Content Menu

● Understanding PCB Carrier SMT

>> The Role of PCB Carriers

>> Integration with SMT Process

● Efficiency Improvements in Electronic Assembly

>> Increased Throughput

>> Enhanced Precision and Quality

>> Automation and Reduced Labor Costs

● Optimizing PCB Design for Carrier SMT

>> Component Selection and Placement

>> Board Design Considerations

>> Material Selection

● Implementing PCB Carrier SMT in Production

>> Carrier Design and Fabrication

>> Process Integration

>> Training and Standard Operating Procedures

● Benefits Beyond Efficiency

>> Enhanced Product Quality

>> Flexibility in Design

>> Cost Savings

>> Environmental Impact

● Challenges and Considerations

>> Initial Investment

>> Carrier Maintenance

>> Design Constraints

● Future Trends in PCB Carrier SMT

● Conclusion

● FAQ

>> 1. What is the primary purpose of a PCB carrier in SMT assembly?

>> 2. How does PCB carrier SMT improve assembly speed?

>> 3. What are the key design considerations for PCBs when using carrier SMT?

>> 4. Can PCB carrier SMT be used for all types of PCBs?

>> 5. What are the long-term cost benefits of implementing PCB carrier SMT?

● Citations:

In the rapidly evolving world of electronics manufacturing, efficiency and precision are paramount. Surface Mount Technology (SMT) has revolutionized the industry, and when combined with PCB carriers, it offers a powerful solution for enhancing productivity and quality in electronic assembly processes. This article explores how PCB carrier SMT improves efficiency in electronic assembly, delving into its benefits, implementation, and impact on the manufacturing landscape.

Understanding PCB Carrier SMT

PCB carrier SMT is an innovative approach that combines the advantages of Surface Mount Technology with specialized carriers designed to support and transport printed circuit boards (PCBs) throughout the assembly process. This combination addresses many challenges faced in traditional electronic assembly methods, particularly when dealing with complex, high-density boards or flexible substrates.

