khj.com.cn/news/the-ultimate-guide-to-smt-splicing-tape-everything-you-need-to-know-143816.html

[4] https://www.gssmt-parts.com/why-is-the-smt-splice-tool-essential-for-efficient-electronics-manufacturing.html

[5] https://kanghongjin.singoosite.singoo.xyz/shop/smt-splice-tape-01series

[6] https://www.kcss-tech.com/product/1145118

[7] https://www.allsmt.com/SMT-splicing-tapes-and-Extenders-a-valuable-aid-in-electronics-production

[8] https://kanghongjin.singoosite.singoo.xyz/blog/continuous-splicing-improves-smt-efficiency-smt-splicing-tape

[9] https://www.khj.com.cn/sale-14390552-universal-01-series-smt-double-splice-tape-with-double-embossed-dots-designed-apply-for-all-sizes-of.html

[10] https://www.gssmt-parts.com/what-is-smt-splice-and-why-is-it-crucial-for-electronics-manufacturing.html