Content Menu

● Understanding SMT and Its Importance

>> The Role of SMT Manufacturing Training

● Key Components of SMT Manufacturing Training

>> Theoretical Knowledge

>> Hands-On Experience

>> Quality Control Techniques

>> Troubleshooting Skills

>> Industry Standards and Certifications

● Benefits of Enhanced PCB Assembly Skills

>> Increased Employability

>> Improved Production Efficiency

>> Higher Quality Products

>> Adaptability to Technological Changes

>> Contribution to Innovation

● Conclusion

● Related Questions

>> 1. What is Surface Mount Technology (SMT)?

>> 2. Why is SMT training important for PCB assembly?

>> 3. What are the key components of SMT training?

>> 4. How does SMT training improve product quality?

>> 5. What career opportunities are available for those trained in SMT?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, particularly in the realm of printed circuit board (PCB) assembly. As technology continues to advance, the demand for skilled professionals in SMT manufacturing is on the rise. This article explores how SMT manufacturing training enhances PCB assembly skills, the importance of such training, and the various components involved in the SMT process.

Understanding SMT and Its Importance

SMT is a method used to mount electronic components directly onto the surface of PCBs. This technique has several advantages over traditional through-hole technology, including reduced size and weight of electronic devices, improved performance, and lower manufacturing costs. The efficiency of SMT allows for higher component density, which is essential in modern electronics where space is often at a premium.

The Role of SMT Manufacturing Training

SMT manufacturing training is crucial for several reasons:

1. Skill Development: Training programs equip individuals with the necessary skills to operate SMT machinery, understand the assembly process, and troubleshoot common issues. This hands-on experience is vital for ensuring quality and efficiency in PCB assembly.

2. Understanding of Equipment: Participants learn about various SMT equipment, such as pick-and-place machines, reflow ovens, and inspection systems. Familiarity with these tools is essential for effective operation and maintenance.

3. Quality Assurance: Training emphasizes the importance of quality control in the SMT process. Trainees learn how to identify defects, implement corrective actions, and ensure that the final product meets industry standards.

4. Process Optimization: SMT training often includes strategies for optimizing the assembly process, which can lead to reduced production times and costs. Understanding how to streamline operations is a valuable skill in any manufacturing environment.

5. Adaptation to New Technologies: The electronics industry is constantly evolving, with new technologies and methods emerging regularly. Training helps professionals stay updated on the latest advancements in SMT, ensuring they can adapt to changes in the industry.

Key Components of SMT Manufacturing Training

Theoretical Knowledge

Training begins with a solid foundation in the theoretical aspects of SMT. This includes understanding the principles of electronics, the types of components used in SMT, and the various stages of the PCB assembly process. Knowledge of soldering techniques, materials, and the properties of different components is also covered.

