Content Menu

● Introduction to SMT PCB Assembly

>> Component Types and Their Impact on Cost

● Factors Influencing SMT PCB Assembly Cost

>> PCB Design Complexity

>> Component Costs

>> Production Volume

● Impact of Component Complexity on Assembly Cost

● Strategies for Cost Optimization

● Pricing Models for SMT Assembly

● Advanced Technologies and Their Impact

>> Role of AI in SMT Assembly

>> IoT Integration

● Supply Chain Considerations

>> Component Sourcing Strategies

● Environmental and Regulatory Factors

>> Impact of Environmental Regulations

● Conclusion

● FAQs

>> 1. What is the primary difference in cost between SMT and through-hole components?

>> 2. How does component density affect SMT PCB assembly costs?

>> 3. What role does production volume play in reducing SMT PCB assembly costs?

>> 4. How can manufacturers optimize SMT PCB assembly costs through design?

>> 5. What are the main cost drivers in SMT PCB assembly?

The cost of Surface Mount Technology (SMT) PCB assembly is influenced by a multitude of factors, with component complexity playing a pivotal role. Component complexity encompasses not only the type of components used but also their size, pitch, and the precision required for their placement. Understanding these factors is crucial for electronics manufacturers aiming to optimize their production costs while maintaining product quality.

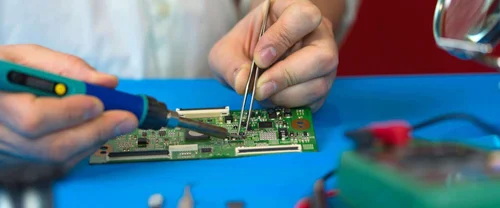

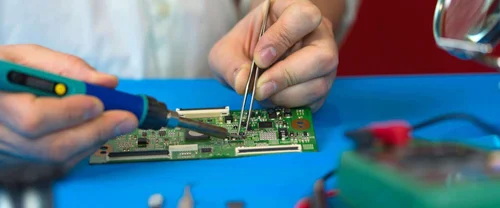

Introduction to SMT PCB Assembly

SMT PCB assembly is a widely used method in electronics manufacturing due to its efficiency and cost-effectiveness, especially for high-volume production. It involves mounting components directly onto the surface of a printed circuit board (PCB) using automated processes like pick-and-place machines and reflow soldering. However, the complexity of components can significantly impact the assembly cost.

Component Types and Their Impact on Cost

1. Surface Mount (SMT) Components: These are generally more cost-effective than through-hole components due to their automated assembly process. However, finer pitch components or those with a high pin count require specialized equipment and precise placement, increasing costs.

2. Through-Hole Components: These components are more labor-intensive to assemble, as they often require manual placement and soldering. This increases labor costs and reduces production speed compared to SMT components.

3. High-Precision Components: Components used in applications like sensors or medical devices require specialized equipment and stringent quality control measures, leading to higher assembly costs.

Factors Influencing SMT PCB Assembly Cost

Several factors contribute to the overall cost of SMT PCB assembly, with component complexity being a key driver.

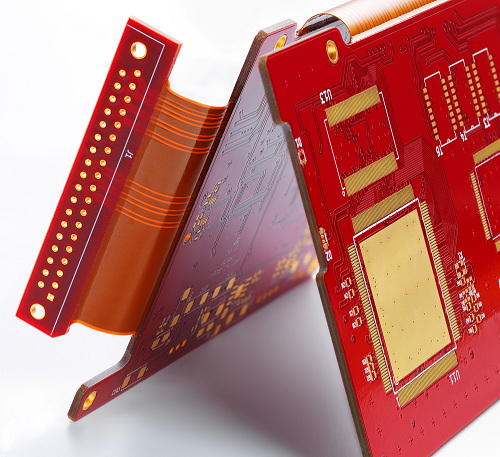

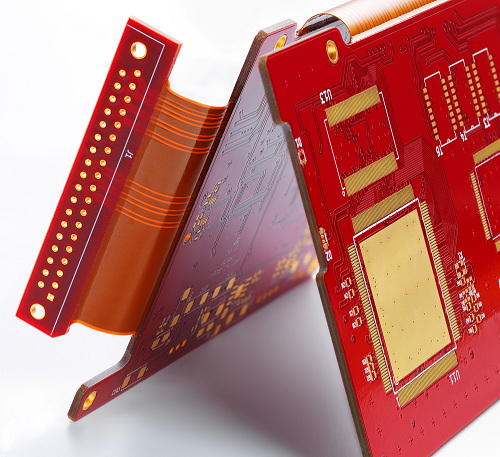

PCB Design Complexity

- Layer Count and Routing: More complex designs with multiple layers and intricate routing require advanced manufacturing techniques and precise alignment, increasing costs.