The Role of PCB Carriers

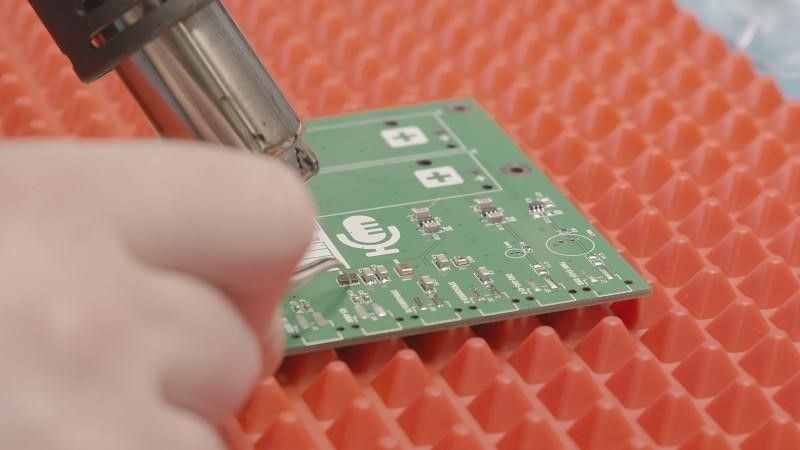

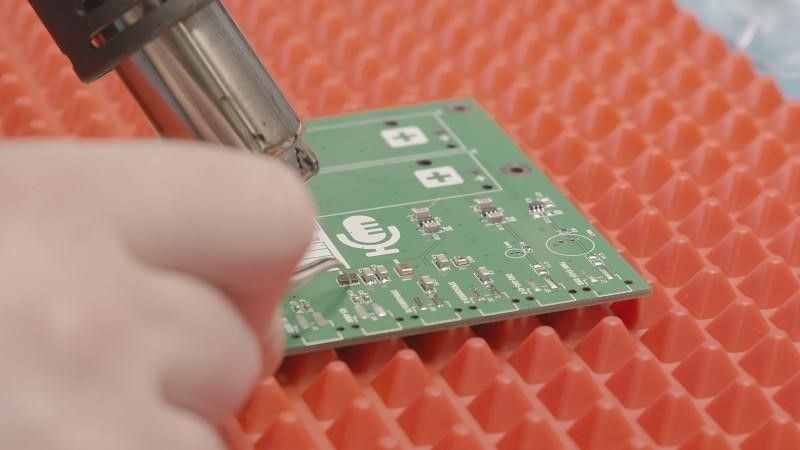

PCB carriers, also known as SMT reflow carriers or pallets, are custom-designed fixtures that hold PCBs securely during various stages of the SMT assembly process. These carriers provide crucial support from solder paste printing through component placement and reflow soldering[9]. By maintaining board flatness and stability, carriers help prevent warpage and ensure consistent quality, especially when working with thinner or more flexible substrates.

Integration with SMT Process

The integration of PCB carriers into the SMT process flow creates a synergy that enhances overall efficiency. Carriers are designed to seamlessly move through automated assembly lines, supporting boards during critical stages such as:

1. Solder paste printing

2. Component placement

3. Reflow soldering

4. Inspection and testing

This integration minimizes handling and reduces the risk of damage or misalignment during transitions between process steps.

Efficiency Improvements in Electronic Assembly

Increased Throughput

One of the primary benefits of PCB carrier SMT is the significant increase in production throughput. By providing a stable platform for PCBs, carriers enable faster processing speeds and reduce the need for manual interventions. Some placement machines can mount over 136,000 components per hour when using optimized carrier systems[5]. This high-speed capability translates directly into increased production capacity and shorter lead times.

Enhanced Precision and Quality

PCB carriers contribute to improved assembly precision by maintaining board flatness and preventing warpage. This is particularly crucial for high-density designs where component placement accuracy is critical. The use of carriers allows for:

- Consistent solder paste deposition: By keeping boards flat during stencil printing, carriers ensure uniform solder paste application across all pads.

- Accurate component placement: Stable boards enable pick-and-place machines to achieve higher accuracy in component positioning.

- Reduced defect rates: By minimizing board movement and warpage during reflow, carriers help prevent solder bridging and other defects.

Automation and Reduced Labor Costs

The implementation of PCB carrier SMT systems facilitates greater automation throughout the assembly process. This automation reduces the need for manual handling and intervention, leading to:

- Lower labor costs

- Reduced risk of human error

- Increased consistency in production quality

Automated systems can operate continuously with minimal downtime, further enhancing production efficiency[4].

Optimizing PCB Design for Carrier SMT

To fully leverage the benefits of PCB carrier SMT, it's essential to optimize PCB designs with this process in mind. Consider the following aspects:

