Content Menu

● Understanding Surface Mount Technology

● Key Advantages of SMT in PCB Assembly

>> 1. Increased Production Speed

>> 2. Enhanced Component Density

>> 3. Cost Reduction

>> 4. Improved Reliability

>> 5. Flexibility and Scalability

● The SMT Assembly Process

● Challenges and Considerations

● Advanced Trends in SMT

● Detailed Examination of Applications

>> 1. Consumer Electronics

>> 2. Automotive Industry

>> 3. Medical Devices

● The Role of Quality Control

● Future Trends Impacting SMT

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does SMT improve production speed?

>> 3. What are the cost benefits of using SMT?

>> 4. Can SMT components be used on both sides of a PCB?

>> 5. What challenges are associated with SMT?

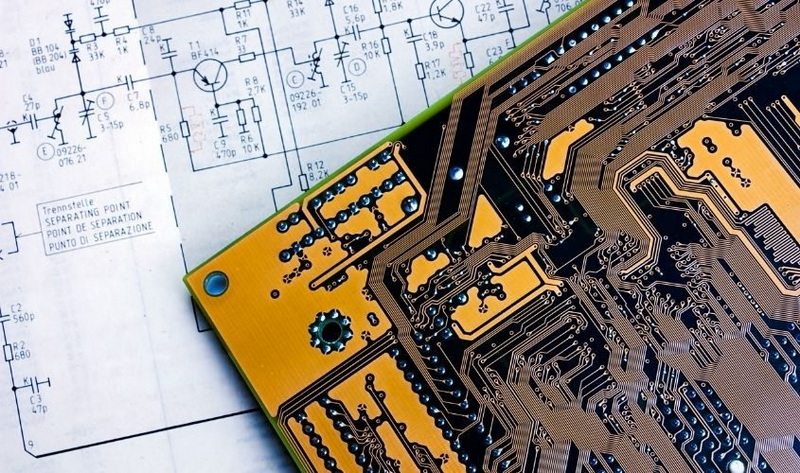

Surface Mount Technology (SMT) has transformed the landscape of printed circuit board (PCB) assembly, offering significant improvements in efficiency, cost-effectiveness, and product reliability. This article delves into the various ways SMT enhances the efficiency of PCB assembly, examining its processes, advantages, and the impact on modern electronics manufacturing.

Understanding Surface Mount Technology

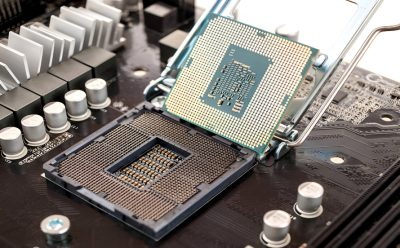

SMT is a method that involves placing electronic components directly onto the surface of a PCB rather than inserting them through holes as done in traditional through-hole technology (THT). This approach allows for higher component density, reduced manufacturing costs, and improved performance characteristics.

Key Advantages of SMT in PCB Assembly

1. Increased Production Speed

One of the most notable benefits of SMT is its ability to significantly increase production speed. Automated pick-and-place machines can place thousands of components per hour with high precision. This automation minimizes manual intervention, reducing assembly time from hours (as seen in THT) to mere minutes for complex boards.

2. Enhanced Component Density

SMT allows for a greater number of components to be placed on a PCB due to its compact design. Since SMT components are smaller and can be mounted on both sides of the board, manufacturers can achieve higher density designs. This is particularly beneficial for devices where space is at a premium, such as smartphones and wearable technology.

3. Cost Reduction

The adoption of SMT leads to lower production costs in several ways:

- Material Savings: The elimination of drilled holes reduces material waste and handling costs.

- Labor Costs: Automation reduces the need for manual labor, which is often more expensive.

- Efficiency Gains: Faster production cycles mean that manufacturers can produce more units in less time, further driving down costs.

4. Improved Reliability

SMT connections tend to be more reliable than those made with THT. The shorter lead lengths reduce inductance and resistance, which enhances electrical performance and signal integrity. Additionally, SMT assemblies are less prone to mechanical failure due to their robust soldered connections.

5. Flexibility and Scalability

SMT processes are highly adaptable, allowing manufacturers to easily switch between different product designs without extensive retooling. This flexibility enables quick responses to market demands and facilitates mass production.

The SMT Assembly Process

The SMT assembly process typically consists of several key steps:

1. Solder Paste Printing: A solder paste printer applies a precise layer of solder paste onto the PCB pads.

2. Component Placement: Automated pick-and-place machines position SMDs on the solder-pasted areas.

3. Solder Reflow: The board passes through a reflow oven where heat melts the solder paste, creating solid connections between components and the PCB.