Hands-On Experience

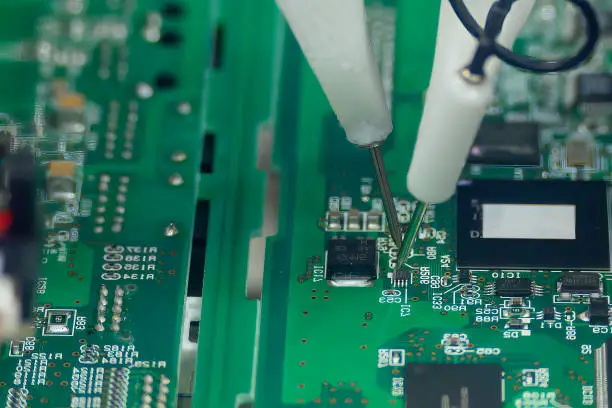

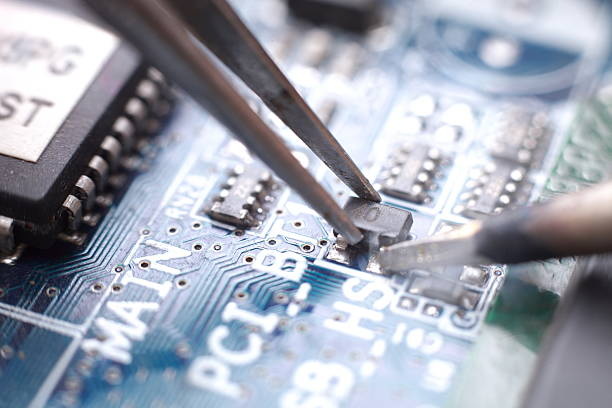

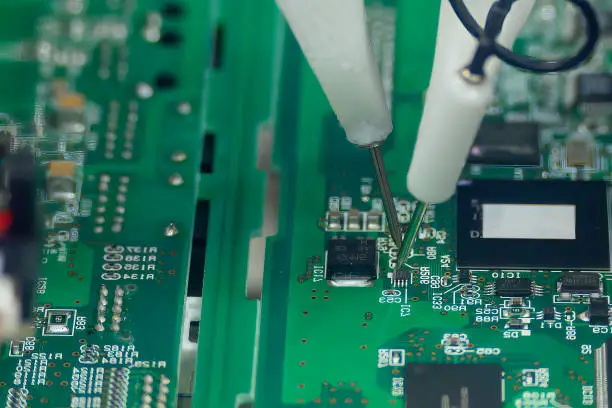

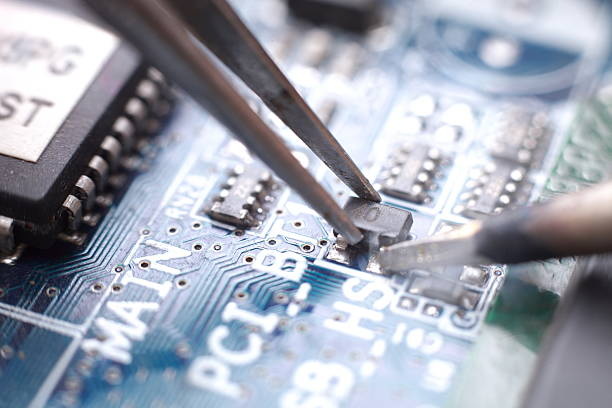

Practical training is a critical component of SMT education. Participants engage in hands-on exercises that simulate real-world scenarios. This includes operating SMT machines, performing soldering tasks, and conducting inspections. Such experience is invaluable for building confidence and competence in the workplace.

Quality Control Techniques

Quality assurance is a significant focus of SMT training. Trainees learn about various inspection methods, including automated optical inspection (AOI) and X-ray inspection. Understanding how to implement quality control measures helps ensure that defects are caught early in the production process, reducing waste and rework.

Troubleshooting Skills

An essential part of SMT training is developing troubleshooting skills. Participants learn how to identify common issues that may arise during the assembly process, such as misalignment of components or soldering defects. Training includes strategies for diagnosing problems and implementing effective solutions.

Industry Standards and Certifications

Many SMT training programs offer certifications that are recognized in the industry. These certifications demonstrate a professional's competence and commitment to quality. Understanding industry standards, such as IPC-A-610 for acceptability of electronic assemblies, is crucial for maintaining high-quality production.

Benefits of Enhanced PCB Assembly Skills

The skills gained from SMT manufacturing training translate into numerous benefits for both individuals and organizations:

Increased Employability

Professionals with SMT training are highly sought after in the electronics manufacturing sector. Their specialized skills make them valuable assets to employers, leading to better job opportunities and career advancement.

Improved Production Efficiency

Trained employees are more adept at operating SMT equipment and understanding the assembly process. This leads to increased efficiency, reduced downtime, and lower production costs, ultimately benefiting the organization's bottom line.

Higher Quality Products

With a focus on quality control and troubleshooting, trained professionals are better equipped to produce high-quality PCBs. This reduces the likelihood of defects and enhances customer satisfaction.

Adaptability to Technological Changes

As the electronics industry evolves, so do the technologies and methods used in SMT. Professionals who undergo training are more likely to adapt to new technologies, ensuring that their skills remain relevant.

Contribution to Innovation

Trained individuals are often at the forefront of innovation in electronics manufacturing. Their understanding of SMT processes allows them to contribute to the development of new products and technologies, driving the industry forward.

Conclusion

In conclusion, SMT manufacturing training plays a vital role in enhancing PCB assembly skills. By providing a comprehensive understanding of SMT processes, equipment, and quality control techniques, training programs equip professionals with the tools they need to succeed in the fast-paced electronics manufacturing industry. The benefits of such training extend beyond individual skill development, positively impacting organizations through improved efficiency, quality, and innovation. As technology continues to advance, the importance of SMT training will only grow, making it an essential component of professional development in the field of electronics.

Related Questions

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method for mounting electronic components directly onto the surface of printed circuit boards (PCBs). It allows for higher component density and smaller device sizes compared to traditional through-hole technology.

2. Why is SMT training important for PCB assembly?

SMT training is important because it equips individuals with the skills needed to operate SMT machinery, understand the assembly process, and ensure quality control, ultimately leading to more efficient and effective PCB assembly.

3. What are the key components of SMT training?

Key components of SMT training include theoretical knowledge of electronics, hands-on experience with SMT equipment, quality control techniques, troubleshooting skills, and understanding industry standards and certifications.

4. How does SMT training improve product quality?

SMT training improves product quality by teaching professionals how to implement quality control measures, identify defects early in the production process, and troubleshoot issues effectively, leading to higher-quality PCBs.

5. What career opportunities are available for those trained in SMT?

Individuals trained in SMT can pursue various career opportunities in electronics manufacturing, including roles as SMT operators, process engineers, quality assurance specialists, and production managers.