- Component Density: Higher component density necessitates precise placement and handling, raising assembly time and costs.

Component Costs

- Market Fluctuations: The cost of electronic components can fluctuate due to market demand and geopolitical factors, impacting assembly costs.

- Sourcing Strategies: Effective Bill of Materials (BOM) sourcing is crucial to mitigate these fluctuations and ensure cost stability.

Production Volume

- Economies of Scale: Higher production volumes reduce per-unit costs by distributing setup costs and benefiting from volume discounts on components.

Impact of Component Complexity on Assembly Cost

Component complexity affects assembly cost in several ways:

- Precision Requirements: Components with finer pitches or high pin counts require specialized equipment and skilled labor, increasing costs.

- Assembly Time: More complex components may require longer assembly times, contributing to higher labor costs.

- Testing and Quality Control: Complex components often necessitate more stringent testing protocols to ensure quality, adding to overall costs.

Strategies for Cost Optimization

To optimize SMT PCB assembly costs, manufacturers can consider the following strategies:

- Design for Manufacturability (DFM): Simplifying PCB designs by using larger component packages and reducing layer counts can lower assembly costs without compromising functionality.

- Automation and Bulk Purchasing: Investing in automated assembly lines and purchasing components in bulk can reduce labor costs and secure better pricing.

- Component Selection: Choosing components with standard sizes and pitches can simplify assembly and reduce costs.

Pricing Models for SMT Assembly

Understanding the different pricing models for SMT assembly is essential for managing costs effectively.

- Per-Pad Pricing: Suitable for simpler designs, this model calculates costs based on the number of solder pads.

- Per-Component Pricing: Reflects the complexity of part placement and is beneficial for designs with varied component types.

- Turnkey Pricing: Offers a comprehensive service covering component sourcing to assembly, ideal for projects requiring streamlined management.

Advanced Technologies and Their Impact

The integration of advanced technologies, such as Artificial Intelligence (AI) and Internet of Things (IoT) components, further complicates PCB assembly. These components often require specialized handling and testing, which can increase costs. However, they also offer opportunities for cost reduction through improved efficiency and automation.

Role of AI in SMT Assembly

AI can enhance the SMT assembly process by optimizing production workflows, predicting component failures, and improving quality control. While the initial investment in AI technology may be high, it can lead to long-term cost savings by reducing waste and improving assembly efficiency.

IoT Integration

IoT components often require additional testing to ensure connectivity and functionality. This can add to the overall assembly cost but also provides opportunities for remote monitoring and predictive maintenance, potentially reducing long-term operational costs.

Supply Chain Considerations

The supply chain plays a critical role in managing SMT PCB assembly costs. Effective supply chain management involves ensuring a stable supply of components, negotiating favorable pricing with suppliers, and managing inventory efficiently to avoid stockouts or overstocking.

Component Sourcing Strategies

- Diversification: Sourcing components from multiple suppliers can mitigate risks associated with supply chain disruptions.

- Inventory Management: Implementing just-in-time inventory systems can reduce storage costs and minimize the impact of component price fluctuations.

Environmental and Regulatory Factors

Environmental regulations and standards, such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment), can influence assembly costs by requiring the use of specific materials and processes. Compliance with these regulations is essential to avoid legal and reputational risks.

Impact of Environmental Regulations

- Material Costs: The use of lead-free solder and other compliant materials may increase component costs.

- Process Adjustments: Adapting manufacturing processes to meet environmental standards can require additional investments in equipment and training.

Conclusion

Component complexity significantly influences the cost of SMT PCB assembly. By understanding the factors that contribute to this complexity, such as component type, PCB design, and production volume, manufacturers can implement strategies to optimize costs while maintaining product quality. Effective cost management in SMT assembly is crucial for remaining competitive in the electronics industry.

FAQs

1. What is the primary difference in cost between SMT and through-hole components?

- SMT components are generally cheaper due to automated assembly, while through-hole components require more manual labor, increasing costs.

2. How does component density affect SMT PCB assembly costs?

- Higher component density increases assembly difficulty and requires precise placement, leading to higher costs due to increased time and precision requirements.

3. What role does production volume play in reducing SMT PCB assembly costs?

- Higher production volumes reduce per-unit costs by spreading setup costs and benefiting from volume discounts on components, leading to economies of scale.

4. How can manufacturers optimize SMT PCB assembly costs through design?

- By simplifying PCB designs, using larger component packages, and reducing layer counts, manufacturers can lower assembly costs without compromising functionality.

5. What are the main cost drivers in SMT PCB assembly?

- Key cost drivers include material costs, labor expenses, equipment utilization, design complexity, and the type of components used.