4. Inspection and Testing: Automated Optical Inspection (AOI) systems check for defects, while functional tests ensure that the assembled PCB operates as intended.

Challenges and Considerations

While SMT offers numerous advantages, it also comes with challenges:

- Component Fragility: SMT components can be more delicate than their THT counterparts, requiring careful handling during assembly.

- Higher Initial Costs: The setup costs for automated SMT lines can be significant; however, these costs are typically offset by long-term savings in labor and materials.

Advanced Trends in SMT

As technology continues to evolve, several trends are shaping the future of SMT:

- Automation Expansion: Automation is increasingly being integrated into pre-SMT and post-SMT processes to minimize human error further and enhance productivity.

- Artificial Intelligence (AI): AI technologies are being utilized for real-time fault detection and predictive maintenance in SMT processes. This integration helps manufacturers optimize component placement and reduce errors during assembly.

- Miniaturization: There is a growing trend towards miniaturization in electronics design. Manufacturers are increasingly using smaller components that allow for more compact designs without sacrificing functionality.

- Eco-Friendly Practices: The industry is moving towards sustainable practices by adopting lead-free soldering techniques and reducing waste throughout the production process.

Detailed Examination of Applications

1. Consumer Electronics

Consumer electronics represent one of the most significant areas where SMT has made an impact. Devices like smartphones, tablets, laptops, and smartwatches rely heavily on compact designs that maximize functionality while minimizing size. The ability to mount components on both sides allows engineers to pack more features into smaller devices without compromising performance or battery life.

2. Automotive Industry

The automotive sector has also embraced SMT due to its reliability under harsh conditions such as vibrations and temperature fluctuations. Modern vehicles incorporate numerous electronic systems ranging from infotainment units to advanced driver assistance systems (ADAS). These systems require high-density PCBs capable of supporting complex functionalities while ensuring safety standards are met.

3. Medical Devices

In medical technology, where precision is paramount, SMT provides an edge by enabling smaller devices with enhanced performance capabilities. Devices like pacemakers or portable diagnostic tools benefit from reduced size without sacrificing reliability or functionality—critical factors when it comes to patient care.

The Role of Quality Control

Quality control is critical in SMT assembly due to the high-speed nature of the process. Automated inspection systems such as AOI and X-ray inspections help identify defects early in production, reducing waste and ensuring that only high-quality products reach consumers.

Moreover, implementing Design for Manufacturing (DFM) principles during the design phase can significantly enhance yield rates by addressing potential issues before they arise in production.

Future Trends Impacting SMT

As we look toward the future of electronics manufacturing with respect to SMT:

- Integration with Additive Manufacturing: The combination of additive manufacturing techniques with traditional PCB assembly methods opens new avenues for creating complex geometries that were previously unattainable.

- Sustainability Initiatives: With increasing regulatory pressures around environmental sustainability, manufacturers are adopting eco-friendly materials and processes within their SMT workflows. This shift not only meets compliance requirements but also appeals to environmentally conscious consumers.

- Smart Manufacturing: The rise of Industry 4.0 emphasizes connectivity between machines via IoT technologies. In this context, smart factories equipped with interconnected devices will leverage data analytics to optimize production schedules dynamically based on real-time demand forecasts.

Conclusion

In conclusion, Surface Mount Technology stands at the forefront of modern electronics manufacturing by enhancing efficiency across various dimensions—from speeding up production cycles to enabling innovative designs that cater to evolving consumer needs across multiple industries. As we advance technologically—integrating AI-driven automation alongside sustainable practices—the role of SMT will continue expanding within global markets while simultaneously driving down costs associated with electronic device production.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in PCB assembly where electronic components are mounted directly onto the surface of a circuit board instead of being inserted through holes.

2. How does SMT improve production speed?

SMT improves production speed by utilizing automated pick-and-place machines that can place thousands of components per hour with high precision, significantly reducing assembly time compared to traditional methods.

3. What are the cost benefits of using SMT?

Using SMT reduces production costs through material savings from fewer drilled holes, lower labor costs due to automation, and increased efficiency from faster production cycles.

4. Can SMT components be used on both sides of a PCB?

Yes, one of the advantages of SMT is that components can be mounted on both sides of a PCB, allowing for higher density designs and more efficient use of space.

5. What challenges are associated with SMT?

Challenges include the fragility of some SMT components requiring careful handling and potentially higher initial setup costs for automated assembly lines.