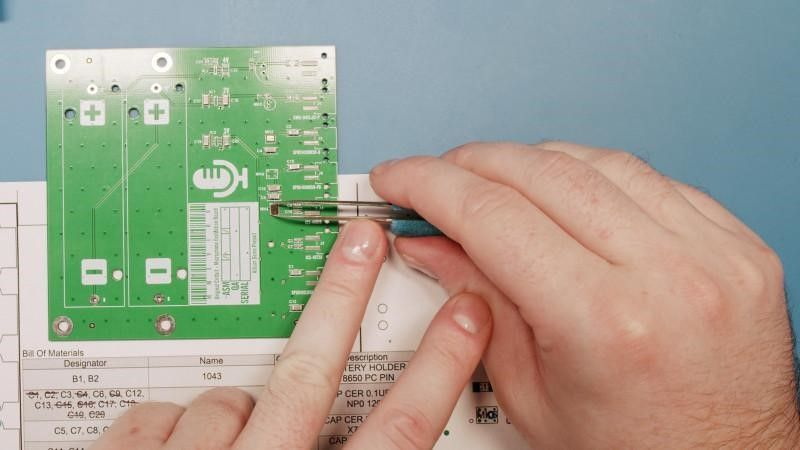

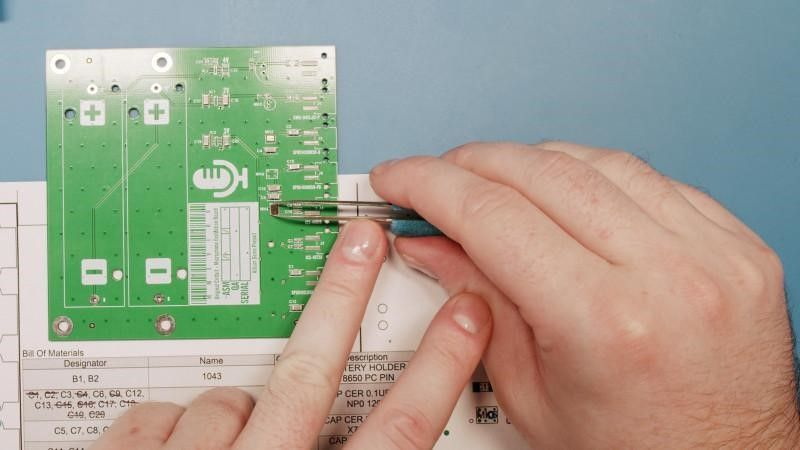

Component Selection and Placement

Choose SMT components that are compatible with automated placement and optimize their layout for efficient pick-and-place operations. This may involve:

- Using standardized component packages

- Aligning components in a consistent orientation

- Leaving adequate spacing for placement heads and inspection cameras

Board Design Considerations

When designing PCBs for carrier SMT, consider:

- Tooling holes: Include precisely positioned tooling holes for accurate alignment with carrier pins.

- Edge clearances: Allow sufficient clearance around board edges for carrier contact points.

- Thermal management: Design with proper thermal considerations, as carriers may affect heat distribution during reflow.

Material Selection

Choose PCB materials that are compatible with the thermal profile of the reflow process and the mechanical stresses of carrier handling. This is particularly important for flex and rigid-flex designs.

Implementing PCB Carrier SMT in Production

Successful implementation of PCB carrier SMT requires careful planning and consideration of several factors:

Carrier Design and Fabrication

Custom carriers should be designed to:

- Securely hold PCBs without interfering with component areas

- Withstand repeated thermal cycling in reflow ovens

- Facilitate easy loading and unloading of boards

- Incorporate features like tapered tooling pins and spring-loaded pushers to maintain board flatness[9]

Process Integration

Integrating carriers into the SMT line involves:

- Adjusting conveyor systems to accommodate carrier dimensions

- Calibrating pick-and-place machines for the new working height

- Optimizing reflow oven profiles to account for the thermal mass of carriers

Training and Standard Operating Procedures

Develop comprehensive training programs and standard operating procedures for staff to ensure proper handling of carriers and loaded PCBs throughout the assembly process.

Benefits Beyond Efficiency

While improved efficiency is a primary advantage of PCB carrier SMT, there are additional benefits that contribute to overall manufacturing excellence:

Enhanced Product Quality

The stability provided by carriers during assembly leads to higher quality end products. This is reflected in:

- Improved solder joint reliability

- Reduced instances of component misalignment

- Better performance in high-frequency applications due to more precise component placement[5]

Flexibility in Design

PCB carrier SMT enables manufacturers to work with a wider range of board designs, including:

- Ultra-thin PCBs

- Flexible and rigid-flex circuits

- High-density interconnect (HDI) boards

This flexibility allows for more innovative product designs and miniaturization of electronic devices.

Cost Savings

Although there is an initial investment in carrier systems, the long-term cost savings are significant:

- Reduced material waste due to fewer defects

- Lower rework and repair costs

- Decreased labor expenses through automation

- Improved yield rates, especially for complex assemblies

Environmental Impact

The efficiency gains and reduced material waste associated with PCB carrier SMT contribute to a more environmentally friendly manufacturing process. This aligns with growing industry trends towards sustainable production methods.

Challenges and Considerations

While PCB carrier SMT offers numerous advantages, there are challenges to consider:

Initial Investment

The upfront costs for carrier systems and associated equipment can be substantial. However, these costs are typically offset by long-term efficiency gains and quality improvements.

Carrier Maintenance

Regular maintenance and cleaning of carriers are essential to prevent contamination and ensure consistent performance. This adds an additional step to the production process that must be managed effectively.

Design Constraints

Some PCB designs may require modifications to accommodate carrier systems, potentially limiting design flexibility in certain applications.

Future Trends in PCB Carrier SMT

As electronic devices continue to evolve, PCB carrier SMT technology is also advancing. Future trends may include:

- Smart carriers: Integration of sensors and RFID tags for real-time process monitoring and traceability.

- Advanced materials: Development of carrier materials with improved thermal properties and durability.

- AI-driven optimization: Use of artificial intelligence to dynamically adjust carrier designs and process parameters for maximum efficiency.

Conclusion

PCB carrier SMT represents a significant leap forward in electronic assembly efficiency. By providing a stable platform for PCBs throughout the SMT process, carriers enable higher throughput, improved quality, and greater flexibility in manufacturing. The benefits extend beyond mere efficiency gains, encompassing enhanced product quality, cost savings, and environmental considerations.

As the electronics industry continues to push the boundaries of miniaturization and complexity, PCB carrier SMT will play an increasingly crucial role in meeting these challenges. Manufacturers who embrace this technology and optimize their processes accordingly will be well-positioned to lead in an increasingly competitive market.

While challenges exist, the advantages of PCB carrier SMT far outweigh the drawbacks for many applications. As the technology continues to evolve, we can expect even greater improvements in efficiency and capability, further cementing the role of PCB carrier SMT as a cornerstone of modern electronic manufacturing.

FAQ

1. What is the primary purpose of a PCB carrier in SMT assembly?

The primary purpose of a PCB carrier in SMT assembly is to provide mechanical support and stability for PCBs throughout the entire assembly process. It helps reduce warpage of rigid PCBs, rigid-flex boards, and flex circuits, which can significantly improve yields, especially when processing thinner substrates[9].

2. How does PCB carrier SMT improve assembly speed?

PCB carrier SMT improves assembly speed by enabling faster processing and reducing the need for manual handling. With carriers, some placement machines can mount over 136,000 components per hour, significantly increasing throughput compared to traditional methods[5].

3. What are the key design considerations for PCBs when using carrier SMT?

Key design considerations for PCBs when using carrier SMT include incorporating precise tooling holes for alignment, allowing adequate edge clearances for carrier contact points, and optimizing component layout for efficient pick-and-place operations. Additionally, thermal management should be considered as carriers may affect heat distribution during reflow.

4. Can PCB carrier SMT be used for all types of PCBs?

PCB carrier SMT is versatile and can be used for a wide range of PCB types, including standard rigid boards, ultra-thin PCBs, flexible circuits, and rigid-flex boards. However, carrier designs may need to be customized for specific board types to ensure optimal support and performance.

5. What are the long-term cost benefits of implementing PCB carrier SMT?

The long-term cost benefits of implementing PCB carrier SMT include reduced material waste due to fewer defects, lower rework and repair costs, decreased labor expenses through increased automation, and improved yield rates, especially for complex assemblies. While there is an initial investment, these factors contribute to significant cost savings over time.

Citations:

[1] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[2] https://www.zjyingxing.com/info/what-are-the-ways-to-improve-the-efficiency-of-88896111.html

[3] https://patents.google.com/patent/CN112040669B/zh

[4] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/how-smt-pcb-assembly-enhances-efficiency-in-electronics-production/

[5] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[6] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[7] https://versae.com/smt-assembly-faq/

[8] https://www.stentech.com/products/solder-pallet/surface-mount-process-carriers

[9] https://madpcb.com/reflow-carrier/